PROCEEDINGS OF THE 111 INTERNATIONAL CONFERENCE ON BIODENTAL ENGINEERING, PORTO, PORTUGAL, 22-23 JUNE 2014

Biodental Engineering 111

Editors

R.M. Natal Jorge

Faculdade de Engenharia da Universidade do Porto, Porto, Portugal

IC. Reis Campos

Faculdade de Medicina Denteria da Universidade do Porto, Porto, Portugal

Mário A.P. Vaz

Faculdade de Engenharia da Universidade do Porto, Porto, Portugal

Sónia M. Santos

MedSupport-Engenl/Oria e Apoio à Decisão, Lda, Portugal

João Manuel R.S. Tavares

Faculdade de Engenl/Oria da Universidade do Porto, Porto, Portugal

~CRC

Press

~

Taylor&.FranclsGroupBoca Ralon London New York Leiden

CRC Press 1s <In imprint of lhe

Taylor fi Frands Croup, an Infonna busine.ss

CRC Press/Balkema is ali imprill[ o[ lhe Taylor & Frallcis Group, ali i1l/orma bus;lless

I!:> 2014 Taylor & Francis Group, London , UK

Typeset by V Publishing Solutions Pvt Ltd., Chennai, India

Printed and bound in Great Britain by CPI Group (UK) Ltd , Croydon, CRO 4YY

Ali rights reserved . Na pau of tbis publicatian ar lhe infarmatian contained hcrein may be reproduced, stored in a retrieval systcm, or transmittcd in any form or by any means, elcctronic, mechanical, by pho-locopying, recording ar atherwise, withoUl written prior pcrmission fram the publisher.

Although ali care is taken to ensure integrity and the quality of tbi s publication and the information herein, no rcspansibility is assumcd by the publishers nor lhe author for any damage to the propcrty ar persons as a result of aperation ar use af this publication and/ar the infarmalion contained herein.

Published by: CRC PressIBalkema

P.O. Box 11320,2301 EH Leiden, The Nethcrlands e-mail: Pub.NL@taylorandfrancis.com

ww\V.crcprcss.com - w\V\V.taylorandfrancis.com

Biodental Engineering 111-Natal Jorge et ai. (Eds)

© 2014 Taylor & Francis Group, London, ISBN 978-1-138-02671-1

Table of contents

Acknowlcdgcmcnts

Prcfacc

Thematic scssions

Scientific committee

COlltriblited papers

ix xi xiii

xv

A variable finitc clemcnt medel of lbe human rnastic3tory sys lcm 3

S. Marfille:. J. LCII:, K. Sclllrei:erllOf & H.1 Sc/tilldle,.

OccJusal splint vs. anterior dcprogrammer in bruxism thcrapy- is surface eleclromyography

a valid tool? 9

B. Dalell'ski & B. Frqc=ak

Fraclure loughncss in interface sys tcrns Ni-Cr/ccramic, alumina/ceramic and

zirconia/ceramic 15

CP.s. Porto, Ai Pareme, R.M.N Jorge, L. C. Pereira & S. Gri:a

The use af GBR in bone rcgcncration: An histologic sludy in the rabbit mode! 21

I Guerra, M.H. Figl/eira/, J. C.R. Campos. F. Branco, M. Vascollcelos, A. Afonso & RZ, Gomes

EIfcet af repcalcd tightcning and loosening cyclcs of prosthctic scrcws in the

micromovcrncnts of lhe abutrnent-irnplant assembly: A pilot study 27

A. JvlessiaJ~ S. Rocha, N Calha, P. Nicolal/, F. Gl/erra & M.A. Nelo

Strcss analysis cf human pcriodontal1igament: Irnplications for its darnage 33

A.P. deI Palomar, U Salllalla-Mora, J. Ceg01iillo. U Salltolla-PCIlill, A. Calvo-Echelli,,"e & M.l Mora

Paramctric cvaluation of cortica! bone thickness behavior on stress/strain

of a dental implant 39

J.P. de Oliveira Freitas. , ~ Bianco. J.H. Rubo, P.J.P. GOllrah'es & E.A. C. Sousa

3D Finitc Elcmcnt biamechanical model af the mandiblc-mucasu -cxpander

apparalus se t 43

1 Braga, D. Rocha, R. Utsch, E. L. Casas. R Andrade, R. Braga, RM.N. Jorge & PA.L.S. Marlills

Computcr-aidcd design and manufacturing of dental implants with irregular geornetries 51

J. Chell, X Chell, X Zhallg, O. Eicl'Sliidl. R. DII, F. Dellg & Z. Zlwllg

Automntic reconstruction of dental CT images using optimization 57

P.H.J. .41110,.;m, T.F. de Moraes, J. J( L. da Si/m, H. Ped,.ini & R.B. Ruben

Overbleaching efTccts on mineral content and roughness af human enamel 63

M.S.F. de Mirallda, R.S. Salllos. M.J. dos Alljos, E.M. da Si/ra & CR Pere=

The assessment of the generated temperature by lhe drill bit in lhe bone tissue 67

C.T Sampaio, E./vI. Fonseca, J.E. Ribeiro & R Cel'qlleira

The CAD lechnology in removablc proslhodontics 73

M.A. Sampaio-Fernandes. M. Sampaio-Fernandes. P. Fomeca.

P.R. Almeida & A1.H. Figl/eira!

ClinicaI trial- ill vivo cndosseous implants rnicrornovcmcnts rncasuring with 3D

DigitaJ Image Correlatíon method 77

T. Rodrigues, F. Aloreira, F. Guerra, P. Nico/all & AI.A. Neto

Simulation af remodeling af ti ssue engineered condylar cartilage under slaLic

hydrostatic pressure 83

C. Bal/deiras, A. Completo & A. Ramos

Cyclic fatigue resistance of /ive rotary endodollLic in struments 89

B. Chol'cli-Dia:, L. Fome1; C Llello, R. Nladureira & F. Tadeu

A biomechanical analysis af a maxillary overdcnture rctained by divergent

ímpIant attacbments 93

A .. Mi/el; A. Correia, IN! Rocha, J C.R. Campos, N r( Ramos & Nf.A. Va:

EITects Df micromovement 00 lhe strain distribution of ao implant supported zirconia

denlal bridge Slructurc during loading: A 3D digilal image corrclation and 3D finite

element ana1ysis 97

N Calha, T. Rodrigues, A. Messias, L. Roseira, P. Nicolau & M.A. Nelo

Compara tive analysis of mandibular symphysis plates 103

1 C Dinis, D. T. Kemmokll, P. Y. Noritomi, 1 J( L. Silva & RB. Ruben

Elfect of hydrogen peroxide on lhe inorganic composition of enarneI 107

RAI. Moreira,

F.s.

Cala:alls, A.C. Lomosa, R.S. Sa1l10s. Ar!.l dos Anjos, 1 T. de Assis & M. S. NfirandaIntegration of irnage processing and 3D techniques to sirnulatc aesthetic

denlallreatmcnlS 113

R. Pulido, 11 Jiméne: & A. Rodrígue:

Al1alysis of autoclave induced dimensional changes on addition silicones 119

lvi. Só,

o.

Lino, P.R . .Almeida, C. Leal, lCR Campos&l Sampaio-FernandesRclationship belIVeen implanl primary slability (lorque and ISQ) and bone densily

assesscd by CBCT -c1inicallrial 125

R.Z. Gomes, L.L. da Si/l'a, 1 Coimbra, I. Guerra. NI. Vasconcelos, A. Correia & A. C Braga

Fraclurc resistance of single-loolh implanl-supporled 131

PA.G. Piloto &JF Piloto

An electromagnetic tracker system for the design of a dental superstructure 137

A.H.l Moreira, S. Queirós, NF. Rodrigues, A. CM Pinho, 1 C. Fonseca & lL Vi/aço

Optirnization of a perfusion bioreactor for tissue engineering 145

D. Freitas, H. A. Almeida & P. Bártolo

Reinforccd PCL scalTolds IVith Eggshcll powdcr 151

S.l Biscaia, T.F. Viana, H.A. Almeida & P. BárlOlo

Optimizing regions for characterization of thermal imagcs in medicai applications 155

A. Duarle, L. Carrão, A1. Espanha, T.F. ViafUl, D. Freitas, P. Bárt%, P. Faria & H.A. Almeida

Mcchanical behavior of denturcs c1asps in acelal resin and cobalt-chrornium:

A numerical analysis 161

A.R.D. Lopes, A. Correia, lC.R. Campos, N J( Ramos & A1.A. Va:

Gingiva Assessmen t Tool-a clinicai decision support system to evaluate the csthetic risk

for gingiva-shade ceramics in a fixed dental prosthesis 169

P. C Vialla, A. Correia, I Lopes, Z. Kovacs & L. Eustáquio

Geometric and structural comparison of anatomic moC:els 173

R Zeibak, D. Freilas, NA. Almeida & P. Bárt%

vi

..

Finitc elemen t ana1ysis of bio-inert mass efTect on stress rcductian in bone-dental

implant interface 179

G Me/uli. A. Bc/arbi. B. Nftmsouri &

z.

A:ariIdeal spacing according to dilTerent types of cement- Everest system (KaVo®) 185

P. Rocha-Almeida. P. Cal/iço, C. Leal, 1 Reis-Campos & 1. Sampaio-Fernandes

Time dcpendenl canstitutive model for a biopalymer dc rivcd from castor oi! palyurethanc 191

A. C Vieira. J< Tita. R. R. C. da Costa & R 1\1. Guedes

lU gene c1uster polymorphisrns and peri-implant disease 197

M Sampaio-Fernandes. P. TIa:, P. Fonseca, J. Reis-Campos & M H. Figueiral

Quality evaluatian af websites with infarmatian an child dental trauma in Portuguese language 201

A1. Cre,lpo, J. Carvalho, A. Correia & P. Mesquita

Numerical ana1ysis af a tccth rcstaratian: A meshless mcthod approach 207

CS.S. Tavares, J. Belillila, L.M.J.S Dillis & R.M.N. Jorge

The bone tissue rcrnodclling analysis in dcntistry using a meshlcss me th od 213

J. Be/ill/w, L.M.J.S Dillis & R. M.N. Jorge

Dcntallissue c1assificatian using computati onal intelligence and digital irnage analysis 221

G Vaccaro & J.I Pelae:

InOucnce of composite temperature on the marginal seal in dental res torations 227

SA. Bale, J.M. 041'1'0.1'0, J.M. Osaria, P.C Labala& M.CM. Céspedes

Raman Conrocal Microscopy to sludy aeslhelie rcsloralivc matcrials 231

S A. Bale, J. M. A r,ayo, J. M. Osaria, P. C Labala & AI. C M. Céspedes

Biomcchanical nnalysis of typicnl slruclurcd dental implants and surrounding bane tissues 235

X

Z/WI/g,X

eilel/, G. Zilal/g & J. eilellCharacterization of trabecular bane morphalogy by iso lalion and canstruction of cubic

models using computcrized microtomography 241

P. Carval/w-Lobato. G. Val/eJpí-l\.1iró, V. Tal/ón- Waltoll. AI, C. Al(lIl:allares-CéJpedes,

I. Valdivia-G(1I1dlll; S, Arro)'o-Bote, 1 Martine:-Arro)'o. J. !v!art Íne:-Osorio &

Nf. Herrera-Lal'O

Optimizatian of the procedure for obtaining DPSCs by meaos of rragilc fracture

in clean roam conditions 249

C. Pagal/elli. A, L(lIIfrwu:hi, F. PorIa, I Valdivia-Gandlll; S. Arro)'o-Bote,

J. N!artÍne:-Arl'Oyo, J. AlartÍne:-Osorio, P. Ca/'l'Olho-Lobato, J-: T allÓIl~J · Val loll &

Nf. C. Mall:(lIlal. es ~ Céspe d es

Evaluation of collagen fibers orienlation around difTcrcnt conneerion implants 253

M.A.R. Aral/ja, D.SM. Caslro, GM.P. JI/al/ila, M.A.P.P.N. Oliveira, CA.M. Bel/!alli, R.S Magil/i, A. Piallelli & C RP. A rllllja

EVaJuulion of the bone forrnation on titanium implants elect rically st imul ated:

Study in dogs 259

L.M. Bil/s-E/)', E.B. Cordera, CA. M. Beufalli & R.S Magil/i

Thcrmal residual slrcsses in functionally graded denlal restorations 263

B. Henl'íqucs, R. AI. Nascimento, G A-fir011da, F. Silva & J. C Ai SOIl:a

Study of the parcelain powdcr injection parameters for the production of zirconia

rcinfarced parcelain composites 267

RL. P. SO/lfOJ~ B, Hell/'üjues, R,!vI. Nascimento. F. J< Motta. F. Silva & J. C ,AI!, Sou:lI

A finite clemen t study of the Quad-helix appliance dcrorrn ation whcn submittcd

to a force 271

A.P. BailO, M.A. Va: & J.M. Uflr,II

Evaluation of orlhodontic forces applied by the Quad-hclix apparatus 275

A.P. BailO, AI. A. Va: & J. M. US I,ell

Degradation modelling of bio-polyrners used as denlal seaffolds J Ta/'/'Ío-Saavedra, S. Naya, J Lópe;:;-Becei/'o, S. Zarago:a, A. A/Jlare:,

S. Quilltalla-Pita & F.I García-Sabáll

Prclimino.ry inertiaJ study af body postures during dental procedures

J-:

Sil~'a, J. Reis-Campos, M.H. Figueira', P. Fonseca, M.E. Pinho & .M.A. Va.:All-eeramie CAD-CAM Maryland bridge- a numerieal slress analysis

l Lopes, A . Correia, P.C Viana, Z. KOl'acs, N. Viria/o. leR. Campos & II1.A. Va:

Evaluation af lhe cITects produced by difTerenl in sertion torques ou lhe internaI surface

af lhe neck af differcnt implants systems

AI. Ferreira, /I1.M. Pinho, lv/o C. Manso, RF. Almeida. 1)1.A. Va: & P. !llesquila

Author indcx

viii

281

287

291

295

Preface

Biodental Engineering 111-Natal Jorge et ai. (Eds)

© 2014 Taylor & Francis Group, London, ISBN 978-1-138-02671-1

Dcntistry is a branch af rncdicine with peculiarities and diverse arcas af aClion, being commonly

consid-crcd as a vcry inlcrdisciplinary area. The developmcnt , validution and clinicai use af more competcntly

techniqucs and tcchnologies have beco af great dcmand and intcrcSL

The purposc af lhese BIODENTAL Conferences 00 Biodcntal Engincering, initiated in 2009, is to

solidify knowlcdgc in the field cf bioengineering applied lO dcntistry promoting a comprehcnsive [orum

for discussion 00 lhe receot advances in lhe related fields in arder to identify potential collaboration

betwecn rcscarchcrs and enct-users [rem different sciences.

This book contuios lhe [uH papers presenled at Lhe 3rd Intcrnational Conference on Biodental Engi-neering (BIODENTAL 20 14), \Vhich \Vas held in Póvoa do Varzim, Porto, Portugal, in June 22- 23 . The

conference had 2 Invited Leclures, and 72 contributed presentations, which \Vere sclected by lhe

con-ference scienlific committec. and originaled from 14 counlries: Belgium, Brazil, China, Chile, Ecuador,

Fronce, Gcrmany, Grccce, Haly, Poland, Portugal, Romania, Spain and lhe United Stales of America,

During BIODENTAL 2014, severaltopics and applications \Vere addressed, induding biomechanical disorders. orthodon tics, implantology, aesthetics, dental rnedicine, medicaI devices and medicai imaging,

The conference co-chairs \Vould like to take this opportunity to express their grotitude to the

confer-ence sponsors, ali mcmbers of lhe conference scientific commiltee, invited lecturers, scssion-chairs and to

ali authors for submitting and sharing their knowledge,

xi

R.M. Natal Jorge IC. Reis Campos Mário A.P. Vaz Sónia M. Santos João Manuel R.S, Tavares

-Biodenlal Engineering 111- Natal Jorge el ai. (Eds)

© 2014 Taylor & Francis Group, London, ISBN 978-1-138-02671- 1

Thematic sessions

Under the auspicious af Bi odenta120 14, two Thcmatic Sessions \Vere organizcd:

Bone tissue rcmodelling nurncrical analysis

Jorge Betinha, IIlSlill/lO de Engenharia kJecâ1lica, Pólo FEUP, Porlllgal

Anlónio Completo, Departamento de ElIgenharia J\1ecânica, Universidade de Aveil'o, Porlllgaf

Biomaterials in oral rehabilitation

Ricardo de Souza Magini, Universidade Federal de Soma Catarina, Bra=i!

Julio Souza, Unil'cl'sidacle Federal de Santa CararinG, Bra::ilI Universidade do NfillllO, Portllgal

Ccsar Benfatti, Universidade Federal de Soma Catarina, Bra:iI

Claudia Volpato, Universidade Federal de Santa Catarina, Bl'a:il

Mareio Frcdcl, Unive/'sh/ade Federal de Sa1lta Catm'illa, Bra=iI

Filipe Silva, UlliJ!el'sidade do MbJ!IO, Portugal

Bruno Hcnriqucs, Ullillershlade do MillllO, Portugal

Mihaela Buciumcanu, Unil'ersidade do 1\1illllO, Portugal

..

Scientific committee

Biodental Engineering 111 - Natal Jorge et ai. (Eds)

© 2014 Taylor & Francis Group, London, ISBN 978-1-138-02671-1

AlI works submittcd to BlODENTAL 2014 were cvaluated by an lntcrnational Scientific CommiUec

composed by 55 cxpcrt rcscarchers from rccognizcd institutions:

• Aronso Pinhão Ferreira, Ulliversily of Porto, Portllgal

• André Correia, Universil.l' of Porto, Portllga/

• Antônio Completo, UnivcrsilY o[ AI'eiro. Portugal

• Carla Roque. IDMEC, PO/'lllgal

• Christopjh Bourauel, BOIIII UlJjversi l. l~ GermalJy

• Cláudia Barros Machado, CESPU. POl'tllgal

• Cometia Kober. Hamburg Unil'crsity of Applied Sciences, Gel'mall)'

• Daniela lacoviello, Sapien:a Universily of Rome. !taly

• Edson Capello. UNESP. Ora=i/

• Eduardo Borges Pires. Ulliversil)' Df Lisboll, Porlllgal

• Eduardo Pires, CalhoUe Univcrsily of Portllgal, Porll/gal

• Elza Maria Morais Fonseca, PolJ'teclmical Insliwle of Bragança, Portugal

• ESlevam Las Casas, Federal Unh1ersily of Afinas Gerais, Bradl

• Fernanda Gentil, IDfl.!/EC, Po/rleclmical IlIstitutc of Porto, POrIlIgal

• Gerhard A. Holzapfel, Gra= UI/il'crsit)' Df TeclmologJ ~ AUSlria

• Helena Figueiral, Unil'crsil.1' Df PorIa, Portugal

• Henrique Almeida, PolJ'tecll1lical Instillltc Df Leiria, Portugal

• Hemani Reis Lopes, Polylcclmical Instilule of Porlo, Porlllgal

• Ioannis Misirlis, Univcrsi/y Df Potras, Grcece

• Iracema Braga, Bra=i1

• João Batista Novaes Júnior. Federal Unil'ersit)' Df Afinas Gerais, Bradl

• João Carlos Pinho, Ullil'l!rsity Df Porto, Portugal

• João Eduardo

P.c.

Ribeiro, Polyteclmical II/stitllfc of Bragan,:a, Portugal• João Manuel R.S. Tavares, Ullil1crsit.1' Df Porto, PO/'lllglll

• João Paulo Flores Fernandes, UllÊ\'crsit)' of Minho, Por/ligaI

• Joaquim Gabriel, Universidade do Porto, Portugal

• Jolm Middleton, Cardiff UlIivCl'sit)', UK

• Jorge Belinha, IDMEC, PO/'/lIgal

• Jorge Marinho, IPO, Por/ligai

• Jose Mário Rocha, Univel'sit)' Df Porto, Portugal

• Kazem Alernzadeh , Universily Df Bristol. UK

• Leopoldo Forner Navarro, Unil1crsily of Valcncia, Spain

• Luis Geraldo Vaz, UNESP. Ora:il

• Luis Pires Lopes. Unil'er.l'ilY Df Lisboll, Porlllgal

• Lui s Vieira Pinlo, Ccramed, AI/akitill, Portugal

• Marcos Parente,IDAfEC, Portugal

• Marcos Pinolti Barbosa , Federal Unil'crsily of i\linas Gerais, Bra:i1

• Maria Cristina Manzanarcs Cespedes, Ullil'c/'sit.1' Df Barcelona, Spain

• Mário Forjaz Secca, Universidade Nova de Lisboa, Porlllgal

• Mário Vasconcelos, Unil'ersity of Porto, Portugal

• Mário Vaz, Unil'ersity of Porto, Portugal

• Mi guel PinLo, Ullivel'sity Df Porto. Portugal ·

• Mildred Ballin Heckc, Federal Unil'ersi/)' of Paraná, Bra:il

• Olivcr Rohrle, UIIil'CI'sU)' of Stllllgart, Ge/'llIallY

• Pablo Jesús Rodrígucz Cervantes, Unive/'si/al faume I, Spain

• Paula Vaz, Unil'ersil.v of Poria, Portugal

• Paulo Alexandre Gonçalves Piloto, Pol)'/ecllllfcallllslilUle Df Bragallça, Portugal

• Paulo Melo, Ul/fllcI'sily of PorIa. Portugal

• Paulo Rui Fernandes, Ullil'crsilY of Lisbol/. Porlllgal

• Pedro Marlins, ID1\lEC, Por/ugal

• Pedro Mesquita, Ullil'crsily

0/

Poria, Portugal• Pedro Miguel Gomes Nicolau, Uni,'crsity of Coimbra, Porlllgal

• PhHippe G. Young, Ullivcrsity of Exelel; UK

• Reis Campos. Ullh'crsity of Porto, Portugal

• Renato Nata11orge, Ullivcrsity Df Porto, Portugal

• Sampaio Fernandes, Ullivcrsily Df Porto, Portugal

• Slephcn Richmond , Cardij/ Ullivcrsity, UK

• Yongjie Zhung. Carl/egie J\1elloll UllivCl'sity. USA

xvi

-Contributed papers

-Biodental Engineering 111- Natal Jorge et ai. (Eds)

© 2014 Taylor & Francis Group, London,lSBN 978-1-138-02671-1

The assessment of the generated temperature by the drill bit

in the bone tis sue

C.T. Sampaio, E.M. Fonseca

&IE. Ribeiro

/J/stifll((} Puliti!C1IiL'O de Bragança, Bragança, Porlllga!

R. Cerqueira

R/li Cerqueira Médü:o-De1llÚ'lll, Ce!orico de Bastv. Pvrlllgal

ABSTRACT: This work aims lo evalualc lhe generated temperature in bone lissue during a drilling

processo DiJTcrent clinic visits were earried Qul to follow-up a dental implantology and collcctcd thcrmo-graphic images for reading the temperature generated during lhe drilling. Simullaneously ao experimental

proccdurc was adoptcd with the acquisition af four blocks Df Sawbone.\' \vith sinúlar propcrties to lhe

trabccular and cortical bone and diITerent densities. The goal cf tbis experiment rcsulted in a drilling process to assess lhe generated temperature on the drill and simultaneously on the bane material. The obtained results allow to conclude that a more dense material reaches highest values. Regarding the tern-peratures recorded in the drill, the largest heating is also rccorded in denser bone. In clínical practice lhe temperature average in the drill are lowcr (nol exceeds 33°C) than the conducted in the experiments (42°C for denser cortical), since the process occurs with Ouids irrigation.

INTRODUCTION

Science and technology applicd to health are mcant to enhance the quality of the human life. In dental implants placement the variables that affect the bane drilling process are: speed, material , diam-eter, length and geometry of the drill point, (Fon-seca et alo 2014; Fon(Fon-seca el al. 2013, Monteiro et alo 2013). There are several researches on how to avoid adverse efTects on the bone patient structure.

HiIlery's research supparled the earlier find-ings of Lundskog highlighting that necrosis can

be induced if the bane is cxposed over 30s at

tempera-tures abovc 50°C (HilIery, 1999). In gen-eral, lhe literature indicates that if the temperature rises above 55°C, in a period of 1,5 minules, several weeks will be needed for a new bane regeneration process (Sousa, 2009). In lhe process of drill-ing lhe question is lhe need, or not, of irrigation

processes. Augustín el al. 2008, studied the

ther-mal osteonecrasís and lhe bone drilling param-eters. Thc study aimed to evaluate lhe inOuence of different parameters of drilling with increasing temperature of lhe bane. With this study it was possible to ascertain lhal when lIsing externai irri-gation lhe tempcratures were lower, nol reaching lhe criticai lemperature (T> 55°C). Without irri-gation, lhe temperalure for lhe same combination of paramelcrs was between 31 ,4--55,5°C. When a drill bit with a diameter of 4.5 mm was used to

67

drill with highcr speeds, temperatures abovc lhe criticai value were rccordcd. If lhe feed rate is high, a less temperature increased in the bone is verified. Thus, they were able to conclude that the external irrigation is the most important facto r of cooling. The increase in diameter and in drill speed caused an increase in the tempcrature of the bone (Augus-lin et aI. 2007). According lo Salgueiredo et aI. 2009, the use of irrigation processes can lead to a

dccrease of tcmperaturc in lhe bane unti14

0c.

The main goal of this work is to evaluale lhe developcd tcmperatures in bone tissue due to a drilling process, and vcrify lhe hypothesis of the thermal necrasis occurrence. Experimental meth-ods were used in lhe laboratory bascd on the use of lhcrmography and lhermocouples during bone drilling in difTerent materials. The follow-up of patienls was also performed during the dental implants placement for data collecting from ther-mographic images.

2 MATERIAL AND METHODS

2.1 Maleria!

The drills used by CNC in experimental setup have

ao angle af 118°, ance in the literature it is stated

that lhe lower temperatures \Vere generated for drills with this value (Basiaga et aI. 2011), The four blocks [rem Sawhones with difTerent densities (+D and - D) have similar properties to lhe human bone (eortical C or trahecular T), Figure 1.

Regarding lhe material dcnsities, the

corti-cal most dense has 800 kg/m3 and lhe less dense

is equal to 80 kg/rnJ• The most densc trabccular

material has a density Df 320 kg/m3 and lhe Iess

with 120 kg/rnJ

,

2.2 Clillical componcnl

Dental health professionals \Vha perform the drill-ing process for placdrill-ing a dental implant has a follow-up protocola0 lhe use af required drills. These drills have a specilic length and diameters depending ou the diameter and the Iength af the implant.

The procedure used at lhe clillic wha collabo-rated on this study was the following: firsl is per-formed a drilling point with a drill ealled spear; then some perforations are performed with twist drills and different diameters, depending on the arca of lhe mandible/maxilla of each palient; after lhe open hole is plaeed the implant. The drilling speed is 800 rprn and the loeation of the mandi-ble/maxilla with drilling is irrigated with saline at room temperaturc. During the clinical study a ther-mographic camcra was used for temperature meas-urement on the drill during the drilling processo Figure 2 represents an example of these images.

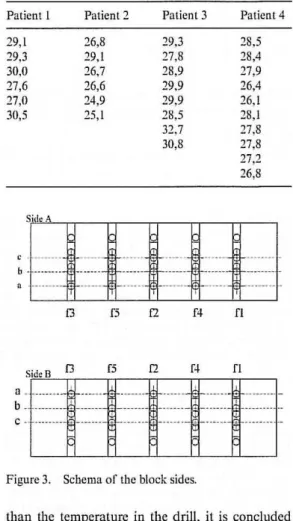

Table 1 represents the temperatures obtained in

the drill, during lhe follow-up for four patients.

Analyzing the Table I the temperature of the

drill was never greater than 32,7°C. Whereas the

temperature generated in the bone is not higher

Figure l. Blocks fram Sawbones (C+D, C-Df T +D.

T-D),

Figure 2. Dental c1inic and thermagraphy.

68

Tablc 1. Values of temperaturc af the drill bit

De.

Patient I29,1 19,3 30,0 27.6 27 ,0 30,5 Patient 2 26,8 19,1 16,7 26,6 24,9 25.1 Patient 3 29,3 27,8 28,9 19,9 29,9 28 ,5 32 ,7 30,8 Paticnt 4 28,5 28,4 27,9 26,4 26,1 28,1 27,8 27,8 27,2 26,8

'f"tll-ll l

b .• mm.~m. __ m ~ mu ~ummu.u .... _.. . 0 . . . . 00'0" · _ _ •• _. . . . • •• _ •••.•

l3 [5 12 [4 fl

~&B

o

6n

~ fia

.1 ...

1

.. _

..

1 .. --.. 1 ...

1

...

1'

_···1-b . mmu ' ; m m : _ u . , . _ ;

_uu_ : 'u'uu ..

c · _~.~ , .~ .... , ~ .... _ , . .

-Figure 3. Schema of the block sides.

than the temperatura in lhe drill , it is concluded that never occurred thermal necrosis.

2.3 Experimental setup

A CAD drawing in SolidWorks was elaborated,

with alI indications to be used during the process

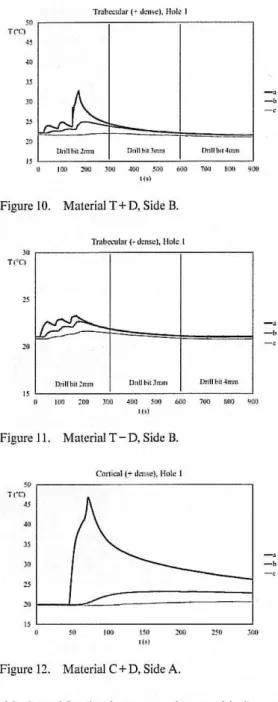

of drilling on lhe CNC machine, Figure 3. In each block, and on one side, 5 drillings are made with only one drill (Side A) and the opposite (Side B) are perforrned 5 drillings but for difTerent passages

of drills. Figure 3 is a schcmatic drawing of the

bloeks sides (Side A and B) where a, b and e repu

resenl lhe lateral holes for lhermocouplcs and fl ,

f2 , D , f4 and f5 represent the sequenee af drilling during the processo

The thermographic camera will analyze the

Figure 4. Drilling in lhe C+ D and thermography.

Figure 5. Drilling in lhe C-D and thcrmagraphy.

Figure 6. Drilling in lhe T+ D und Ihermography.

Figure 7. Drilling in lhe T - D and thermography.

2.3.1 Tell1perarurc allal)'sis 011 ,lte drill

With the use or thc thcrrnographic camcra, temM

perature values were recorded in lhe drills at the end of the drilling, on the surface block.

Table 2 shows the nurnber of samples, the rncan

and standard dcvialion of lhe lcmperalures va l~

ucs for difTerenl drills during the drill in difTerenl matcrials.

Analysing lhe average values it tums out lhat ror material "C

+

D" the highcsl lemperature wasrccorded using lhe driU with a diamelcr of 4 mm, folM

lowed by the 2 mm and linally the drillwith 3 mm. Regarding material "C - D " the drill bit with a diamcter equal to 4 mm achieves the highcst tem per-ature, but lhe drill with 3 mm registers a tcmpcrature sligh tly above the drill with a diameter of 2 mm.

69

Table 2. Tcmpcraturcs obtaincd in 3 phascs af drilling (Sido B).

Drill bit diamctcr (mm)

Material clt 2 ~3 $4

C+D C-D T+D T-D

(5) 39,20 ± 1,68 (5) 37,84 ± 2,07 (5) 48,04 ± 1,98 (5)2I ,84±O, 15 (5)2I ,90±O,36 (5)22,58 ± 0,84 (5)24,30 ± 0,62 (5)24,52 ± 1,02 (5) 26.70 ± 1,J3 (5) 22.28 ± 0.49 (5) 22,54± 0,80 (5) 23,44 ± 0,91

Note: N = Samples: M = Avcrage; 50 = Standard

Dcviation.

Tablc 3. Tcmperaturcs obtuincd in ane phasc drilling

(Sidc A). Material C+ D C-D T+D T-D

Orill bit diamclcr (mm)

(4) 66,80 ± 0,99 (5)24,24±O,70 (5)30,90 ± 2, 13 (5) 23,54± 1.16

Note: N = Samples; M = Averagc; SO = $tundard

Deviutian .

In relalion lo lhe malerial "T

+

D ", lhe behav-iour was similar to lhe " C- D " but with higherval-ues, i.e, the deill bit with 4 mm has a lcmperature

higher lhan lhe drill wilh 3 mm and this lempera-ture higher lhan the drill bit with 2 Olm.

The material "T - D " also has a similar

behav-iour lo lhe malerial " C-D" allhough wilh higher

tcmperatures, lhe drill bit with 4 mm has lhe

high-esl lemporalurc followcd by lhe drill wilh 3 mm later by lhe 2 mm.

In general, it is possible to amem lh at lhe highest

rccorded temperature was when using a 4 mm drill.

In Table 2 it can be seen that lhe highcr

lcrn-perature values are obtained with deill bit in lhe more densc material. In this material the drilling

cITort is higher compared to a less dense material,

which meaos greatcr chip amount. For lhe

stand-ard devialion, it lurns oul that has highcr values

in lhe malerial "C

+

D". Also lhe drill bil with a diamcter af 4 mm has a standard deviation higher lhan lhe values of lhe rcmaining drills, exccpt in the denscr material.Table 3 sho\Vs lhe number af samples, lhe mean and lhe standard deviation of lhe temperaturc val-ues obtained with a single drilling pass and with a diamctcr cqual to 4 mm for alI difTcrent materiais.

Analysing lhe average values in lablc 3, lhe

highest lcmperature rccordcd in the drill bit WilS

"T+O", "C -O" and finally the "T-O". Onee more, lhe denser material has lhe greater the tem-perature value. However the material "T - D" has a density higher thao material "C -D", but as the first has a spongy structure there is a greatcr rclcase af temperature. With respect to the standard devia-tion values, the highest value was recorded in lhe material "T+D",

2.3.2 Temperallfre mwlysis in bone

The use af thermocouples allows lO read and record the generated temperature in the material.

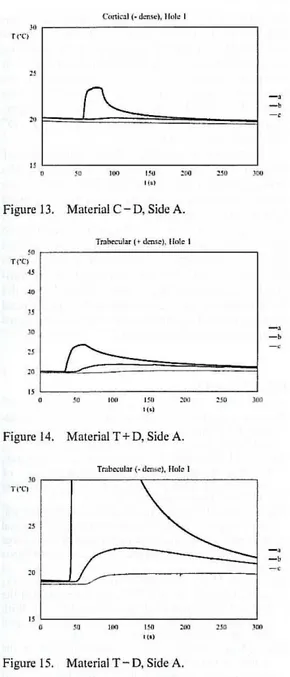

As reprcsented in Figure 3, thermocouples \Vere placed at difTerent distances [rom the maio hole. The following figures show the results obtained with thermocouples, only to the hole 1 af alI 4 blocks in question , considering the side B af lhe block lhat inc1udes lhe 3 drilling passes.

Analyzing the figures 8 to 11 it is possible to check that the material with highest temperature values is the material "C+ D", followed by the material "T+ D", "T - D" and finally the 'IC - D". The material with highest density has high values of lemperatures. lt is verified that the drill bit with 2 mm provides greater warming in material, this drill produces a greater eITort in relalion to the drills used subsequently. The results on eaeh bloek,

TI 'C)

"

"

"

C"r1Í<::1I ( + dcm~l. Hvlc I

",\

~

I~

Ormhlt~rnrtr U"lI bOll<r,tn 1J"II N t~m:n

o 100 ~ ~ ~ ~ ~ ~ ~ ~

1(.)

Figure 8. Material C + D, Side B.

Contrai (- dcruc). lllll~ I ~ ,---;---,---,

Tl'q

'"

0,.,11 hi, """" n"lI t~ J, ~m IJrlll bu4m.'l1

,; L-______ ~ _________ _L ______ __"

100 ~ M 400 '00 ~ ~ ~ ~

11.)

Figure 9. Material C - D, Sidc B.

-.

- ,

70

"

" "Cl"

"

"

Tr:lbo::ular ( '- d::ns.:l. Hole I

~

IJnU bit 21"m nrrll bir 3,,,,,, rmllb,,~,r _ll

U 100 ~ 300 _ ~ ~ ~ ~ ~

tlOl

Figure 10. Material T + D, Side B.

~r---'--- ---'--- ,

T (' O

Drillhi':n:m U"llh;tlmn ' Drillb lt4nun

" "

'00 "no ' 00 ' 00 '00 ~ >00"'"

..

'1 >1

Figure 11. Material T - D, Side B.

conkal ( + donse). Hole I

"

Tn.1"

'"

"

"

"

~"

'"

'00'"

,.,

; ~o'"'

t( .)

Figure 12. Material C+ D, Side A.

-.

-.

-"

-,

side A, and for the thermocouples, considering one drilling phase, are prcsented in Figures 12 to 15. for hole 1 of each material as an cxample.

'" r---,

r ~ ' q

"

"

"

'00

I ! <l '00 ~ """

l U'

Figure 13. Material C - D, Sidc A.

Trnh=J!3r (, dm\=), Unlc I

"

Teu H'"

H"

"

~

"

"

"

'"' 1$0 ' 00 ~, ~1 (. 1

Figure 14. Material T + D, Sidc A.

TrJh«ul..r (. dtll>l:' . Bole 1

"

T( 'C)

"

'"

", L---- "c---- ,~, . ---- ,~ " c---~, oo c---~ , ,, c---~ ,.

1 ( .)

Figure 15. Material T - O. Side A.

-.

-"

-.

the use af three drills for oDe passage, verifies that

lhe dcnscr materials have higher lemperature with

lhe drill bit Df 2 mm and less dense materiais have

higher lemperature when using the drill with 4 mm,

So it is possible to conclude that in denser

materi-aIs it is prcferable to use larger diameter af lhe drill bits and in less dense materiais srnaller diameler of drill bils.

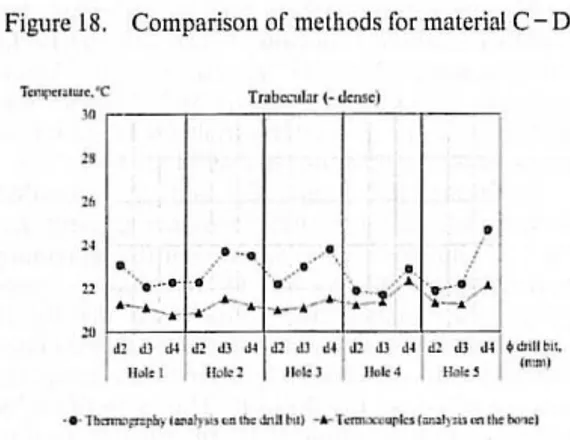

2.3.3 COJHparisoll be/ll'ee/l/nethods

For the comparison betwecn lhe tWQ used

experi-mental methods lhe temperature charts behaviour were obtained, in the drill bit and in the bone, for the

71

differenl material densities. To proceed with temper-ature registration in the drill bit, only the values out lhe drill bit were obtained with the thermogmphic cumera, Concerning the temperature in the bone, the average temperatures of the positions a, b and c (Figure 3) were obtained with the thernlOcouples.

Analysing lhe graphs relating to materials with higher densities, Figures 16 and 17, "C + D" und

"T + D", with 800 and 320 kg!m3 respectively, a

simi-lar behaviour was observed. Howevcr, in more dense cortical material, the temperatures were rccorded higher compared to lhe denser trabccular.

With regard to materiaIs with lower density also there are a similar behaviour, Figures 18 and 19. In

lhis case, malerial "C - D Uhas adensily of80 kg/mJ

while lhe "T- D" has a densily Df 120 kg/mJ

• The

method that has a greater variability is lhe meas-urement of temperatures in drill bits.

Analyzing the Figure 20 and lhe recorded temperaturc, material with a higher den sity, Le.

"C + D", has the highest values. For lhe remaining

materiaIs "T+ D" and "C+ D" lhe recorded

tem-perature are higher lhao of lhe lower density. It

is possible to conclude lhat for more dense mate-rial and without cavities, greater is the tempera-ture recorded on lhe drill bit. This is juslified by the greater eiTort required by the drill bit during cutting and chip amount production, For recorded

i ·

i i

...

i

\

•

..

'

•

..

' .. J

"

Figure 16. Comparison 01' methods for material C+ D.

"

-

.-.

"

..

-... .

l' 1"-" ':::.

~ : .:: : ::::.

...' ! .:: : ~

...

~ :: : "

A- A-- A - ~

W<!1 dJ ~~ ~: dJ J-I 1.c di J-I 1.u dJ <l-' I.u dJ J-I t drill bll.

11":. J ll. ~, 1 1l •• 1;: l rr o l .~ rrole ' <m."O)

Figure 18. Comparison of methods for material C- D.

T .. ,~" , .... 'C

Tr~b crub l t-drru::'::.'_,_ ---;

Figure 19. Comparison of mcthods for material T- D.

"

e c o ele

~ ~-c c

Cele e,

0. ". c. c,c,

c'I 'Óill Ht.0 ~;~õ~~ ~~ ~~~~~~~uu ~~ I ~l

1\1>1.1 11 " 1 "~ Ile!<l H .!< ~ J \uI,: ~

Figure 20. Comparison of methods for ali materials.

tcmperalure on lhe mate rial lhere are some varia-lioos. However in most cases the denser material prese nls lhe highest lemperature values.

3 CONCLUSION

The results obtained in dental surgery show that with the use of irrigation and combining difTerenl drill-iog paramelers, lhe lhermal nccrosis does nol occurs ooce lbe lempcralure did nOI cxceed lhe 32,7°C.

Given Lhe experimental se tup, il is possible lo concJude thal lhe lemperalure increases in lhe driJI, is according lhe densily and lhe slructure of

72

the materiaJ, i.e., if lhe material is denscr, lhe tem-peralure in the drill is highcr than lhe Iess dense material. If the material has cavities in its struclure, lhe temperature on lhe drill is not as high as in compacl material. As rcgards the evaluation of the tempcraturc in lhe material it is concluded that lhe

malerial "C

+

D" has lhe high est values of temper-alure, followed by lhe malerial "T+D", "T -D"

and linally lhe "C - D".

Comparing the graphics related with the use of three driU bits for single drill, it is ve rified lhal lhe drill with 4 mm releases greater heat in less dense materiais and the drill with 2 mm relcases more hcat in denser materiais.

Comparing the two rnetbods it is possible to

observe that the temperaturc in lhe drill is always higher than lhe temperature of the material. Tak-ing into aeeount lhe data provided by thermo-grapltie eamera and lhe resllJts obtained with lhe thermoeouples, can be concluded lhat the thermal necrosis doesn't occurred, since the material lem-peralure never bcen above 50°C.

REFERENCES

Augustin, G., Davila, S., Mihoci. K., Udiljak , T.,

Vcd-rina, T.S. , Antabak. A. 2007. Thcrmal osteonccrosis

and bone drilling parametcrs revisitcd. Spril/ger.

Basiaga, M., Paszcndo., l., Szewczenko, 1., Kaczmarck,

M. 2011. Numerical and experimental analyses 01'

driUs used in osteosynthcsis. Aeta

vI

Bioellgil1l.!eril/gmui BivII/edumics 13(4): 29-36.

Fonseca, E., Magalhães, K., Fernandes, M., Barbosa,

M. , Sousa, G. 1014. Numerical Model of Thermal Necrosis duc a Dental Drilling Process, In Natal Jorge

ct ai (Eds), 8iodcntal Enginccring lI, Ttl)'ior & Fl'lIl/cis

GrulIp: 69-73.

Fonseca, E.M.M., Magalhães, K. , Fernandes, M.G..

Sousa. G., Barbosa, M.P. 2013. The Assessmenl of the

Thermal Necrosis due a Drilling Dental Process With

ar WithoUl Irrigation, IEEE 3rd Portllglle.l"L' MCt!lillg

ill Biucngincerillg (ENBENG): 157-159.

Hillery, M.T., Shuaib, I. 1999. Temperature efTccts in the

drilling of human and bovine bone. lOllrlm/

oI

Alateri-aIs Proc:essing Tedlllolog)', 92- 93: 302-308.

Monteiro, D.C.A ., Fonseca, E.M.M, Barreira, L.M .S. ,

Magalhães, K., 201 3. Metodologia para Determi-nação da Necrose Tcrmicn por Furação num Modelo 3D de uma Mandíbula Humana. In Renato Natal ct aI.

(Eds), ..leIas do 5° CUl/gres.\"U Nadul/al de Biomec:tillit:a:

217-221.

Salgueiredo, E., Almeida , EA., Amaral, M., Fernandes, AJ., Costa, F.M., Silva , R.E , Oliveira. FJ. 2009. CVD micro/nanocrystallinc diílmond (MCDINCD) bilaycr

coated odonlological drill bits. Ditlllw/UlllIul Rclmed

M(I( e ,.i(1I .\~ 264-170.

Sousa, P.F.B.D. 2009. Estudos de processos térmicos

decorrentes da usinagem: aplicação de problemas

inversos em furação. Tese de Dal/lU,. t'1II ElIgell/wria