THE INTERFACE BETWEEN MARKETING AND MANUFACTURING: A STRATEGIC AND A FUNCTIONAL PERSPECTIVE

Rui Soucasaux Sousa

Faculdade de Ciências Económicas e Empresariais,

Universidade Católica Portuguesa - Centro Regional do Porto Rua Diogo Botelho, 1327

4150 PORTO PORTUGAL and

London Business School Sussex Place, Regent’s Park LONDON NW1 4SA UNITED KINGDOM

This paper takes two perspectives on the interface between marketing and manufacturing: a strategic perspective and a functional perspective. The former addresses the strategic links between the two functions, whereas the latter focuses on the more operational aspects of co-ordination between the two functions. While integration of marketing and manufacturing strategies is important, it can only be effective if the two functions operate in a co-ordinated manner.

Although some of the issues discussed here also apply at a more general level to the interface between operations - comprising manufacturing and service operations - and marketing, this paper addresses the specific case of the marketing-manufacturing interface. The manufacturing function is viewed here as the producer of goods for customers, and not as the buyer of inputs to produce the goods.

A narrow view of the marketing-manufacturing interface is adopted, by excluding product design and new product development (NPD) from consideration. Although design and NPD need both marketing and manufacturing inputs, in essence they are subject areas with an identity of their own. And although there are interfaces between product design and NPD and both marketing and manufacturing, this paper does not regard these as part of the marketing-manufacturing interface.

Finally, given the multitude of links between the two functions, the paper favours breadth over depth, choosing to provide an overview of the links between marketing and manufacturing at the strategic and functional levels, rather than focusing on a particular link.

THE MARKETING-MANUFACTURING INTERFACE: A STRATEGIC PERSPECTIVE

Given the early nature of research in this area, the literature is highly varied and eclectic. I address the importance of linking marketing and manufacturing strategies, and provide an overview of the strategic links between the two functions, i.e., areas that overlap marketing and manufacturing and that need strategic awareness.

The Importance of the Marketing-Manufacturing Strategic Link

It is essential for manufacturing strategyi to be aligned with marketing strategy and developed in a manner that improves the competitive capability of the organisation. In addition to simple inter-functional co-ordination, manufacturing and marketing strategy decisions must be aligned and linked to the business strategy of the firm. Deane, McDougall and Gargeya (1991) in their empirical study of new venture firms, conclude that the synergy between marketing and manufacturing strategy decisions is more closely related to firm success than either marketing or manufacturing decisions alone. They further hypothesise that the marketing and manufacturing interaction may be just as important to the success of established firms. Gupta et al (1991), provide additional empirical evidence of the importance of the relationship between manufacturing strategy and marketing objectives. They found that to achieve different market share objectives (dominant firm, major competitor or minor competitor), firms adopted different manufacturing strategies in terms of manufacturing process structure complexity and product line complexity.

Blois (1980) provides the only marketing perspective on the strategic links with manufacturing that was found in the literature. He questions whether a marketing orientation, by which marketing identifies a need and expects manufacturing to adapt its structure to meet this need, is appropriate, and argues that a manufacturing/marketing orientation may be required instead.

Hill (1985) stresses the importance of the strategic link between the two functions by emphasising the significant and fixed nature of investments in manufacturing. While corporate marketing decisions can be relatively transient in nature should a company so decide, manufacturing decisions bind the business for years. As a consequence, the linkage between marketing and manufacturing requires strategic awareness. This same author introduces the important concept of order-winning criteria (defined as those criteria that win customer orders in a specific market) as a mechanism for linking manufacturing and marketing strategies. Hill proposes that manufacturing decisions should be driven by the relevant order winning criteria for the markets being served.

Overview of the Strategic Links Between Marketing and Manufacturing

Several main strategic links between the two functions were identified in the literature. Hayes and Wheelwright (1984) address the relationship between the manufacturing process choice and the product life-cycle. In their product-process matrix, they advocate that firms consciously relate manufacturing process choice (e.g., project, job-shop, batch, line) to the product life cycle, since the manufacturing capabilities that are necessary change with the phase of the products’ life cycles. Hill (1985) notes that besides manufacturing processes (the ‘hardware’ dimension), manufacturing infrastructures (the ‘software’ dimension: supporting structures, controls, procedures, communications, and other systems) also need to be in line with the market needs.

Several authors (Gupta et al, 1991; Hill, 1985; Berry et al, 1991) stress the importance of segmentation of the market being performed on bases that are meaningful to both marketing and manufacturing. Generally, most organisations segment their market on the basis of product sold or customer type. Management typically assumes that the segmentation used for marketing strategy is adequate for manufacturing strategy. This assumption, however, can deter the effective development of manufacturing strategy. With markets increasingly characterised by difference instead of similarity, a single

facility cannot respond effectively to all segments of a market. Thus a market segmentation based on operations capabilities should be employed to define segments that are homogeneous in terms of the manufacturing capabilities that are necessary to serve them. This would enable the creation of ‘focused factories’ by which companies would focus the demands to which individual facilities must respond. Furthermore, viewing a market in terms of operations, and not only in terms of marketing attributes, can actually enrich the strategic alternatives considered by marketing by making explicit unique operations capabilities that marketing managers might not be aware of (Berry et al, 1991).

Nicol (1994) and Hayes and Wheelwright (1984) address the relationship between long-term production capacity strategies and market growth. The authors note that given the significant and fixed nature of investments in production facilities, capacity increases occur only from time to time in a stepwise fashion. Since sales growth is gradual, this means that two capacity strategies are possible: anticipating the market (resulting in production underload) or following the market (resulting in production overload).

Finally, a fifth link emerges in the literature: quality management. The best known quality management philosophy is Total Quality Management (TQM), which has drawn practising managers from many parts of an organisation to work together across traditional functional boundaries to improve quality and productivity (see for example, Crosby, 1979 and Deming, 1986). In TQM it is frequently stressed that quality should not be managed just as the interface between customer and supplier, but instead should encompass all relationships within the organisation through the creation of internal marketing programmes (Chaston, 1994). Christopher et al (1991) suggest that "quality has become the integrating concept between production and marketing (...) making operational the connection between what the customer wants and the activities of the firm". Ghose and Makhopadhyay (1993) provide a conceptual model for quality as the interface between marketing and manufacturing. Their associated empirical study concludes that quality can indeed serve as an effective interface variable for the two functions.

THE MARKETING-MANUFACTURING INTERFACE: A FUNCTIONAL PERSPECTIVE

In order for a firm to integrate the marketing and manufacturing strategies in any meaningful way, the marketing and manufacturing actions must be co-ordinated. This section addresses the interface between marketing and manufacturing from a functional perspective. Before examining the literature on the particular interface between the two functions, I analyse marketing's interface with other functions in general.

Marketing’s Interface with other Functions

Several researchers advocate a market orientation that integrates all business functions (Shapiro, 1988; Kohli and Jaworski, 1990; Narver and Slater, 1990; Kotler, 1991; Liechtenthal and Wilson, 1992). An organisation cannot be marketing-oriented unless all its members embrace the marketing concept and so marketing is generally seen as a co-ordinating activity. Cannon (1986) for example writes: “Co-ordination with other departments within the firm - finance, personnel, production - is as important as managing the specific aspects of the marketing mix under their control”.

Marketing personnel often play a co-ordinating role, linking demands from outside the organisation with the functional departments inside the firm that are capable of satisfying those demands. There is an extensive body of literature on the inter functional interaction between marketing and the other functions. However, few authors address the web of relationships between marketing and other functions in an integrated manner, and few attempts are made to develop theoretical frameworks (some exceptions are Wind, 1981, Hutt and Speh, 1984, and Ruekert and Walker, 1987). Ruekert and Walker (1987) characterise the existing literature as usually:

- “addressing the specific problems associated with the relationship between marketing and one particular functional area, such as manufacturing and R&D, in a manner not generalisable across other functions”.

- “written from a normative perspective, i.e., describing - primarily on the basis of experiential evidence - how marketing personnel should interact with one or more other departments with the intent of either improving the effectiveness of the interaction or reducing conflicts”.

The next sections review the subset of the above literature addressing the specific relationship between marketing and manufacturing. Although many of the issues concerning the functional interaction between marketing and manufacturing are situated at the tactical/operational level (such as scheduling, materials and inventory management, quality assurance, planning and performance, and productivity), this paper does not address these levels in detail. The detailed coverage of the tactical and operational levels is left to specific manufacturing texts (see for example, Buffa and Sarin, 1987; Hill, 1991; Muhlemann et al, 1992; Schroeder, 1989).

The Marketing-Manufacturing Functional Interface

The interface between marketing and manufacturing is especially important since these two functions are charged with managing the essential value-adding activities, and, as such, make many decisions that carry tremendous implications for competitive performance. Although the activities and responsibilities of marketing and manufacturing are fundamentally different, they are highly interdependent. This relationship is often described as conflict prone (Shapiro, 1977; Wind, 1981; Hutt and Speh, 1984; St. John, 1991; St. John and Hall, 1991), and as several researchers have suggested, the degree of co-ordination achieved between departments is important for organisation effectiveness (see for example Dess, 1987). This section addresses the functional interdependence/conflict between marketing and manufacturing. It reviews the literature in what concerns problem areas, causes of problems, and suggested conflict reduction mechanisms.

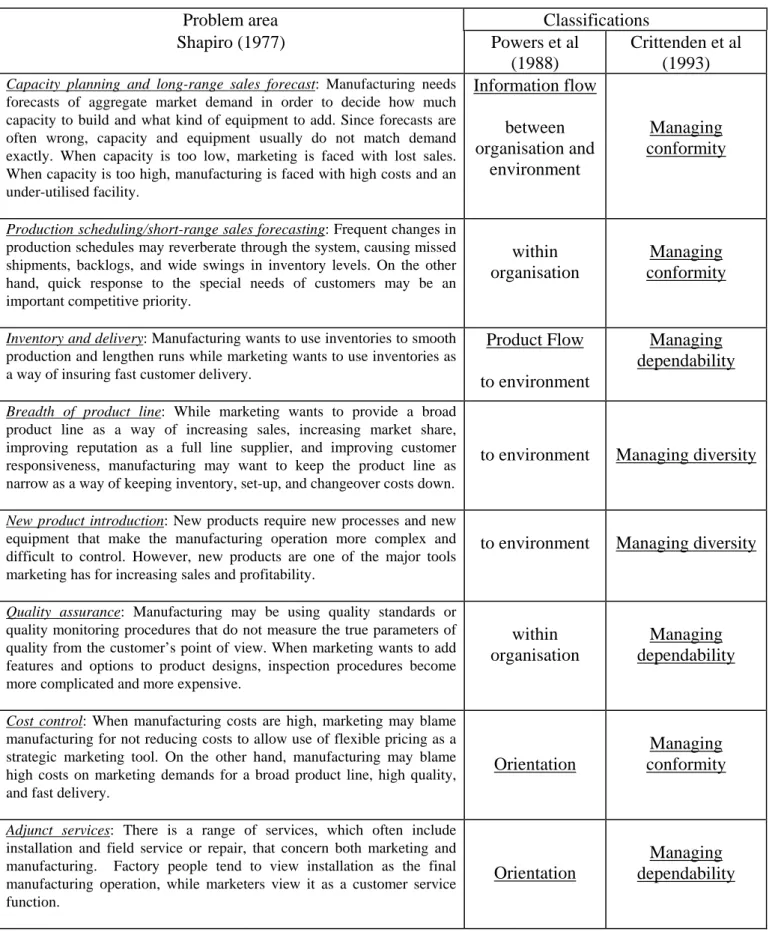

Problem areas. Since the seminal article of Shapiro (1977), several authors have addressed areas of potential conflict between the marketing and manufacturing functions (for example, Powers et al, 1988; St. John and Hall, 1991; Crittenden et al, 1993). There is a high degree of consensus in the literature over the problem areas identified by Shapiro, although authors have addressed them from different perspectives. Table 1 summarises the problem areas and classifies them according to the perspectives of several authors.

TABLE 1: Typology of problem areas.

Problem area Classifications

Shapiro (1977) Powers et al

(1988)

Crittenden et al (1993)

Capacity planning and long-range sales forecast: Manufacturing needs

forecasts of aggregate market demand in order to decide how much capacity to build and what kind of equipment to add. Since forecasts are often wrong, capacity and equipment usually do not match demand exactly. When capacity is too low, marketing is faced with lost sales. When capacity is too high, manufacturing is faced with high costs and an under-utilised facility. Information flow between organisation and environment Managing conformity

Production scheduling/short-range sales forecasting: Frequent changes in

production schedules may reverberate through the system, causing missed shipments, backlogs, and wide swings in inventory levels. On the other hand, quick response to the special needs of customers may be an important competitive priority.

within organisation

Managing conformity

Inventory and delivery: Manufacturing wants to use inventories to smooth

production and lengthen runs while marketing wants to use inventories as a way of insuring fast customer delivery.

Product Flow to environment

Managing dependability

Breadth of product line: While marketing wants to provide a broad

product line as a way of increasing sales, increasing market share, improving reputation as a full line supplier, and improving customer responsiveness, manufacturing may want to keep the product line as narrow as a way of keeping inventory, set-up, and changeover costs down.

to environment Managing diversity

New product introduction: New products require new processes and new

equipment that make the manufacturing operation more complex and difficult to control. However, new products are one of the major tools marketing has for increasing sales and profitability.

to environment Managing diversity

Quality assurance: Manufacturing may be using quality standards or

quality monitoring procedures that do not measure the true parameters of quality from the customer’s point of view. When marketing wants to add features and options to product designs, inspection procedures become more complicated and more expensive.

within organisation

Managing dependability

Cost control: When manufacturing costs are high, marketing may blame

manufacturing for not reducing costs to allow use of flexible pricing as a strategic marketing tool. On the other hand, manufacturing may blame high costs on marketing demands for a broad product line, high quality, and fast delivery.

Orientation

Managing conformity

Adjunct services: There is a range of services, which often include

installation and field service or repair, that concern both marketing and manufacturing. Factory people tend to view installation as the final manufacturing operation, while marketers view it as a customer service function.

Orientation

Managing dependability

Powers et al (1988) classify the problem areas in terms of information flows, product flows and role orientation. Information flows can take place between the organisation and its environment (mainly its customers) or within the organisation. Product flows can occur within the organisation or between the organisation and the environment. Role orientation concerns the background of the marketing and manufacturing people. Crittenden et al (1993) opt to classify problem areas in terms of conflicts in managing diversity (product line length and breadth, product customisation, and product line changes), conformity (product scheduling and capacity and facilities planning) and dependability (delivery and quality control).

Causes of conflicts. The causes of conflict between marketing and manufacturing can be classified into three categories: 1) evaluation and reward; 2) orientation/experience/cultural differences; and 3) inherent complexity.

1) Evaluation and reward: Several authors (Shapiro, 1977; Powers et al, 1988; Konijnendijk, 1993) acknowledge that one prime reason for the marketing-manufacturing conflict is the fact that the two functions are evaluated on the basis of different criteria and receive rewards for different activities. On the one hand the marketing people are judged on the basis of profitable growth of the company in terms of sales, market share, and new markets entered. Unfortunately, the marketers are sometimes more sales-oriented than profit-oriented. On the other hand, manufacturing people are often evaluated on running a smooth operation at minimum cost. Similarly unfortunately, they are sometimes more cost-oriented than profit-oriented. Clearly, the criteria on which the two functions are evaluated may be incompatible. Since marketers and manufacturers both want to be evaluated positively and rewarded well, each function responds as the system asks it to in order to protect its self-interest, thus leading to conflict.

2) Orientation, experience and cultural differences: Another basic cause of conflict relates to exposure, both current and past, of the managers involved (Shapiro, 1977). Industrial marketers are most likely to have come up through the sales route, while their counterparts in manufacturing often begin as foremen and worked up through the production operation. Each marketing and each manufacturing manager is more aware of his own organisational situation and problems. Several empirical studies provide evidence of these differences. For example, Clare and Sanford (1984), in their study of the can and tube industry, found that many people create artificial distances between themselves and their role partners by attributing dissimilar values to them (inter functional stereotyping). While marketing-manufacturing communications were considered important, they were also viewed as faulty, with many people tending to blame their counterpart function for the problem. Kahn and Mentzer (1994), in their study of normsii that distinguish between marketing and manufacturing, report that marketing managers perceive greater dependence on manufacturing, whereas manufacturing managers perceive less dependence on marketers. Since the implementation of a marketing orientation requires a collective effort to serve the customer, this lack of reciprocity may be an inhibiting factor.

3) Inherent complexity: Shapiro (1977) considers the complexity of the marketing-manufacturing interface itself as a cause of conflict. Complexities include handling two different types of data (qualitative marketing data versus quantitative

manufacturing data), the fact that any issue at the interface involves the core of the company (given the central importance of marketing and manufacturing), and conceptual and operational complexities at the analysis, policy formulation, and implementation levels.

Conflict reduction mechanisms. There is evidence that the use of co-ordination mechanisms can reduce inter functional disagreement (St. John, 1991; St. John and Hall, 1991; St. John and Rue, 1991; Rho et al, 1994). Several conflict reduction mechanisms are put forward in the inter functional research literature. Crittenden et al (1993), reviewing this literature, group these mechanisms into four major “facilitating mechanisms” for improving inter functional co-ordination - organisational design, communication, evaluation system and models - and suggest their application to the marketing-manufacturing relationship. The following is a brief summary of the co-ordinating mechanisms recognised in Crittenden et al’s review, extended by other suggestions identified in the literature.

a) Organisational design: Organisational structure plays a critical role since it determines the power of people in organisations and their perceptions of their roles. Crittenden et al (1993) identified the following co-ordination suggestions in the organisation theory literature: mixed structures, decentralisation of authority, teams and transplanting people into various functional roles for a limited time, and matrix organisations. Child et al (1991), making suggestions for reducing organisational complexity, also stress decentralisation of authority and rotation of people among different functions, and add the creation of small organisational units that include all the functions necessary to complete a task.

b) Communication: Several authors have stressed the need for improved communications for inter functional effectiveness. Crittenden et al (1993) report several mechanisms to improve inter functional communication: “the protocol” concept, workshops, and combined nominal interacting group consensus mechanisms. Shapiro (1977) adds mediation and arbitration by top management. The development and promulgation of clear, straightforward corporate policies is also a recurrent suggestion in the literature (Shapiro, 1977; Powers et al, 1988). Such policies provide a set of rules within which the marketing and manufacturing people can operate, thus facilitating communication. Clare and Sanford (1984) suggest the use of training programs which focus on the need for reality orientation in order to overcome inter functional stereotyping.

c) Evaluation system: Evaluation systems should reflect concerns of both parties in an internal exchange relationship. The evaluation and reward systems should be modified to stress inter functional co-operation and be aligned with corporate policies (Crittenden et al, 1993; Kahn and Mentzer, 1994). Marketing people should be judged on variables viewed as important to the manufacturing operation (for example, good sales forecasting might be rewarded instead of going over the sales quota) and vice-versa (for example, manufacturing people might be judged on delivery response time rather than just on asset management). Management by objectives linked to performance appraisal on the common strategic vision is also reported in the literature as a conflict reducing mechanism (St. John, 1991; St. John and Rue, 1991).

d) Models: Crittenden et al (1993) propose the employment of models bringing together the marketing and manufacturing concerns. Existing marketing models do not take into account manufacturing strategy decisions that could change conclusions drawn from them. In turn, existing manufacturing models are not well adapted to the dynamic nature of many marketing components (e.g., the economic order quantity tool of lot sizing assumes known and constant demand and that the cost of units remains constant for any order size, while the just-in-time philosophy emphasises standard product configuration and standardised parts). The authors emphasise the need for the models to be of practical use and include both marketing and manufacturing concerns and constraints. St John and Hall (1991) also suggest the use of rule-based control procedures such as statistical quality control, standard costing systems, operations research-based scheduling and inventory control.

St John and Hall's (1991) study of the carpet industry concluded that the simultaneous use of a variety of co-ordinating mechanisms led to a significant decrease in interdepartmental disagreement, suggesting that the simultaneous use of the several mechanisms mentioned above may be beneficial.

Despite the reasonable extension of the literature about marketing-manufacturing co-ordination, there seems to be two issues that are poorly addressed. First, there is insufficient empirical research into the role of co-ordination mechanisms across different industries, types of firms, and environments. It seems that most of the literature analyses problem areas and solutions on a one-size-fits-all basis. Konijnendijk (1993) takes an original approach by identifying the problem areas with more significance in companies with different logistics structures: make-to-stock, make-to-order, and engineer-to-order. He concludes that the degree of importance of problem areas differ between the types of companies, and so should solutions to co-ordination. However, his study is exploratory and descriptive in nature (thus with limited generalisability), and no effort is made towards providing different solutions to different types of firms. Nevertheless, his results make the case stronger for contingency-type research of the marketing-manufacturing functional interface. Identifying which problem areas are most critical and which co-ordination mechanisms are more effective under different conditions would be a valuable contribution to knowledge in the field.

Second, there doesn’t seem to exist studies explaining how to implement the proposed co-ordination mechanisms in actual business settings. Given the conflicting and complex nature of the two functions’ interface, success in implementation of the co-ordinating mechanisms should not be taken for granted. A recent empirical study of companies in North America, Western Europe, South Korea and China (Whybark, 1994) reports the lack of effective co-ordination between marketing and manufacturing. Although the issue is not addressed in this particular study, the poor co-ordination between the two functions could be not only due to the non-implementation of co-ordinating mechanisms, but also due to ineffective implementation of these.

RESEARCH AGENDA FOR THE MARKETING-MANUFACTURING INTERFACE

Most of the literature addressing the strategic links between marketing and manufacturing originated from research conducted by Production/Operations Management researchers. At the strategic level, there is the need for marketing researchers to be more aware of the strategic links of this function with manufacturing. This need is so more important as new manufacturing developments carry major implications for marketing strategy. The development of advanced manufacturing technologies, with increased flexibility and responsiveness, must be well understood by marketing academics so that they can increase the knowledge on how to use manufacturing as a competitive weapon. Research on the implications of manufacturing developments on marketing strategy is thus necessary. Research in the opposite direction is also needed. As markets change, further progress is necessary in manufacturing, in order to satisfy the new market needs. Recent market trends that will no doubt influence manufacturing include shorter product life cycles and time-based competition, increased market segmentation, demands for increased product reliability, global competition, and increased use of subcontracting (Blois, 1991). These trends are most likely to demand a closer than ever tie between marketing and manufacturing.

At the functional level, marketing researchers are well aware of this function's interface with manufacturing. Nevertheless, two areas seem little explored: contingency-based approaches to the functional interface, and research on implementation of co-ordination mechanisms on actual business settings. Increased knowledge in these areas would be very valuable in helping managers achieve a better co-ordination between the two functions.

REFERENCES

Berry, W. L., Bozarth, C. C., Hill, T. J., and Klompmaker, J. E. 1991. Factory focus:

Segmenting markets from an operations perspective, Journal of Operations Management, Vol. 10, No. 3, 363-387.

Blois, K. J. 1980. The manufacturing/marketing orientation and its information

needs, European Journal of Marketing, 14, 5/6, 354-364.

Blois, K. J. 1991. Trends in marketing and their implication for manufacturing,

International Journal of Technology Management, Vol. 6, Nos. 3/4, 385-394.

Buffa, E. S., and Sarin, R. K. 1987. Modern production and operations management, 8th Ed., New York: Wiley.

Cannon, T. 1986. Basic marketing: Principles and practice, London: Cassell Educational.

Chaston, I. 1994. Internal customer management and service gaps within the UK

manufacturing sector", International Journal of Operations & Production Management, Vol. 14, No. 9, 45-56.

Child, P., Diederichs, R., Sanders, F., and Wisniowski, S. 1991. SMR Forum: The

management of complexity, Sloan Management Review, Fall, 73-80.

Christopher, M., Payne, A., and Ballantyne, D. 1991. Relationship marketing:

Bringing quality, customer service and marketing together, Butterworth-Heinemann,

Oxford.

Clare, D. A., and Sanford, G. D. 1984. Cooperation and conflict between industrial

sales and production, Industrial Marketing Management, 13, 163-169.

Crittenden, V. L., Gardiner, L. R., and Stam, A. 1993. Reducing conflict between

marketing and manufacturing, Industrial Marketing Management, 22, 299-309.

Crosby, P. B. 1979. Quality is free, McGraw-Hill.

Deane, R. H., McDougall, P. P., and Gargeya, V. B. 1991. Manufacturing and

marketing interdependence in the new venture firm: An empirical study, Journal of Operations Management, Vol. 10, No. 3, 329-343.

Deming, W. E. 1986. Out of the crisis, Cambridge, MA: Massachusetts Institute of Technology.

Dess, G. G. 1987. Consensus on strategy formulation and organisational

performance: Competitors in a fragmented industry, Strategic Management Journal,

8, 259-277.

Ghose, S., and Mukhopadhyay, S. K. 1993. Quality as the interface between

manufacturing and marketing: A conceptual model and an empirical study, Management International Review, Vol. 33, Special Issue, First Quarter, 39-52.

Gupta, Y. P., Lonial, S. C., and Mangold, W. G. 1991. An examination of the

relationship between manufacturing strategy and marketing objectives, International Journal of Operations & Production Management, Vol. 11, No. 10, 33-43.

Hayes, R. H., and Wheelwright, S. C. 1984. Restoring our competitive edge:

Competing through manufacturing, New York: John Wiley and Sons.

Hill, T. 1985. Manufacturing Strategy, The Macmillan Press Ltd.

Hill, T. 1991. Production and operations management: Text and cases, 2nd Ed., Englewood Cliffs, NJ: Prentice-Hall.

Hutt, M. D., and Speh, T. W. 1984. The marketing strategy center: Diagnosing the

industrial marketer's interdisciplinary role, Journal of Marketing, Fall, 53-61.

Kahn, K. B., and Mentzer, J. T. 1994. Norms that distinguish between marketing and

Kohli, A. K., and Jaworski, B. J. 1990. Market orientation: The construct, research

propositions, and managerial implications, Journal of Marketing, 54, April, 1-18.

Konijnendijk, P. A. 1993. Dependence and conflict between production and sales,

Industrial Marketing Management, 22, 161-167.

Kotler, P. 1991. Marketing management: Analysis, planning, implementation, and

control, 7th ed, Prentice Hall, Inc., Englewood Cliffs, New Jersey.

Lichtenthal, D. J., and Wilson, D. T. 1992. Becoming market-oriented, Journal of

Business Research, 24, 191-207.

Muhlemann, A., Oakland, J., and Lockyer, K. 1992. Production and operations

management, 6th Ed., London: Pitman.

Narver, J. C., and Slater, S. F. 1990. The effect of a market orientation on business

profitability, Journal of Marketing, 54, October, 20-35.

Nicol, L. 1994. The interface with manufacturing in Wilson, I. (Ed.), Marketing

Interfaces, Pitman Publishing.

Powers, T. L., Sterling, J. U., and Wolter, J. F. 1988. Marketing and manufacturing

conflict: Sources and resolution, Production and Inventory Management Journal,

First Quarter, 56-59.

Rho, B., Hahm, Y., and Yu, Y. 1994. Improving interface congruence between

manufacturing and marketing in industrial-product manufacturers, International Journal of Production Economics, Vol. 37, No. 2, November, 27-40.

Ruekert, R. W., and Walker, O. C. Jr. 1987. Marketing's interaction with other

functional units: A conceptual framework and empirical evidence, Journal of Marketing, Vol. 51, January, 1-19.

Schroeder, R. G. 1989. Operations management, 8th Ed., Maidenhead: Mc-Graw-Hill.

Shapiro, B. S. 1977. Can marketing and manufacturing coexist?, Harvard Business

Review, 55, September-October, 104-114.

Shapiro, B. P. 1988. What the hell is market-oriented?, Harvard Business Review, 66, November-December, 119-136.

Skinner, W. 1969. Manufacturing: Missing link in corporate strategy, Harvard

Business Review, May-June, 136-145.

St. John, C. H. 1991. Marketing and manufacturing agreement on goals and planned

actions, Human Relations, Vol. 44, No. 3, 211-229.

St. John, C. H., and Hall, E. H. 1991. The interdependency between marketing and

manufacturing, Industrial Marketing Management, 20, 223-229.

St. John, C. H., and Rue, L. W. 1991. Co-ordinating mechanisms, consensus between

marketing and manufacturing groups, and marketplace performance, Strategic Management Journal, Vol. 12, No. 7, October, 549-555.

Whybark, D. C. 1994. Marketing's influence on manufacturing practices,

International Journal of Production Economics, 37, 41-50.

Wind, Y 1981. Marketing and the other business functions, in Research in Marketing, Vol. 5, Sheth, J. N. (ed), Greenwhich, CT: JAI Press, Inc., 237-264.

i

Manufacturing strategy is defined here as a statement of how manufacturing supports the overall business objectives through the appropriate design and utilisation of manufacturing resources and capacities (Skinner, 1969).

ii

Norms are expectations for appropriate/inappropriate attitudes and behaviour and socially created standards that help interpret and evaluate events.