Braz. J. of Develop.,Curitiba, v. 6, n.5, p.25202-25207 may. 2020. ISSN 2525-8761

Xanthan gum production by semissolid and submerged processes using

potato peel as substrate

Produção de goma xantana por processos semissólidos e submersos

usando casca de batata como substrato

DOI:10.34117/bjdv6n5-102

Recebimento dos originais:15/04/2020 Aceitação para publicação:07/05/2020

Augusto de Souza da Silva

Mestre em Ciência e Tecnologia de Alimentos pela Universidade Federal de Sergipe Instituição: Universidade Federal de Sergipe

Endereço: Cidade Univ. Prof. José Aloísio de Campos, Av. Marechal Rondon, s/n – Jd. Rosa Elze, São Cristóvão – SE, Brasil CEP 49100-000

E-mail: augustoss@hotmail.com.br

Fabiana Propheta dos Santos

Engenheira de Alimentos

Instituição: Universidade Federal de Sergipe

Endereço: Cidade Univ. Prof. José Aloísio de Campos, Av. Marechal Rondon, s/n – Jd. Rosa Elze, São Cristóvão – SE, Brasil CEP 49100-000

E-mail: fabianapropheta28@gmail.com

Ana Karla de Souza Abud

Doutora em Engenharia Química pelo Programa de Engenharia Química da COPPE/UFRJ Instituição: Universidade Federal de Sergipe

Endereço: Cidade Univ. Prof. José Aloísio de Campos, Av. Marechal Rondon, s/n – Jd. Rosa Elze, São Cristóvão – SE, Brasil CEP 49100-000

E-mail: ana.abud@gmail.com

ABSTRACT

Xanthan gum is an exopolysaccharide synthesized by fermentation via bacteria of the genus

Xanthomonas and its success in the market is due to the application in the food,

pharmaceutical, agrochemical and petrochemical industries, presenting properties of forming viscous solutions in low concentrations, broad range of stability to pH and temperature, as well as their rheological characteristics. The objective of this work was to study the production of xanthan gum in different fermentation processes (submerged and semisolid) from the fermentation of an alternative substrate (potato peel) using strains of Xanthomonas campestris pv. manihotis ISBF 1182. The results obtained proved the possibility of producing xanthan gum in potato peel, and the semisolid process showed the highest yield (20.9 g/L, 48 h) in relation to the submerged (2.03 g/L, 72 h).

Braz. J. of Develop.,Curitiba, v. 6, n.5, p.25202-25207 may. 2020. ISSN 2525-8761

RESUMO

A goma xantana é um exopolissacarídeo sintetizado por fermentação por bactérias do gênero Xanthomonas e seu sucesso no mercado se deve à aplicação nas indústrias alimentícia, farmacêutica, agroquímica e petroquímica, apresentando propriedades de formação de soluções viscosas em baixas concentrações, ampla faixa de estabilidade pH e temperatura, bem como suas características reológicas. O objetivo deste trabalho foi estudar a produção de goma xantana em diferentes processos fermentativos (submersos e semissólidos) a partir da fermentação de um substrato alternativo (casca de batata) utilizando linhagens de Xanthomonas campestris pv. manihotis ISBF 1182. Os resultados obtidos provaram a possibilidade de produzir goma xantana em casca de batata, e o processo semi-sólido apresentou o maior rendimento (20,9 g / L, 48 h) em relação ao submerso (2,03 g / L, 72 h).

Palavras-chave: Xanthomonas, produção, processo de fermentação, casca de batata

1 INTRODUCTION

Xanthan gum is an extracellular, water-soluble, anionic and branched heteropolysaccharide, produced by Xanthomonas campestris Gram-negative bacteria strains, with unique rheological properties, such as highly pseudoplastic behavior, where the viscosity of the solutions is almost unchanged at temperatures between 4 and 93 °C and pH between 1 and 13, which contributes to their applications as stabilizing agents, thickeners and emulsifiers in the petroleum, food, pharmaceutical, hygiene and cosmetic industries (Diniz et al., 2012; Menezes et al. , 2012).

The production of this biopolymer depends on factors such as fermentative scale, agitation, aeration, temperature, medium composition and nutrient used, as well as the type of

Xanthomonas strain used in the process (Brandão et al., 2013). Thus, it is possible to obtain a

variation in the yields and in the quality of the polymer, parameters that directly influence this molecular structure and properties (Casas et al., 2000; García-Ochoa et al., 2000; Mesomo, 2009).

These residues of potato peel are traditionally used for animal feed, as fertilizers or as raw material for the biogas production, leading to waste materials rich in nutrients (Wu, 2016). Only in Brazil, more than 300 thousand tons of potato peels are discarded annually after the preparation of the most varied dishes of this tuber (Fernandes et al., 2008).

The inclusion of the industrial by-products as substrates for the synthesis of biopolymers reduces the amount of residues discarded in the environment and minimizes costs in the treatment of effluents (Mesomo, 2009). As a result, the present work evaluates the viability of the use of potato peel in the production of xanthan gum in submerged and semisolid cultures.

Braz. J. of Develop.,Curitiba, v. 6, n.5, p.25202-25207 may. 2020. ISSN 2525-8761

2 MATERIALS AND METHODS

The experiments were conducted using potato peel extract, collected from street vendors of potato chips around Federal University of Sergipe, being washed and stored in a freezer until the time of treatment to avoid degradation process.

The strain Xanthomonas campestris pv. manihotis ISBF 1182 was used in the experiments. This species was obtained from the Biological Institute of São Paulo. To obtain the inoculum, the strain was cultivated in yeast malt (YM) medium (0.3% malt extract, 0.3% yeast extract, 0.5% bacteriological peptone, and 1.0% glucose) and incubated at 28 °C for 24 h at 200 rpm.

The submerged fermentation occurred crushing the potato peel in a blender with distilled water in a ratio 1:2 (w:v) and filtered. To this broth was added to 0.01% (w/v) urea and 0.1% (w/v) potassium phosphate, adjusting the pH to 7.0, distributing in 250 mL Erlenmeyer flasks and sterilized at 121 °C for 15 min. The fermentation started with the addition of 6.5% (v/v) of the inoculum and was conducted in a shaker at 200 rpm and 28 °C for 96 h, with collections performed every 24 h.

The semisolid process was conducted in a 250 mL Erlenmeyer flask, covered with cotton plug, containing 10 g of potato peel powder, previously cut, sanitized, dehydrated in a forced air circulation at 50 °C up to constant weight, crushed and sieved. The volume of mineral solution that was added was previously defined, seeking a final moisture content of around 90%, adjusting the pH to 7.0. The mineral solution used was 10 g/L of yeast extract and 0.01 g/L of K2HPO4. The flasks were autoclaved at 121 °C for 15 min. The fermentation

started with the addition of 6.5% inoculum. After inoculation, the Erlenmeyers were incubated at 28 °C, and samples were collected every 24 h. For extraction, cold water was added to the solid medium in the ratio 1:10 (w:v), leading to stirring for 30 min on an orbital shaker at 200 rpm and ambient temperature.

The samples were pasteurized at 90 °C for 15 min and separated from the cells by centrifugation at 7500 rpm and 20 min at 4 °C. Cell growth, total reducing sugars (TRS) and xanthan gum production (product) were evaluated. These results were expressed by the average ± standard deviation of triplicate measure. Cell growth was determined by measuring optical density of cells at 560 nm in the fermentation broth and correlated with dry cell weight (105°C until constant weight). The total reducing sugars (TRS) were determined by the DNS colorimetric method (Miller, 1959), after hydrolysis of the extract with H2SO4 1.5 M and

Braz. J. of Develop.,Curitiba, v. 6, n.5, p.25202-25207 may. 2020. ISSN 2525-8761 from the supernatants by adding 96 °GL ethanol (1:2). The gum samples were separated and transferred to plates, dried at 50 °C for 24 h and stored in a sealed flask for analysis. The yield from each residue was calculated and the values were expressed in g/L (grams of gum per liter of culture medium) (Costa et al., 2014).

3 RESULT AND DISCUSSION

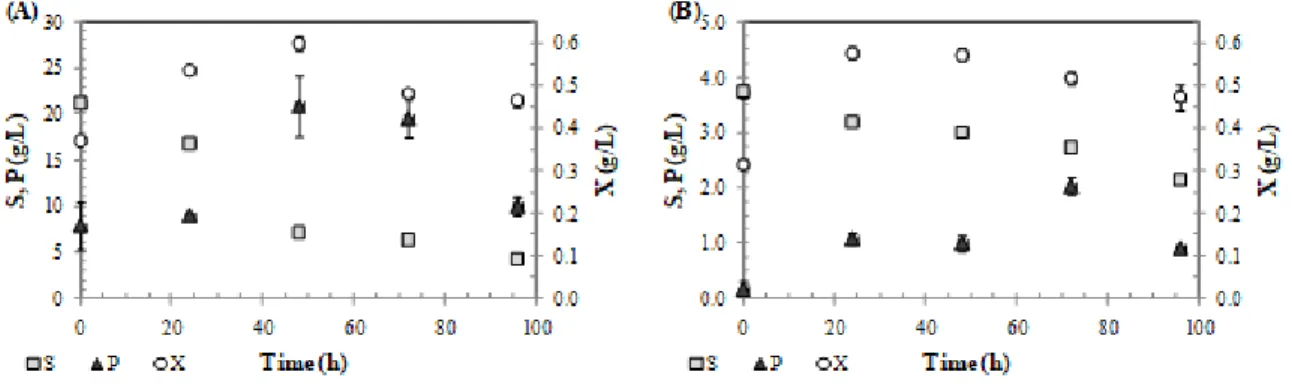

The kinetic fermentation profiles [cell growth (X), substrate consumption (S) and product formation (P)] are shown in Figure 1. The two cultures presented a log phase of growth in the first 24 h. However, in the last fermentation time (96 h), the semisolid culture viability was less than the submerged assay. The maximum growth concentration was around 0.6 g/L.

Figure 1. Behavior of kinetic variables of semisolid (A) and submerged (B) fermentations.

Semisolid cultures presented 19.3% of initial substrate when compared to the submerged studies. This may have occurred due to the preparation of the broth in the submerged fermentations, where the proportion of potato peel and water led to a greater dilution of the substrates present, whereas in the semisolid culture the drying process concentrated the potato peel components that later would be used as the basis for the growth of Xanthomonas.

Taking into account the appearance and characteristics in the precipitation stage, the gums obtained by the submerged fermentation proposed to present better yields, due to their easy precipitation and good consistency. However, the gums obtained by semisolid process result in higher yields (20.9 g/L, 48 h) in relation to the submerged (2.03 g/L, 72 h), although in the latter condition the results were similar to those obtained with shrimp shells (2.64 g/L) (Costa et al., 2014) and sucrose (2.48 g/L) (Diniz et al., 2012). Due to this, it is important to

Braz. J. of Develop.,Curitiba, v. 6, n.5, p.25202-25207 may. 2020. ISSN 2525-8761 perform analysis of the rheological properties to evaluate the efficiency of these biopolymers and its pseudoplasticity.

4 CONCLUSIONS

It was possible to produce xanthan gum from potato peel, generating comparable yields to the literature. The semisolid process, despite the visual characteristics in the precipitation stage, generated a yield 10 times higher than the process obtained by the submerged fermentation, possibly as a function of the dilution of the residue in water.

REFERENCES

Brandão, L. V., Assis, D. J., López, J. A., Espiridião, M. C. A., Echevarria, E. M., Druzian, J. I. Bioconversion from crude glycerin by Xanthomonas campestris 2103: xanthan prodution and characterization. Brazilian Journal of Chemical Engineering, v. 30, n. 4, p. 737-746, 2013. Casas, J. A., Santos, V. E., Garcia-Ochoa, F. Xanthan gum production under several operational conditions: molecular structure and rheological properties. Enzyme and Microbial Technology, v. 26, n, 2-4, p. 282-291, 2000.

Costa, L.A.S., Campos, M.I., Druzian, J.I., Oliveira, A.M., Oliveira, Junior, E.N. Biosynthesis of xanthan gum from fermenting shrimp shell: yield and apparent viscosity. International Journal of Polymer Science, p.1-9, 2014.

Diniz, D. M., Druzian, J. I., Audibert, S. Produção de goma xantana por cepas nativas de

Xanthomonas campestris a partir de casca de cacau ou soro de leite. Polímeros, v. 22, n. 3, p.

278-281, 2012.

Fernandes, A. F., Pereira, J., Germani, R., Oiano-Neto, J. Efeito da substituição parcial da farinha de trigo por farinha de casca de batata (Solanum tuberosum Lineu). Ciência e Tecnologia de Alimentos, v. 28, p. 56-65, 2008.

García-Ochoa, F., Santos, V. E., Casas, J. A., Gómez, E. Xanthan gum: production, recovery, and properties. Biotechnology Advances, v. 18, p. 549-579, 2000.

Menezes, J. D. S., Druzian, J. I., Padilha, F. F., Souza, R. R. Produção biotecnológica de goma xantana em alguns resíduos agroindustriais, caracterização e aplicações. Revista Eletrônica em Gestão, Educação e Tecnologia Ambiental, v. 8, n. 8, 1761-1776, 2012.

Braz. J. of Develop.,Curitiba, v. 6, n.5, p.25202-25207 may. 2020. ISSN 2525-8761 Mesomo, M. C., Silva, M. F., Boni, G., Padilha, F. F. Mazutti, M., Mossi, A., Oliveira, D., Cansian, R. L, Luccio, M. D., Treichel, H. Xanthan gum produced by Xanthomonas

campestris from cheese whey: production optimization and rheological characterization.

Journal of the Science and Food Agriculture, v. 89, p. 2440-2445, 2009.

Miller, G.L. Use of dinitrosalicylic acid reagent for determination of reducing sugar. Analytical Chemistry, v. 31, n. 3, p. 426-428, 1959.

Silva, C.E.F., Gois, G.N.S.B., Silva, L.M.O., Almeida, R.M.R.G., Abud, A.K.S. Citric waste saccharification under different chemical treatments. Acta Scientiarum Technology, v. 37, n. 4, p. 387-395, 2015.