In addition, monitoring and operation from the AE-200 can be done by connecting the EW-50 in the same way. Assign an address equal to the address of the main indoor unit with the lowest address in the group plus 200. We recommend using the IP addresses in the following table for the AE-200/AE-50/EW-50, TG-2000A, and other equipment when using a dedicated LAN .

External dimensions

Location of main parts

If another system controller is connected to the same M-NET, disconnect the power switch to supply power to the M-NET from the power supply unit. CN5 External I/O Connects to an external input/output adapter (PAC-YG10HA) by cutting out the knockout hole.

Electrical wiring diagram

How to remove and attach the cover

Hook the claws onto the top of the service cover on the EW-50 unit and then secure the cover with the mounting screws. Note: When attaching the service cover, ensure that the power cable and transmission line are not pinched between the EW-50 unit and the service cover.

Product specifications

AE-200/AE-50/EW-50 unit functions and Web

The elements to prohibit operation from a local remote control can be selected per group, per block or per floor or together. Note: The items that can be prohibited vary depending on the model of the air conditioner, LOSSNAY, etc. Resetting the filter plate The filter plate can be reset per group, per block or per floor or together.

Note: The items that can be displayed vary depending on the models in the group. Displaying the filter sign The filter sign can be displayed per group, per block or per floor or together. The list screen group name display and filter label show/hide options can be set.

However, you can use the emergency stop input by adjusting the DIDO controller switch settings. You can check the Oracle Java plug-in version by clicking [Java] in the control panel.

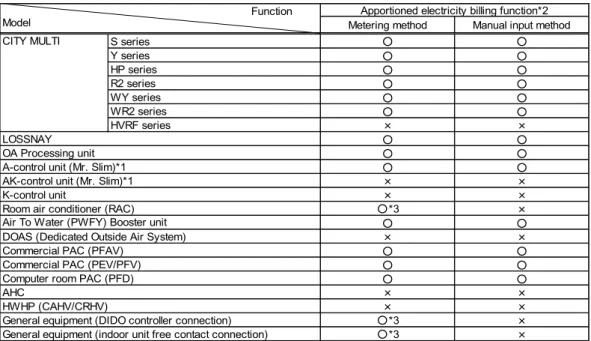

Functions and required equipment and materials

When using the peak cut function, please understand that Mitsubishi Electric cannot reimburse any damages in the event that the electricity consumption exceeds the electricity values of the contract due to an error in the setting of the control, the failure of an AE-200/AE-50 /EW-50, PLC, PI controller, E-Energy or demand controller or other problem. The Peak Cut Control Units are the blocks of indoor units and outdoor units in the AE-200/AE-50/EW-50 unit. For the electricity meter peak reduction control, which is performed using the counting function of a PI controller or PLC, the electricity meter to be monitored by the AE-200/AE-50/EW-50 must be only one, and this can be set for any AE-200/AE-50/EW-50.

Peak cut control cannot be used with air conditioning units to be controlled by an AE-200/AE-50/EW-50 in a system with two or more connected electricity meters. This method directly inputs a peak clipping level signal to the AE-200/AE-50/EW-50 via an external input adapter (PAC-YG10HA). The PLC method sends a peak cut level signal from the demand controller to the AE-200/AE-50/EW-50 via a PLC.

The split electricity billing function of the AE-200 and the split electricity billing function of the TG-2000A cannot be used at the same time.

Functions and licenses

Method 1: While the Monitor/Operation screen is displayed on the AE-200/AE-50, press the button in the upper right corner of the screen to display the login screen. Method 2: The software version is displayed on the Registration of Optional Functions screen for AE-200/AE-50/EW-50 in the web browser. How to determine the cause and fix the problem based on the AE-200/AE-50/EW-50 detected error display.

1 Are AE-200/AE-50/EW-50, PC, PLC, HUB, power supply unit and other equipment and air conditioner turned on. If you answered "No" to any of the above items, remove the cause of that item.

List of error codes for errors detected by the

Error and preliminary error code list

How to determine the cause and resolve trouble based

The detection address displayed on the error monitor and in the error history is the address of the controller that detected the error. The allocated electricity bill function of the AE-200 does not work while this error code is displayed. Error detected when the allocated data is not restored when the AE-200/AE-50/EW-50 is replaced while the allocated electricity bill function of the AE-200 is enabled.

To prevent the loss of backup data, the AE-200's split electricity billing function does not work while this error code is displayed. The split electricity billing function of the AE-200 does not work while this error code is displayed. Communication error - polarity not specified 1. Error detected .. when the transmission processor, which is the communication component of M-NET, cannot check the + and - polarity of the M-NET transmission line voltage.

Check for power on the AE-200/AE-50/EW-50 M-NET transmission line and correct any wiring errors. An address has been set that does not exist in the group registration, interlock LOSSNAY settings, or measurement settings of the AE-200/AE-50/EW-50.

Error judgment based on the STATUS LED display of

Troubleshooting depending on the trouble symptoms

Insert the connector of the LAN cable properly into the LAN port on the back of the AE-200/AE-50/EW-50. Set the IP address of the router that the AE-200/AE-50/EW-50 will connect to as the gateway address.

About the preliminary check items

About the check method using ping

If a proxy server is set, enter the IP address of the AE-200/AE-50/EW-50 in the exception field to enable a connection that is not through the proxy server. Is the gateway address of the router and the gateway address set on the AE-200/AE-50/EW-50 the same. The IP address of the AE-200/AE-50 can be checked on the [Initial Settings] - [Network] screen.

The IP address of the AE-50/EW-50 can be checked by selecting the equipment to be displayed (“Controller”) in the [Initial Settings] - [Network] screen. Successfully pings the IP address of the AE-200/AE-50/EW-50 when the control PC is connected to HUB 2. Successfully pings the IP address of the AE-200/AE-50/EW-50 when the PC for the check is connected to HUB 1.

It is successful to ping the IP address of TG-2000A when the connector is removed from the LAN port connecting AE-200/AE-50/EW-50 and then the computer is connected for control. Close all open Internet Explorer windows, and then open Internet Explorer again and check that the web browser function of the AE-200/AE-50/EW-50 can be used (web page is displayed). Contact the dealer or distributor and inform them of the serial number of the AE-200/AE-50/EW-50.

Be sure to test run the air conditioning units first before performing the test run check of the AE-200/AE-50/EW-50.

Test run check sheet

Update all AE-200/AE-50/EW-50 and make sure the software version matches. If the equipment will not be separated from the existing (local) LAN, please contact the network administrator and obtain permission to connect to the upgrade computer and obtain an IP address for temporary use. 1 If the update takes longer than about three minutes, an error may be displayed on the local remotes.

The update may take about 10 minutes depending on the software version and communication conditions, so please inform the administrator and other persons as necessary that an error may occur. Check the settings of these functions in advance and perform the update when stopping the functions will have the least effect. Measurement trend monitoring (use a PI controller and AI controller) 01:05-01:15 (8) Do not update via a VPN router connected to the Internet.

Note: If the update will be performed with a PC already connected to a local LAN, the subnet mask may differ from the above. When the computer is connected to a local LAN, obtain permission from the network administrator before configuring the network settings and performing the update.

About the peak cut settings check list

About the peak cut operation check

Perform the maximum trim check and check that the air conditioning units are operating or set as specified below for each control level. Change the target power values in [Function1] - [Peak cut control] in Web Administrator, and then perform control at each peak cut level. When using the split electricity billing function, be sure to perform the billing test.

To run the billing test with the AE-200, run the test run check sheet with the Initial Setting Tool and then run the check. When using the dedicated electricity billing function with the TG-2000A, refer to the Operation Manual (Site Customization).

Preparation

Notes about expansion

Work procedure

Air conditioners will continue to operate even if this happens, so local remote controls will be enabled (allowed). 2 Whether the air conditioners will stop abnormally or display an error depends on the model. After the software update is completed, check the operation status of the air conditioners, and if the air conditioners that have been working are stopped, operate them manually if necessary.

Work procedure 1: Update computer settings] (Procedure using a web browser) (1) Change the computer's IP address. For the * part, enter a number that is different from the IP address of the AE-200/AE-50 to be updated. A USB memory device may not be recognized if it is removed and inserted within a short period of time.

If there is a problem with the USB memory device or update file, "The USB memory cannot be recognized normally." or "A data read/write error has occurred" appears.