C Metal Matrix Composites using Laser Treatment

Texto

Imagem

Documentos relacionados

In summary, the mechanical properties of metal matrix composites (MMCs) prepared by ex-situ synthesis technique improved little because of the large size of reinforcement

Ceramic matrix composites (CMCs), constituted of a silicon boron oxycarbide (SiBCO) matrix and unidirectional carbon fiber rods as a reinforcement phase, were

Using correct conditions of pressure and temperature, the titanium matrix composites produced by this process present a good matrix consolidation without porosity and a

An investigation in the present research was made to fabricate and evaluate the microstructure and mechanical properties of metal matrix composites developed using cryogenically

This paper investigates the mechanical properties and corrosion behavior of Metal Matrix Composites prepared using Al7075 alloy as a matrix, Silicon Carbide and Titanium Carbide

The addition of HA in the polymeric matrix of PHB promoted decrease of the mechanical strength of the PHB/HA composites, due to formation of discontinuities on the

[r]

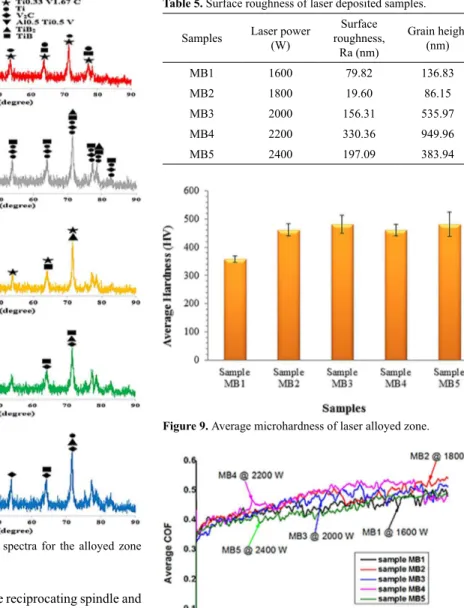

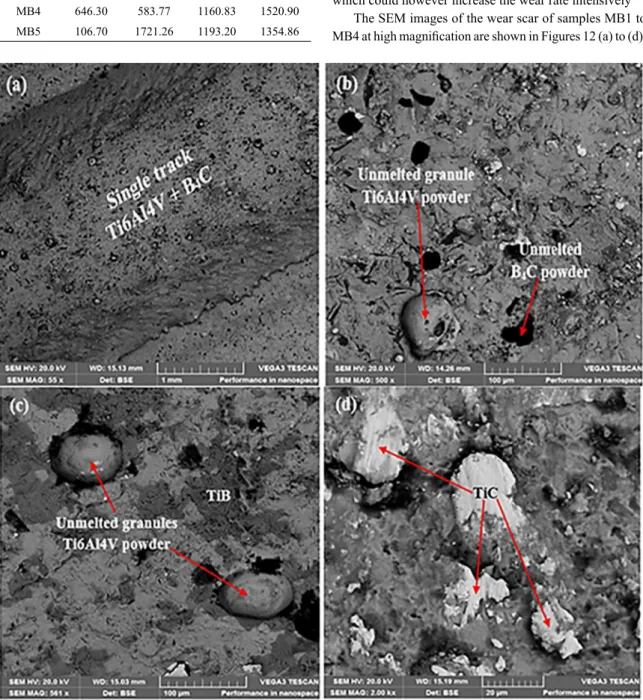

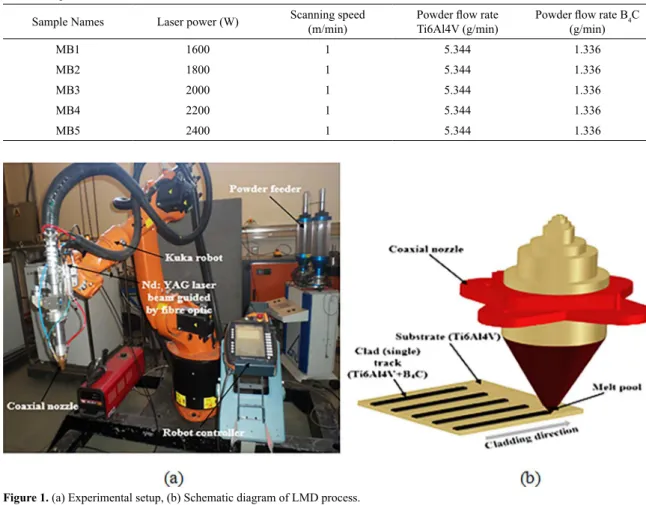

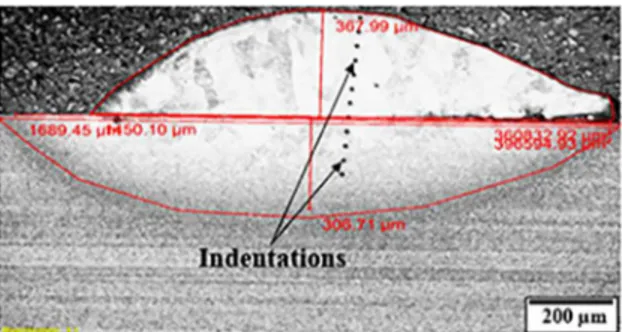

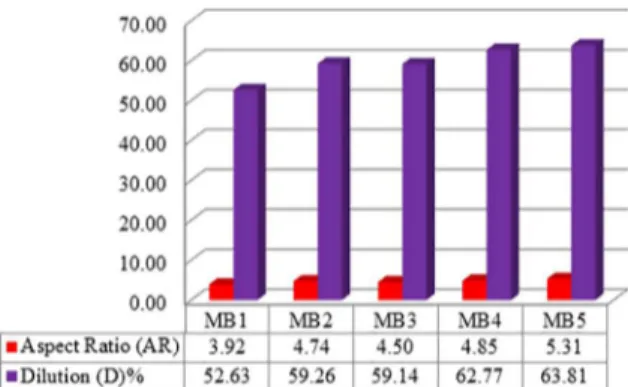

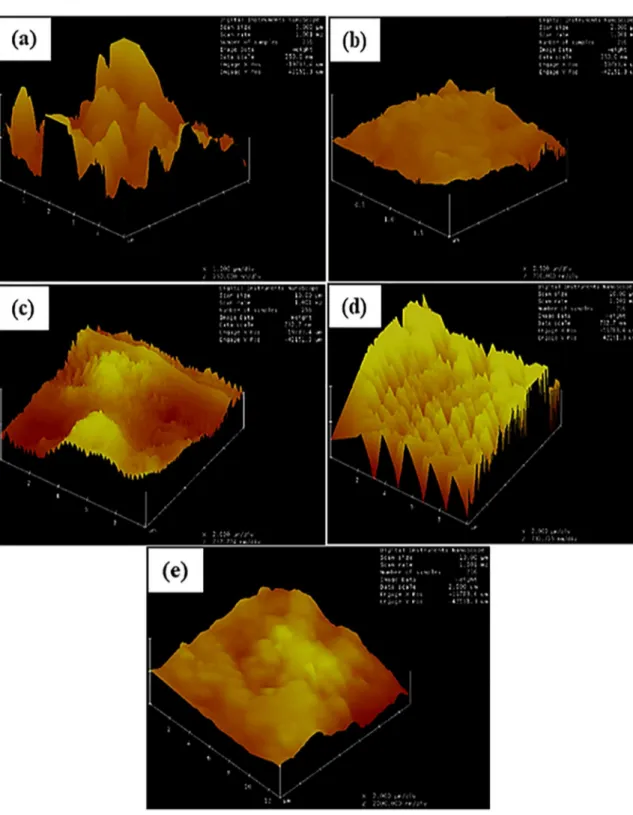

HIS paper presents the report on the influence of process parameters on the characterization of porosity behaviour of titanium composites and its relationship