NUMERICAL METHOD TO PREDICT VOID FORMATION DURING THE LIQUID COMPOSITE MOLDING PROCESS

Texto

Imagem

Documentos relacionados

(2000) Surface tension measurements of liquid metals by the.. quasi containerless pendant drop method. Fat.ralated surface tension and wetting properties of milk. Foodborne pathogens

Demais a mais, correlacionando os dados da Polícia Civil apresentados pelo Relatório Estatístico sobre Criminalidade da Secretaria de Estado da Defesa Social (ALAGOAS, 2010) para

Entretanto, dizer que as representações do es pirito são sexuaes e que não ha, fóra dahi, outro impulso ingenito para a vida e para o pensamento é

Keywords: void formation, surface tension, capillary pressure, mass conservation, free boundary flow, mesolevel analysis, dual porosityZ. 1

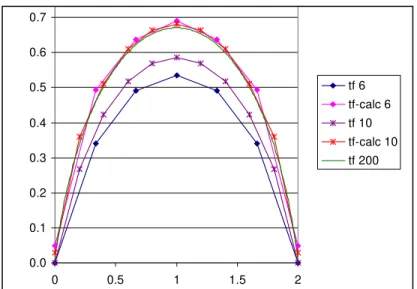

In this paper two techniques for post-processing a finite element solution are presented and tested on several examples, in order to evaluate their efficiency in infiltration

Keywords: Post-processing techniques, Darcy’s flow, Stoke’s flow, Free boundary flows, Mesolevel analysis, Capillary pressure, Liquid composite molding.. Reliable flow

resin transfer molding (RTM), resin film infusion (RFI), and hand lay-up, the problem of void formation is also related to the manufacturing process parameters such as fiber

Nesse quadro, parece ainda mais irreal o alcance dos objetivos centrais da quebra eficiente do contrato, quais sejam: (i) aumento da utilidade para a parte que rompeu o