Particles in Silicate Based Electrolytes on Microstructure and Mechanical Properties of Micro Arc Coated Ti6Al4V Alloy

Texto

Imagem

Documentos relacionados

The COR of Fe-20Cr alloy coated with RE oxide gels varied and it was shown that COR depends on the thickness of the chromium dioxide layer formed on the alloy surface. In the

In the present study, Ti-6Al-7Nb samples were processed by ECAP following thermomechanical processing which effects on the microstructure of Ti-6Al-7Nb alloy were investigated

The severe plastic deformation process using HPT proved to be an effective way of refining the microstructure of Ti-6Al-7Nb alloy, enhancing mechanical properties, manifested by

In this paper, we investigated the effect of Nb as a substitutional solute on the mechanical properties of Ti-Nb alloys, prepared in an arc-melting furnace and characterized

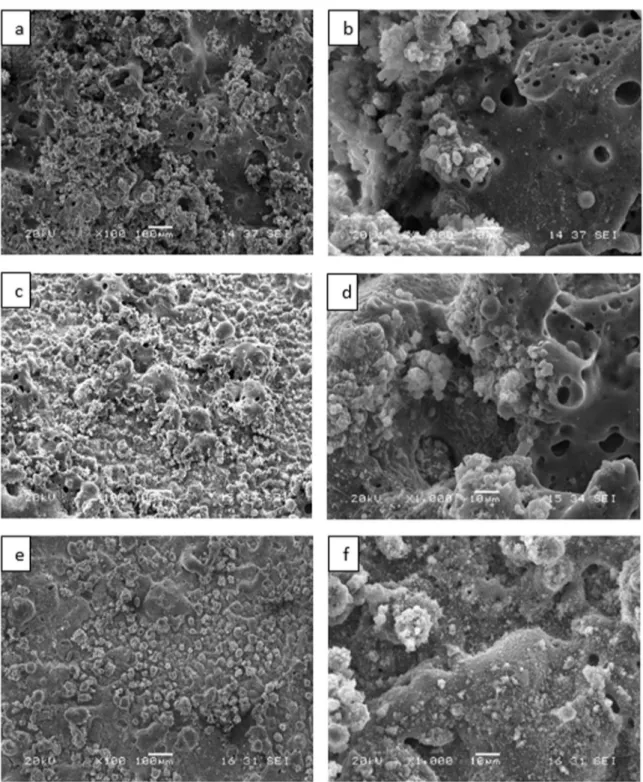

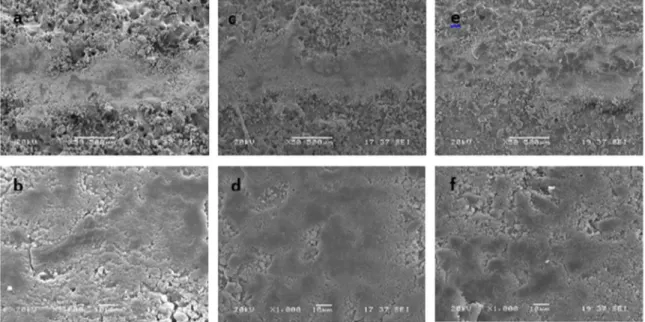

The surface modification by MAO process of Ti-6Al- 4V alloy for biomedical purpose using the parameters employed in this study, did not modify the fatigue behavior of the

The corrosion resistance improvement of the new Ti-6Al-4V-1Zr alloy in comparison with ternary Ti-6Al-4V alloy in Ringer-Brown solution was proved by the more

The soldering is done using the lead free Sn/Cu solder with and without the Nano-Structured Coating of Zirconium oxide Nano particles and using different gaseous

Considering those results, it can be verified that the Ti- 6Al-4V alloy it presents better mechanical properties than the CP Ti and that the increase of 50ºC and 100ºC, above