h tt p : / / w w w . b j m i c r o b i o l . c o m . b r /

Biotechnology

and

Industry

Microbiology

Biopharmaceuticals

from

microorganisms:

from

production

to

purification

Angela

Faustino

Jozala

a,

Danilo

Costa

Geraldes

b,

Louise

Lacalendola

Tundisi

b,

Valker

de

Araújo

Feitosa

c,

Carlos

Alexandre

Breyer

d,

Samuel

Leite

Cardoso

e,

Priscila

Gava

Mazzola

f,

Laura

de

Oliveira-Nascimento

f,g,

Carlota

de

Oliveira

Rangel-Yagui

c,

Pérola

de

Oliveira

Magalhães

h,

Marcos

Antonio

de

Oliveira

d,

Adalberto

Pessoa

Jr

c,∗aUniversidadedeSorocaba(UNISO),DepartamentodeTecnologiaeProcessoAmbiental,Sorocaba,SP,Brazil

bUniversidadedeCampinas(UNICAMP),InstitutodeBiologia,ProgramadePós-Graduac¸ãoemBiociênciaseTecnologiadeprodutos bioativos,Campinas,SP,Brazil

cUniversidadedeSãoPaulo,DepartamentodeBioquímicaeTecnologiaFarmacêutica,SãoPaulo,SP,Brazil dUniversidadeEstadualdeSãoPaulo(UNESP),InstitutodeBiociências,CampusdoLitoralPaulista,SP,Brazil

eUniversidadedeBrasília,FaculdadedeCiênciasdaSaúde,ProgramadePós-Graduac¸ãoemCiênciasFarmacêuticas,Brasília,DF,Brazil fUniversidadeEstadualdeCampinas,FaculdadedeCiênciasFarmacêuticas,Campinas,SP,Brazil

gUniversidadeEstadualdeCampinas,InstitutodeBiologia,DepartamentodeBioquímicaeBiologiaTecidual,Campinas,SP,Brazil hUniversidadedeBrasília,FaculdadedeCiênciasdaSaúde,DepartamentodeFarmácia,Brasília,DF,Brazil

a

r

t

i

c

l

e

i

n

f

o

Articlehistory:

Received6September2016 Accepted22September2016 Availableonline26October2016 AssociateEditor:NelsonDurán

Keywords: Biopharmaceuticals Fermentationprocess Biotechnology Upstreamprocess Downstreamprocess

a

b

s

t

r

a

c

t

Theuseofbiopharmaceuticalsdatesfromthe19thcenturyandwithin5–10years,upto 50%ofall drugsindevelopmentwill bebiopharmaceuticals.In the1980s,the biophar-maceuticalindustryexperiencedasignificantgrowthintheproductionandapprovalof recombinantproteinssuchasinterferons(IFN␣,,and␥)andgrowthhormones.The pro-ductionofbiopharmaceuticals,knownasbioprocess,involvesawiderangeoftechniques.In thisreview,wediscussthetechnologyinvolvedinthebioprocessanddescribetheavailable strategiesandmainadvancesinmicrobialfermentationandpurificationprocesstoobtain biopharmaceuticals.

©2016SociedadeBrasileiradeMicrobiologia.PublishedbyElsevierEditoraLtda.Thisis anopenaccessarticleundertheCCBY-NC-NDlicense(http://creativecommons.org/

licenses/by-nc-nd/4.0/).

∗ Correspondingauthor.

E-mail:pessoajr@usp.br(A.PessoaJr).

http://dx.doi.org/10.1016/j.bjm.2016.10.007

1517-8382/©2016SociedadeBrasileiradeMicrobiologia.PublishedbyElsevierEditoraLtda.ThisisanopenaccessarticleundertheCC BY-NC-NDlicense(http://creativecommons.org/licenses/by-nc-nd/4.0/).

Introduction

Biopharmaceuticalsaremostlytherapeuticrecombinant pro-teinsobtainedbybiotechnologicalprocesses.Theyarederived frombiologicalsourcessuchasorgansandtissues, microor-ganisms, animal fluids, or genetically modified cells and organisms.1,2 Althoughseveraldifferentexpressionsystems may beemployedincluding mammaliancell lines, insects, and plants, new technological advancements are contin-uously being made to improve microorganism production of biopharmaceuticals. This investment is justified by the well-characterized genomes, versatility ofplasmid vectors, availabilityofdifferenthoststrains,cost-effectivenessas com-paredwithotherexpressionsystems.2,3

Bioprocessingisacrucialpartofbiotechnology.Thereisan anticipationthatwithinthenext5to10years,upto50%ofall drugsindevelopmentwillbebiopharmaceuticals.Examples includerecombinantproteinsobtainedthroughmicrobial fer-mentationprocess.2,3 Bioprocessing forbiopharmaceuticals productioninvolvesawiderangeoftechniques.Inthisreview, wedescribethemainadvancesinmicrobialfermentationand purificationprocesstoobtainbiopharmaceuticals.

Biopharmaceuticalsandthepharmaceuticalindustry Drugdevelopmentisan extremelycomplex and expensive process. According to the Tufts Center for the Study of DrugDevelopment4(http://www.csdd.tufts.edu),itmaytake approximately 15 years of intense research from the ini-tial idea to the final product and development and costs usually exceed $2 billion. Low-molecular mass molecules aregenerically namedasdrugswhilehigh-molecular mass drugs,whicharerepresentedbypolymersofnucleotides(RNA or DNA)or aminoacids (peptidesand proteins), are called biopharmaceuticals.5 Biopharmaceuticals based in nucleic acids,suchassmallinterferingRNA(siRNA),DNAvaccines, andgenetherapy,areverypromisingstrategies.However, clin-icalprotocols wereapprovedonlyvery recently6 andjust a fewnucleicacids-baseddrugshavebeentherapeuticallyused todate7andrecentreviewsaddressedthestateoftheartof nucleicacidsintherapies.8,9Inthisreview,wefocusedon pep-tidesandproteinsbecausetheyrepresentthemajorclassof biopharmaceuticals.10

Theuseofproteinsasdrugshasbeenhighlightedmainly bythehighversatilityofthesebiomolecules,whichhave dif-ferent physiological roles in the human body including as catalysts,receptors,membranechannels,macromolecule car-riers,andcellulardefenseagents.10,11Someproteintherapies providehigh specificity, suchasreplacement ofapatient’s defective protein or evenfulfill its absence due to genetic defectsorimmunologicalcomplications.10

Biopharmaceuticals:reference,biosimilars,andbiobetters Itisworthemphasizingthatthesamegeneproduct,which encodestheidenticalaminoacidsequence,couldbeobtained byextractionfromananimaltissueorbyrecombinantDNA techniques. However,thesame protein producedby differ-entmanufacturerspresentdifferentcharacteristics.Inorder

to differentiate the products, the first biopharmaceutical version ofthesame therapeuticproteinisset asthe refer-encemedicine,whereasthefollowingonesaredenominated biosimilars. Biosimilars may present differences because ofpost-translational modifications (phosphorylation, glyco-sylation) and different manufacturing processes. The term biobetter,alsonamedbiosuperiors,wasrecentlyusedtorefer totherapeuticmacromoleculesofthenextgeneration,which present more effective drug delivery system, are modified by chemical methods (e.g., PEGylation) and/or engineered bymeansofmolecularbiologytechniquestopresentbetter pharmacologicpropertiessuchashigheractivity,enhanced stability, fewerside effects, and lower immunogenicity.12,13 Therefore, while a biosimilar represents a generic version of the original biopharmaceutical, biobetters need original research and development and the costs are significantly higher.14

Additionally,whilethefirstbiopharmaceuticalswere pre-dominantlydeliveredbyinjections,biobettersadoptdifferent approaches todrugdeliveryadministrationasoral, derma-tological and inhaled formulations which are related with differentencapsulationapproachesaimingtominimizethe biologicinstabilitycausedbyproteinaggregationand dena-turation as consequence of physicochemical modifications processes of the biodrug as deamination, hydrolysis, oxi-dation, among others.15 Protein engineering and rational modificationisalsoaverypromisingareainnew biopharma-ceuticalsandsomeaspectswillbediscussedlater.

Theuseofbiopharmaceuticalshasgrownworldwideinthe lastfewyears.In2016,thetotalnumberofproductsapproved bytheFoodsandDrugsAdministration(FDA)andEuropean MedicinesAgency(EMA)foruseinhumansreached1357,of which>130havedifferentformulations(referenceproducts), 737are biosimilars,andtheremaining482areclassifiedas biobetters16(http://www.biopharma.com).From2013to2016, 73 biopharmaceuticals were approved for use in humans. Among them, high prominence was given to monoclonal antibodies (23 approvals)widely used inseveral diagnostic procedures,treatmentofinflammatorydiseases,and neoplas-tictumors16(http://www.biopharma.com).

Inaddition,theEuropeanMedicineAgency(EMA)licensed two new products based on gene therapy (insertion of a corrective gene able to produce a normal protein in the patient’sgenometocureageneticdisease)foruseinhuman therapeutic protocols.These productswere Glybera, devel-oped by the German company UniQure for the treatment oflipoproteinlipasedeficiency,andStrimvelis,developedby GlaxoSmithKline(GSK)forthetreatmentofadenosine deam-inasedeficiency.17Althoughbiopharmaceuticalscanbevery effectivefordiseasecontrolorcure,treatmentcostscanreach upto$1millionperpatient.18

Biobettersbasedinproteinstructureengineering

Oneofthemostpromisingareas ofthe biobettersreliesin proteinstructureengineeringaimingthedevelopmentof bio-drugswithbetterpharmacologicalpropertiesincludinghigher activity,fewerside effects,and lower immunogenicity.The breakthroughinthedeterminationofproteinstructuresand their useas medicinesdatesfrom 1980sasaconsequence

of the advances in recombinant DNA technology. In turn, structuralbiochemistryhasrevolutionizedour understand-ingofproteinbiologyandaffordedthebeginningofprotein engineeringprocessesthatcancreateproteindrugsthatare moreeffective thanwild typeproteins.Proteinengineering mayincreasecatalyticactivity,stability,lower immunogenic-ity,andsusceptibilitytoproteolyticprocesses.11,19–21

Protein engineering involves manipulating the protein sequence at the molecular level in order to change its function. Themost common manipulations in the protein sequencearebasepaircutsandexchanges.However,changes in protein structure caused by oxidation or irreversible reductionofdisulfides are alsoconsidered.Onefactorthat contributeddecisivelytoproteinengineeringwasthe develop-mentoftechniquesthatallowthedeterminationofproteins three-dimensional structure at the atomic level. Among these techniques, more emphasis is given to X-ray crys-tallography because of its high resolution (reaching<1 ˚A). Morerecently,nuclearmagneticresonance(NMR)and Cryo-electron microscopy (cryo-EM) have also gained space as alternativetechniquesforsolvingstructures.22

Genemanipulation(e.g.,codonreplacement)bymolecular biologyisabletomodifyproteinstructureinaspecificmanner. Amongthe severaltechniquesusedforgenemanipulation, wehighlightsite-directedmutagenesis(SDM).Thistechnique allows rational protein engineering based on its three-dimensionalstructure.23,24UsingSDM,onecanreplace,delete, orinsertoneormoreaminoacidsinthesequenceofaprotein. Examplesincludetheinsertionofpost-translational modifi-cationsites(glycosylation,acetylation,phosphorylation,etc.), enhancementofkineticcharacteristicsbymodificationofthe activesiteenvironment,and modificationofprotein aggre-gation paths.25–28 (Fig. 1) Biobetters generated by protein engineering and gene manipulation may present superior characteristicsoverthereferencebiopharmaceuticaland rep-resentsthemajorgrowingclassamongbiopharmaceuticals.

Thereferencerecombinant proteinisexpressed inhigh amountsandthemolecularstructureisdeterminedatatomic levels (crystallography or NMR). Afterwards, the protein is analyzed using bioinformatic tools and regions of interest areidentified.AftergenemanipulationbySDM,themodified recombinantprotein(biobetter)isobtained.

Upstream

processing

on

biopharmaceuticals

production

Themanufacturing technology forbiopharmaceuticals can be divided into up- and downstream processes (Fig. 2). Upstreamprocessisdefinedasthemicrobialgrowthrequired to produce biopharmaceuticals or other biomolecules and involves a series of events including the selection of cell line, culture media, growth parameters, and process opti-mizationtoachieve optimalconditionsforcellgrowth and biopharmaceuticalproduction.Themaingoaloftheupstream processisthetransformationofsubstratesintothedesired metabolicproducts.29Thisrequireswell-controlledconditions andinvolvestheuseoflarge-scalebioreactors.Severalfactors shouldbeconsideredsuchasthetypeofprocess(batch, fed-batch,continuous,etc.)temperature,pH,andoxygensupply

High amounts of target by heterologous expression

3D structure determination

Structural analysis at atomic level (binding sites, aggregation paths,

Rational modification by SDM

Protein with superior characteristics (Biobetter)

Negatively charged path Uncharged

path

Fig.1–Pipelineofproteinengineeringtoobtainbiobetters.

Theproteinisrepresentedbymolecularsurfaceand

colorizedbycoulombicforces(blue=positive,

red=negative,andwhite=neutral).

control,sterilizationofmaterialsandequipmentemployed, andmaintenanceoftheenvironmenttoensureitisfreeof contaminatingmicroorganisms.30

Biopharmaceuticalsproducedbymicroorganisms Bacteria

The use of protein biopharmaceuticals in human health datesfromthe19thcenturywiththeuseofdiphtheria anti-toxin therapy.31 The antidote consistsof immunoglobulins extracted from the serum ofimmunized animalsthat rec-ognizeandneutralizethetoxin(e.g.,horseorsheep).31,32 In fact,severalantitoxinsareavailabletotreatenvenomationby snakes,scorpions,andwasps,orinfections.However,theuse ofnon-humananimalantibodiescancausehypersensitivity ofthepatienttotheanimalserum,whichisknownasserum sickness.33

Culture at –80ºC

Plate or Stock Flask

Inoculum preparation

Production bioreactor

Centrifugation or filtration

(cell harvesting) Precipitation and/or liquid liquidextraction

Low resolution purification steps

Final biophameceutical Quality control and packaging Liofilization Formulation: (Protein + Buffer + Salt + Protectants)

High resolution purification steps

Diafiltration Viral filtration Polishing cromatography Viral inactivation Cromatography

Fig.2–Thebiopharmaceuticalmanufacturingtechnologyflowchartexemplifyingtheupstreamandthedownstream

bioprocess.

The20thcenturyexperiencedtheuseofseveralmolecules comingfromanimalsourcessuchasinsulin,growthhormone (GH),glucagon,and asparaginase.34–36 However,the discov-eryofthepriondiseasesrelatedtotheadministrationofhGH revealedanotherpotentialriskassociatedwithnon-human animal proteins. This reinforced the need for the produc-tionofproteinpharmaceuticalsfromothersources.37Atthis time,thebiopharmaceuticalindustrylookedatheterologous expressionofproteindrugsbymeansofrecombinantDNA techniquesinmicroorganisms.38

Withtheadvancesofmolecularbiologyandrecombinant DNA, human proteins could be obtained by heterologous expressionusingEscherichiacoli,aswellasotherbacteria.The classicexampleishumaninsulin,whichisusedtotreat dia-betesmellitustypesIandII(DMIandDMII).Initially,insulin was purifiedfrom the extracts ofbovineand porcine pan-creas.However,theprocesswasexpensiveandmanycasesof immuneresponsescausedbyanimalinsulininpatientswere reported10,39Thehumaninsulingenewasthenisolatedand thehumanproteincouldbeobtainedbyheterologous expres-sionusingE.coli(Fig.3).

Filamentousfungi

The great diversity of molecules produced by filamentous fungi justifies the exploitation ofthese organisms. In par-ticular, the isolation and identification of taxol-producing endophyticfungiisanewandfeasibleapproachtothe pro-duction of this antineoplasticdrug. The development and useoftaxol-producingfungihavemadesignificantprogress worldwide.40 Taxol was produced by Fusarium oxysporum grown in potato dextrose broth. In addition, the filamen-tousfungusAspergillusnigerisolatedfromTaxuscuspidatewas foundtoproducetaxol.41

Extracellularenzymesproducedbyfilamentousfungihave alsobeenexplored.-d-galactosidase(lactase–EC.3.2.123)is theenzymeresponsibleforthecatalysisoflactosetoglucose

andgalactose.Globalmarketforlactasehasbeenincreasing significantlyduetoitsimportanceinlactoseintolerance treat-ment.Lactaseismarketedintabletorcapsulestobeusedasa foodsupplementforindividualsintoleranttolactosebefore the intake of milkor dairy products.42,43 Lactase also par-ticipatesinthegalactooligosaccharides(GOS)synthesiswith applicationsinfunctionalfoodssuchaslow-caloriefoodsand asanadditiveinfermenteddairyproducts,breads,anddrinks. GOS,agroupofoligosaccharides,arenotdigestibleand are beneficialtothehumanoranimalbody.ThebenefitsofGOS ingestionarisefromapopulationofbifidobacteriainthecolon thatsuppresstheactivityofputrefactivebacteriaandreduce theformationoftoxicfermentationproducts,avoiding intesti-nalconstipationandincreasingtheproductionofvitaminsB complex.44,45

Another biological drug of importance in fungi is the asparaginaseenzyme.Thisenzymeisusedforthetreatment ofselectedtypesofhematopoieticdiseasessuchasacute lym-phoblasticleukemiaandnon-Hodgkinlymphoma.Astumor cellsaredependentontheexogenoussupplyofasparaginefor theirproliferation,thepresenceofthedrug,whichdepletes thebloodstreamfromasparagine,causesitsselectivedeath. However,thedrug,whichisobtainedfromE.coli(ELSPARTM) andErwiniachrysanthemi,causessevereimmunological reac-tions.Thus,thefungienzymecouldprovideanalternativeto thebacterialenzymesasananti-tumoralagentasitpresents stabilityandoptimumpHnearphysiologicalconditions.

Li et al. (2015)46 demonstrated the production of a moleculewithantifungalactivityagainstastrainofCytospora chrysosperma by submerged fermentation in a shaker. The activecompoundwasobtainedbyextractioninorganic sol-vents,liquidchromatography,andthin-layerchromatography. Svahnetal.(2015)47producedandisolatedamphotericinBby usingastrainofPenicilliumnalgiovenseisolatedfrom Antarc-tica.ItwasthefirsttimethatamphotericinBwasisolatedfrom adifferentorganismasitisusuallyisolatedfromStreptomyces

Human insulin gene Bacterial plasmid

Recombinant plasmid

Bacterial transformation and heterologous expression

Protein purification (recombinant insulin)

Fig.3–Recombinantproteinproduction.Using

recombinantDNAtechniques,thetargethumangenecan

beisolatedandligatedtoavector(plasmid).Theplasmid

containingthehumangeneisusedtotransformbacterial

cells,whichareabletoproducehighamountsofthe

recombinantprotein.

nodosus.AmphotericinBalsoshowedaminimuminhibitory concentrationof0.125mg/mLagainstCandidaalbicans.

Collagenolytic proteases (KollagenaseTM) have been directly used in clinical therapy, including woundhealing, sciaticainherniatedintervertebraldiscs,retainedplacenta, and asa pretreatment forenhancing adenovirus-mediated cancergene therapy.48 Another alkalineprotease with col-lagenolyticactivity was produced byA. nigerLCF9 and the enzyme hydrolyzed various collagen types without amino acidreleaseandliberatedlowmolecularweightpeptidesof potentialtherapeuticuse.49

Carrezetal.(1990)50detectedthepresenceofinterleukin-6 upto25ng/mLinamodifiedstrainofA.nidulansexpressing thehumaninterleukin-6.Yearslater,Yadwadandcolleagues

Table1–Biopharmaceuticalsobtainedfromfilamentous fungi.

Compound Organism

Taxol Taxomycesandrenae

Beta-galactosidase A.foetidus

Lovastatin Monascusrubber,

A.terreus

l-asparaginase A.terreus

Ergotalkaloids Clavicepspurpurea

Griseofulvin P.griseofulvum

Proteases Aspergillussp

Penicilliumsp

AmphotericinB Penicilliumnalgiovense

(1996)51 producedapproximately54mg/Lofinterleukin-6in anair-liftfermenterwitharecombinantstrainofA.nidulans andamediumsupplementedwithsalts,fructose,and threon-ine.

The production of biopharmaceuticals by filamentous fungiiswellstudied,buttheapplicabilityofbiomolecules pro-ducedbysuchorganismsisstillrestrictedbythehighcostof purificationofsomemoleculesandbydifficultyinfilamentous fungalcultivation(Table1).52Nonetheless,theuseof filamen-tousfungifortheproductionofcompoundsofinterestisstill aninterestingstrategy.

Downstream

process:

Isolation

and

purification

of

Biophamaceuticals

Downstreamprocessingincludesallstepsrequiredtopurify a biological product from cell culture broth to final puri-fiedproduct.Itinvolvesmultiplestepstocapturethetarget biomoleculeandtoremovehostcellrelatedimpurities(e.g., hostcellproteins,DNA,etc.),processrelatedimpurities(e.g., buffers,leachedligands,antifoam,etc.)andproductrelated impurities(e.g.,aggregates,fragments,clippedspecies,etc.). Each purification stepis capableofremoving oneor more classes of impurities.53,54 Downstream processing usually encompasses threemainstages, namely(i) initialrecovery (extraction or isolation), (ii) purification (removal of most contaminants),and(iii)polishing(removalofspecified con-taminantsandunwantedformsofthetargetbiomoleculethat mayhaveformedduringisolationandpurification).53,55,56

Initialrecoveryinvolves theseparationbetweencell and supernatant(brothclarification).Forthispurpose,themain operationsemployedarecentrifugation,filtration, sedimen-tation, and flotation. If the target biomoleculeis produced extracellularly,theclarifiedbrothissubmittedto concentra-tion(e.g.,ultrafiltration)followedbypurification.Forexample, secretedandsolubleproteinsintheculturemediaofP. pas-toriscanbedirectlyrecoveredbycentrifugation.Samplescan thenbeconcentratedandthetargetproteinpurifiedfromthe supernatantbyprocessessuchasultrafiltration,precipitation, and/orchromatography.57Forintracellularbiomolecules,the cellsharvestedmustbesubmittedtolysis(e.g.,high-pressure homogenizer,sonication,passingthroughmills,etc.)followed byclarificationtoremovecelldebris.Thetargetbiomolecule ispurifiedfromtheclarifiedcellhomogenate(usuallyby pre-cipitation and/orchromatography).Incaseswhereproteins

areexpressedasinclusionbodies(assomerecombinants pro-ducedby E. coli), anextra step ofprotein refolding(buffer exchange) is required. These additional steps significantly contributetoincreasesinproductiontimeandcostsfor intra-cellularbiomolecules.58

Efficientrecoveryand purificationofbiopharmaceuticals havebeenreferredasacriticalpartoftheproductionprocess. Purificationprocessmustberobust,reliable,easilyscaled-up, andcapableofremovingbothprocesses-andproduct-related impurities to ensure product safety. The achieved purity, the speed of process development, overall recovery yield, andthroughputare someofthemainkeyparametersthat mustbetakenintoconsiderationduringdownstreamprocess development.55Toreachthestringencyofpurityrequiredin the biopharmaceuticalindustry,sometimesexceeding 99%, chromatographystepsareusuallyrequired.Chromatography allows for high resolution and has traditionally been the workhorse forproteinpurification and polishing.53,56 How-ever,chromatographyhasalsobeenthemajorcostcenterin purificationprocesses,mainlyduetomediacostandrelatively longcycle times.Inaddition, thebiopharmaceutical indus-trystillfacespracticallimitationsintermsofthroughputand scalability.55

Chromatography

Different strategies based on sequences of classical chro-matographyhavebeendescribedfornucleicacids,peptides, andproteinspurification.Infact, chromatographyisavery effectivepurificationtechniquewithawiderangeof indus-trialapplicationsandcurrentlyrepresentsthefavoritechoice duetoitshighresolutioncapacity.56Theseparationprinciple inchromatographyisbasedonthedifferencesintheaffinityof thespeciescarriedbyafluidmobilephasetowardasolid sta-tionaryphase.Whenasampleisintroducedandtransported by the eluent along the column, some of its components will have more powerful interactions with the stationary phasethanothers,generatingconcentrationprofilesthatwill percolate the chromatographic columnatdifferent speeds. Thelessretainedspecieswilleluteearlierfromthecolumn thanthemostretainedones,eventuallyallowingthe collec-tionoftheproductsofinterestwithahighpuritydegree.59 Basedontheinteractionbetweenthesolidstationaryphase andbiomolecules,chromatographictechniquescanbe sum-marized into five classes: (i) affinity, (ii) ion-exchange, (iii) hydrophobicinteractions,(iv)sizeexclusion,and(v) mixed-modechromatography.60

Affinity chromatography simulates and exploits natural biological processes such as molecular recognitionfor the selectivepurificationoftargetproteins.61Thisclassof chro-matographyisprobablytheonlytechniquecurrentlyavailable thatiscapableofaddressingkeyissuesinhigh-throughput proteomicsand scale-up.62 Themost common example of anaffinityprocessisprotein-Achromatography, whichhas been appliedforover adecade inindustrial andacademic settingsforthecaptureandpurificationofantibodies.60 Sim-ilarly,protein-Lmaypossiblycometoplayaroleinantibody fragmentspurification.59Anotheraffinity-basedstrategywell establishedforrecombinantproteinspurificationistheuse offusiontags,whichare aminoacidsequencesattachedto

recombinant proteins withselective and high affinitiesfor achemicalorbiologicalligandimmobilizedona chromato-graphiccolumn.Inparticular,thepolyhistidine(xHis)taghas beenfrequentlyusedtopurifyrecombinantproteinsdueto itsbindingcapacitytowarddivalentmetalcations.60Despite thefactthataffinitymethodsusuallyeliminatepurification steps,increaseyields,anddownsizecapitalequipment,they dopresentsomedrawbacks,particularlyregulatoryonessince completewithdrawalofleachedligandsisarequirement.61

Traditional choices in chromatographic set ups include particle-based resins, batch mode operation, and packed columns. In order to address the drawbacks from these standardparameters,someprocessalternativesareattracting thepharmaceuticalindustry,especiallythechromatographic separationsbasedonsimulatedmovingbed(SMB),expanded bedadsorption(EBA),andsingleblockmonolithcolumns.

SMB chromatography is the preferred choice for enan-tiomer separation of synthetic drugs in pharmaceutical industry.However,justrecently,itsusemadeasignificantrise inbiotechnologycompanies,especiallyforproteinrefolding andcontinuousdownstreamprocess.63Thesystempresents multiple smallchromatographic columnssequentially con-nected and operated with countercurrent flow of fluids. Simulatedmovingcomesfromtheperiodicalswitchof mul-tiportinlets/outletsfromcolumntocolumn,inthedirection offluidflow,whichgivestheimpressionthatthecolumnbed ismoving.Theseinlet/outletvalves(feed,desorbent,raffinate, andextract)arepositionedinawaythatminimizedeadzones, allow desorbent recycling, optimize product recovery, and functionassemi-continuousmode.64Especiallyforrefolding, SMBtogetherwiththerecyclingofaggregatesleadtoa the-oreticalyieldof100%,excludingthefoldingequilibriumasa limitingfactorforproductivity.65Nevertheless,SMBismore complextoimplementandrequiresahigherinvestmentcost. EBAchromatographyisa3-in-1processintendedto cap-turetheproductdirectlyfromthecellsuspension,combining clarification,concentration,andinitialpurification.The bot-tomfeedfromtheEBAsystemcreatesaflowthatgradually expandstheresinandformastableparticlegradient.66This gradientconsistsofparticlesofdifferentsizerangesand dif-ferentdensities,whichrequiresanarrowrangeofcalculated flow rates. All adsorbents in direct contact with the feed-stock may bind tocells/cell debris, disruptingthe gradient and reducingrecovery.Thisissueisaddressedwithstudies onadsorptionpHtoidentifyconditionswithmaximum prod-uctadsorptionandminimumcelladhesion.67Severalstudies haveshownthe valueofEBA.Itefficientlyremoves precip-itates and captures target proteins from refold pools of E. coli-basedproduction68anditpromotesenhancedrecoveryof HumanEpidermalGrowthFactorfromE.colihomogenateand Pichiapastorisculturemedium.67

Particle-basedresinsrelyonmasstransfermainlythrough diffusion, requiring long times for large biomolecules. On the other hand, the single block monolith column has interconnectedchannelsthattransfermassmainlythrough convection, which allows for high flow velocity. In addi-tion,monolithdoesnothavethepackingstepandtolerates the passage ofair, reducing costs, and time with packing validationandrepacking/replacingsolidphaseduetoair inter-ruption.Othersignificantadvantagesareeasyscale-updueto

Table2–Unitoperationsforcontinuousdownstreamprocess.

Centrifugation Filtration Precipitation/crystallization Chromatography

Split-bowlcentrifuge Singlepasstangentialflow Tubularreactor Expandedbed

Disknozzlecentrifuge Batchtoppedoff Simulatedmovingbed

Membranecascades Annular

Diafiltration

flowindependentofdynamicbindingandcompatibilitywith severalorganic,polymer-based, andinorganicmedia.69 The disadvantageofhigherbufferconsumptioncanbedecreased withtheSMBsetup,whichcanalsobecombinedwithsingle usetechnology.Monolithsarewidelyappliedtotherecovery ofproteinssuchascoagulationfactorIX(ionexchange)70and IgG(affinitychromatography)29fromavarietyofcellculture includingP.pastoris71andE.coli.69

Alternativeseparationtechniques

Withaburgeoningbiotechnologymarket,thereisanongoing searchfornewandimprovedalternativestochromatography inanefforttolowercostsandimproveyields,while maintain-inghighproductpurity.56Severalpromisingalternativeshave beendescribed inliteratureincludingaffinity precipitation, high-performancetangentialflowfiltration,filtration strate-giesbasedonthiophilicandaffinityinteractions,two-phase aqueoussystems,high-gradientmagneticfishing,preparative electrophoresis,andisoelectricfocusing.53,55,56,58

Magneticseparationwithimmunocapturesupportsstands among the techniques used in purification kits, but just recentlyitsapplicationtoindustrialscaleshowedviablepaths. Theinitialhighcostsofthebeadsfromthekitsweresurpassed withnew materialsand broader size dispersion and bind-ingcapacity,withoutdecreasingbatch-to-batchconsistency. Sub-micronsuperparamagneticparticlesofcoatedmagnetite crystalscanbefunctionalizedaccordingtothedesired selec-tivity.Theseparticleshavebeenusedforthepurificationof enzymesandinclusionbodies.29

Filtrationwithion-exchangemembranessubstitutes flow-through chromatography for polishing steps. They remove host-cellproteins,nucleicacids,andviruseswithincreased flow rates, reduce buffer consumption and time, when

compared to traditional polishing. Hydrophobic interac-tion membranes can remove dimers and aggregates from monoclonalantibodyproductionand substitutemore chro-matographysteps.72

Generaltrends

The aim of downstream process should be to deliver the highestyieldofthepurestproductattheshortesttime/cost. However, traditional processes and quality control does not bringthe efficiency neededto keep pace with current upstreamproduction.Toaddresscurrentissues,somegeneral trends emerge asmost relevantincluding singleuse mod-ules, continuous production, process analytical technology, andqualitybydesign.73

Thedisposableunitsarecompatiblewithcontinuousmode and bringfaster routine operationbecause no cleaning or cleaning/validation hastobeperformed.73 Continuous pro-cesses generally result in higher productivity, less buffer consumption, and smaller footprint.A general end-to-end continuous process can beaccomplished byperfusion cell reactors coupled with a continuous capture step, inte-gratedwithsomeofthedownstreamtechnologiesdescribed

in Table 2. A recent and extensive review on continuous

downstreamprocessingofbiopharmaceuticalsdescribesand discusseseachsetupoptionindetail.64

Processconsistencyovertimecanbeassuredwiththeaid ofprocessanalyticaltechnology(PAT)andQualitybyDesign (QbD)conceptsdescribedintheInternationalCouncilfor Har-monisation ofTechnical Requirementsfor Pharmaceuticals for Human Use (ICH) guidelines. QbD preconizes that the productistheprocess.Therefore,itisessentialtoknowthe criticalprocessparametersandlinkthemwithcritical mate-rial attributestopredictand adjusttheirimpacton critical

Table3–Examplesoftherapeuticnativeproteinsobtainedbypurificationfromnaturalsources.

Biopharmaceutical Commercialname Hostorganism Clinicaluse

BotulinumtoxintypeA Botox Clostridiumbotulinum Severalkindsofdystonia;

cosmeticprocedures

BotulinumtoxintypeB Myoblock C.botulinum Severalkindsofdystonia;

cosmeticprocedures

Collagenase Collagenase,santyl Clostridiumhistolyticum Treatmentofthechronic

dermalulcersandburned

areas

l-Asparaginase Elspar E.coli Acutelymphocytic

leukemia(ALL)

PEG-l-asparaginase Oncaspar E.coli Chemicallymodified

asparaginase(PEGylated)to

theALLtreatment

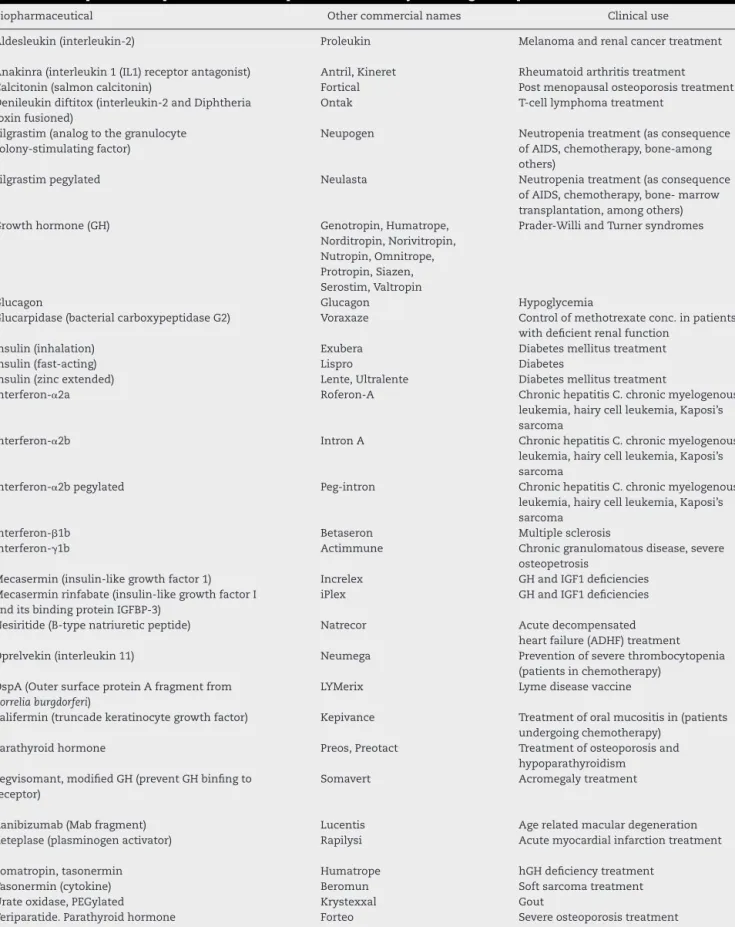

Table4–ExamplesoftherapeuticrecombinantproteinsobtainedbyheterologousexpressioninE.coli.

Biopharmaceutical Othercommercialnames Clinicaluse

Aldesleukin(interleukin-2) Proleukin Melanomaandrenalcancertreatment

Anakinra(interleukin1(IL1)receptorantagonist) Antril,Kineret Rheumatoidarthritistreatment

Calcitonin(salmoncalcitonin) Fortical Postmenopausalosteoporosistreatment

Denileukindiftitox(interleukin-2andDiphtheria

toxinfusioned)

Ontak T-celllymphomatreatment

Filgrastim(analogtothegranulocyte

colony-stimulatingfactor)

Neupogen Neutropeniatreatment(asconsequence

ofAIDS,chemotherapy,bone-among

others)

Filgrastimpegylated Neulasta Neutropeniatreatment(asconsequence

ofAIDS,chemotherapy,bone-marrow

transplantation,amongothers)

Growthhormone(GH) Genotropin,Humatrope,

Norditropin,Norivitropin,

Nutropin,Omnitrope,

Protropin,Siazen,

Serostim,Valtropin

Prader-WilliandTurnersyndromes

Glucagon Glucagon Hypoglycemia

Glucarpidase(bacterialcarboxypeptidaseG2) Voraxaze Controlofmethotrexateconc.inpatients

withdeficientrenalfunction

Insulin(inhalation) Exubera Diabetesmellitustreatment

Insulin(fast-acting) Lispro Diabetes

Insulin(zincextended) Lente,Ultralente Diabetesmellitustreatment

Interferon-␣2a Roferon-A ChronichepatitisC.chronicmyelogenous

leukemia,hairycellleukemia,Kaposi’s

sarcoma

Interferon-␣2b IntronA ChronichepatitisC.chronicmyelogenous

leukemia,hairycellleukemia,Kaposi’s

sarcoma

Interferon-␣2bpegylated Peg-intron ChronichepatitisC.chronicmyelogenous

leukemia,hairycellleukemia,Kaposi’s

sarcoma

Interferon-1b Betaseron Multiplesclerosis

Interferon-␥1b Actimmune Chronicgranulomatousdisease,severe

osteopetrosis

Mecasermin(insulin-likegrowthfactor1) Increlex GHandIGF1deficiencies

Mecaserminrinfabate(insulin-likegrowthfactorI

anditsbindingproteinIGFBP-3)

iPlex GHandIGF1deficiencies

Nesiritide(B-typenatriureticpeptide) Natrecor Acutedecompensated

heartfailure(ADHF)treatment

Oprelvekin(interleukin11) Neumega Preventionofseverethrombocytopenia

(patientsinchemotherapy)

OspA(OutersurfaceproteinAfragmentfrom

Borreliaburgdorferi)

LYMerix Lymediseasevaccine

Palifermin(truncadekeratinocytegrowthfactor) Kepivance Treatmentoforalmucositisin(patients

undergoingchemotherapy)

Parathyroidhormone Preos,Preotact Treatmentofosteoporosisand

hypoparathyroidism

Pegvisomant,modifiedGH(preventGHbinfingto

receptor)

Somavert Acromegalytreatment

Ranibizumab(Mabfragment) Lucentis Agerelatedmaculardegeneration

Reteplase(plasminogenactivator) Rapilysi Acutemyocardialinfarctiontreatment

Somatropin,tasonermin Humatrope hGHdeficiencytreatment

Tasonermin(cytokine) Beromun Softsarcomatreatment

Urateoxidase,PEGylated Krystexxal Gout

Teriparatide.Parathyroidhormone Forteo Severeosteoporosistreatment

qualityattributes ofthe finalproduct. Processes developed underQbDknowledgecontaindesignspacesinsteadof sin-glevalueorextremelynarrowparameters;valuesinsidethe designspaceresultsingoodproductperformanceandbrings the necessary flexibility to continuous processing.74 How-ever, knowledge ofthe process requires process analytical technology(PAT)toolsthatincludeanalyticalchemistryand mathematicalandstatisticalmodeling/analysis.Amongthe options,nearinfraredspectroscopyandprincipalcomponent analysisaretrendingchoicesforanalyticalandmathematical tools,whichcanbeappliedtoseveralsteps.75

Global

consumer

market

of

microbial

biopharmaceuticals

In 1982, human insulin was the first recombinant protein that was FDA approved for use in humans as a biophar-maceuticalproduct.10,39Inthe1980s,thebiopharmaceutical industryexperiencedasignificantgrowthintheproduction andapprovalofrecombinantproteinsincludinginterferons (IFN␣,,and␥)andgrowthhormones.Inthe1990s,thefirst monoclonal antibodies (MAb) and related products experi-encedanextraordinarygrowth,andin2015,theseproducts representedtwo-thirdsoftheproductsapprovedfor commer-cialuse inthe worldaccording to the Biotrack database76 (Fig.4).

Currently,thetotalmarketsalesfrommicrobial recombi-nantproductsreachedapproximately$50billion,representing one-thirdofthetotalsalesofbiopharmaceuticals.Thechoice

30 25 20 15 10 5 0 20052006 2007 T otal n umber of products 2008 2009 2010 2011 2012 2013 2014 2015 Monoclonal antibody related products

Recombinant proteins

Fig.4–Commercialbiopharmaceuticalproductsapproved

from2005to2015.Darkgreenbarsrepresentmonoclonal

antibodyrelatedproductsandnon-relatedtotal

recombinantproteinsarerepresentedinred.Thedataused

concerningthenumberofbiopharmaceuticalapprovalsare

availableatbiopharmabiopharmaceuticalproducts16

(http://www.biopharma.com/approvals).

of microorganism inthe production ofbiopharmaceuticals relieson many factors includinglow costproduction, easy manipulation,andpropagation,andmolecularbiology meth-ods.Someofthemostimportantbiopharmaceuticalsobtained bynaturalsourcesorbyheterologousexpressionareshownin

Tables3–5.

Table5–ExamplesoftherapeuticrecombinantproteinsobtainedbyheterologousexpressioninS.cerevisiae.

Biopharmaceutical Commercialname Clinicaluse

Albumin Recombumin Manufactureofhumantherapeutics

HepatitisBsurface antigen Engerix,Fendrix RecombivaxHB HepatitisBvaccine HepatitisBsurface

antigenandhepatitisAvirusinactibated

Ambirix,Twinrix HepatitisAandBvaccine

Hirudine Refludan,Revasc Anticoagulant

HPVvaccine Gardasil HPVvaccine

HPVsurfaceantigens Silgard HPVvaccine

Glucagonlikepeptide1,Liraglutide Victoza Diabetesmellitustreatment

Insulin Humulin,Novolin,Protaphane,

Mixtard,Insulatard,Actrapid,

Actraphane,

Diabetesmellitustreatment

Insulinaspart;insulinglulisine;insulinlispro

(fast-actinginsulinanalog)

Novolog(aspart),Apidra(glulisine),

Humalog(lispro)

Diabetesmellitus

Insulindetemir(long-actinginsulin) Levemir Diabetesmellitus

Isophaneinsulin(intermediate-actinginsulin) HumulinN Diabetesmellitus

PlateletDerivedGrowthFactor-BB Regranex Treatmentofneuropathic,chronic,

diabeticulcer

Parathyroidhormone Preos,Preotact Treatmentofosteoporosisand

hypoparathyroidism

Rasburicase Ranibizumab,Fasturtec Treatmentofleukemia,lymphomaand

tumorlysissyndrome

Somatropin(GH) Valtropin GHdeficiencytreatment

Sargramostim Leukine Neutropeniatreatment(asconsequence

ofAIDS,chemotherapy,bone-marrow

transplantation,amongothers)

b r a z i l i a n j o u r n a l o f m i c r o b i o l o g y 4 7 S (2 0 1 6) 51–63

Table6–Top-10biopharmaceuticalsbasedonsalesrevenuesin2015.AccordingtoGal77andIgea78.

Rank Product® Producttype Productionsystem Company Use 2015sales(US$

million)

Patentexpiry

U.S.A E.U.

01 Humira(Adalimumab) Anti-TNF␣MAb CHO AbbVie(U.S.) Inflammatory

diseases

14,021 2016 2018

02 Enbrel(Etanercept) Anti-TNF␣MAb CHO Amgen(U.S.)

Pfizer(U.S.) TakedaPharm. (Japan) Inflammatory diseases 9027 2028a 2015

03 Remicade(Infliximab) Anti-TNF␣MAb SP2/0 Johnson&Johnson

(U.S.) Merck(U.S.) MitsubishiT.(Japan) Inflammatory diseases 8957 2018 2014

04 Lantus(Insulinglargine) Insulinanalog E.coli Sanofi(France) Diabetes 7209 2014 2014

05 Avastin(Bevacizumab) Anti-VEGFMAb CHO Roche(Switzerland) Cancer 6905 2019 2022

06 Herceptin(Trastuzumab) Anti-HER2MAb CHO Roche(Switzerland) Cancer 6754 2019 2015

07 Prevnarfamily Polysaccharides

conjugatedto diphtheriaprotein Streptococcus pneumoniaeand Corynebacterium diphtheriae

Pfizer(U.S.) Pneumococcal vaccine

6245 2026 n.a.

08 MabThera/Rituxan (Rituximab)

Anti-CD20MAb CHO Roche(Switzerland) Cancerand

autoimmune diseases

5827 2015 2013

09 Neulasta(PEGfilgrastim) RecombinantG-CSF E.coli Amgen(U.S.)

Cancer-related infections

4715 2015 2017

10 Lucentis(Ranibizumab) Anti-VEGFFAb E.coli Novartis

(Switzerland) Roche(Switzerland)

Macular degeneration

3630 2020 2022

a ThemainpatentonEnbrel(Etanercept)wasoriginallyexpectedtoexpireonOctober2012,butowingtoafilingloophole,Amgensecuredanadditional16-yearperiodofexclusivity.n.a.,datanot

Biopharmaceuticalsarerevolutionaryinthe pharmaceuti-calindustry.Accordingtoglobalrevenues,10biotechnological relatedproductsfiguredamongthetop-25best-sellingdrugs in2015;4ofthemproducedbymicroorganisms77,78(Table6). Thesebiopharmaceuticalsaremarketedbyleading pharma-ceutical companies primarily located in U.S.A, Japan, and Europeandcompriseanarrowscopeoftreatmentprofile,with mostdrugsforthetreatmentandmanagementof inflamma-torydiseases(e.g.rheumatoidarthritis)andcancer.

Patents for cloning and production of several original-generation(branded)biopharmaceuticalshaveexpiredorwill expire within the next years (Table 6). Similar to chemi-caldrugs,oncethepatentofabiologicalproductisexpired the marketing of biosimilars and generics is possible.79 These patent expirations, combined with rising healthcare costs and population aging worldwide are paving the way forthedevelopmentofbiosimilars andbiobetters, opening newcommercialopportunities.80,81Manybiosimilarsare cur-rentlyunderdevelopmentandthesefollow-onproductswill inevitablyplaysubstantialcompetitionandanincreasingrole inhealthcareinupcomingyears.79,82InBrazilthescenariois modest,butconsideringtheglobalpanelandrecent govern-mentincentiveforthenationalbiopharmaceuticalindustry development,weexpecttoseemorepatentsinthenearfuture andalsonovelopportunitiesforbiosimilarsandbiobetters.

Conclusion

and

future

trends

Newtechnologicaladvancementsare continuouslymadeto improvethediscovery,rationalmodification,production,and purification ofbiopharmaceuticals. Innovative strategies to identifydifferentspeciesofmicroorganismsfromthe Brazil-ianbiodiversitymustbeinvestigatedtargetingthediscovery ofalternativehostsforheterologousexpression.

Conflict

of

interest

Theauthorsdeclarenoconflictsofinterest.

r

e

f

e

r

e

n

c

e

s

1.Valderrama-RinconJD,FisherAC,MerrittJH,etal.An

engineeredeukaryoticproteinglycosylationpathwayin

Escherichiacoli.NatChemBiol.2012;8(5):434–436.

2.RodríguezV,AsenjoJA,AndrewsBA.Designand

implementationofahighyieldproductionsystemfor

recombinantexpressionofpeptides.MicrobCellFact.

2014;13:1–10.

3.SekhonBS.Biopharmaceuticals:anoverview.ThaiJPharm

Sci.2010;34:1–19.

4.TuftsCenterfortheStudyofDrugDevelopment.TuftsCSDD assessmentofcosttodevelopandwinmarketingapproval foranewdrugnowpublished.Availablefrom:

http://csdd.tufts.edu/news/completestory/tuftscsddrd

cost studynowpublished[Accessed12.07.16].

5.CrommelinDJ,StormG,VerrijkR,DeLeedeL,JiskootW,

HenninkWE.Shiftingparadigms:biopharmaceuticalsversus

lowmolecularweightdrugs.IntJPharm.2003;266(1–2):3–16.

6.CoxDBT,PlattRJ,ZhangF.Therapeuticgenomeediting:

prospectsandchallenges.NatMed.2015;21(2):121–131.

7.ChenHL,ChangJK,TangRB.Currentrecommendationsfor

theJapaneseencephalitisvaccine.JChinMedAssoc.

2015;78(5):271–275.

8.DengY,WangCC,ChoyKW,etal.Therapeuticpotentialsof

genesilencingbyRNAinterference:principles,challenges,

andnewstrategies.Gene.2014;538(2):217–227.

9.WittrupA,LiebermanJ.Knockingdowndisease:aprogress

reportonsiRNAtherapeutics.NatRevGenet.

2015;16(9):543–552.

10.LeaderB,BacaQJ,GolanDE.Proteintherapeutics:a

summaryandpharmacologicalclassification.NatRevDrug

Discov.2008;7(1):21–39.

11.ZawairaA,PooranA,BarichievyS,ChoperaD.Adiscussion

ofmolecularbiologymethodsforproteinengineering.Mol

Biotechnol.2012;51(1):67–102.

12.BeckA,Biosimilar.Biobetterandnextgenerationtherapeutic

antibodies.MAbs.2011;3(2):107–110.

13.StrohlWR.Fusionproteinsforhalf-lifeextensionof

biologicsasastrategytomakebiobetters.BioDrugs.

2015;29(4):215–239.

14.SandeepV,ParveenJ,ChauhanP.Biobetters:thebetter

biologicsandtheirregulatoryoverview.IntJDrugRegulAff.

2016;4(1):13–20.

15.MitragotriS,BurkePA,LangerR.Overcomingthechallenges

inadministeringbiopharmaceuticals:formulationand

deliverystrategies.NatRevDrugDiscov.2014;13(9):

655–672.

16.BIOPHARMA:BiopharmaceuticalProductsintheU.S.and EuropeanMarkets.ThisisalistofnewfullFDAapprovalsfor biopharmaceuticalproducts(unlessotherwisenoted). Availablefrom:http://www.biopharma.com/approvals.html

[Accessed12.07.16].

17.MullardA.EMAgreenlightssecondgenetherapy.NatRev

DrugDiscov.2016;15(5):299.

18.CarrDR,BradshawSE.Genetherapies:thechallengeof

super-high-costtreatmentsandhowtopayforthem.Regen

Med.2016;11(4):381–393.

19.CarterPJ.Introductiontocurrentandfutureprotein

therapeutics:aproteinengineeringperspective.ExpCellRes.

2011;317(9):1261–1269.

20.CourtoisF,SchneiderCP,AgrawalNJ,TroutBL.Rational

designofbiobetterswithenhancedstability.JPharmSci.

2015;104(8):2433–2440.

21.ChirinoAJ,AryML,MarshallS.Minimizingthe

immunogenicityofproteintherapeutics.DrugDiscovToday.

2004;9(2):82–90.

22.WhitfordD.Thethree-dimensionalstructureofprotein.In:

Proteins:StructureandFunction.1sted.WestSussex,England:

JohnWiley&Sons;2005:39–83.

23.CourtoisF,AgrawalNJ,LauerTM,TroutBL.Rationaldesignof

therapeuticmAbsagainstaggregationthroughprotein

engineeringandincorporationofglycosylationmotifs

appliedtobevacizumab.MAbs.2016;8(1):99–112.

24.HuangM,ShaoY,HouJ,etal.Structuralasymmetryof

phosphodiesterase-9aandauniquepocketforselective

bindingofapotentenantiomericinhibitor.MolPharmacol.

2015;88(5):836–845.

25.AprileFA,SormanniP,VendruscoloM.Arationaldesign

strategyfortheselectiveactivityenhancementofa

molecularchaperonetowardatargetsubstrate.Biochemistry.

2015;54(32):5103–5112.

26.CarterP.Site-directedmutagenesis.BiochemJ.1986;237:1–7.

27.HsiehP,VaisvilaR.Proteinengineering:singleormultiple

site-directedmutagenesis.MethodsMolBiol.

2013;978:173–186.

28.KowalskyCA,FaberMS,NathA,etal.Rapidfine

conformationalepitopemappingusingcomprehensive

mutagenesisanddeepsequencing.JBiolChem.

29.GronemeyerP,DitzR,StrubeJ.Trendsinupstreamand

downstreamprocessdevelopmentforantibody

manufacturing.Bioengineering.2014;1(4):188–212.

30.SchmidellW,LimaUdeA,AquaroneE,BorzaniW.

BiotecnologiaIndustrial.v.2.1aed.EngenhariaBioquímicaSão

Paulo,Brasil:Blucher;2001.

31.ParkWH,AtkinsonJP.Therelationofthetoxicityof

diphtheriatoxintoitsneutralizingvalueuponantitoxinat

differentstagesinthegrowthofculture.JExpMed.

1898;3(4–5):513–532.

32.BaxterAG.Theoriginandapplicationofexperimental

autoimmuneencephalomyelitis.NatRevImmunol.

2007;7(11):904–912.

33.IgeaJM.Thehistoryoftheideaofallergy.Allergy.

2013;68(8):966–973.

34.GrafCJ,WoodworthJR,SegerME,HolcombeJH,BowsherRR,

LynchR.Pharmacokineticandglucodynamiccomparisonsof

recombinantandanimal-sourceglucagonafterIV,IM,and

SCinjectioninhealthyvolunteers.JPharmSci.

1999;88(10):991–995.

35.LopesAM,Oliveira-NascimentoL,RibeiroA,etal.

Therapeuticl-asparaginase:upstream,downstreamand

beyond.CritRevBiotechnol.2015;23:1–18[Epubaheadofprint].

36.SyedYY,McCormackPL.Exenatideextended-release:an

updatedreviewofitsuseintype2diabetesmellitus.Drugs.

2015;75(10):1141–1152.

37.Powell-JacksonJ,WellerRO,KennedyP,PreeceMA,

WhitcombeEM,Newsom-DavisJ.Creutzfeldt-Jakobdisease

afteradministrationofhumangrowthhormone.Lancet

(London,England).1985;2(8449):244–246.

38.DemainAL,VaishnavP.Productionofrecombinantproteins

bymicrobesandhigherorganisms.BiotechnolAdv.

2009;27(3):297–306.

39.RosenfeldL.Insulin:discoveryandcontroversy.ClinChem.

2002;48(12):2270–2288.

40.LimJC,ChoiH-I,ParkYS,etal.Irreversibleoxidationofthe

active-sitecysteineofperoxiredoxintocysteinesulfonicacid

forenhancedmolecularchaperoneactivity.JBiolChem.

2008;283(43):28873–28880.

41.ZhaoK,PingW,LiQ,etal.Aspergillusnigervar.taxi,anew

speciesvariantoftaxol-producingfungusisolatedfrom

TaxuscuspidatainChina.JApplMicrobiol.

2009;107(4):1202–1207.

42.O’ConnellS,WalshG.Applicationrelevantstudiesoffungal

beta-galactosidaseswithpotentialapplicationinthe

alleviationoflactoseintolerance.ApplBiochemBiotechnol.

2008;149(2):129–138.

43.OliveiraC,GuimarãesPMR,DominguesL.Recombinant

microbialsystemsforimproved-galactosidaseproduction

andbiotechnologicalapplications.BiotechnolAdv.

2011;29(6):600–609.

44.Ruiz-MatuteAI,Corzo-MartínezM,MontillaA,OlanoA,

CopoviP,CorzoN.Presenceofmono-,di-and

galactooligosaccharidesincommerciallactose-freeUHT

dairyproducts.JFoodComposAnal.2012;28(2):164–169.

45.ZabianBassettoR,RodriguesMCC,AlmeidaMM,de

ChiquettoNC.Caracterizac¸ãodaproduc¸ãode

galactooligossacarideosporfermentac¸ãosequencial.

EvidênciaCiênciaeBiotecnogia.2014;14:57–68.

46.LiC-W,SongR-Q,YangL-B,DengX.Isolation,purification,

andstructuralidentificationofanantifungalcompound

fromatrichodermastrain.JMicrobiolBiotechnol.

2015;25(8):1257–1264.

47.SvahnKS,ChryssanthouE,OlsenB,BohlinL,GöranssonU.

PenicilliumnalgiovenseLaxaisolatedfromAntarcticaisanew

sourceoftheantifungalmetaboliteamphotericinB.Fungal

BiolBiotechnol.2015;2(1):2–8.

48.WatanabeK.Collagenolyticproteasesfrombacteria.Appl

MicrobiolBiotechnol.2004;63(5):520–526.

49.KumarCG,TakagiH.Microbialalkalineproteases:froma

bioindustrialviewpoint.BiotechnolAdv.1999;17(7):561–594.

50.CarrezD,JanssensW,DegraveP,etal.Heterologousgene

expressionbyfilamentousfungi:secretionofhuman

interleukin-6byAspergillusnidulans.Gene.1990;94(2):

147–154.

51.YadwadVB,WilsonS,WardOP.Effectofcultureconditions

andinductionstrategiesonproductionofhuman

interleukin-6byarecombinantAspergillusnidulansstrain.

MycolRes.1996;100(3):356–360.

52.MarasM,vanDieI,ContrerasR,vandenHondelCA.

Filamentousfungiasproductionorganismsforglycoproteins

ofbio-medicalinterest.GlycoconjJ.1999;16(2):99–107.

53.AzevedoAM,RosaPAJ,FerreiraIF,Aires-BarrosMR.

Chromatography-freerecoveryofbiopharmaceuticals

throughaqueoustwo-phaseprocessing.TrendsBiotechnol.

2009;27(4):240–247.

54.RathoreAS,KapoorG.Applicationofprocessanalytical

technologyfordownstreampurificationofbiotherapeutics.J

ChemTechnolBiotechnol.2015;90(2):228–236.

55.RosaPAJ,FerreiraIF,AzevedoAM,Aires-BarrosMR.Aqueous

two-phasesystems:aviableplatforminthemanufacturing

ofbiopharmaceuticals.JChromatogrA.

2010;1217(16):2296–2305.

56.FieldsC,LiP,O’MahonyJJ,LeeGU.Advancesinaffinity

ligand-functionalizednanomaterialsforbiomagnetic

separation.BiotechnolBioeng.2016;113(1):11–25.

57.WeinackerD,RabertC,ZepedaAB,FigueroaCA,PessoaA,

FaríasJG.ApplicationsofrecombinantPichiapastorisinthe

healthcareindustry.BrazJMicrobiol.2013;44(4):1043–1048.

58.RoqueACA,LoweCR,TaipaMA.Antibodiesandgenetically

engineeredrelatedmolecules:productionandpurification.

BiotechnolProg.2004;20(3):639–654.

59.FariaRPV,RodriguesAE.Instrumentalaspectsofsimulated

movingbedchromatography.JChromatogrA.

2015;1421:82–102.

60.SaraswatM,MusanteL,RavidáA,ShorttB,ByrneB,

HolthoferH.Preparativepurificationofrecombinant

proteins:currentstatusandfuturetrends.BiomedResInt.

2013;2013:1–18.

61.LoweCR.Combinatorialapproachestoaffinity

chromatography.CurrOpinChemBiol.2001;5(3):248–256.

62.LoweCR,LoweAR,GuptaG.Newdevelopmentsinaffinity

chromatographywithpotentialapplicationinthe

productionofbiopharmaceuticals.JBiochemBiophysMethods.

2001;49(1–3):561–574.

63.WarikooV,GodawatR,BrowerK,etal.Integratedcontinuous

productionofrecombinanttherapeuticproteins.Biotechnol

Bioeng.2012;109(12):3018–3029.

64.JungbauerA.Continuousdownstreamprocessingof

biopharmaceuticals.TrendsBiotechnol.2013;31(8):479–492.

65.FreydellEJ,BulsinkY,vanHaterenS,vanderWielenL,

EppinkM,OttensM.Size-exclusionsimulatedmovingbed

chromatographicproteinrefolding.ChemEngSci.

2010;65(16):4701–4713.

66.CramerSM,HolsteinMA.Downstreambioprocessing:recent

advancesandfuturepromise.CurrOpinChemEng.

2011;1(1):27–37.

67.RostiIA,RamananRN,TanJS,LingTC,AriffAB.Recoveryof

microquantitiesofhumanepidermalgrowthfactorfrom

EscherichiacoliHomogenateandPichiapastorisculture

mediumusingexpandedbedadsorption.SepSciTechnol.

2014;49(5):702–708.

68.XuX,HirparaJ,EptingK,etal.Clarificationandcaptureof

high-concentrationrefoldpoolsforE.coli-basedtherapeutics

usingexpandedbedadsorptionchromatography.Biotechnol

Prog.2014;30(1):113–123.

69.RajamanickamV,HerwigC,SpadiutO.Monolithsin

70.RibeiroDA,PassosDF,FerrazHC,CastilhoLR.

Anion-exchangepurificationofrecombinantfactorIXfrom

cellculturesupernatantusingdifferentchromatography

supports.JChromatogrBAnalTechnolBiomedLifeSci.

2013;938:111–118.

71.KrainerFW,PletzenauerR,RossettiL,HerwigC,GliederA,

SpadiutO.Purificationandbasicbiochemical

characterizationof19recombinantplantperoxidase

isoenzymesproducedinPichiapastoris.ProteinExprPurif.

2014;95:104–112.

72.LiF,LeeB,ZhoJX,TresselT,YangX.Currenttherapeutic

antibodyproductionandprocessoptimization.BioProccessing

J.2006;5:16–25.

73.GottschalkU.Thefutureofdownstreamprocessing.

BioPharmInt.2011;24(9):38–47.

74.YuLX,AmidonG,KhanMA,etal.Understanding

pharmaceuticalqualitybydesign.AAPSJ.2014;16(4):771–783.

75.GlasseyJ,GernaeyKV,ClemensC,etal.Processanalytical

technology(PAT)forbiopharmaceuticals.BiotechnolJ.

2011;6(4):369–377.

76.bioTRAKdatabase.Availablefrom:http://bptc.com[Accessed 14.07.16].

77.GalR.Biosimilars:ReviewingUSlawandUS/EUpatents; bottomupmodelsuggests12productsand$7-$8Bmarketby 2020.BernsteinResearch.Availablefrom:http://www. gabionline.net/layout/set/print/content/view/full/2030

[Accessed06.10.16].

78.DezzaniL.Top25PharmaceuticalProductsin2015.Available from:

https://igeahub.com/2016/04/30/top-25-pharmaceutical-products-in-2015/[Accessed11.10.16].

79.PolimeniG,TrifiròG,IngrasciottaY,CaputiAP.The

adventofbiosimilarsforthetreatmentofdiabetes:current

statusandfuturedirections.ActaDiabetol.2015;52(3):

423–431.

80.KresseG-B.Biosimilars–science,status,andstrategic

perspective.EurJPharmBiopharmOffJArbeitsgemeinschaftfür

PharmVerfahrenstechnikeV.2009;72(3):479–486.

81.HuaS,OhMJ,OzcanS,SeoYS,GrimmR,AnHJ.

Technologiesforglycomiccharacterizationof

biopharmaceuticalerythropoietins.TrACTrendsAnalChem.

2015;68:18–27.

82.DörnerT,KayJ.Biosimilarsinrheumatology:current

perspectivesandlessonslearnt.NatRevRheumatol.