Correlation between C intensity and HHV and comparison between raw materials, hydro-chars and lignite. The effect of different combinations of maize, barley and sludge on carbon content and HHV of hydrocarbons.

Research Objectives

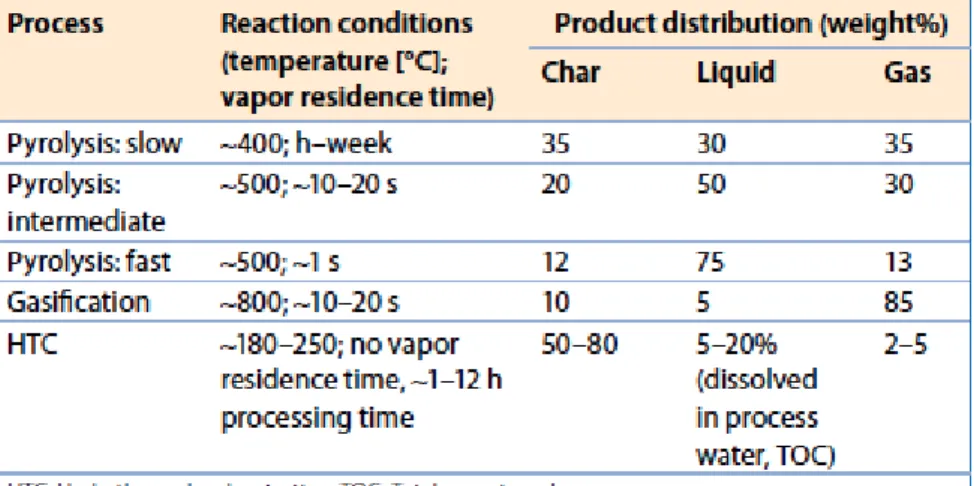

Tripathi et al. al, 2015, I. Oliveria et al., 2013) have been worked on improving HTC technique, investigating different types of biological materials as inputs, changing parameters and laboratory conditions to achieve a better quality of hydro-char in order to be more effective and comparable to lignite using different reactors and autoclaves; also to be more reasonable to use hydro-char as a renewable energy source worldwide. Research on the HTC method, hydro-char and other products of this specific process is relatively less and limited, compared to studies done on dry pyrolysis (J. A Libra et. al., 2011).

FUNDAMENTALS

Biomass; Structure and Properties

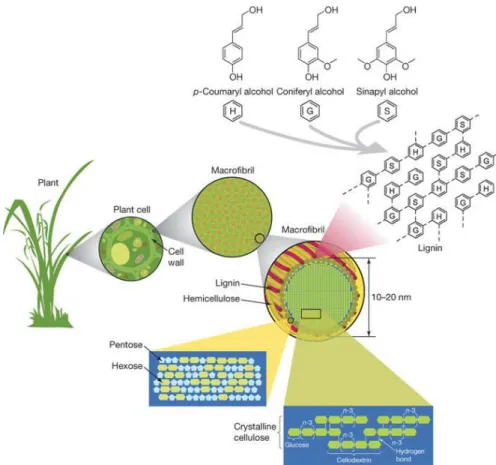

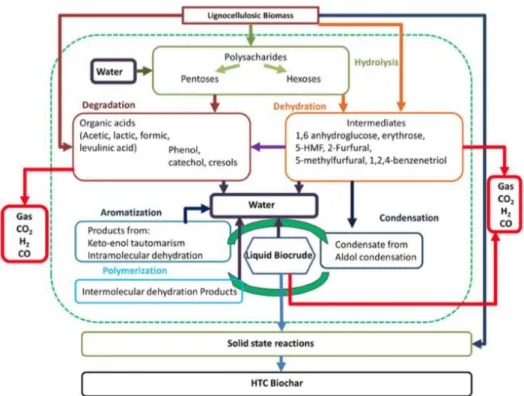

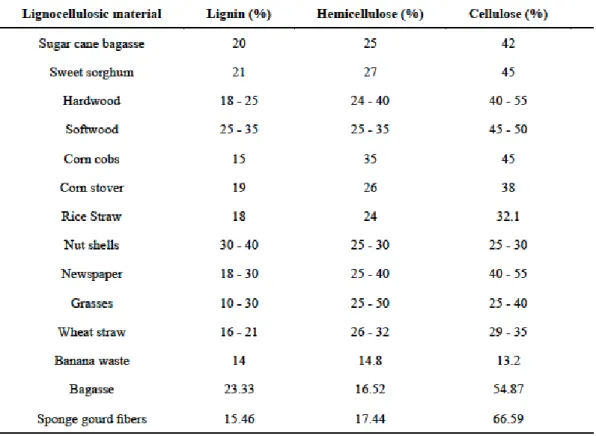

In general, however, the proportion of carbon is the largest of all other elements (M. Tripathi et. al, 2015). Accordingly, the composition of the materials used as inputs of hydrothermal processes influences the quality of the product (J. A Libra et. al., 2011); thus, cellulose and hemicellulose, as well as lignin, which are fiber components (A. Lilliestral, 2007), influence the product yield (M. Tripathi et. al, 2015).

Overview of Hydrothermal Carbonization Process .1 Background of Carbonization and Char Production

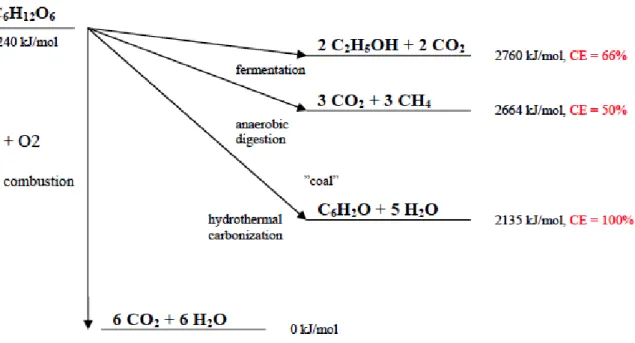

During HTC, about 950 KJ/mol of heat (H. Ramke et al., 2009) is released per carbohydrate (C6H12O6) by a based simple chemical process (dehydration); or according to A. It can be calculated from the heat of all substances during reactions, and products (C. J. Coronella et al., 2014). The CO2 concentration in the gas lies between 70 - 90% depending on substrate and severity of reaction (H. Ramke et al., 2009).

Nanostructured carbon materials can also be generated from HTC process through different changing temperature, time and raw material to reach different sizes, structures and functionalities of hydro-char (J. A Libra et. al., 2011).

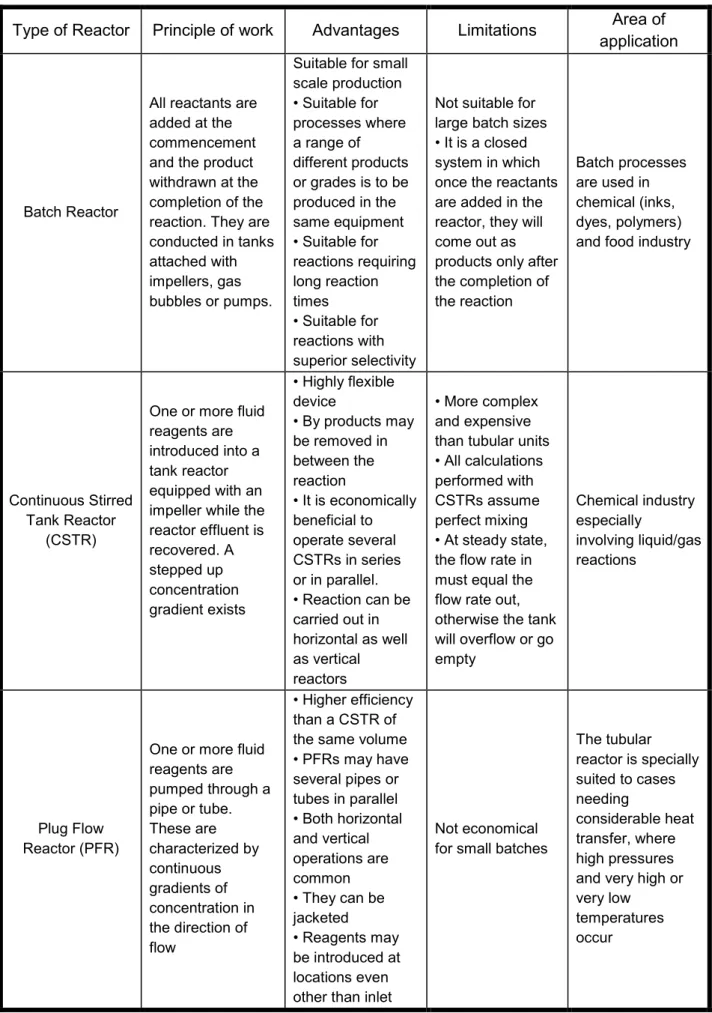

HTC Reactors

All the reactants are added at the beginning and the product is withdrawn at the end of the reaction. It is a closed system in which once the reactants are added to the reactor, they will come out as products only after the reaction is complete. One or more liquid reagents are introduced into a tank reactor equipped with a propellant while the reactor effluent is recovered.

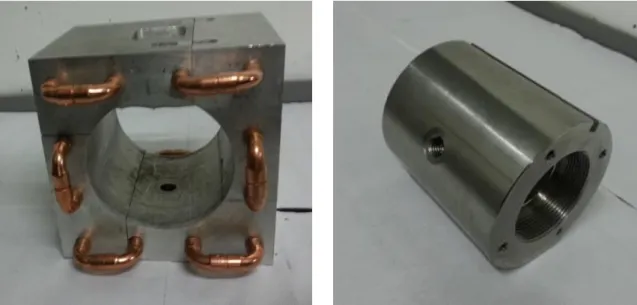

This optical cell was presented in a thesis entitled “Setup and process control of an optical cell used for hydrothermal carbonization” (F. Haiböck, 2015). The general idea behind the construction of this optical cell was to allow the experimenter to see inside the cell through a sight glass to monitor the physical changes during the chemical processes of hydrothermal carbonization. The optical cell is a mm aluminum cube with copper tubes (Fig. 7) and a 44 ml stainless steel cylindrical container (Fig. 8) located inside the cube and fixed with screws.

A Haake N6 temperature controller connected to a vessel with a pump is used to heat the cell which helps to transmit non-hazardous hot mineral oil through flexible tubes to the optical cell cube (F. Haiböck, 2015). A wire connector from the hardware attached to the cell body transferred the heat data to software installed on a computer. The power system is programmed to read the temperature and pressure from the reactor, and the desired temperature is also set in the system to control the heat of the reactor.

Materials and Methodology 1 Materials

Methodology

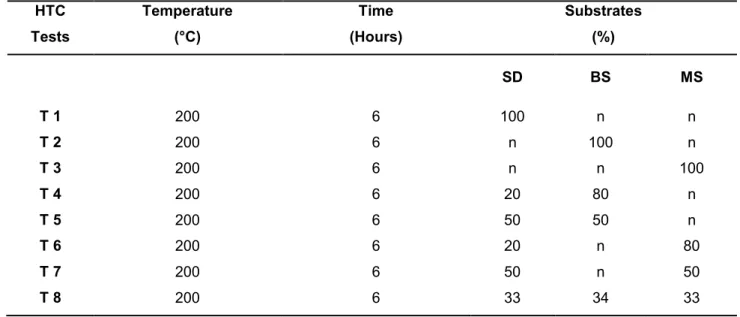

An experimental design of substrate mixtures shown in Table 11 shows what percentage of a substrate was applied in which trial. The moisture content value is one of the parameters that improves the reactions in the HTC process. Two-thirds of the reactor must be filled to have some free space in order to avoid overpressurization during the HTC process.

The power system was programmed to read temperature and pressure from the reactor and the desired temperature was also set on the system to control the reactor heat up to 200°C. Cooling system is a kind of water pumping machine which can be simply connected by pipes to a pipe attached to the body of the reactor. Products from the HTC test had to be separated as solid and liquid phase and weighed immediately after emptying the reactor.

Then again the dry matter was weighed to calculate the water and solid fraction of the output product. After adding 1 ml of water to the container, its door was closed and the pressure of the ship bomb was fixed at 30 bar and placed in the water container. The device was filled with water to the marked area, and then the rest of the process was executed automatically after giving the device the actual pellet weight.

RESULTS AND DISCUSSION

Process Parameters

Mass Balance

The main characteristic of carbonaceous coals is that they have a higher C content and a lower H/C ratio than the raw materials used as input materials. The following table 15 shows the characteristics of carbon carbons due to their composition C; H; N and S. According to Figure 20, which represents the high carbon content of the coals (T1h-T8h), it is clearly explained that HTC significantly increased the carbon intensity of the products compared to the raw materials.

This is clearly observable when values of raw materials are compared with hydro-chars results. In graph 24, status of hydro-chars is compared with a van Kerevelen diagram derived from a thesis by A. By mixing figures 22 and 23, it is indicated that hi-chars are suitable for the peatland.

What is shown in Figure 25 is exactly the expected result of HTC; the carbon content of hydrocarbons is significantly higher compared to the raw materials. Carbon content and HHV of hydro-chars showed a low difference with lignite, except for T1h, which is hydro-char with 100% SD. Carbon content and HHV of hydro-coal in this study were also compared with the results of I.

Seed Germination Discussion

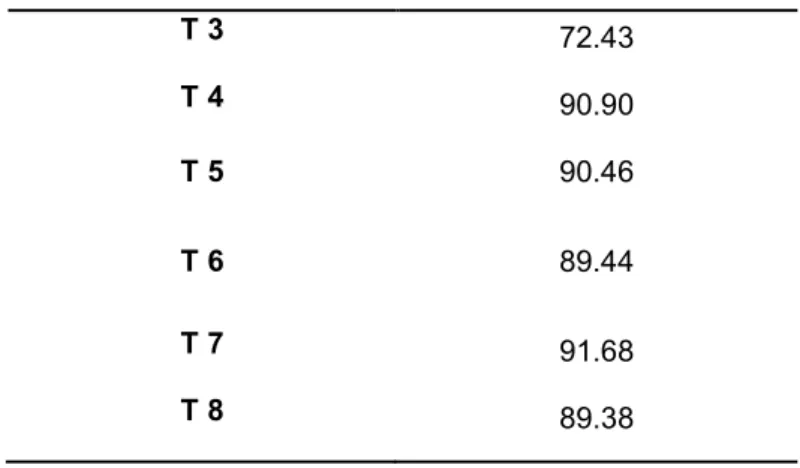

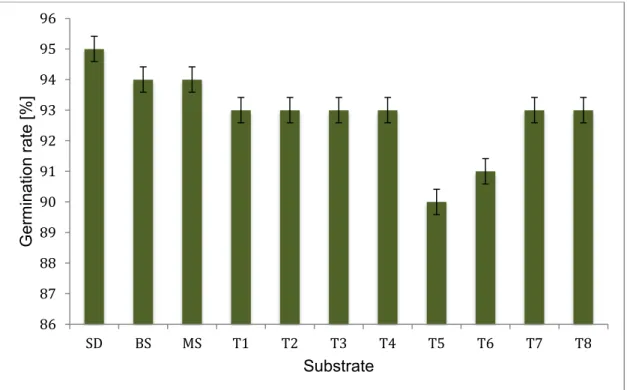

Comparison of the effect of input combination (measured) and hydrocarbon combination (calculated) on C% changes. In the last stage, the so-called drainage effect, T7h (MS50%) had the highest total germination rate and T4h (BS80%) had the highest number of ungerminated seeds (index 6). Tables 19, 20 and 21 show the number of germinated seeds counted at different stages for each germination test.

The highest number of seeds that germinated in the leachate phase was related to SD (T1f) and BS (T2f), which in comparison with their hydro-chars (T1h; T2 h) also had better results. It could be interpreted from the increase in the number of germination between MS (T3f) and T3h that there was no effect of hydro-char in that particular case (Table 19). In volatile phase again the increase of germinated seeds in BS hydro-char shows no effect of hydro-char.

Here, in contrast to the leachate phase, the reduction occurred in the case associated with T3h, which represents the negative effect of carbonaceous charcoal (Table 20). In general, the number of germinated seeds is lower compared to the other two stages in the range 27-28 and 24 associated with T5h. Lower results can be considered as a negative effect of the seed in contact with the sand.

CONCLUSIONS AND RECOMMENDATIONS

The results of germination tests showed more than 90% germination rate, which represents a positive hydro-char effect on soil fertility. Therefore, this study proposes to use hydro-char as a highly efficient soil fertilization, due to high germination rate that represents no phytotoxic effect and a rather positive hydro-char effect on soil fertility. Further research is recommended on more detailed findings on the reason for approximately 1-2% germination rate reduction in hydro-chars.

Kauriinoja, A., (2010): Small-Scale Biomass-to-Energy Solutions for Northern Peripheral Regions, Master's thesis, Mass and Heat Transfer Process Laboratory, Department of Process and Environmental Engineering, Oulun Yliopisto (University of Oulu) http://nortech.oulu.fi/MicrE_files/Anu_MSc_thesis.pdf (access date: 04 May 2016). Lehmann, J., Joseph, S., (2009): Biochar for Environmental Management: An Introduction, http://www.biochar-international.org/images/Biochar_book_Chapter_1.pdf (access date: July 13, 2016). Nanda, S., (2008), Reactors and Fundamentals of Reactors Design for Chemical Reaction, http://www.eng.unideb.hu/userdir/deak.krisztian/REACTORS+AND+FUNDAMENTALS+OF%20highlighted.pdf (access date: March 16, 2017).

Robbiani, Z., (2013), Hydrothermal carbonization of biowaste / faecal sludge, https://www.eawag.ch/fileadmin/Domain1/Abteilungen/sandec/publikationen/SWM/Anaerobic_Di gestion/carbonization.pdf (date of visit: 16 March 2017). Steinbeiss S., Gleixner G., Antonietti M., (2009): Effect of biochar amendment on soil carbon balance and soil microbial activity. 2011): Assessment of the energetic efficiency of a continuously operating.

APPENDIX

The raw material was fed through the small opening of the dip bottle and the bottle was sealed. The reactor is designed to handle a combination of wet biomass (20 - 60% TS) consisting of anaerobically digested sewage sludge from a WWTP (40%) and biowaste chopped into 2 cm pieces (60%) as input materials. An elaborate heat recovery system allows the hot, pressurized outlet stream to preheat and pressurize the inlet stream.

The input material is fed into a slot of a rotating cylinder made airtight with an oil-activated graphite seal system. In the same way, the output material goes into another rotating cylinder facing the feed cylinder. The start of operation of the plant was delayed due to technical problems with the operation of the reactor.

The reactor consists of a cylindrical pressure vessel closed with a flat end at the bottom and a flange at the top. A heat recovery system is planned to convert and store the excess heat in the form of electricity using the Seebeck effect. Because the factory was built with structural steel (and not stainless steel), it had to be shut down after 5 years.