Optimization and application of spray-drying process on oyster cooking soup byproduct

Texto

Imagem

Documentos relacionados

3.3 Drying kinetics and effect of air-drying temperature on chemical composition of Phyllanthus amarus and Phyllanthus niruri …

capsules (Table 3) of larvae fed on different host plants did not differ significantly from one another, indicating that the host plant and temperature did not influence the

The application of molybdenum rates mixed with glyphosate for desiccation in no-tillage system did not affect seed yield and leaf content of molybdenum and nitrogen in bean plants,

The DM gain remarkably differed among plants; for instance, NaCl did not significantly ( P > 0.05) affect total DM of Prosopis juliflora and Piptadenia macrocarpa.. contrary to

The application of leaching fractions (saline treatments), compared with freshwater, did not affect significantly the Na content in the leaf tissue, despite the increase in its

Embora Portugal apresente legislação sobre avaliação que acompanha o que actualmente se prescreve em termos teóricos, mantém também em contrapartida algumas medidas que

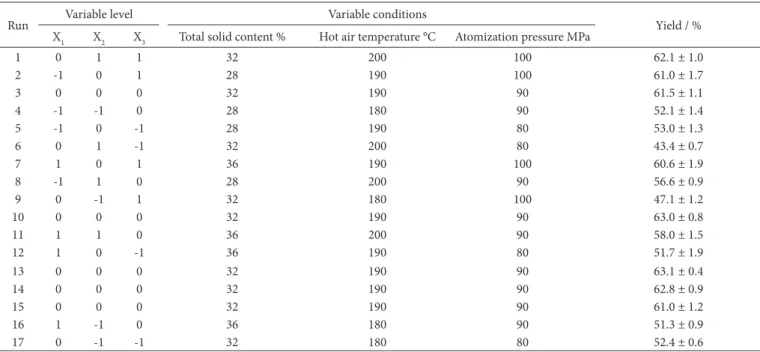

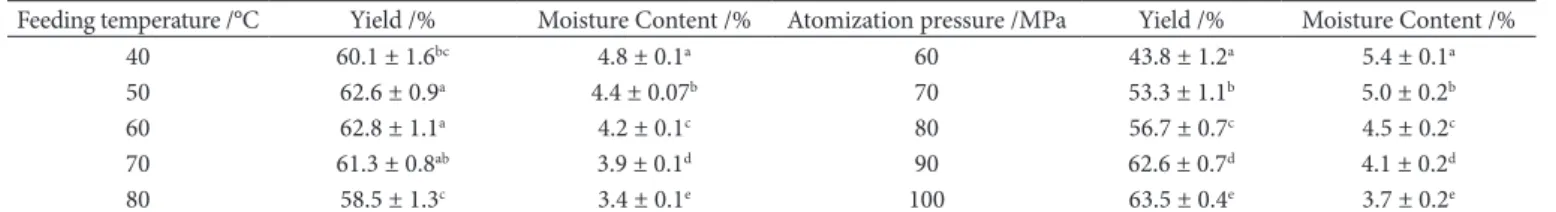

The following optimum conditions for the spray drying of oyster powder were obtained by optimizing our mathematical prediction model: total solid content of 30%, hot air

However comparing the amount of total phenolic compounds in the coffee did not change significantly (p>0.05) with different degrees of roasting (traditional and extra dark)