Heat treatment of AlSi9Mg alloy

Texto

Imagem

Documentos relacionados

Remelted zone of the probes after treatment with current intensity of arc plasma – 100 A, lower bainite, retained austenite and secondary cementite.. Because the secondary

We also determined the critical strain rate (CSR), understood as the tangent of the inclination angle between the tangent to the crack development curve and the crack development

Figure 2 presents the electrical conductivity curves as a function of heat treatment time (solution annealing) at 550 °C for sheet bottom samples of the AA4006TRC alloy. Figure

The results of the experiments conducted on Nickel and Carbon free Co-Cr-Mo alloy by applying heat treatment followed by hot forging process reveal that the yield strength of

One poured specimens of the investigated alloy in the following conditions: without vibrations, with 50%ampliture of the vibrations (0,4 mm), with 100% amplitude of the vibrations

Water glass modification with the colloidal solution of ZnO nanoparticles in propanol confirmed the effect of modifier on the water glass wettability of sand

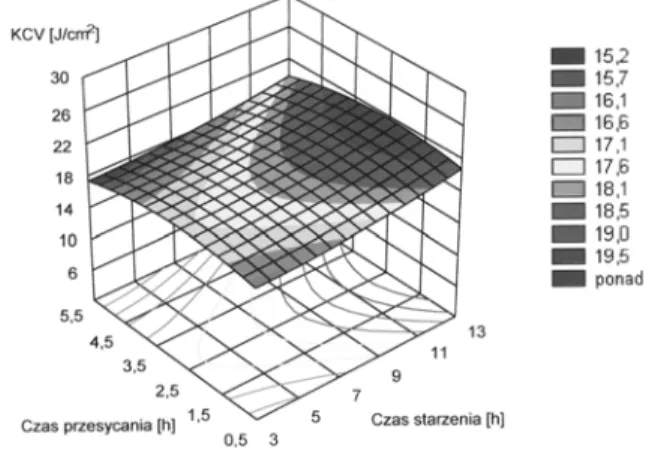

Making analysis of an impact of individual variables change on growth of the mechanical properties it should be noticed, that they impact in diverse way and with various „force” on

social assistance. The protection of jobs within some enterprises, cooperatives, forms of economical associations, constitute an efficient social policy, totally different from