A R C H I V E S

O f

F O U N D R Y E N G I N E E R I N G

Published quarterly as the organ of the Foundry Commission of the Polish Academy of Sciences

ISSN (1897-3310)

Volume 11

Issue 2/2011

101–104

20/2

The modification process of AlSi21CuNi

silumin and its effect on change of

mechanical properties of the alloy

J. Pezda *

Chipless Technology Department, ATH Bielsko-Bia

ł

a, Willowa 2, 43-309 Bielsko - Bia

ł

a

*Correspondence address: e-mail:

Hjpezda@ath.bielsko.pl

HReceived 11.04.2011; accepted in revised form 26.04.2011

Abstract

Due to difficulties present during machining operations and with segregation of crystals of primary silicon, hypereutectic silumins can be used after modification only. It is why elaboration of effective modification methods is necessary for complete utilization of such alloys for machinery parts made from castings. In the paper are presented test results concerning an effect of modification with phosphor copper and strontium of AlSi21CuNi silumin on change of its mechanical properties (RBmB, AB5B) and its structure. Investigated alloy was melted in

electric resistance furnace. All smelting processes were performed in temperature of 800 – 820P

o

PC. Obtained results concern light

microscopy and strength tests of the investigated alloy. Performed tests have shown that application of phosphorus in form of CuP10 and AlSr10 master alloy as an inoculant gives positive results in form of refinement of primary crystals of silicon. Modification with phosphorus has enabled obtainment of clearly visible growth of tensile strength, RBmB.

Keywords: modification, mechanical properties

1. Introduction

Essence of modification of silumins boils to change of form or size of silicon crystals present as eutectic or primary ones. Perfect sliding properties and high abrasion resistance of hypereutectoid silumins result from their structure, which can be characterized by precipitations of primary crystals of silicon in soft eutectic groundmass. Primary crystals of silicon are unfavorable due to their impact on machinability of material. They bring about considerable wear of tools and have negative effect on conditions of machined surface (big roughness). In case of hypereutectic silumins, by introduction of active nucleuses of crystallization are refined mainly a brittle, hard precipitations of primary silicon [1]. High content o silicon results in necessity of superheating of the alloy in limits of 850 – 900 C and keeping it

for 1-2 hour in order to dissolve (at least partially) big and thick precipitations of silumin [1]. In such temperatures occur intensive oxidation of alloy-forming elements and growth of its gassing. During solidification of the alloy, primary silicon can crystallize in form of big crystals, what reduces its mechanical and technological properties.

Considering mechanism of modification of these precipitations one should take into account that effect of modification of hypereutectic silumins depends on earlier transition to liquid phase of sparingly soluble crystals of primary silicon [1-3]. Tests performed by authors of the studies [4-10] enable utilization of modification treatments together with making use of a various micro additives in order to improve properties of hypereutectoid alloys.

Hypereutectoid silumins are modified with P as well as Bi and Ti [2].

Phosphorus, which can be introduced to metal bath in free form, as a master alloy or a salt, belong to well-known modifiers of hypereutectic silumins. It has been confirmed [2] that in such case the aluminum phosphide, AlP, becomes the nucleus of the crystallization. In the studies [11-12] is presented a new view on interaction of phosphorus in process of modification of hypereutectic silumins, which is an effect of local overcooling in micro-areas caused by evaporation and expansion of bubbles of phosphorus vapours. Indispensable quantity of phosphorus in the alloy was determined as interval of 0,01 ÷ 0,05 % [1-3].

Modification with phosphorus results not only in refinement of primary crystals of silicon, but also in distinct transition of the crystals from irregular forms into polydendric forms. In bibliography are often and often met test results concerning modification of Al-Si alloys with complex additives [4,5].

Pouring temperature belongs to very important factors in obtainment of correct results of the modification. Hypereutectoid silumins are characteristic of good castability even in temperatures close to liquidus curve, what suggests implementation of low temperature of casting. However, such method of casting creates conditions to easy coarsening of primary crystals of silicon and their non-uniform distribution on microstructure of the casting. Rate of cooling of the alloy poured into mould has also an effect on results of the modification.

2. Methodology of the research

Due to high abrasion resistance, high mechanical properties in increased temperatures and very low thermal expansion, AlSi21CuNi alloy belongs to hypereutectic alloys commonly used to production of heavy-duty pistons to combustion engines. Investigated alloy was melted in electric resistance furnace. All melts were performed in temperature of 800 – 820P

o

PC.

Investigated alloy was poured into metallic moulds heated to temperature of 200 – 250P

o

PC. Process of refining was performed

with use of hexachloroethane in quantity of 0,15% mass of charge. After removal of slag from metal-level one performed treatments of the modification.

Test pieces to strength tests were poured into metal mould, heated to temperature of 200 - 250P

o

PC and were prepared

according with PN-88/H-88002 standard. Static strength tests were performed on strength tester of ZD-20 type.

To the tests one used alloy having chemical composition presented in the Table 1.

Table 1 Chemical composition of the

AlSi21CuNi

alloySi 21,8 % Mn 0,13% Fe 0,38% Ni 0,91% Zn 0,02% Ti 0,004% Pb 0,003% Cu 1,27% Mg 0,47% Sn 0,03% Al rest

For each modifier were performed 3 melts.

Modifications with phosphorus were carried out by adding CuP10 in quantity of 0,2; 0,4; 0,6% mass of charge. Castings of test pieces to strength tests were produced for not modified alloy

and after 10; 30 and 60 minutes from introduction of the modifier to metal batch.

Modifications with strontium were performed adding AlSr10 master alloy in quantity of 0,2; 0,4; 0,6% mass of charge. Castings of test pieces to strength tests were produced for not modified alloy and after 10; 30 and 60 minutes from introduction of the modifier to metal bath.

3. Description of obtained results

In the Table 2 are presented mechanical properties obtained during performed tests for the alloy modified with phosphorus in form of CuP10.

Table 2. Mechanical properties of the alloy modified with CuP10

RB

m B[MPa] AB

5B[%] not modified modified not modified modified

135 - 145 158 - 191 0,7 – 0,8 0,3 – 0,7

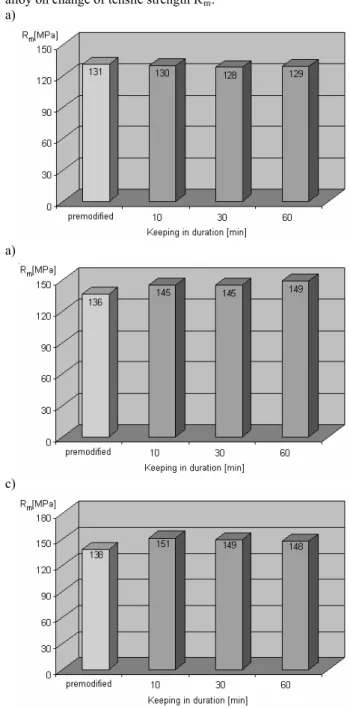

In the Figs. 1-2 are presented effect of keeping in duration of the alloy and quantity of modifier on tensile strength, RBmB.

a)

b)

Fig. 1. Tensile strength RBmB of the alloy for additive of:

a) 0,2% CuP10, b) 0,4% CuP10

A R C H I V E S O F F O U N D R Y E N G I N E E R I N G V o l u m e 1 1 , I s s u e 2 / 2 0 1 1 , 1 0 1 – 1 0 4

Fig. 2. Tensile strength RBmB for additive of 0,6% CuP10

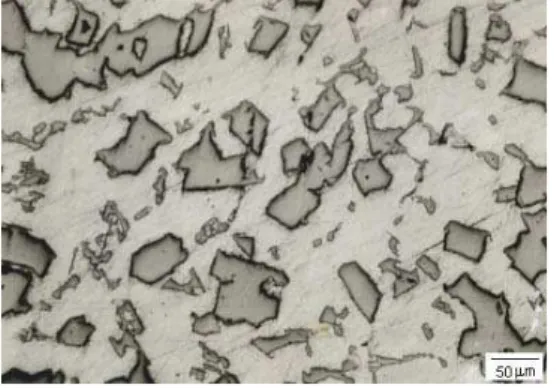

Microstructures of test pieces after modification with CuP10 are shown in the Figs. 3-4.

Fig. 3. Microstructure of the alloy modified with phosphorus (0,6% CuP10, 30 minutes after modification)

Fig. 4. Microstructure of alloy modified with phosphorus (0,6% CuP10, 60 minutes after modification)

In result of used CuP10 modifying agent one obtained considerable refinement of crystals of primary silicon. The best modified structure (Fig. 3) corresponds to modification with 0,6% CuP10 after 30 minutes. Also for the same test piece one obtained the highest tensile strength RBmB (191 MPa).

In the Table 3 are presented mechanical properties obtained during performed investigations for the alloy modified with strontium in form of master alloy AlSr10.

Table 3. Mechanical properties of the alloy modified with AlSr10

RBm B[MPa] AB5B[%] not modified modified not modified modified

132 - 138 129 - 151 0,6 – 0,8 0,5 - 1

In the Fig. 5 are presented effect of keeping in duration of the alloy on change of tensile strength RBmB.

a)

a)

c)

Fig. 5 Tensile strength RBmB of the alloy for additive of:

a) 0,2% AlSr10, b) 0,4% AlSr10, c) 0,6% AlSr10

In case of modification with strontium, its effect can be observed not before than content of 0,04% Sr. In result of application of such modifying agent one obtained significant refinement of the structure. The best modified structures are presented in the Figs. 6-7. They were obtained in result of additive of 0,4% AlSr10 and keeping in duration of 60 minutes, as well as additive of 0,6% AlSr10 and keeping in duration of 10 minutes.

Improvement of mechanical properties testifies for correct course of modification process of the alloy. Application of suitable temperatures, durations of remelting as well as keeping in of the alloy and suitable modification is a condition of obtainment of improved mechanical properties of AlSi21CuNi silumin.

Continuation of the research shall be connected with determination of optimal, with respect to mechanical properties, additive of phosphorus for the alloy destined to heat treatment.

References

[1] S. Pietrowski, Silumins, Wydawnictwo Politechniki

Łódzkiej, Łódź, 2001 (in Polish).

[2] Z. Poniewierski, Crystallization, structure and properties of silumins, WNT Warszawa 1989 (in Polish).

[3] Z. Górny, Casting alloys of non-ferrous metals, PWN, Warszawa 1992 (in Polish).

[4] F. Romankiewicz, Modification of AK20 silumin, Solidification of Metals and Alloys, vol. 2 No 44 (2003) (in Polish).

[5] J. Piątkowski, The phosphorus interaction on the process forming of primary structure of hypereutectic silumins, Archives of Foundry Engineering, vol. 9, Iss. 3 (2009) 125-128.

Fig. 6. Microstructure of the alloy modified with strontium (0,4% AlSr10, 60 minutes after modification)

[6] TH. Zhang,T Microstructure and mechanical properties of

hypereutectic Al-Si alloy modified with Cu-P, Rare Metals, Iss. 1 (2008) 59-63.

[7] Yaping Wu, Shujun Wang, Hui Li, Xiangfa Liu, A new technique to modify hypereutectic Al–24%Si alloys by a Si–P master alloy, Journal of Alloys and Compounds 477 (2009) 139–144.

[8] M. Faraji, I. Todd, and H. Jones, Effect of Phosphorus and Strontium Additions on Formation Temperature and Nucleation Density of Primary Silicon in Al-19 Wt Pct Si Alloy and Their Effect on Eutectic Temperature, Metallurgical and Materials Transactions, vol. 40A (2009) 1710-1715.

[9] J. Chang, I. Moon Ch. Choi, Refinement of cast microstructure of hypereutectic Al-Si alloys through the addition of rare earth metals, Journal of Materials Science, 33 (1998) 5015 – 5023.

Fig. 7. Microstructure of the alloy modified with strontium (0,6% AlSr10, 60 minutes after modification)

[10] M. Piękoś, S. Rzadkosz2, J. Kozana 3,W. Cieślak, Effect of upgrading treatments on properties of aluminum-silicon alloys having hypereutectoid composition, Foundry Faculty AGH, XXXII-th Scientific Conference, Nationwide Polish Foundryman Day (2009) 1-6.

4. Conclusions

Performed investigations have confirmed positive effect of phosphorus as modifying agent for AlSi21CuNi alloy, expressed both as considerable refinement of primary crystals of silicon and improvement of tensile strength RBmB.

[11] F. Bińczyk, J. Piątkowski, A. Smoliński, Hypothesis of modification of ak20 silumin using phosphorus, Solidification of Metals and Alloys, No 38 (1998) 71-76 (in Polish).

Modification with strontium effects in refinement of structure with simultaneous slight increase of tensile strength RBmB and

elongation AB5B.

[12] Binczyk, F.; Piątkowski, The interaction of phosphorus in hypereutectoid silumins - analysis of the hypotheses, Ores and Non-ferrous Metals, vol. 46, Iss. 8 (2001) 363-369.

A R C H I V E S O F F O U N D R Y E N G I N E E R I N G V o l u m e 1 1 , I s s u e 2 / 2 0 1 1 , 1 0 1 – 1 0 4

![Table 2. Mechanical properties of the alloy modified with CuP10 R B m B [MPa] AB 5 B [%]](https://thumb-eu.123doks.com/thumbv2/123dok_br/18264669.343810/2.871.453.796.524.980/table-mechanical-properties-alloy-modified-cup-mpa-ab.webp)