Rev. Esc. Minas vol.66 número2

Texto

Imagem

Documentos relacionados

The Effect of Weld Geometry and Post-Weld Heat Treatment on the Corrosion Behaviour of Austenitic Stainless Steel Immersed in 1.0 M NaCl Solution.. Oladele Isiaka Oluwole,

Aiming to improve the knowledge on the low- temperature plasma nitriding of sintered PIM 316L austenitic stainless steel, the effect of nitriding temperature and time on the

In this work, the inluence of working pressure on the characteristics of the layers produced by the nitriding treatment on the AISI 316 austenitic stainless steel surface using

In addition to carbon diffusion and its subsequent incorporating problems such as carbides formation in the fusion zone of low alloy and carbon steels to stainless steels joints,

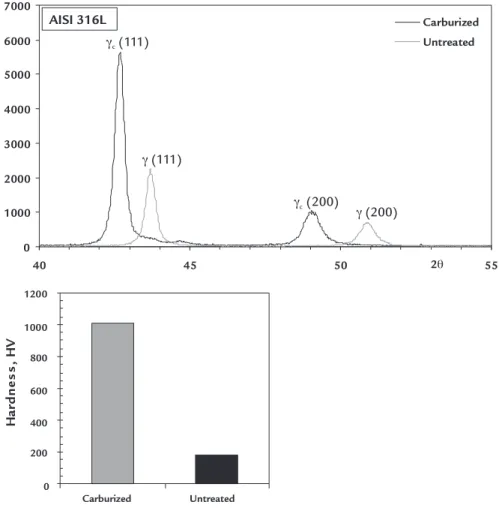

thermochemical treatment of austenitic stainless steels 15-17. Those authors have shown that the presence of copper and molybdenum in solid solution allowed higher content of

This suggests that diffusion in the austenitic phase of duplex stainless steel has an energy barrier similar to that found for the diffusion of nitrogen in expanded austenite

The micrographs of Figure 14 show signs of wear through the risks / grooves presented on the tracks, especially in the cases of plasma and solid nitriding treatment. SEM

in yield strength with increasing cooling rate, as observed in figure 4, can be related to the lower content of pearlite, the presence of low strength ferrite, and some austenite