Departamento ti Inhenieria ti Kimika, Unibersidad ti Almeria, Kanada San Urbano, E-04120-Almeria, Espania. Dibision ti Bioteknolohia ni Julio Cesar de Carvalho, Pederal nga Unibersidad ti Parana, CEP 81531-970 Curitiba-PR, Brasil.

INTRODUCTION

Compared to open ponds, closed photobioreactors may have higher photosynthesis efficiency and higher biomass production (Wang et al., 2012). However, closed photobioreactors have a high initial cost and only microalgal strains with specific physiologies should be used (Harun et al., 2010). , 2012).

BIOTECHNOLOGY AND MICROALGAE

The aim of this study was to present the advantages and disadvantages of open ponds compared to other photobioreactors and to investigate factors influencing the cultures and the bioproducts obtained.

OPEN POND SYSTEMS

The company is located in South India (Oonaiyur) and the crops are grown in open ponds, covering an area of 130 hectares (Parry Nutraceuticals, 2012). In Brazil, since 1998, the Laboratory of Biochemical Engineering (LEB) of the Federal University of Rio Grande (FURG) has developed a project that studies the cultivation of spirulina on a pilot scale in an open pond (Figure 1.1) on the edge of the Mangueira Lagoon . (Morais et al., 2009), for addition to children's meals.

MAIN MICROALGAE CULTIVATED IN OPEN POND SYSTEMS

Spirulina

There are many controversies in the morphology and taxonomy of cyanobacteria of the genera Spirulina and Arthospira. Many studies have described the properties of Spirulina max-im and Spirulina platensis, and both species are considered to be of the genus Arthospir and not Spirulina. The differences between the genera are based on the genera content of DNA and lipid profile (Romano et al., 2000). The number of cells in the hormogonium increases by cellular fission, while the cytoplasm is granulated and the cells take on a bright blue-green color.

Chlorella

The first pure culture of microalgae to be scientifically proven was Chlorella vulgarisin 1890 by the microbiologist M. Depending on the culture conditions, this microalgae can provide 60% of the protein with essential amino acids for human consumption.

Dunaliella

In 1919, Otto Warburg published papers on the use of this microalgae in culture to study its physiology. Since it also has a high iron content, this microalgae is a product indicated for the treatment and prevention of anemia.

REACTOR DESIGN

LIGHT REGIME

One strategy to optimize light utilization is to reduce antenna size, which makes cells less opaque and facilitates light transmission (Chen et al., 2011). However, the performance of outdoor systems is lower than indoor ones, and they require large areas of land (Chen et al., 2011).

HYDRODYNAMICS OF THE REACTOR

Each antenna complex acts as a funnel that collects light energy and directs it to a specific location where it can be efficiently used (Alberts et al., 2008). Several studies have been developed to improve the efficiency of light use and reduce the cost of artificial lighting systems.

FIXATION OF CARBON DIOXIDE (CO 2 )

TEMPERATURE

Some mechanisms of temperature control in closed photobioreactors include immersion of the culture in water, water spraying, shading, or incorporating a heat exchanger with the photobioreactor (Wang et al., 2012). In cultivation with the addition of CO2, the concentration of this gas can be the dominant factor that will determine the pH of the cultivation.

STERILITY OF CULTIVATION

The high pH can increase the removal of ammonia through its volatilization and phosphorus through its precipitation (Craggs, 2005).

BIOMASS HARVEST

- Sedimentation Using Gravity

- Flocculation

- Centrifugation

- Filtration

- Flotation

- Electrophoresis

The collection of microalgae by sedimentation can be carried out in sedimentation tanks (Uduman et al., 2010). The charges on the surface of algae can be changed by the addition of flocculant (Harun et al., 2010).

DRYING OF BIOMASS

Gravity sedimentation is usually more dilute than the centrifugation method, which affects the downstream process (Mata et al., 2010). For low-value products such as biofuels and protein, the spray-drying method is not economically feasible (Mata et al., 2010).

OTHER MICROALGAL CULTURE SYSTEMS

Closed Photobioreactors

The use of dehydration increases the shelf life of the biomass as well as the final product. Due to the high water content, the sun drying method is not efficient in turning moist biomass into powder.

Hybrid Photobioreactors

APPLICATIONS OF BIOMASS

- Food

- Drugs

- Biopigments

- Biopolymers

- Biofuels

- Biofertilizers

Biogas is the product of anaerobic digestion of organic matter and can be obtained from domestic sewage, animal waste, solid waste or aquatic biomass, such as macro- and microalgae (Omer and Fadalla, 2003; Gunaseelan, 1997). Non-heterocyst-forming filamentous microalgae, such as Oscillatoria and Phormidium, can fix nitrogen in the absence of oxygen and in the presence of nitrogen and carbon dioxide.

CONCLUSION

Development of suitable photobioreactors for CO2 sequestration addressing global warming using green algae and cyanobacteria. Growth parameters of microalgae tolerant to high levels of carbon dioxide in batch and continuous-flow photobioreactors.

INTRODUCTION

The limitations and challenges that large-scale microalgae cultivation may face are addressed and discussed.

FACTORS AFFECTING MICROALGAE GROWTH AND BIOFUELS PRODUCTION

- Carbon Sources

- Nitrogen Source

- Light Supply

- Temperature

- Salinity

Some literature describes the effect of light intensity on the lipid content of microalgae. Lv et al. It has been reported that a salinity of 35% (standard seawater) or higher resulted in a reduction in the growth rate and the efficiency of photosynthesis and dark respiration (Jacob et al., 1991).

PHOTOBIOREACTOR DESIGN PRINCIPLES

Hence, appropriate operating configurations with innovative design of microalgal cultivation system are required to achieve commercially viable production of microalgal biomass and target products. On the other hand, circulation is also very important in the outdoor microalgae cultivation system.

MICROALGAE CULTIVATION IN CLOSED AND OPEN PBRs FOR BIOFUEL PRODUCTION

Open Systems

Raceway ponds are a modified version of an open pond system that has a different flow pattern compared to a simple pond. The same deficiencies observed in the operation of open ponds are also found in canals.

Closed Systems

Based on the circulation mode, the design of an airlift reactor can be further classified into one of two forms: inner loop or outer loop (Loubie`re et al., 2009). Scaling up the flat plate system is potentially difficult due to the increase in hydrostatic pressure with increasing volume.

General Discussion of Microalgae Cultivation Systems

COMMERCIAL MICROALGAE CULTIVATION SYSTEMS FOR BIOFUEL PRODUCTION

Algenol's goal is 20 billion gallons per year of low-cost ethanol by 2030. green farm raw in New Mexico, USA. Seambiotic grows microalgae cultures in open ponds using flue gases like carbon dioxide and nitrogen from a nearby coal plant as nutrients.

CONCLUSIONS

Effect of incubation temperature on macromolecule and lipid content of phytoflagellate Ochromonas danica. Effects of nutrients, salinity, pH and the light:dark cycle on reactive oxygen species production in the marine alga Chattonella.

INTRODUCTION

In addition, transcriptomics, proteomics and metabolomics studies have provided new insights into gene regulatory networks and coordinated cellular activities that determine the physiological flexibility and metabolic adaptation of microalgae. This review summarizes recent progress in elucidating molecular and cellular mechanisms of cellular physiology relevant to fuel production in microalgal systems, with an emphasis on developing metabolic engineering strategies to increase fuel production.

BIODIESEL

In green algae, acetyl CoA groups are probably derived mainly from glycolysis (Hu et al., 2008). Additionally, a SQUAMOSA promoter-binding protein domain transcription factor has been implicated in lipid biosynthesis under nitrogen-deficient conditions ( Boyle et al., 2012 ).

BIOHYDROGEN

Biochemical evidence supports the presence of hydrogenase activity in a variety of Chlorophycophyta (Brand et al., 1989). To develop a culture system for continuous H2 production, an inducible chloroplast gene expression system has been proposed (Surzycki et al., 2007).

OTHER STRATEGIES .1 Optimization of Light Conversion Efficiency (LHCB)

Recycling and Recovery of Co-products

One approach is to establish an integrated system that exploits the variable genetic modification capability of the Escherichia coli (E. coli) system. In a small-scale experiment, the authors successfully converted hydrolyzed microalgae protein biomass into alcohol fuels.

CHALLENGES AND PERSPECTIVES

Differential regulation of Fe-hydrogenase during anaerobic adaptation in the green alga Chlamydomonas reinhardtii. Control of hydrogen photoproduction by a proton gradient generated by cyclic electron flow in Chlamydomonas reinhardtii.

INTRODUCTION

Microalgal Metabolism

The sheets of the photosynthetic membranes are usually arranged parallel, close to the cell surface. This makes microalgae the most important carbon-fixing group and oxygen producer in the world.

Photosynthesis

CO2þ4Hþ2NADPHþ3ATP$ðCH2OÞ ð4:2Þ Carbon dioxide is available in water in three different forms: CO2, bicarbonate (HCO3) or carbonate (HCO32) (Figure 4.1), the relative amounts of which depend on pH. CO2 FIGURE 4.2 The dark process of CO2 capture and transformation by photosynthetic microalgal metabolism (modified from Masojı´dek et al., 2004).

Microalgae Culture Fundamentals

The use of complex media (those whose composition is not determined, such as industrial residues) in the cultivation of microalgae is an alternative to make the production of some microalgae metabolites economically feasible. In connection with residue composition and microalgae metabolism, knowledge of the microalgae's needs can save time (and money) in the development of a process.

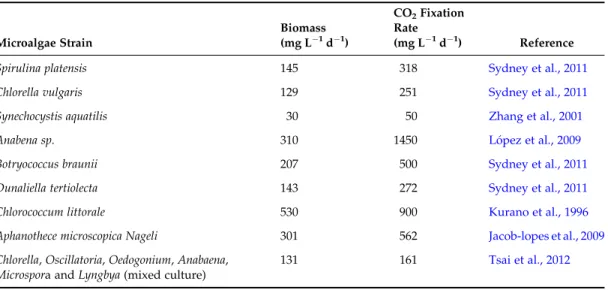

CARBON DIOXIDE FIXATION BY MICROALGAE .1 Carbon Dioxide’s Role in Photobioreactors

Methods of CO 2 Fixation Quantification

Determination of global carbon dioxide sequestration rates through CO2 mass balances in the liquid or gas phase of systems (Eriksen et al., 2007) provides more complete data. It has been found that between 70% and 88% of the carbon dioxide consumed is used for biomass production.

Carbon Fixation of Industrially Important Microalgae

Some studies (Chinassamy et al., 2009; Morais and Costa, 2007) indicate that the best concentration of CO2 in the gas supplied to C. Phosphorus and nitrogen are also important factors in the accumulation of hydrocarbons by the microorganism (Jun et al., 2003).

PRACTICAL ASPECTS OF MASS CULTIVATION FOR CO 2 FIXATION

Cultivation Vessels

Alternatively, the mixotrophic (Guerin et al., 2003; Gonza´les et al., 2009) and heterotrophic (Hata et al., 2001) metabolism, which uses acetate as a carbon source, has also been studied and documented; however, these conditions have not been applied to commercial scale cultures and are not interesting in terms of carbon sequestration.

Light Diffusion

In outdoor photobioreactors, the light regime is also influenced by geographical location, time of day and weather conditions. For example, although light/dark cycles of 94/94 ms were short enough to increase photosynthetic efficiency in cultures of Dunaliella tertiolecta, light/dark cycles of 3/3 ms were too long and PE decreased compared to continuously illuminated cultures (Janssen et al., 2001).

Mixing

The light regime itself is affected by incident light intensity, reactor design and dimension, cell density, cell pigmentation, mixing pattern, etc. This refers to the theory of photosynthesis, in which carbon fixation does not depend on the presence of light because enough energy has been absorbed.

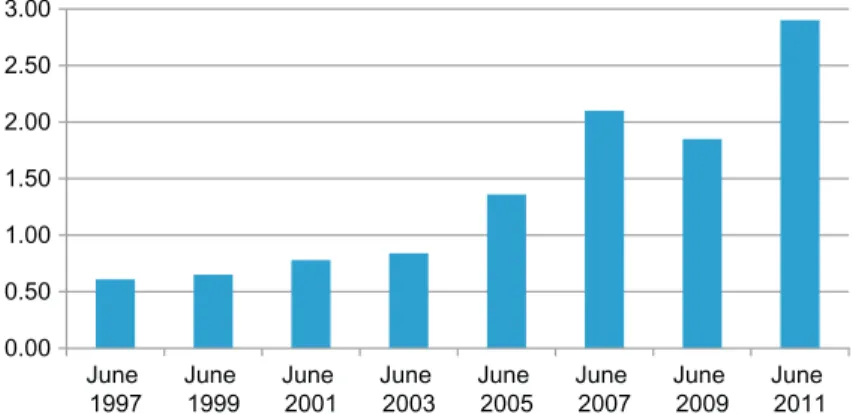

CARBON MARKET FOR MICROALGAL TECHNOLOGIES

A study of carbon dioxide capture and sequestration methods - sustainability of the photosynthetic bioreactor approach. Evaluation of a vertical flat plate photobioreactor for outdoor biomass production and carbon dioxide biofixation: effects of reactor dimensions, irradiance and cell concentration on biomass productivity and irradiance utilization efficiency.

INTRODUCTION

In addition, wastewater enriched with nutrients such as nitrogen and/or phosphorus can be used as a growth medium for algae cultivation, thus eliminating the need for fertilizers from fossil energy. Existing stages for biodiesel production from algae involve a production scheme starting with the development and cultivation of algae strains, followed by harvesting through separation of the algal biomass from the supporting media and subsequent further processing such as dewatering, drying, oil extraction and fractionation (Figure 5.1) ).

STABILITY AND SEPARABILITY OF MICROALGAE

This can be exceeded by the kinetic energy of the particles or, alternatively, by lowering the energetic barrier. Increase in drag forces as in the Scenedesmus species, which contain seta (Conway and Trainer, 1972).

METHODS OF ALGAE HARVESTING

- Screening

- Coagulation-Flocculation

- Filtration

- Gravity Sedimentation

- Flotation

- Centrifugation

- Electrophoresis, Electroflotation, and Electroflocculation Techniques

- Ultrasonic Methods

A fungal pelleting-assisted bioflocculation process for algae harvesting and wastewater treatment has been developed (Zhou et al., 2012). Use of ozone-induced flotation for algae recovery and wastewater treatment has been studied (Betzer et al., 1980).

CHALLENGES AND PROSPECTS

The potential of anaerobic digestion of waste oil cakes from oil extraction as a way of reducing external energy demand and recycling part of the mineral fertilizers needs to be further investigated (Lardon et al., 2009). Algal biofuel production using renewable substrates may be a potential answer to overcome some of the economic constraints.

CONCLUSIONS

Algae removal by electrocoagulation process, application for treatment of the effluent of an industrial wastewater treatment plant. Effects of chlorine and ozone on algal cell properties and removal of algae by coagulation.

INTRODUCTION

Due to the significant features such as rapid growth, ultra-high cell density and high oil productivity associated with heterotrophic algae, the heterotrophic production of algal oils has gained significantly more interest and is being sought to scale production for potential commercialization, although it may be considered less economically viable than the use of autotrophic growing algae cultures for the production of lipid-based biofuels. The way forward for further expansion of heterotrophic algal oil production with regard to both challenges and opportunities is also discussed.

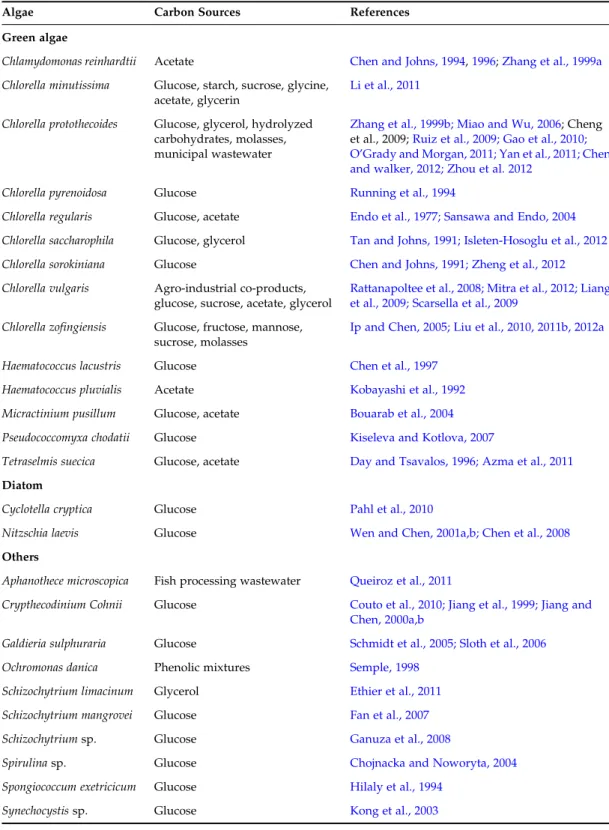

HETEROTROPHY OF MICROALGAE

This chapter provides an overview of the current status of the use of heterotrophic algae - in particular, Chlorella - for oil production. The dominant role of a PP pathway was also demonstrated in the heterotrophic culture of the cyanobacterium Synechocystissp.

POTENTIAL OF HETEROTROPHIC ALGAL OILS

In contrast, the EMP pathway serves as the main stream of glucose metabolism in algae in the presence of light (Yang et al. propose the regulation of light by glycolysis. Table 6.2 shows the central metabolic network of glucose in heterotrophic algae with stoichiometric reactions. Chlamydomonas .reinhardtii Acetate Chen and Johns Zhang et al., 1999a Chlorella minutissima Glucose, starch, sucrose, glycine, .

FACTORS AFFECTING HETEROTROPHIC PRODUCTION OF ALGAL OILS

Low nitrogen levels promote the accumulation of intracellular lipids (Scarsella et al., 2009; Xiong et al., 2010a). Phosphorus deficiency has also been reported to promote lipid accumulation in some algae (Lombardi and Wangersky, 1991; Scarsella et al., 2009).

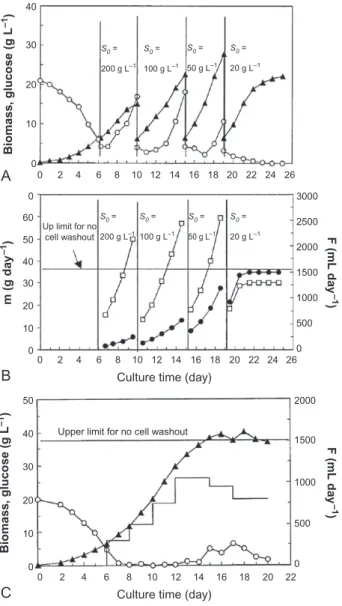

HIGH CELL DENSITY OF HETEROTROPHIC ALGAE

Fed-Batch Cultivation

Continuous Cultivation

Continuous Cultivation with Cell Recycling

A modified perfusion culture system that introduces cell bleeding during perfusion operation has also been developed for heterotrophic production of algae (Figure 6.5c;Wen and Chen, 2001b). An experimental optimization is required for a selected algal strain to demonstrate which culture system is best for the heterotrophic production of oils.

CHLORELLA AS THE CELL FACTORY FOR HETEROTROPHIC OILS

Oil Production Potential

The properties of C.protothecoides-derived biodiesel were assessed and most were found to meet the limits set by the American Society for Testing and Materials (Xu et al., 2006). The scaling up from 5 to 11,000 L just caused a slight drop in productivity, suggesting that the C.protothecoides may be a potential producer of oils for commercial large-scale production (Li et al., 2007a).

Downstream Processes

The harvesting and drying processes can contribute 20–30% of the total cost of photoautotrophic algal biomass production (Molina Grima et al., 2003). In contrast, alkali catalyzes a much higher transesterification rate, as it is unfavorable for free fatty acids (Fukuda et al., 2001).

POSSIBLE IMPROVEMENTS OF ECONOMICS IN HETEROTROPHIC ALGAL OILS

The introduction of a bacterial hemoglobin into various hosts has been shown to contribute to growth enhancement in oxygen-limited conditions (Zhang et al., 2007). Theoretically, increased oil content can be achieved by the direct genetic engineering of oil biosynthetic pathways, e.g. overexpression of the genes involved in fatty acid/lipid synthesis (Madoka et al., 2002; Lardizabal et al. 2008); the manipulation of transcriptional factors.

CONCLUSIONS

A TPR family membrane protein gene is required for light-activated heterotrophic growth of the cyanobacterium Synechocystissp. Heterotrophic growth and nutritional aspects of the diatom Cyclotella cryptica (Bacillariophyceae): Effect of some environmental factors.

INTRODUCTION

- The Energetic Issue

- Culture Medium

- Vinasse

- Market Value

- Pyrolysis

For preferential production of the liquid phase, fast pyrolysis is often chosen. Table 7.1 summarizes the conditions and main effects of residence time and temperature in gaseous, liquid and solid product generation. Due to its tendency to preferentially form bio-oil, combined with high-speed reaction and greater productivity, fast pyrolysis is the best model for the production of biofuels from algae.

FAST PYROLYSIS

Combustion of incondensable gases, such as CO, H2 and CH4 (Cortez et al., 2008), is the best option that generates enough heat for autothermal operation of the reactor, but this entails the acquisition of additional equipment. On the other hand, controlled burning of part of the material fed to the reactor is easier to handle, but means loss of product (about 10% of the material must be burned to maintain the reactor temperature, according to Mesa-Pe´rez, 2005).

YIELDS AND CHARACTERISTICS OF PYROLYSIS OF ALGAL BIOMASS

The volumetric energy density was then calculated to be 9,927.33 kcal/L, which means the amount of energy that 1 liter of bio-oil can provide. The average price of one ton of microalgae biomass is about 310 USD; one liter of bio-oil produced with this technology on a pilot scale costs almost US$1.20 per liter.

CONCLUSIONS

Desenvolvimento de um bioprocesso para a produção de biocombustíveis obtidos por pirólise rápida de microalgas. Estudo da Pirólise Rápida de Capim Elefante em Leito Fluidizado Rotativo com Caracterização de Carvão Fino.

INTRODUCTION

Compared to fossil fuels, microalgae-based biofuels are renewable, biodegradable and environmentally friendly (Ma and Hanna, 1999; Knothe, 2006; Vicente et al., 2010). Algae-derived biodiesel is currently being promoted as a third-generation biofuel feedstock, as algae do not compete with food crops and can be grown on non-arable land (Dragone et al., 2010).

CELLULAR BIOCHEMISTRY TOWARD LIPID SYNTHESIS

- Glucose Accumulation Inside the Cell

- Formation of Acetyl-CoA/Malonyl-CoA

- Synthesis of Palmitic Acid

- Synthesis of Higher Fatty Acids

The first reaction of the fatty acid biosynthetic pathway towards the formation of malonyl-CoA from acetyl-CoA and CO2 is catalyzed by the enzyme acetyl-CoA carboxylase (ACCase). During this process, seven molecules of acetyl-CoA and seven molecules of CO2 form seven molecules of malonyl-CoA.

NUTRITIONAL MODE OF MICROALGAE

Photoautotrophic Mechanism

This is one of the most prevalent environmental conditions for the common growth of microalgae (Chen et al., 2011). Large-scale microalgae cultivation systems (such as open/road ponds) are usually operated under photoautotrophic conditions (Mata et al., 2010).

Heterotrophic Mechanism

The highest lipid productivity (3,700 mg/L/d) was also reported using an improved group-fed culture strategy in the heterotrophic feeding mode, where lipid productivity was 20 times higher than that obtained by photoautotrophic cultivation (Xiong et al., in 2008). Moreover, cost effectiveness, relative simplicity of operation and easy maintenance are the main attractions of the heterotrophic growth approach (Perez-Garcia et al., 2011).

Mixotrophic Mechanism

The advantages of mixotrophic nutrition are its independence with respect to both photosynthesis and growth substrates (Kong et al., 2012). Mixotrophic cultivation has been shown to be a good strategy to achieve a large biomass and high growth rates (Ogawa and Aiba, 1981; Lee and Lee, 2002), with the added benefit of producing photosynthetic metabolites (Chen, 1996; Perez-Garcia et al. ., 2011).

SUBSTRATES FOR MICROALGAE GROWTH AND LIPID PRODUCTION

Wastewater

Five characteristically different ecological water bodies (mixotrophic) were evaluated to assess the biodiesel production capability of their native microalgae (mixed) (Venkata Mohan et al., 2011). The lipid composition of the microalgal oil varied according to the supplied nutrients (Prathima Devi et al., 2012).

MICROALGAE CULTIVATION

Open Pond Cultivation Systems

Cultivation of microalgae in open ponds presents relatively low construction and operating costs, which invariably result in low production costs (Stephenson et al., 2010; Chen, 1996; . Tredici, 2004). Inefficient mixing in open cultivation allows poor mass transfer rates, resulting in low biomass productivity (Pulz, 2001; Harun et al., 2010).

Closed Cultivation Systems (Photobioreactors)

Based on the flow mode, these vertical tube photobioreactors can be classified as bubble column reactors and air transport reactors (Ramanathan et al., 2011). In general, an air transport photobioreactor exists in two forms: inner loop and outer loop (Chisti, 1989; Miron et al., 2000).

PREPARATION OF ALGAL FUEL/BIODIESEL

Cell Disruption

Breaking open algal cells prior to extraction is of particular importance because the content of the extracted lipids is determined according to the breaking open method and equipment used. The bead-beating method involves applying beads to break up the algal cell wall.

Extraction of Algae Oil

The electric field enlarges the pores of the cell membranes and expels their contents (Guderjan et al., 2004). The disadvantages associated with the process are lack of commercial feasibility and inapplicability for mass cultures (Halim et al., 2011).

TRANSESTERIFICATION

- Direct Transesterification

- Acid-Catalyzed Transesterification

- Base-Catalyzed Transesterification

- Enzyme-Catalyzed Transesterification

The main disadvantage of the process is the formation of soap at high concentrations of free fatty acids (Furuta et al., 2004). However, the low feasibility of the process makes the reaction complex (Helwani et al., 2009; Watanabe et al., 2001).

ALGAL FUEL PROPERTIES

Base-catalyzed transesterification of microalgal oil is most commonly used and involves the presence of a base catalyst (hydroxides/carbonates) to precede the reaction (Meher et al., 2006; Vargha and Truter, 2005). Fully saturated methyl esters have high oxidative stability and a high cetane number, but suffer from poor cold flow properties (Harrison et al., 2012).

CONCLUDING REMARKS

Biofuels from microalgae: a review of technologies for the production, processing and extraction of biofuels and co-products. Heterotrophic cultivation of mixed microalgae for lipid accumulation and wastewater treatment during sequential growth and starvation phases.