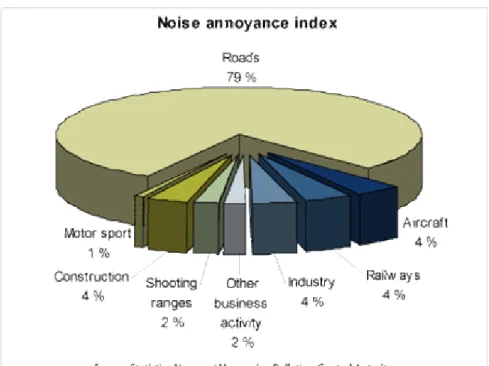

This report has a dual purpose - the first is to summarize research on reducing noise at source, including low-noise road surfaces, with tires. Europe and the Nordic countries have ambitious targets when it comes to reducing noise.

Little progress in noise emissions reduction

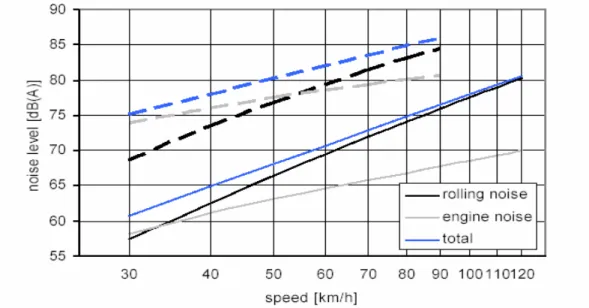

An even more important factor has been the failure to address interactions between tires and road surface noise, which dominate at speeds above 30 and 55 km/h for passenger cars and heavy vehicles respectively, see Figure 1.2. Relations for passenger cars are indicated by solid lines, while relations for heavy vehicles are indicated by dashed lines.

New optimism with respect to noise reduction

Removing road dust particles contributes to the reduction of particulate resuscitation and thus improves air quality. Road surface wear leads to a rapid deterioration in the quality of the road surface texture, leading to increased noise emissions and large amounts of road dust clogging porous asphalt.

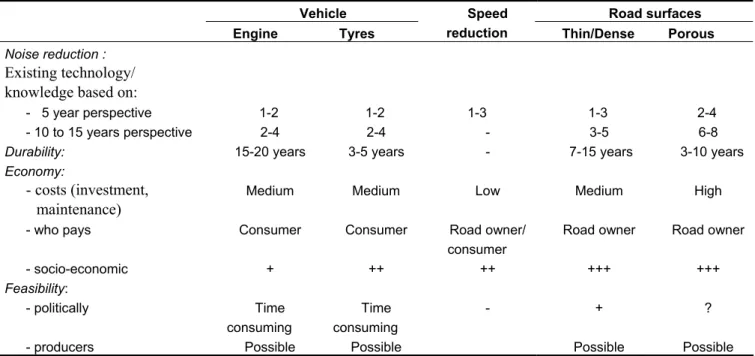

Categories of noise abatement measures

Maintenance (suction and high-pressure washing) of road surfaces is an important part of a road-laying strategy. These include measures such as: encasing noisy engines, using sound-absorbing materials in the vehicles, using road surfaces that emit less noise than conventional surfaces and reducing vehicle speeds.

The aim of noise reduction at the source

However, it should be borne in mind that it may be necessary to use a combination of different types of noise reduction measures to obtain the desired results. These types of measures are usually part of a comprehensive road surfacing policy and are described as part of noise reduction at source initiatives.

Cost benefit analyses of noise abatement efforts

Certification procedures that test noise emissions and procedures to verify that limits are not exceeded during use fall into this category, as do measures to ensure that environmental standards are maintained when original parts such as car tires are replaced. Some porous road surfaces are not laid on the road itself, but along sidewalks and other areas between the roadway and residential areas, etc.

Method

Black areas are defined to be areas exposed to Lden values of 65 dB or more, while gray areas cover the noise exposure range from 55-64 dB. These areas are often "belts" along the main road system and where the black areas are closest to the road, while the gray areas are areas screened from the main road system by distance, intervening buildings or noise barriers.

Noise abatement efforts at the source: global or local?

The adverse impact of road traffic noise mainly affects the black and gray areas of European urban areas.

A limited number of road stretches need to be considered

It follows that only limited stretches of the road network should be considered as targets for local noise reduction measures. A small part of the road system is responsible for a large part of environmental problems.

Noise impact maps should indicate efficient measures

The advantage of impact maps is that these isolate the road sections that have the greatest impact on the population better than exposure maps. These are the stretches of road where the noise affects many residents who live near the road. Focusing on certain stretches means that local noise reduction measures are used where they are most beneficial.

In such mixed situations, where heavy vehicle restrictions are not an option, it may be necessary to use absorption mats embedded in the road surface, noise barriers adapted to screen the right lane of heavy traffic to reduce engine noise to take advantage of the noise reductions achieved in terms of for rolling noise.

Optimal noise reduction efforts achieved by cooperation

Reducing rolling noise by using low noise tires or surfaces, limiting the use of studded tires or reducing speed can be very effective in these conditions. In areas where vehicle speeds are in the range of 50-60 km/h there will be engine noise from heavy vehicles and rolling noise from light and heavy vehicles.

The Dutch noise innovation program (IPG)

Germany’s research programme “Mobility and traffic”

The program activities focus on noise abatement (road, rail and air traffic) at source, as this is considered the most sustainable and efficient way of solving the traffic noise problem (Heinzelman 2004). The research network Leise Verkehr (silent transport) was established in 1999 as part of the research programme.

Finnish guidelines and action plan for noise abatement

Noise strategy for Denmark

Noise targets in Sweden

Noise targets in Norway

Different types of propulsion noise

According to Morgan et al (2003), approximately 50 percent of the noisiest cars on the street have engines that can no longer be considered state-of-the-art. The difference in noise emitted by the loudest and least noisy vehicles on the market is approximately 7 dB(A) (Morgan et al 2003).

Propulsion noise from heavy vehicles

Measures to reduce propulsion noise

Factors that affect noise emissions

Rolling resistance was very similar to the reference tire, but wet friction was worse and needs to be improved. One of the major problems surrounding tire noise is the EU directive from 2001 (EU directive 2001/43/EC). The noise limits agreed in the directive are so moderate that a large part of the tires produced today already meet the limits and will do so until at least 2011.

Therefore, the directive gives no incentive to tire manufacturers to improve the noise qualities of their tires in the near future.

Tyres must fulfil several requirements

Vehicle speed

Noise reduction of up to 3 dB(A) can be achieved by choosing a speed level that is as constant as possible and optimal (depending on the gear) based on the driving situation and the vehicle type (Paikkala el al 2003). Heavy vehicle propulsion noise can dominate in uphill situations and therefore speed limits may need to differ in both situations. Lower speed will reduce particulate suspension, but may have a detrimental effect on combustion pollution.

The reduction of speed from 90-80 km/h to 70-60 km/h has a positive effect on safety and the environment (Amundsen and Ragnøy 2002, European commission Transport RTD 1998).

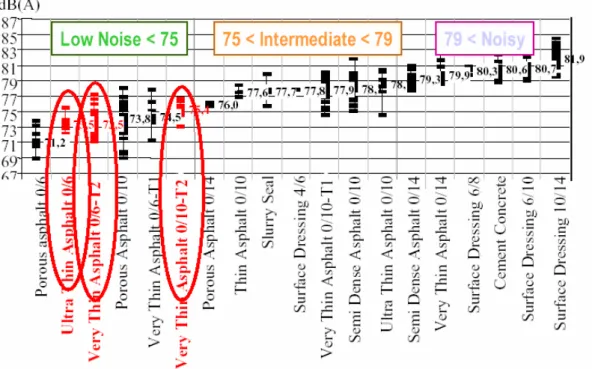

Different types of road surfaces

Skid resistance: A good road surface should provide good skid resistance and thus a high level of road safety. Tire and Vehicle Wear: A good road surface should not cause tire or car damage or greatly accelerate normal wear. Rolling resistance: A good road surface should not unduly increase rolling resistance, thereby leading to increased fuel consumption.

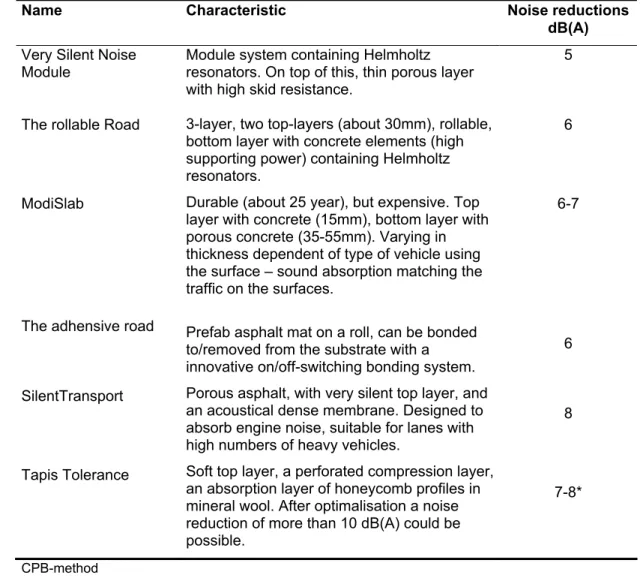

The downside of some of the road surfaces that have been tested to have the best noise reduction properties is their cost and inferior durability.

Thin surfaces

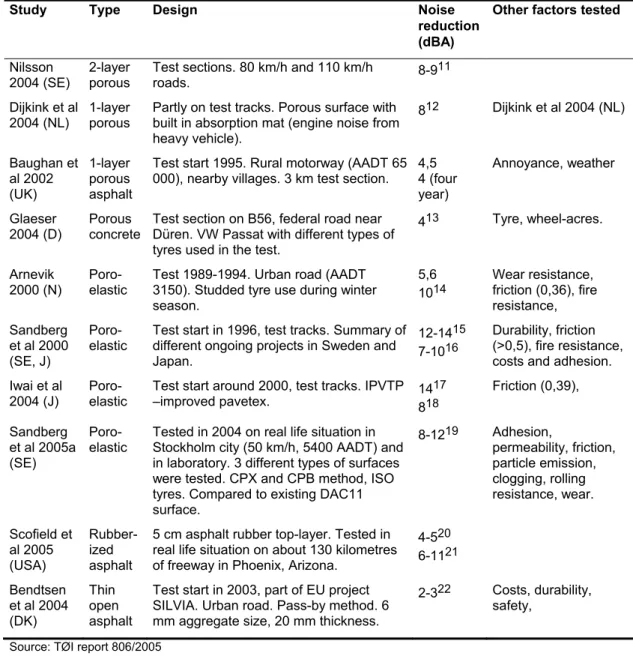

Factors other than noise must be considered to develop the best type of surfaces. Most of the tests carried out in Europe on low-noise surfaces are now focused on porous surfaces (with two or more layers), poroelastic surfaces or thin surfaces. Tests have just started, so there are no results yet, but experiences from the Netherlands show noise reductions of 1.5-2 dB(A) (Miljøstyrelsen 2003).

At the same time, mixes and laying techniques are optimized to produce smooth surfaces that reduce vibrations from the tires.

Porous surfaces

Danish results

The surfaces were two-layer asphalt with a top layer of 8 or 5 millimeters of fine aggregate and various thicknesses. This was done to evaluate various surface characteristics (noise, clogging, friction, durability, etc.). Twice a year, surfaces were cleaned with high-pressure water spraying and vacuuming to reduce clogging.

At the end of the two-year period, clogging was somewhat higher in the surfaces with the smallest aggregate size (Bendtsen et al 2002).

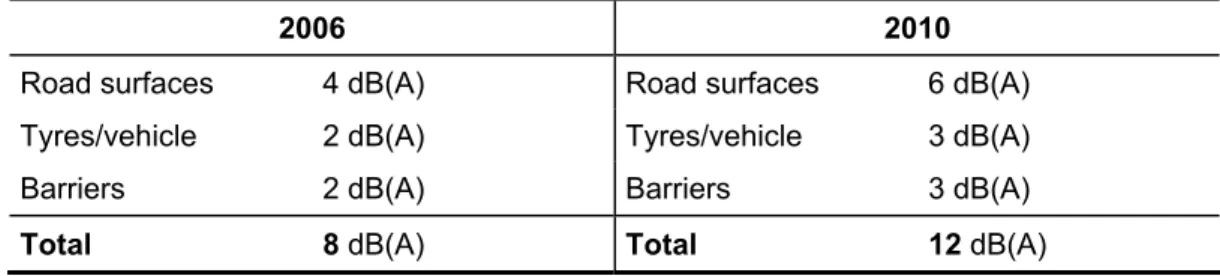

Results from the Netherlands

Abrasion of surface road particles and other contamination on dense asphalt layers adjacent to the porous asphalt resulted in significant clogging of the porous asphalt in the lane where vehicles transitioned from dense to porous layers. This means that an additional 100 meters of porous asphalt may be needed to act as a buffer area to reduce clogging of the roadway along the areas where noise reduction is important. After four years, most of the test sections are well within the 2006 4 dB(A) target.

But measurements on some test sections show poor skid resistance (Fafiè 2002 in Hofman and Koij 2003).

Results from Japan

Poroelastic surfaces

Norwegian experiences under winter conditions

Swedish and Japanese results

American rubber asphalt

Costs

Safety aspects

Study overview

The time aspect is important when choosing a measure to implement and predicting the possible effects of the measure. It is difficult to compare different studies when the study conditions are so unequal. Engines should have the same lifespan as the rest of the vehicle, even if the noise reduction effect is slightly reduced.

It has been politically difficult to promote the reduced speed because most of the public is against it, but this may change if information is spread about why the speed is reduced.

Noise abatement measures at the source should be pursued

Testing and research efforts over 8-15 years period necessary

After establishing a database on the characteristics of different surfaces depending on different climate conditions, different traffic volumes, etc., it should be possible to find some general noise emission characteristics of surfaces in use, and a Nordic establishing "normal" reference road surface description. A standard road surface contract with minimum standard regarding: noise quality, coefficient of friction, durability under certain conditions (specified level of maintenance and use of speckled tire) should be developed. In order to exploit the competence and knowledge that road paving companies possess in terms of optimizing the properties of current non-porous road surface layers, they must be provided with an incentive to lay road surfaces that have good properties.

For most road networks, other road surface parameters are more important.

Improving today’s surface types most important

Parallel efforts should explore new road surface solutions

Here, the extensive knowledge from researchers in Denmark and the Netherlands should be used by involving their researchers in ongoing efforts to adapt surfaces to Nordic conditions. In other words, their general competence in such surfaces should be used in a sustained collaborative effort together with experts in Nordic winter conditions to solve the winter condition and. The extensive testing and know-how developed in Denmark should be used especially for the laying of test surfaces of porous asphalt or other low-noise surface technologies.

Larger cities where the climatic conditions mean that the main road system is free of snow and ice for most of the winter, where there are restrictions on the use of studded tires, and where many residents are affected should be prioritized.

Road surface description standard for the Nordic countries

In urban residential areas with lower speeds, a dense low-noise layer may be a better alternative. In uphill areas with many heavy vehicles, absorption mats that absorb engine noise (tested in the Netherlands) can be a good alternative. This is an expensive measure, but is likely to be cost-effective on certain road sections in urban areas.

Incentives should be built into road surface laying contracts

Tyre initiatives need to consider the type of road surfaces that are laid

The socio-economic costs of studded tyre use should be re-examined

Results of the Dutch Noise Innovation Program Road Traffic (IPG) and Roads to the Future Program (WnT). Converting costs and benefits to monetary terms – inputs to cost-benefit analyzes of measures to control road traffic noise. Study the timescale for availability and implementation of new future key technologies for reducing road traffic noise in the EU.