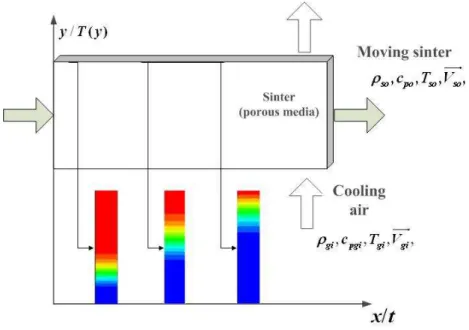

Numerical simulation and analyses for sinter cooling process with convective and radiative heat transfer

Texto

Imagem

Documentos relacionados

[27], the absorbing heat flux and releasing heat flux of the fifth endoreversible Carnot heat engine can be obtained by using the heat transfer between the working fluid and

A three dimensional incompressible steady model has been developed to investigate the effects of Reynolds number, aspect ratio, rarefaction, Prandtl number and

[13] adopted a numerical model to analyze heat transfer process during solidification of sample melted in an Arc-image furnace [14,15], in which the melt cooling rate and

Fig. Homogenized heat transfer coefficient for 10.. 3) For small size of the inclusions a 1 and various values of heat transfer the equivalent heat transfer parameter

The model implemented in this work captures the effect of the fluid velocity associated with the step inclination angle on the phase change process and the conduction heat

A numerical study of steady state laminar forced and free convective and radiative heat transfer in an inclined rotating rectangular duct with a centered circular tube

Heat Transfer Coefficient in a Shallow Fluidized Bed Heat Exchanger with a Continuous Flow of Solid Particles This work shows the experimental study of a continuous

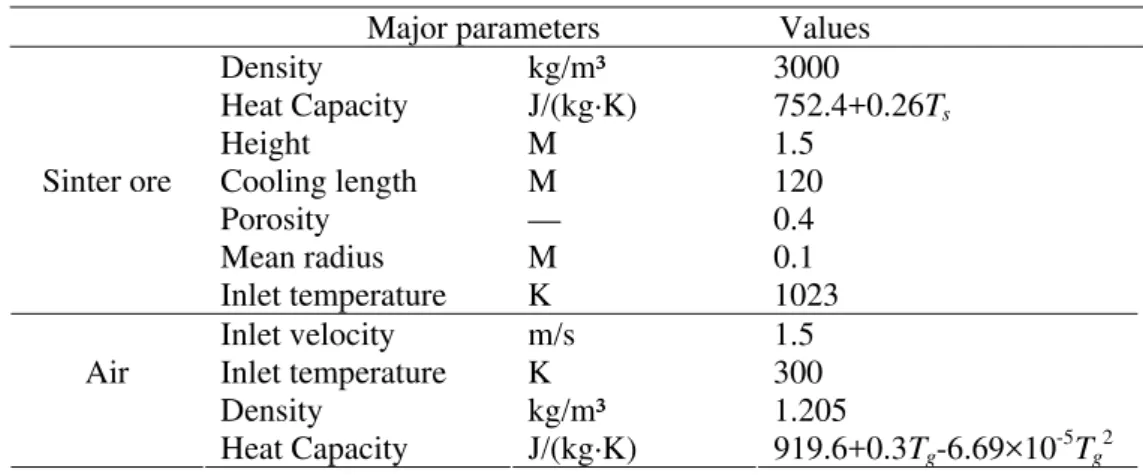

Table 2 shows the heat transfer surface and the estimated values of the global heat transfer coefficient for each exchanger, as well as the estimated mass transfer coefficients