Additive manufacturing of a high resistance steel by MIGMAG

Texto

Imagem

Documentos relacionados

Considerando o panorama apresentado, a Saúde Comunitária (SC) desponta como uma perspectiva recente no âmbito da saúde pública de reversão da compreensão e atuação sobre

In severe HF patients with restrictive left ventricular filling assessed both by pulsed-wave Doppler echocardiography of the mitral flow and simultaneous pulmonary

The latest classified metal transfer mode is free flight one with buried electrode that happened in high voltage, high wire feed speed and high current. It means it happened in high

The objective of this research was to quantify the influence of the cutting speed, feed per tooth and depth of cut, mainly at high-speed machining, on the microhardness

• AcombinationofMQLlubricatingmode,highcutting speed, low feed rate, high nose radius with low depth of cut is helpful for achieving the minimal surface

The combustion mode, propagation velocity of combustion wave, combustion temperature and product structure were investigated.. The combustion wave propagated along a spiral

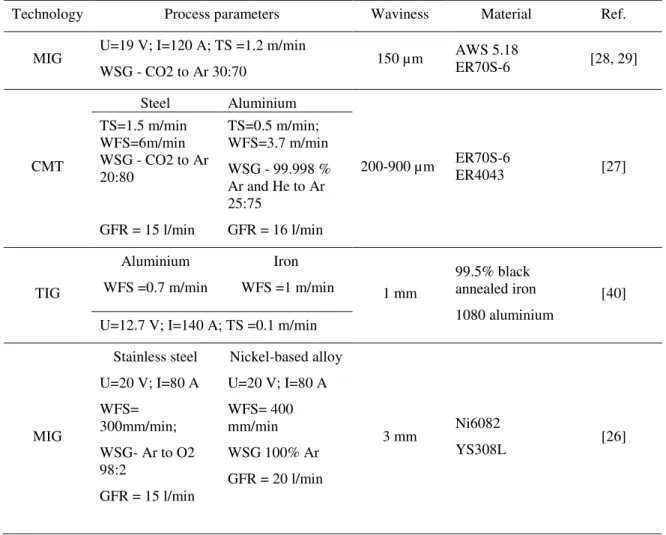

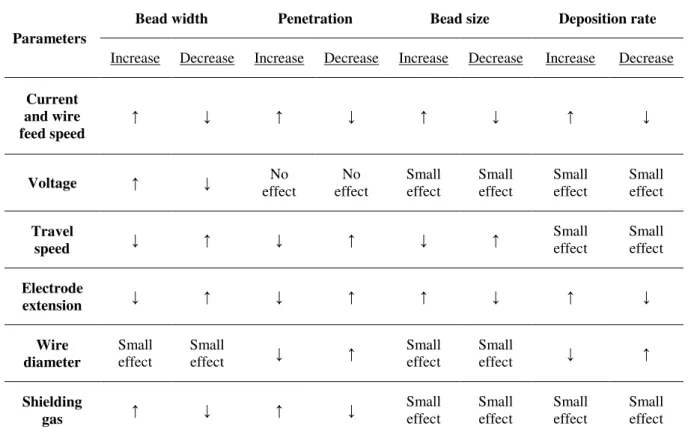

The problem was to choose the near-best values of three control variables (welding voltage, wire feed rate and welding speed) based on four quality responses (deposition

The effects of diesel-natural gas substitution ratios, engine speed, and load on the equivalent brake specific fuel consumption and gaseous emissions of

![Figure 2.9 Example of welding current waveform and droplet in pulsed transfer mode [49]](https://thumb-eu.123doks.com/thumbv2/123dok_br/16560845.737567/37.892.212.704.671.944/figure-example-welding-current-waveform-droplet-pulsed-transfer.webp)