Corrosion Behavior of Duplex and Lean Duplex Stainless Steels in Pulp Mill

Texto

Imagem

Documentos relacionados

Figure 6. Crystallographic microtexture of duplex stainless steels S32304 of the samples as received, cold rolled and annealed.. ferrite, the components that were present in

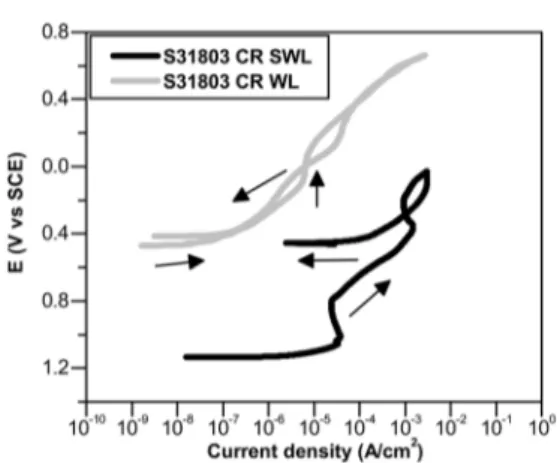

The goal of this study was to examine the changes caused in stress corrosion cracking and the critical pitting temperature behavior of a UNS S31803 duplex stainless steel due

Neste trabalho o objetivo central foi a ampliação e adequação do procedimento e programa computacional baseado no programa comercial MSC.PATRAN, para a geração automática de modelos

Ousasse apontar algumas hipóteses para a solução desse problema público a partir do exposto dos autores usados como base para fundamentação teórica, da análise dos dados

This study investigated the effects of different cooling rates on microstructure and corrosion resistance of SAF 2205 duplex stainless steel (2205 DSS) solution annealing

14 , evaluated the sensitization of UNS S31250 duplex stainless steels Inluence of Deleterious Phases Precipitation in the Corrosion Resistance Measured by Double

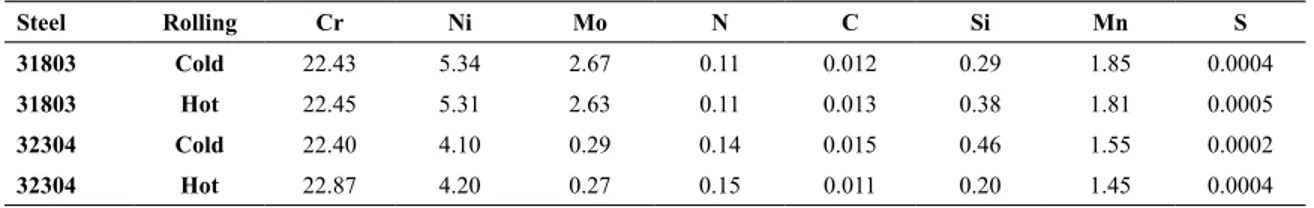

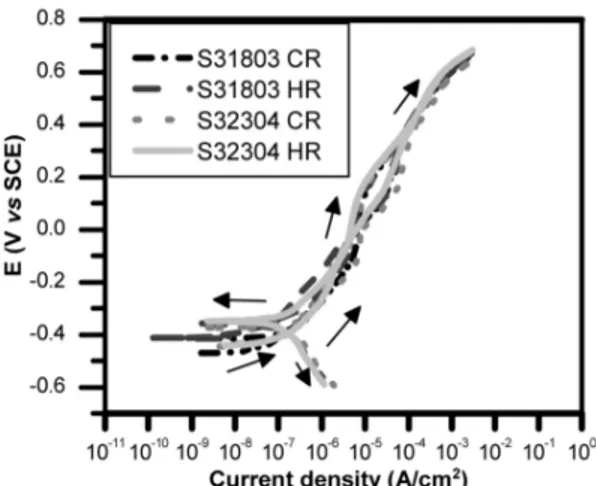

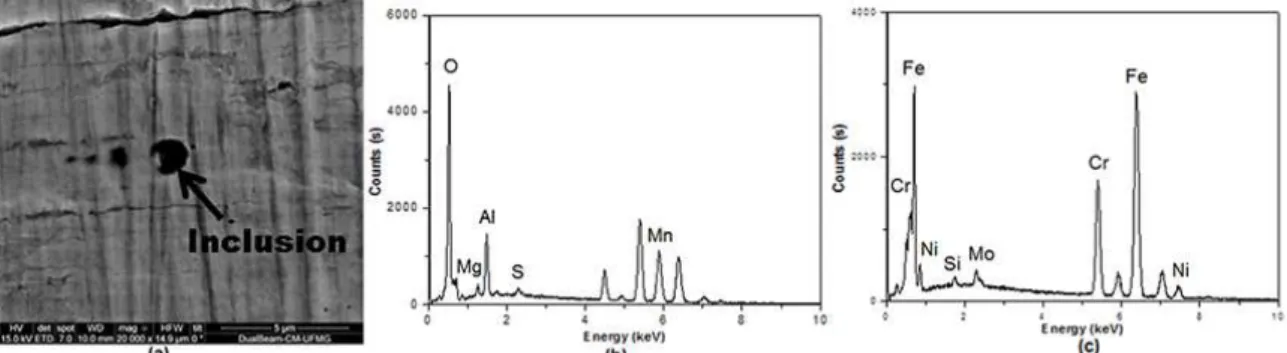

This study has also investigated the inluence of microstructure of cold and hot rolled duplex steels on electrochemical properties of duplex and lean duplex steels in white,

The welded joints exhibited higher values of corrosion potential than the lean duplex steel in the as received condition, except for the root region of joint welded using SMAW