Mat. Res. vol.18 número6

Texto

Imagem

Documentos relacionados

Keywords: Friction stir welding (FSW), viscoplastic modeling, three-dimensional modeling, finite elements model, aluminum butt

The corrosion behavior at different positions (top and bottom) of the weld nugget zone along the thickness plates in AA6061-T6 aluminum alloys welded by friction stir lap

Although numerical models of heat transfer and material low have contributed to understand the underlying mechanisms of friction stir welding (FSW), there are certain input

side experienced large plastic deformation with high grain boundary storage energy and the temperature at the retreating side was higher than that of the advancing side during the

Among all the welding condition lower tensile strength values were displayed by the specimens welded under the tool rotational speed of 1400rpm, welding speed of 100mm/min and

Keywords: Aluminum Alloy 5052, Friction Stir Welding, Response Surface Method, Tensile Strength, Microstructure, Grey relational analysis.. *e-mail:

The higher value of tensile strength was obtained 192 MPa at rotational and welding speeds of 1000 rpm and 150 mm/min which was 76.80% of parent material and maximum hardness was

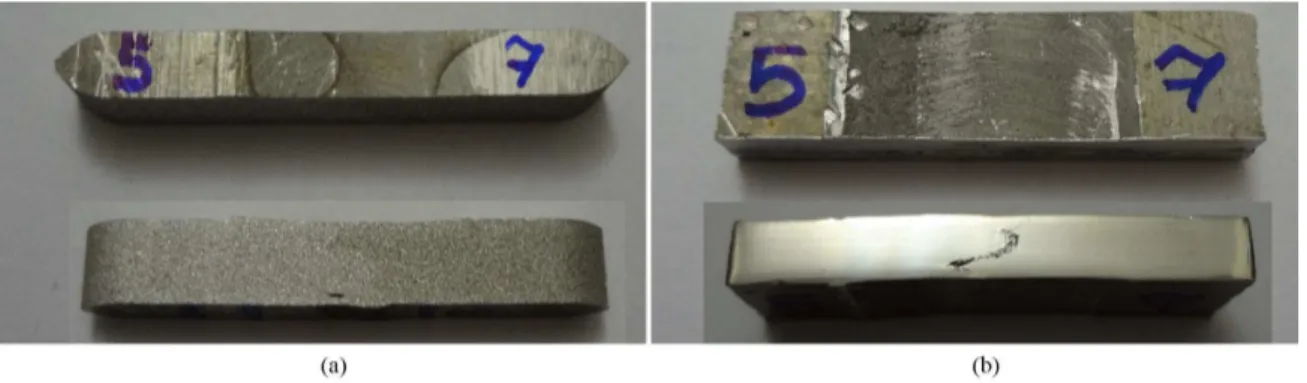

Figure 15: Specimens after three-point bending tests: (a) as-welded (b) PWHTed.. Nahit Oztoprak et al. Effects of post-weld heat treatment on the microstructural evolution