Heat Transfer in MHD Mixed Convection Flow of a Ferrofluid along a Vertical Channel.

Texto

Imagem

Documentos relacionados

Hayat T, Yasmin H, Alsaedi A (2014) Convective heat transfer analysis for peristaltic flow of power-law fluid in a channel.. Parsa AB, Rashidi MM, Hayat T (2013) MHD boundary-layer

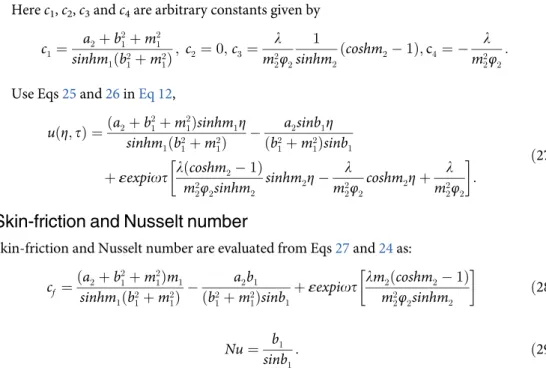

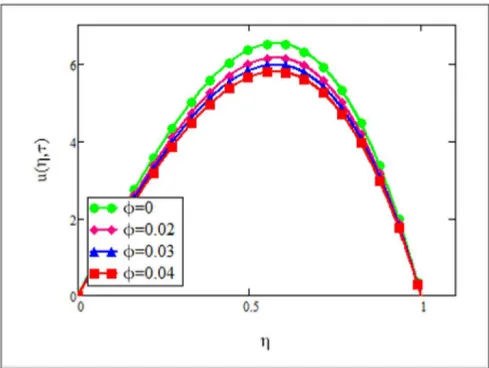

Therefore we examine here the mixed convective peristaltic transport of nanofluid in an inclined asymmetric channel in the presence of inclined magnetic field.. Channel asymmetry

Effects of non-uniform wall temperature or mass transfer in finite sections of an inclined plate on the MHD natural convection flow in a temperature stratified high-porosity

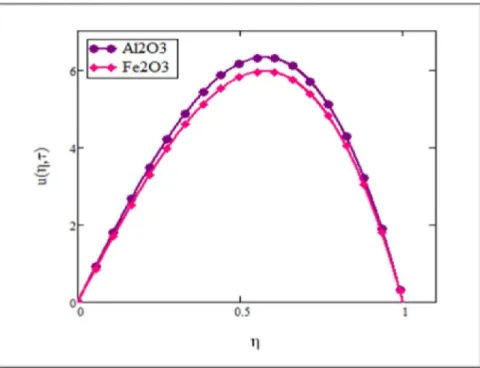

In the present study, Lattice Boltzmann method is employed to investigate a two dimensional mixed convection heat transfer of Al 2 O 3 -water nanofluid in a horizontal annulus

As such in this paper it can be seen that, both viscosity and thermal conductivity vary linearly with temperature ref [3], [5], [8] and [9] and make a numerical study of the

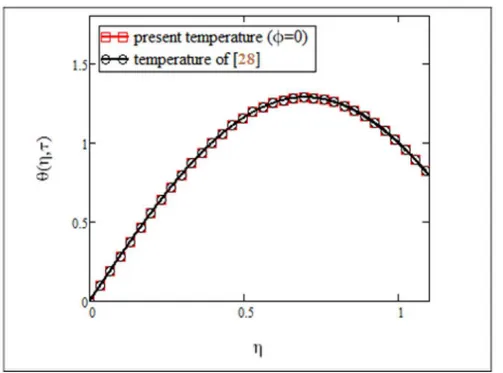

The results for the case of mixed convective heat and mass transfer in the case of binary liquid inside a vertical channel has been tested successfully by comparing the

This cell is more intense compared to the case of the injection mode (Fig. The corresponding isotherms are more tightened at the level of the heated vertical wall indicating a

The complex heat transfer process, including three modes of heat conduction inside the sinter ore particles, gas-solid convection and radiation in the trolley, is taken into

![Fig 8. Comparison of present velocity results φ = 0 with published results of [30].](https://thumb-eu.123doks.com/thumbv2/123dok_br/18310561.348704/11.918.304.817.652.1023/fig-comparison-present-velocity-results-φ-published-results.webp)