Rev. Esc. Minas vol.68 número1

Texto

Imagem

Documentos relacionados

Results of the quantitative metallography performed on weld metals in the as welded condition, where AF = acicular ferrite, PF(G) = proeutectoide ferrite, PF(I) = polygonal

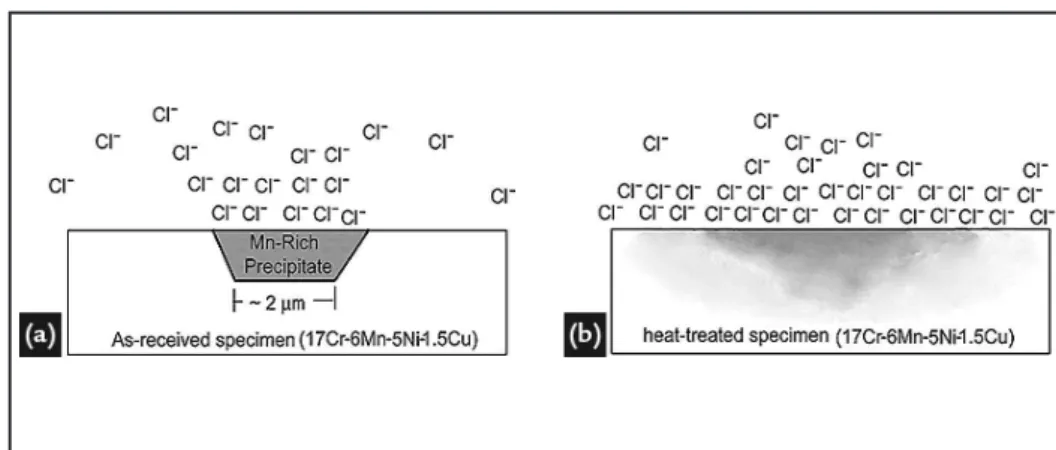

The pitting corrosion susceptibility of the oxide ilms formed on the stainless-steel samples in the three situations (as received and grown in the presence and

The electrochemical results evidenced the presence of an oxide layer onto the 316L stainless steel (316 SS) which in conjunction with pitting potential values ensures the

The effect of intercritical heat treatment temperature on the tensile properties and work hardening behavior of ferrite-martensite dual phase steel sheets. Materials Science

Hardness, tensile and yield strength of the UNS S46500 steel after lower aging temperature, 510ºC (H950), are higher than the ones found in the 538ºC (H1000) aged steel.This result

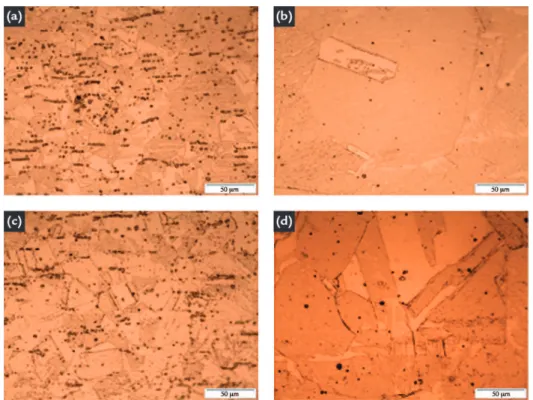

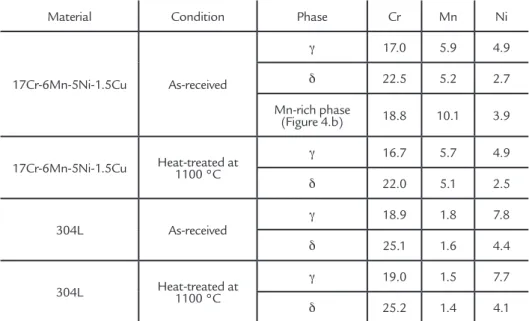

ferrite phase content on the electrochemical properties of new SSS, with ferrite between 30 and 60%, and their microstructure and corrosion resistance were evaluated

martensite in AISI 301LN stainless steel [17] ; to analyze the effect of process parameters on the properties of spot welded cold de- formed AISI 304 grade austenitic stainless

The goal of this study was to examine the changes caused in stress corrosion cracking and the critical pitting temperature behavior of a UNS S31803 duplex stainless steel due