SHIFTS AND HARVESTING SYSTEMS ON QUALITY OF IMPURITIES SAMPLES IN SUGARCANE

Texto

Imagem

Documentos relacionados

Therefore, this work uses an MIP model to represent the programming and scheduling sugarcane harvesting front problem and proposes heuristic methods to solve this problem in

(2012) that when evaluated soil losses of organic matter and nutrients in area with sugarcane cultivation, subjected to mechanical harvesting, using plots with

The experiment, conducted in a mechanical green harvesting area cultivated with sugarcane, consisted of two stages: in the first stage, the mechanical straw cutting

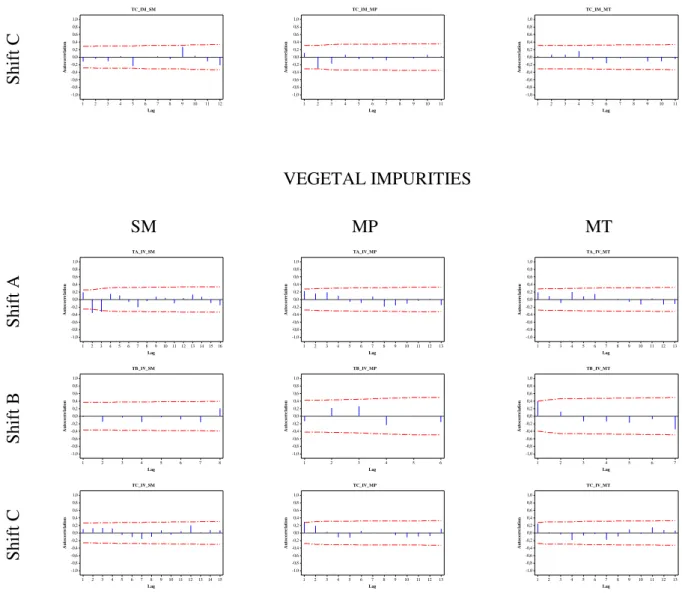

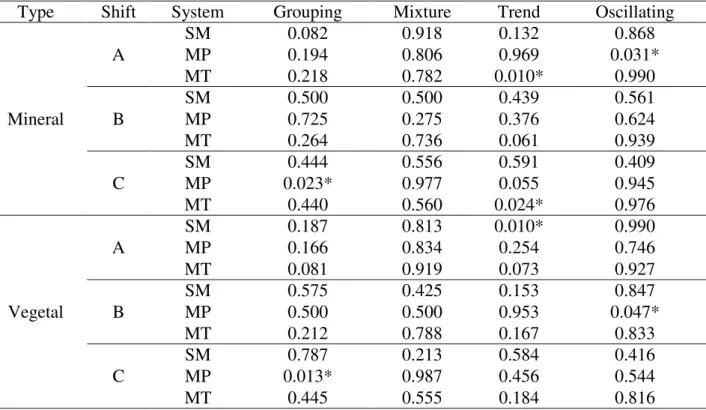

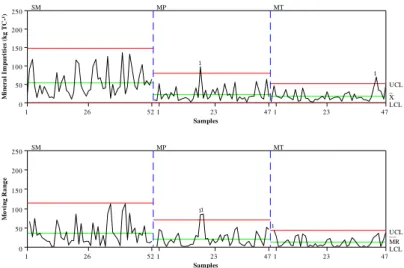

It is also perceived that only five points outside control limits are equivalent for the three control chart models, a situation that portrays the quantity

Foi concluído também que as possíveis explicações biológicas para tal associação podem estar relacionadas a um aumento da atividade trombogênica, dado pelo aumento da

Dos pacientes com litíase urinária, 28% apresentaram alterações urinárias associadas, sendo a dilatação pielocalicial a mais freqüente, seguido de cisto. renal

Analysis of variance was used to compare the average worker productivity of the three methods of harvesting (manual, mobile p latform with and without use of an