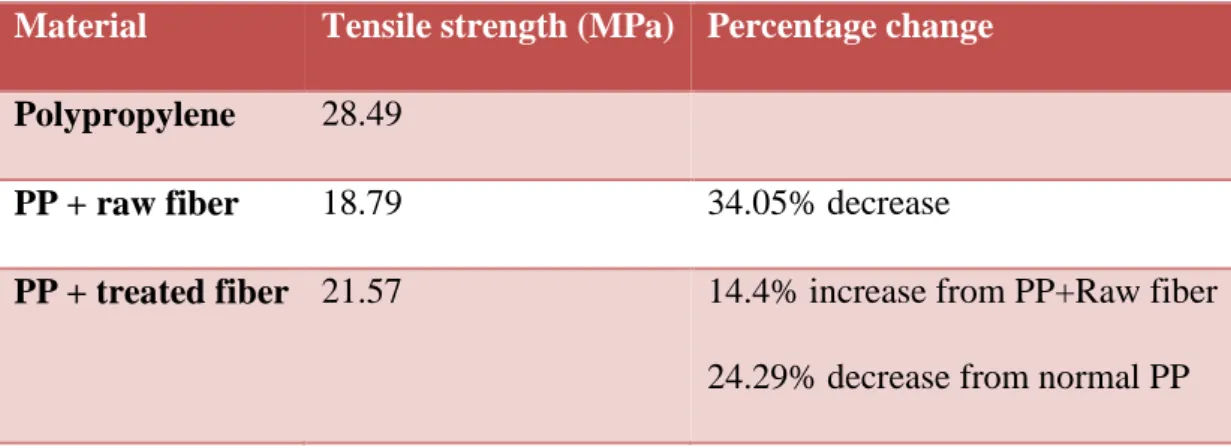

Tests were carried out to determine the mechanical properties of the compounds, density and water absorption. The morphology of the fibers and composites was also studied using scanning electron microscopy (SEM). However, composite density decreased by 4.7% when treated fibers were used instead of raw fibers, and water absorption was similarly decreased by 2.3%.

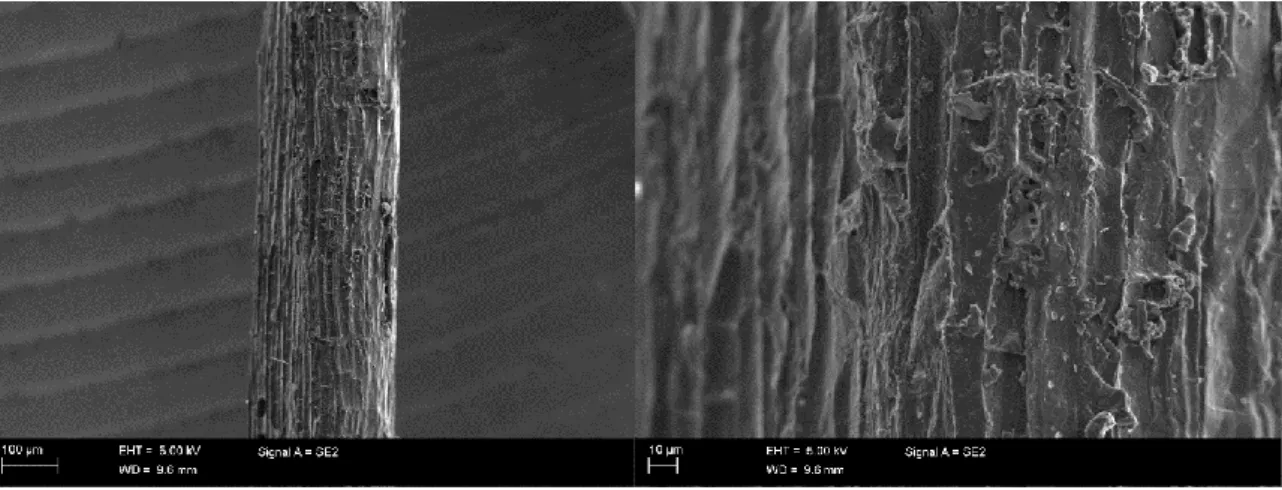

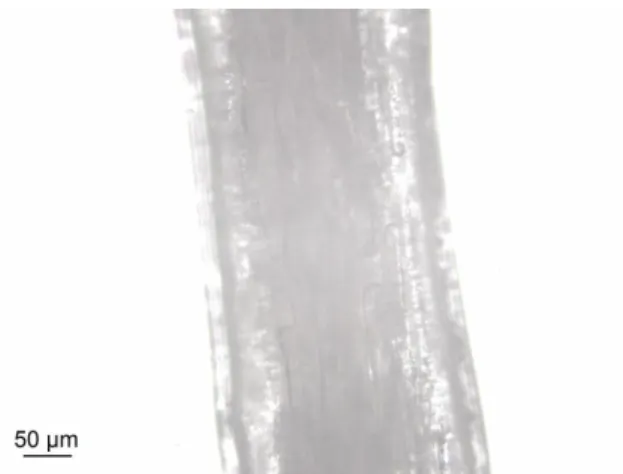

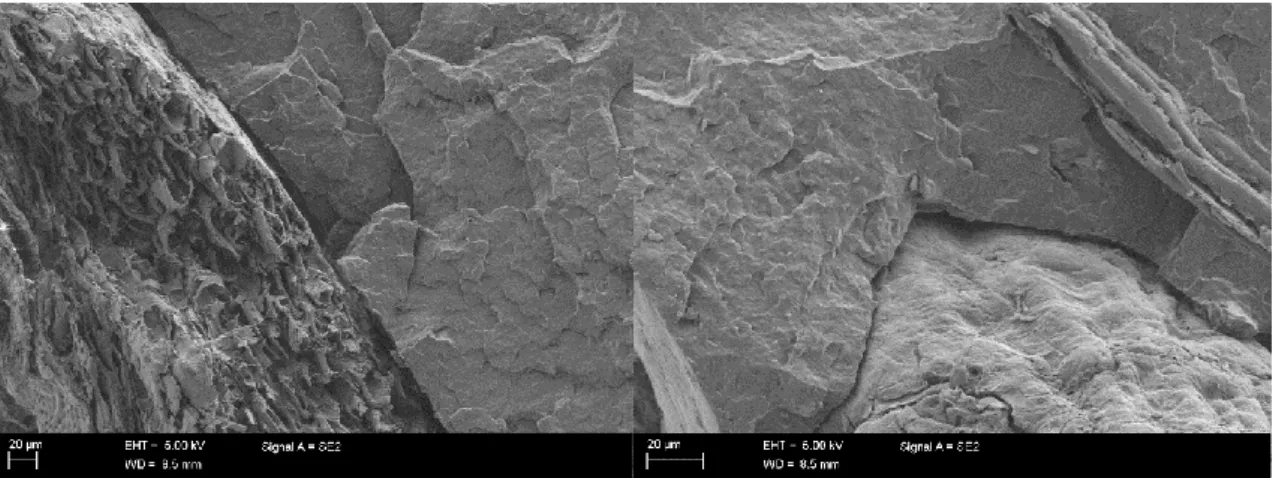

From the SEM images, better adhesion was observed at the fiber-matrix interface of the treated fiber composite.

INTRODUCTION

The properties of the natural fibers used as reinforcements affect the properties of the resulting polymer composites. The properties of such polymer composites however also depend on the extent of fiber matrix adhesion or the ability of the fibers to bond effectively to the polymer matrix. This problem reduces the mechanical properties of the composition; Premature failure usually occurs at the weak interface between fibers and polymers.

Finally, a conclusion of the findings and efficacy of the entire research will be provided in the fifth and final chapter.

NATURAL FIBER BASED COMPOSITES

- Structure and properties of natural fibers

- Effects of fiber surface treatments

- Natural fibers as reinforcements in polymer composites

- Summary

Henequen fibers were treated with 0.033% concentration of silane in water/ethanol solution and this improves the tensile strength of the resulting composite [31]. Similarly, 37.5 percent by volume of the same fiber in the composite increased Young's modulus by 81%. The use of 20 w-% hemp fibers in vinyl ester increased the polymer's flexural strength by 7% and flexural modulus by 22.5%, while also increasing Young's modulus by 10% [60].

It will also determine whether prior chemical treatment affects the properties of the fiber and the composite.

![Fig. 2.2. Structural representation of a plant fiber [6]](https://thumb-eu.123doks.com/thumbv2/9pdfco/1889900.266066/14.892.165.867.299.573/fig-structural-representation-plant-fiber.webp)

MATERIALS AND METHODS

- Materials and their sources

- Surface treatment procedures

- Fiber tests

- Optical microscopy

- Moisture content test

- Tensile test

- Water absorption test

- Density measurement

- Polypropylene composite production

- Composite properties tests

- Tensile test

- Bending test

- Impact test

- Density measurements

- Moisture content tests

- SEM procedures

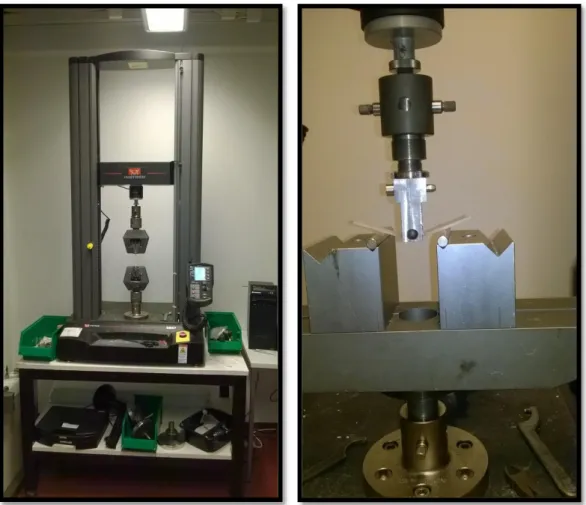

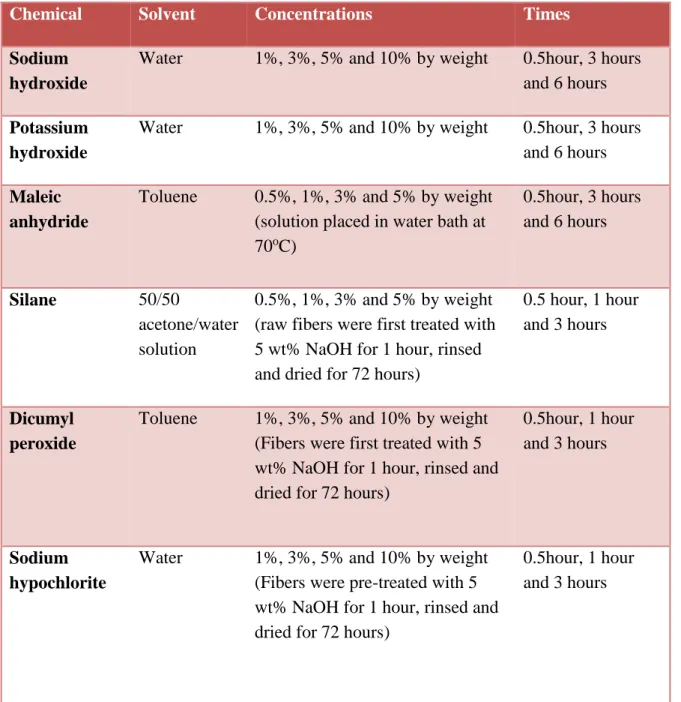

Fiber bundles were selected from different parts of the processed fiber mass and immersed in different chemicals for surface treatment. Moisture content test was performed to determine the moisture content of the fibers after the initial processing stage before the treatments. The mechanical properties of the polymer composites were tested according to SFS/ISO (SFS-EN 15534-1) standards for testing plastics and composites [65].

The boiling test was used to study the moisture resistance of the polymer and its composites according to SFS/ISO standards (SFS-EN 15534-1, ISO-EN 317).

RESULTS AND ANALYSIS

Fiber characterization results

- Visual observations

- SEM images of fibers

- Moisture content

- Water absorption

- Density

- Tensile strength

- Tensile modulus

- Fiber selection

The fiber treated with DCP shows some level of deformation of the fiber structure, probably due to the drastic action of the peroxide in contact with the fiber surface. The percentage of water absorption for different concentrations and treatment times was integrated by the software to present a clear understanding of the relationship between these parameters. The surface graphs present the statistical behavior of the water absorption properties at different concentrations and times.

In general, the curves in the following response surface diagrams show relative decrease in percent water absorption of the fibers with increasing concentration and time of treatment. The contour diagrams in RSM are basically used to select the optimal property – in this case water absorption – of the material. The regions in different shades of color represent areas with similar property values, and selection is made based on the specific level or value of the property required.

The measured density of the different concentrations and treatment times was integrated by the software to easily observe the relationship between these parameters. The areas in different shades of color represent areas with similar property values, and the selection is made based on the particular level or value of the desired property. In general, there were reductions in the density of the fibers due to the treatments.

Density gives an idea of the amount of lignin and other non-fibrous content still remaining in the fiber bundle after treatment. The values obtained for Young's modulus of the fibers agree with some reported values for similar plant fibers, e.g.

Mechanical properties of polymer and composites

- Tensile strength

- Tensile modulus

- Elastic strain

- Bending strength

- Bending modulus

- Impact strength

The percentage change indicates the effect of the fiber on the tensile modulus of the original polymer, and also the effect of pretreatment of the fiber on this property of the composite. This increase in modulus of the material could be attributed to the increase in the stiffness of the polymer when fibers were added. More fiber content could increase this function further and then increase the modulus of the material.

The percentage change indicates the effect of the fiber on the elasticity of the original polymer, and also the effect of pre-treatment of the fiber on this property of the composite. Both raw and treated fiber composite show a 37.5% reduction in stress compared to that of the polymer. The percentage change indicates the effect of the fiber on the flexural strength of the original polymer, as well as the effect of the pre-treatment of the fiber on this property of the composite.

The percentage change indicates the effect of the fiber on the flexural modulus of the original polymer, and also the effect of fiber pretreatment on the flexural modulus of the composite. The values of the impact strength and percentage changes due to reinforcement are given in table 4.8. The percentage change indicates the effect of the fiber on the impact resistance of the original polymer, and also the effect of the pre-treatment of the fiber on this property of the composite.

The impact resistance of the polymer decreased with the addition of the fibers, both in the raw and treated fiber composites. The raw fiber composite has a slightly higher impact resistance than the treated fiber composite.

Physical properties of composite

- Density

- Moisture resistance

It is a measure of the energy required to break a material, or the amount of energy the material can absorb before breaking. This is due to the increased stiffness or modulus induced by the fiber reinforcements, and the additional increase in stiffness due to fiber pretreatment. The density of the material depends on the composition of this material, and for a composite it depends on the density of the different materials in the composite.

The increase in density obtained after reinforcement with raw fibers is due to the introduction of fibers whose natural content, such as cellulose and lignin, gives it a high density. Moisture resistance means the polymer or component's resistance to moisture or water absorption. Here it is represented by the percentage of water absorption, where less water absorption means higher resistance to moisture.

The percentage change indicates the effect of the fiber on the moisture resistance of the original polymer, and also the effect of pretreatment of the fiber on this property of the composite. Reinforcement of PP with raw fibers resulted in increased water absorption of the composite. However, the moisture resistance of the composite was slightly improved by the pretreatment of fibers as evidenced by the slight reduction (2.264%) in water absorption.

Natural fibers are generally hydrophilic and this explains the sharp increase in the value of the water absorption percentage of the polymer reinforced with the fibres. Chemical treatment, on the other hand, reduces water absorption by changing the chemical and physical structure of the fibers, making the composite produced with treated fibers slightly more hydrophobic.

Scanning electron microscopy of composite

On the other hand, treated fibers bonded better with polymer matrix as shown in figure 4.49. This is consistent with the general belief that fiber surface treatment improves adhesion between natural fibers and polymer in a composite. The adhesion is promoted by the chemical reaction between the polymer and active sites of the treated fiber, as well as the improved mechanical interlocking of the polymer with the delignified fibers.

Reliability of the research

CONCLUSION

Polypropylene is a thermoplastic; it would be interesting to know the effect of these fibers on the properties of thermosets such as polyester or epoxy. The processing method and conditions may have contributed to the resulting properties of the composites. High temperature process was used to melt the polymer and mix it with the fiber; the effect of this on the fiber is unknown.

Future studies could use other processing methods, or use longer fibers to determine the effect this would have on the mechanical properties of the composite. 2] Mohanty, A.K., Misra, M., and Drzal, L.T., Sustainable biocomposites from renewable resources: opportunities and challenges in the world of green materials. 16] Joseph K., Thomas S., Effect of chemical treatment on the tensile properties of short sisal fiber-reinforced polyethylene composite, Polymer.

21] Valadez-Gonzalez A., Cervantes-Uc J.M., Olayo R., Herrera-Franco P.J., Effect of fiber surface treatment on the fiber-matrix bond strength of natural fiber reinforced composites, Compos B: Eng. 23] Sarkar B.K., Ray D., Effect of defect concentration on the fatigue strength of untreated and alkali-treated jute-vinyl ester composites under normal and liquid nitrogen atmospheres, Compos Sci Technol. 27] Mohd Ishak Z.A., Ariffin A., Senawi R., Effect of hygrothermal aging and a silane coupling agent on the tensile properties of injection molded short glass fiber reinforced poly(butylene terephthalate) composite, Eur Polym J Lee G.JW., Lee N. Jang J., Lee K.J., Nam J.D., Effects of surface modification on.

32] Paul A., Joseph K., Thomas S., Effect of surface treatment on the electrical properties of low density polyethylene composites reinforced with short suction fibers, Compos Sci Technol. 34] Sreekala M.S., Thomas S., Effect of fiber surface modification on water absorption properties of oil palm Original fibers, Compos Sci Technol Manikandan Nair K.C., Thomas S., Groeninckx G., Thermal and Dynamic Mechanics. 42] van de Velde K., Kiekens P., Influence of material and process parameters on the mechanical properties of unidirectional and multidirectional flax/polypropylene composites, Compos Struct.

44] Joseph K., Filho R.D.T., James B., Thomas S., de Carvalho L.H., 'n Oorsig oor sisalveselversterkte polimeersamestellings, Revista Brasileira de Engenharia Agricola e Ambiental.

![Fig 2.1. Classification of plant fibers [8]](https://thumb-eu.123doks.com/thumbv2/9pdfco/1889900.266066/13.892.172.767.656.1025/fig-classification-of-plant-fibers.webp)