The first stage of the empirical part was to identify criteria for key suppliers based on theory. The supplier survey cover letter in appendix 1 outlines the survey areas and response instructions.

Background and purpose of the study

Theoretical framework

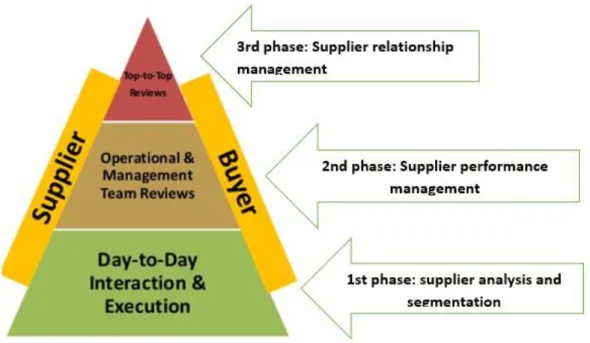

Second phase supplier performance management will be based on the 11 key purchasing performance areas in Carrus Delta and for theory part in chapter 3 and 6. Results of the key supplier survey are analyzed against the theory and key performance areas.

Case company Carrus Delta Oy

History background

1986 Wiima Oy owner Ilmari Mustonen buys Ajokki Group 1989 Ajokki Group changes its name to Carrus Oy. 2008- Volvo Bus Finland Oy Lieto Factory is taken over by a group of Finnish bus body experts with over 100 years of combined experience in the bus body industry.

Organizational structure and strategy

The business environment and processes are gathered around customer needs and the main principle of maintaining a high level of product quality. Cooperation with Volvo Bus Corporation also leads the operation to high levels of quality and Volvo standards through shared global suppliers and conditions.

Supplier management

Purchasing management

Supply chain management

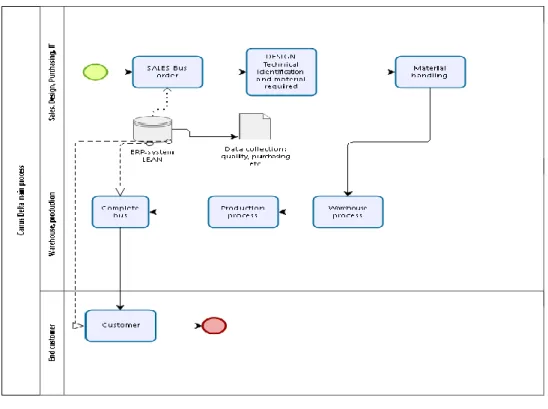

Overview of the supply chain in Carrus Delta

Key process of the Carrus Delta is to produce a complete bus in a certain timescale with the best quality and that meets the customer's needs. Customer is the end user of the finished product and a supplier is a material and information supplier to Carrus Delta.

Different purchasing dimensions

First the customer orders a bus or several buses and the sales confirms the order for the customer.

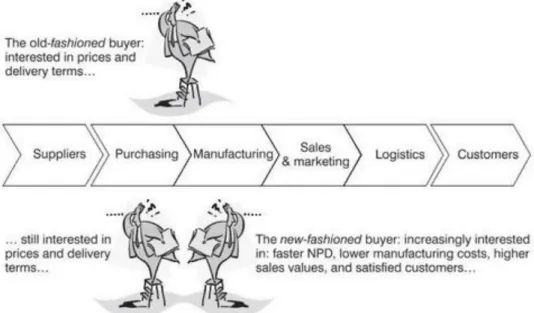

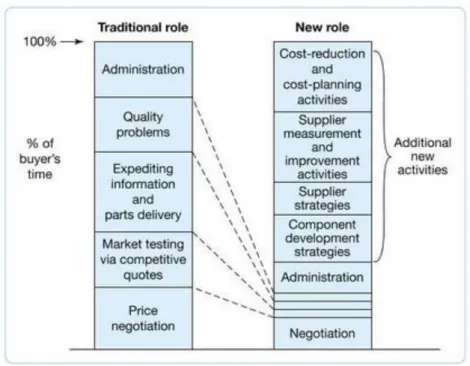

Purchasing role in the past and nowadays

Effective purchasing will create value and increase profit from an overall understanding of the cost structure in the supply chain.

Procurement

Key purchasing activities in Carrus Delta

Needs assessment will not be necessary if there is a created structure for the material and demand for the production material in the system. Requests for quotations (RFQ) will be sent to selected suppliers and quotations received will be agreed or rejected.

Material and supplier handling

As Carrus Delta is a license manufacturer with Volvo Bus Corporation, it will use common global suppliers with the same terms and conditions of trade. Supplier evaluation will be based on the Supplier Evaluation Model (SEM) tool as in Table 1.

Purchasing performance

Key purchasing performance indicators in Carrus Delta

KPIs monitored quarterly are payment terms, number of active suppliers in the system and supplier delivery accuracy. Other KPIs are the number of missing production materials, transportation costs and new designed materials and their part numbers.

Key supplier selection

Supplier market

Supplier analysis methods

Strategic fit refers to discovering the supplier's core competencies and value propositions for the relationship. Measures are performed by comparing the price level with similar types of suppliers, the percentage of material rejection and the number of late or early deliveries. The purpose of the audit is to fully investigate the supplier's manufacturing process and quality function.

Product and supplier positioning

- Strategic products

- Leverage products

- Bottle neck products

- Routine products

Horizontal variable is the risk of procurement, and a vertical variable is the supplier's impact on the company's profits. Buyer-dominated segment the power is in purchasing function and the relationship with suppliers is not balanced, e.g. The product portfolio consists of four different types of products or materials, depending on their importance for the company.

Strategic products are often purchased from one available supplier and the products are highly customized to the customer, e.g. These kinds of strategic materials play a major role in the material costs of the complete bus and the supplier cannot be replaced by another supplier due to exact customer adjustments and long-term contracts. These types of products do not have special quality standards and there are several suppliers on the market.

Bottleneck products usually have a low influence on material costs, but there is a risk in the supply and the delivery times can vary. First division tactical makes easy the supplier has no major role with the buyer and the time spent with the supplier is minimal.

Carrus Delta`s key suppliers

Relationship type

Key factors of the supply chain relationships

Implementing of the strategic partnerships

Relationship power balance

Advantages and disadvantages of the partnerships

The advantages of partnership relationships are created by reduced supplier control and increased levels of trust. Accurate and continuous exchange of information between partners will be the basis for effective functions. The price may be too high or too low and pricing policies are not understood.

Sensitive information may be leaked to the competitor due to the lack of mutual agreement on information sharing. Supplier opportunism and negative behavior can have a major impact or even inhibit the partnership.

Supplier strategies

- Performance based partnership

- Competitive bidding

- Securing the supply

- Category management

The balance of power of the relationship can be guided to a balance of power through an open cost accounting. The purpose of the performance-based partnership is to create a mutual readiness for cost, process and improvement objectives. Products in this segment are leveraged and purchasing is based on competitive requests for quotations.

Leverage products can be entered into at the company level and other business units within the company are able to use the agreed prices and delivery times with the suppliers. The procurement strategy will be based on ensuring the supply of these bottleneck products and on the other hand reducing supplier dependency. The testing costs for the supplementary products may be at a high level due to confirmation of the correctness of the products.

A risk analysis must be carried out for the security of supply in the short and long term. After measuring the impact of the bottleneck products on the business activities, the basis will be for agreeing the lead times of the products or the agreement that the supplier will keep part of the bottleneck products on its own premises.

Risk management

Supplier relationship management (SRM)

New approach of SRM

New aspects of supplier relationship management are realized and further linked to the business.

Performance measurement

How has the supplier performed its activities, e.g. quality, delivery accuracy, correct shipments and additional costs of incorrect shipments?. What role has the supplier's knowledge and reputation played for the new and existing customers? What kind of organizational collaboration has there been, how has it worked and what has been achieved.

Supplier performance management

Suppliers will understand that the customer is able to cope with the supply market and use other substitute means of delivery. Providing the necessary information about the business situation will help the supplier to perform in the current state and evaluate its own actions.

Qualitative research

Case study method

Case study process and analysis

Good research questions are the kind of questions that will enable you to achieve your goal and that can be answered in research settings. In structured observation, the researcher is observing outside the case carefully and in a specified manner. Analyzing the results of the case study should consider areas such as the variety of different types of evidence, the skill needed to arrive at the evidence for a coherent narrative, maintaining a defined focus for reaching the research questions, and making a version coherent explanations of the theory. (Gillham.

First is a lack of static reliability and validity, secondly case studies generate hypotheses but do not test those hypotheses and thirdly there is a generalizability basis of the case studies. There are also positive issues in case studies, such as challenging the existing order of the issues and the insight of the people's lives will help to understand daily issues and attitudes.

Justification for the case study in this research

Data collection will take place through a semi-structured survey of suppliers, which also includes some open questions. The analysis of the research work will be based on theory and similarities in the functioning of e.g. The reliability and validity of the data collection will be achieved by preliminary testing of the research questions and the functioning of the survey.

Research questions are based on procurement key performance indicators and the supplier's willingness to develop collaboration and problem-solving capabilities.

Content of the supplier survey

The survey responses were divided between seven (36.8%) responses from domestic suppliers and responses from foreign suppliers. There were also nine responses to open questions and six responses to free comments.

Results of the survey questions

Analysis of the survey results

Delivery precision is one of the KPIs used in the purchasing function of the Carrus Delta. As with the chargeback cases, a large proportion of respondents recognize that the most important aspect of handling chargebacks is to ensure that the issue is avoided in the future. The results of the audits will be communicated to the suppliers involved and corrective actions requested.

Role of the information about changes and quick problem response is highly valued among the respondents. The majority of respondents see that material availability issues will have a major impact on supply chain functionality and beyond to shipments. Regarding the purchase order template, the majority of respondents indicate that there is all the necessary information for the order.

Expanding the collaboration with Carrus Delta plays a very important role for the vast majority of respondents. Some of the respondents believe that the level of cooperation with Carrus Delta is sufficient.

Conclusions and recommendations to purchasing function

As stated in section 6 of the theory, the purpose of SPM supplier performance management is to detect areas of risk in the early stages and develop actions continuously. However, the author finds that developing relationships with key suppliers requires reporting on supplier performance and their development actions. This is also covered in Figure 9 section “Monitor your suppliers” by sending monthly reports and providing ongoing feedback.

The balance in the relationship with Carrus Delta's key suppliers can be assessed based on the customer service received and accurate information, flexibility in shipments and new material development. The relationship strength balance can be evaluated using the product and supplier portfolio model in Chapter 4. The results of the KPIs should be evaluated directly at the end of the follow-up time and inform the supplier about the performance.

Available: https://www.cips.org/supply-management/opinion/2015/february/the-five-secrets-of-supplier-relationship-management/. Available at: http://www.volvogroup.com/en-en/about-us/our-values/code-of-conduct-and-other-policies.html.