REDUCTION OF CYANOGENIC GLYCOSIDES BY EXTRUSION - INFLUENCE OF TEMPERATURE AND MOISTURE CONTENT OF THE

PROCESSED MATERIAL

Dušica S. Čolović*, Jovanka D. Lević, Radmilo R. Čolović, Ljubinko B. Lević, Vojislav V. Banjac, Slađana M. Rakita, Olivera M. Đuragić

University of Novi Sad, Institute of Food Technology, Bulevar cara Lazara 1, 21000 Novi Sad, Serbia

he paper presents results of the investigation of the influence of extrusion tempera-ture and moistempera-ture content of treated material on the reduction of cyanogenic glycosides (CGs) in linseed-based co-extrudate. CGs are the major limitation of the effective usage of linseed in animal nutrition. Hence, some technological process must be applied for de-toxification of linseed before its application as a nutrient. Extrusion process has demon-strated several advantages in reducing the present CGs, since it combines the influences of heating, shearing, high pressure, mixing, etc. According to obtained results, the incre-ase in both temperature and moisture content of the starting mixture decreincre-ased the con-tent of CGs in the processed material. HCN concon-tent, as a measurement of GCs presence, ranged from 25.42 mg/kg, recorded at the moisture content of 11.5%, to 126 mg/kg, de-tected at the lowest moisture content of 7%. It seems that moisture content and tempera-ture had the impact on HCN content of equal importance. However, the influence of ex-trusion parameters other than temperature and moisture content could not be neglected. Therefore, the impact of individual factorshas to be tested together.

KEY WORDS: Linseed, cyanogenic glycosides, extrusion, temperature, moisture, HCN

INTRODUCTION

Over fifty countries all over the world cultivate linseed (Linum usitatissimum) as a commercial plant (1-3). It has been considered the third most productive oil crop, after sunflower and winter oilseed rape (4, 5). It yields seeds whose maturity occurs 30-60 days after flowering, and which are a rich source of both edible and non-edible oils (6, 7). In addition to a large amount of oil, linseed contains approximately 20-30% of crude protein (1, 8). Although linseed oil is mostly used in chemical industry, there has been a growing interest in its usage as a food or feed, due to the high concentration of linoleic (LA, 18:2, n-6) and especially α-linolenic acid (ALA, 18:3, n-3), representatives of omega-6 (n-n-6) and omega-3 (n-3) polyunsaturated fatty acids (PUFAs) (9, 10). Moreover, linseed is the richest oilseed source of ALA (11). Cereals and oilseeds, or meals commonly used in animal diet

predominantly contain low level of n-3 FAs (12). Therefore, intensive inclusion of linseed in animal nutrition could have significant role in the improvement of FA composition of feed.

The main limitation in the exploitation of linseed as a nutrient lies in the presence of antinutritive components, which are cyanogenic glycosides (CGs) and antivitamin B6 (linatine). Negative effect of antivitamin B6 can be eliminated by adding vitamin B6 to the diet (13), which cannot be said for CGs. CGs may be defined chemically as glycosides of the α-hydroxynitriles, and are secondary metabolites produced by plants. They are amino acid-derived plant constituents (14). The reason for their toxicity is the release of hydrogen cyanide (HCN) due to the action of a -glucosidase enzyme (oxynitrilase), thus their level in food or feed is expressed through the content of HCN (mg) per kg of examined material.

Different heat treatments, such as autoclaving, pelleting, extrusion or microwave roas-ting are commonly used to reduce the content of CGs (15-17). Dry hearoas-ting is not recom-mended because the detoxification is based only on deactivation of glucosidase. Conse-quently, CGs can be synthesised again after entering into animal gut, and HCN can be re-leased under the action of enzymes of intestinal microflora. High temperature in com-bination with moisture intensifies the hydrolysis of CGs, which results in intensive removal of HCN (15). Extrusion has been considered a suitable process for the removal of HCN from the material, because it combines a number of different processes: grinding, mixing, heating under high pressure in the presence of moisture, friction and shearing. However, the extrusion of oilseeds, such as linseed, is difficult achieve due to the lubrication and limited expansion of the produced extrudates. Another disadvantage which is the separation of the oil from the solid phase, thereby changing the nutritional composition of produced extruda-te, as is the case with the extrusion (17). In order to overcome the aforementioned problem, oil crops are often added to another raw material, usually a protein component, which shows good ability of oil adsorption, such as pea or sunflower meal (18-20).

Bearing in mind all the above, the aim of the present study was to find out how extru-sion parameters affect temperature changes in the extruder barrel, and furthermore to exa-mine the influence of the process temperature on reduction of CGs in linseed-sunflower meal co-extrudate. Since the presence of moisture highly influences CGs decomposition, three levels of moisture content of starting material were applied.

EXPERIMENTAL

Material

Linseed and sunflower meal used for production of co-extrudate originated from Serbia. Linseed indigenous sort “Ljupko” was cultivated in the valley of the river Beli Timok (South-Eastern Serbia). Before processing, linseed was cleaned and impurities were remo-ved. Sunflower meal was produced in the local oil factory in Vojvodina (northern Serbian province), and it contained approximately 38% of protein expressed on dry matter (d.m.).

Extrusion process

double-shaft paddle mixer - steam conditioner (Muyang SLHSJ0.2A, China). Water and steam were added into material during conditioning, in order to adjust the initial moisture content of the mixture at a desired level. Extrusion of the mixture was done on a single screw extruder (OEE 8, AMANDUS KAHL GmbH & Co., KG Germany), with the L/D ratio 8.5:1. The extrusion parameters were set according to the levels determined in the applied experimental design. The extruded product was dried in a fluid bed dryer/cooler (FB 500x200, AMANDUS KAHL GmbH & Co., KG Germany) for 10 minutes at the tempera-ture of 25oC, and a material flow rate of 18 kg/h.

Determination of HCN in the co-extrudate

The determination of HCN was performed according to AOAC official method 915.03, part B, (alkaline titration method). Silver nitrate (AgNO3) standard solution was

used for titration. The volume of AgNO3 standard solution consumed during the titration

was recorded (21). Equation (1) was used to calculate the HCN content in the sample:

m aliquot dilution V

C

X = × ×54× ×1000 [1]

where X is the content of cyanide (including HCN) in the sample (mg/kg); m is the mass of the sample (g); C is the concentration of the AgNO3 standard solution (mol/L); and V

is the consumed volume of the AgNO3 standard solution (mL).

All measurements were done in triplicate.

Experimental design, temperature measurement and statistical analysis

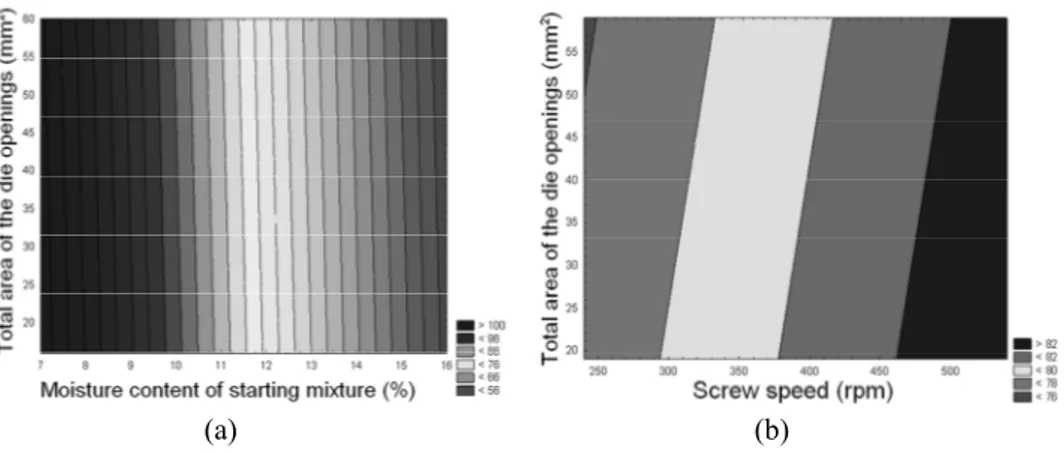

The effects of the following extrusion parameters on the temperature in the extruder barrel were examined: extrusion screw speed, moisture content of the starting mixture, feeding rate and total area of the die openings. The experiment was planned according to the Box-Behnken experimental design. The levels of independent parameters applied in the experiment are shown in Table 1.

Table 1. Independent process variables and their levels

Independent variable Variable level

-1 0 1 Moisture content of the starting mixture (%) 7 11.5 16

Extrusion screw speed (rpm) 240 390 540

Feeding rate (kg/h) 16 24 32

Total area of the die openings (mm2) 19.8 39.6 59.4

STATISTICA software version 12 (Statsoft, Tulsa, OK, USA) was used to analyze vari-ations (analysis of variance – ANOVA) and for Tukey’s HSD comparison of the means of measured temperatures and HCN content in the co-extrudates. Differences among means with the probability p ≤ 0.05 were accepted as indicators of statistically significant differ-rences, and the differences among means with 0.05 ≤ p ≤ 0.10 were accepted as indicators of differentiating tendencies.

RESULTS AND DISCUSSION

The single screw extruder which was used in the experiment did not have the possi-bility of setting the temperature at a specific value. Thus, other extrusion parameters were varied, which indirectly affected the working temperature. Table 2 shows all temperatu-res measured in the experiment. As it can be seen, the process temperature ranged from 52.82 to 116.02oC.

Table 2. Influence of extrusion parameters on the temperature in the extruder barrel

As it is evident from the obtained results, the increase in the moisture content in the starting material resulted in a decrease of the temperature in the extruder barrel (Fig. 1 a), which was caused by lowering the viscosity of the material and its fast passage through the barrel of the extruder. The same trend was observed in the work of Abecassis et al.

Extrusion parameter

t (oC) Moisture content of

starting mixture (%)

Extrusion screw speed (rpm)

Feeding rate (kg/h)

Total area of the die openings (mm2)

11.5 240 32 39.6 57.52

11.5 540 32 39.6 73.33

11.5 240 16 39.6 71.38

11.5 540 16 39.6 73.94

11.5 390 24 39.6 75.18

11.5 390 24 39.6 74.03

11.5 390 24 39.6 74.60

16 390 24 19.8 53.16

16 240 24 39.6 63.80

16 540 24 39.6 68.54

16 390 32 39.6 58.99

16 390 16 39.6 52.82

16 390 24 59.4 70.23

11.5 390 16 19.8 82.50

11.5 390 32 19.8 79.18

11.5 540 24 19.8 79.16

11.5 240 24 19.8 78.00

11.5 390 16 59.4 84.93

11.5 390 32 59.4 70.38

11.5 240 24 59.4 67.75

11.5 540 24 59.4 76.53

7 390 24 19.8 113.14

7 240 24 39.6 104.51

7 540 24 39.6 114.39

7 390 32 39.6 111.18

7 390 16 39.6 116.02

(1994). According to their results, the increased moisture content of materials lowered the temperature, especially at the exit of the extruder barrel, while the effect was slightly lower in the extruder zone close to the entrance (22).

On the other hand, the increase of the extrusion screw speed increased the tempera-ture, which was expected, since the increase in the extrusion screw speed influences in-tensification of the forces of shearing, torsion and friction, and consequently increase the working temperature (Fig. 1 b). The highest working temperatures at the constant inter-mediate levels of feeding rate and moisture content were achieved at the moisture content of 7% and extrusion screw speed of 540 rpm.

(a) (b)

Figure 1. Influence of the process parameters on temperature in the extruder: moisture content of starting material and total area of the die openings (a);

screw speed and total area of the die openings (b)

The lowest temperatures in the extruder barrel were achieved at the highest moisture content of 16% and the minimum feeding rate. In this case, the material remained shortly in the extruder and easily passed through the matrix, due to the compaction of the mate-rial and absence of the accumulation. Hence, the measured temperatures were low.

the material remained in the extruder barrel long enough so that the temperature of ap-prox. 70oC was sufficiently high to accelerate the hydrolysis of CGs.

Figure 2. Influence of temperature on the HCN content in the co-extrudate at a constant moisture content of the starting material: 7% (A), 11.5% (B) and 16% (C)

Based on the obtained results it can be concluded that the HCN content decreased with the increase in temperature at constant moisture content. However, if we compare the results for the different moisture contents, no regularity can be seen. The reason for that could be that the other process parameters (pressure, friction, milling, etc.) influenced the CGs reduction. It also seems that the influences of temperature and moisture content of the material are equally important for the hydrolysis of CGs. Extrusion is considered to be very suitable for detoxification of linseed because of the simultaneous effect of several factors on the CGs. Milling and heating of the material in the presence of moisture accelerates the process of hydrolysis and the formation of HCN. After the decrease in the operating pressure at the exit of the material from the barrel of the extruder, the acid formed evaporates rapidly together with water. At the same time, the high pressure in the extruder barrel destroys molecules CGs, thereby preventing the release of HCN (15, 18).

CONCLUSION

The present study demonstrated how the temperature and content of moisture reduce the content of CGs in linseed-based product during the extrusion process. The highest HCN content in the experiment (126 mg/kg) was recorded at the lowest moisture content of the starting material (7%) and temperature of 116.02oC, while the lowest content of HCN (25.42 mg/kg) was measured at the moisture content of 11% and temperature of 70.2oC. It was found that the increase in the temperature decreased the HCN content, and that increased moisture content positively affected the HCN reduction. However, the ef-fectiveness of the HCN reduction varied depending on several process factors. Since ex-trusion is a complex process, the impacts of individual factors cannot be considered independently from the influence of other process parameters.

Acknowledgement

The presented results are part of the Integrated and Interdisciplinary Research Project No. III 46012, funded by the Ministry of Education, Science. and Technological Deve-lopment of the Republic of Serbia.

REFERENCES

1. Karlović, Đ.; Andrić, N. Kontrola kvaliteta semena uljarica. Tehnološki fakultet Novi Sad, Savezni zavod za standardizaciju, Beograd, Serbia, 1996.

2. Gabiana, C.P.: Gabiana, C.P. Response of linseed (Linum usitatissimum L.) to irrigati-on, nitrogen and plant population. MSc Thesis, Lincoln University, Canterbury, New Zealand, 2005.

3. Copur, O; Gur, M.; Karakus, M.; Demirel, U. Determination of correlation and path analysis among yield components and seed yield in oil flax varieties (Linum usita-tissimum L.). J. Biol. Sci. 2006, 6, 738-743.

5. Zajaç, T.; Olesky, A.; Stokłosa, A.; Klimek-Kopyra, A.; Kulig, B. The development competition and productivity of linseed and pea-cultivars grown in a pure sowing or in a mixture. Eur. J. Agron. 2013, 44, 21-33.

6. Rubilar, M.; Gutiérrez, C.; Verdugo, M.; Shene, C.; Sineiro, J. Flaxseed as a Source of Functional Ingredients. J. Soil Sci. Plant Nutr. 2010,10 (3), 373-377.

7. Matheson, E.M. Vegetable Oil Seed Crops in Australia; Holt, Rinehart & Winston, Sydney, Australia, 1976, pp. 111-121.

8. Ivanov, D.; Kokić, B.; Brlek, T.; Čolović,R.; Vukmirović, Đ.; Lević, J.; Sredanović, S. Effect of microwave heating on content of cyanogenic glycosides in linseed. Ratarstvo i povrtarstvo 2012, 49, 63-68.

9. Beare – Rogers, J.; Dieffenbacher, A.; Holm, J.V. Lexicon of lipid nutrition (IUPAC Technical report). Pure Appl. Chem. 2001, 73(4), 685-744.

10.Łukaszewicz, M.; Szopa, J.; Krasowska, A. Susceptibility of lipids from different flax cultivars to peroxidation and its lowering by added antioxidants. Food Chem. 2004, 88, 225-231.

11.Juárez, M.; Dugan, M. E. R.; Aldai, N.; Aalhus, J. L.; Patience, J.F.; Zijlstra R.; Beau-lieu A. D. Feeding co-extruded flaxseed to pigs: Effects of duration and feeding level on growth performance and backfat fatty acid composition of grower-finisher pigs. Meat Sci. 2010, 84, 578-584.

12.Csengeri, I. Dietary effects on fatty acid metabolism of common carp. Arch. Anim.

Nutr. 1996, 49(1), 73-92.

13.Klosterman, H.J. Vitamin B6 antagonist of natural origin. J. Agr. Food Chem. 1974, 22

(1), 13-16.

14.Vetter, J. Plant cyanogenic glycosides. Toxicon 2010, 38, 11-36.

15.Feng, D.; Shen, Y.; Chavez, E. Effectiveness of different processing methods in redu-cing hydrogen cyanide content of linseed. J. Sci. Food Agr. 2003, 83, 836-841. 16.Wu, M.; Li, D.; Zhou, Y.-G.; Brooks, M.S.-L.; Chen, X.D.; Mao, Z.H. Extrusion

de-toxification technique on linseed by uniform design optimization. Sep. Purif. Tech.

2008, 61, 51-59.

17.Ivanov, D.; Čolović, R.; Vukmirović, Đ.; Lević, J.; Kokić, B.; Lević, Lj.; Đuragić, O. Influence of process parameters on temperature profile and nitrogen solubility index of linseed co-extrudate, 1st International Symposium on Animal Science, Belgrade, 8-10. October, 2012, Book of papers, 511-515.

18.Čolović, D. Ispitivanje uticaja procesa ekstrudiranja na dobijanje i stabilnost funkcio-nalnog hraniva za životinje na bazi lanenog semena. Ph.D. Thesis, Univeristy of Novi Sad, June 2014.

19.Htoo, J.K.; Meng, X.; Patience, J.F.; Dugan, M.E; Zijlstra, R.T. Effects of coextrusion of linseed and field pea on the digestibility of energy, ether extract, fatty acids, protein, and amino acids in grower-finisher pigs. J. Anim. Sci., 2008, 86 (11), 2942-2951. 20.Thacker, P.A.; Racz, V.J.; Soita, H.W. Performance and carcass characteristics of

growing-finishing pigs fed barley-based diets supplemented with Linpro (extruded whole linseed and peas) or soybean meal. Can. J. Anim. Sci. 2004, 84 (4), 681-688. 21.AOAC (2000) In Official Methods of Analysis, 17th edn. Ed. W. Horwitz, AOAC Int,

22.Abecassis, J.; Abbou, R.; Chaurand, M.; Morel, M.-H.; Vernoux, P. Influence of ex-trusion conditions on exex-trusion speed, temperature and presure in the extruder and on pasta quality.Cereal Chem. 1994, 71 (3), 247-253.

23.Mayak, W.; McDiarmid, R.E.; Hall, J.W.; Cheng, K.J. Factors that determine rate of cyanogenesis in bovine ruminal fluid in vitro. J. Anim. Sci. 1990, 68, 1648-1655. 24.Mazza, G.B.; Oomah, D. Flaxseed, dietary fiber, and cyanogens, In Flaxseed in Human

Nutrition; Cunnane S.C. and Thompson L.U. Eds.; AOCS Press, University of Illinois, Champaign, III, 1995, pp. 56-81.

ɊȿȾɍɄɐɂȳȺɐɂȳȺɇɈȽȿɇɂɏȽɅɂɄɈɁɂȾȺȿɄɋɌɊɍȾɂɊȺȵȿɆ - ɍɌɂɐȺȳ

ɌȿɆɉȿɊȺɌɍɊȿɂȼɅȺȽȿɌɊȿɌɂɊȺɇɈȽɆȺɌȿɊɂȳȺɅȺ

. , . , . , . ,

. , ђ M. , M. Ђ

, , 1,

21000 ,

( )

-.

. , ,

, , .

-, ђ ,

: , , , , .

, ђ

,

HCN - , . HCN

25.42 mg/kg,

11.5%, 126 mg/kg, 7% (

).

. ,

HCN ђ

-,

.

-. ,

.

Ʉʂɭɱɧɟɪɟɱɢ: , , , ,

, HCN