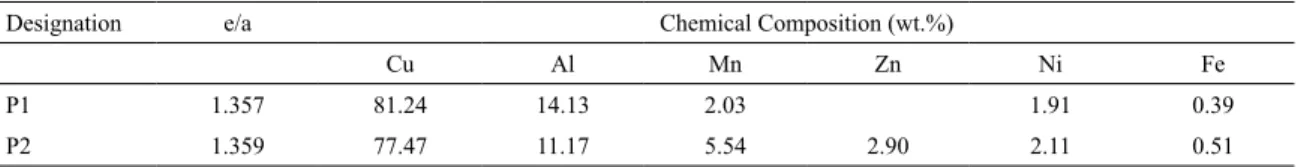

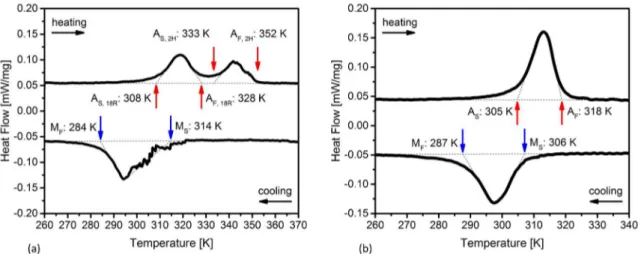

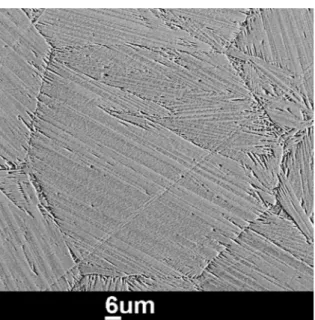

Impact of Alloy Composition and Thermal Stabilization on Martensitic Phase Transformation Structures in CuAlMn Shape Memory Alloys

Texto

Imagem

Documentos relacionados

Comparative study of mechanical properties of various Ni-Ti based shape memory alloys in view of dental and medical applications. Phe- nomenological modeling and numerical simulation

Phase Formation, Thermal Stability and Mechanical Properties of a Cu-Al-Ni-Mn Shape Memory Alloy Prepared by Selective Laser Melting.. Piter Gargarella a * , Cláudio Shyinti

Martensitic Transformation Under Compression of a Plasma Processed Polycrystalline Shape Memory CuAlNi Alloy.. Fábio de Oliveira Braga a,b *, Anatoliy Nikolaevich Matlakhov c

and Pacheco, P.M.C.L., 2005, “A constitutive model for shape memory alloys considering tensile-compressive asymmetry and plasticity”, International Journal of Solids and

The appearance of BCT martensite in Fe-Pd-based ferromagnetic shape memory alloys, which develops at lower temperatures than the thermoelastic martensitic transition,

That is not the case for Cu-Al-Mn shape memory alloys that do not appear to exhibit significant changes on the overall tensile properties of the welded joints, when compared

The device is able to dissipate a considerable amount of energy, while minimizing a set of adverse effects, related with cyclic loading and aging effects, that hinder the

- F. Schell, On the Mechanisms for Martensite Formation in YAG Laser Welded Austenitic NiTi , Shape Memory and Superelasticity, vol 2, 114-120, 2016. Braz Fernandes, High