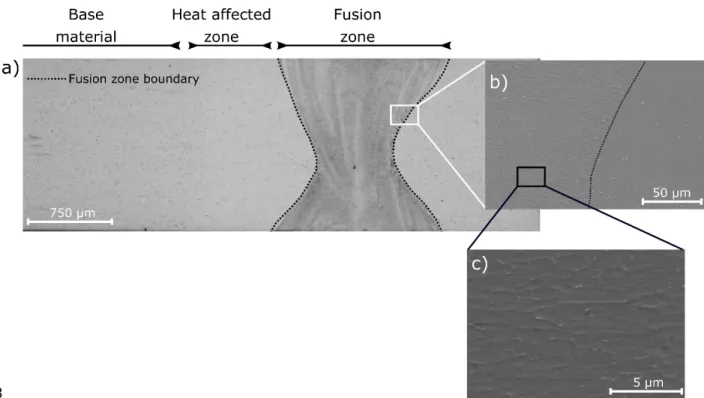

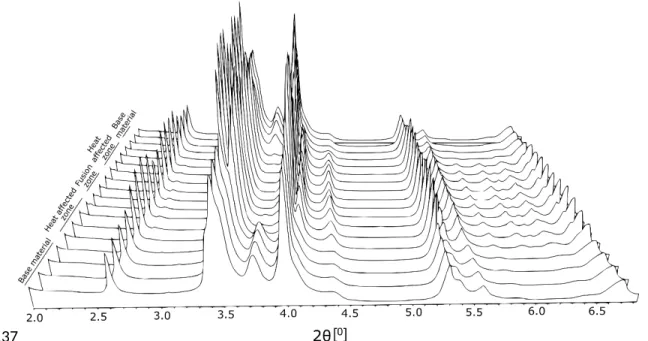

Laser welding of precipitation strengthened Ni-rich NiTiHf high temperature shape memory alloys: Microstructure and mechanical properties

Texto

Imagem

Documentos relacionados

The objectives of the current study are to analyze the effects of laser welding in the weld shape of both similar and dissimilar joints of NiTi to stainless steel and titanium

The literature reported that Ti-Ni shape memory alloys can also absorb hydrogen because Ti has high affinity for hydrogen and the addition of Ni accelerates hydrogen absorption

The effects of Al 2 O 3 reinforcements on microstructure, corrosion and toughness properties of dissimilar aluminum alloys joint fabricated by friction stir welding (FSW)

However, laser beam welding of Al-alloys expectations might be greatly reduced by the occurrence of two main defects:

Thought TIG has a higher heat input it has some similarities to conduction laser weld mode since there is no filler material and an inert gas is used.. Additionally,

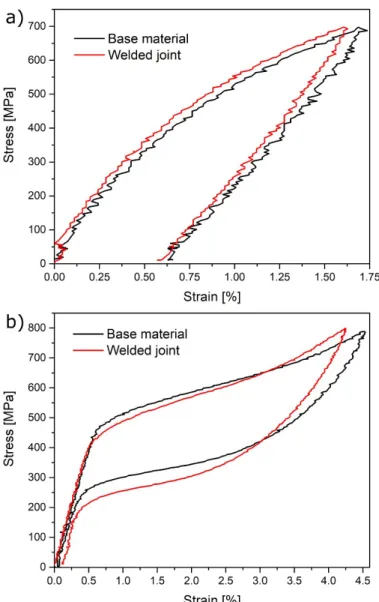

That is not the case for Cu-Al-Mn shape memory alloys that do not appear to exhibit significant changes on the overall tensile properties of the welded joints, when compared

Comparative study of mechanical properties of various Ni-Ti based shape memory alloys in view of dental and medical applications. Phe- nomenological modeling and numerical simulation

Alloys of CuAlMn are known as cheap, high strength shape memory alloys with an excellent damping capacity within their austenitic-martensitic phase transformation, compared to