Mat. Res. vol.20 número5

Texto

Imagem

Documentos relacionados

NAC-treated worms showed increased survival after 10 h of 35°C heat stress compared to the untreated control worms ( p =0.009).. Resistance to UV irradiation also

Within the limitations of this study, it was concluded that the hard denture reline showed lower values of surface hardness and impact resistance when compared to

The Effect of Electroless Bath Parameters and Heat Treatment on the Properties of Ni-P and Ni-P-Cu Composite Coatings.. Seyyed Hashem Mousavi Anijdan a , Masoud Sabzi b *,

The green banana gels showed higher values to the apparent viscosity when compared with corn gels, which allows the calculation of the pumping requirements and the heat

It would be expected that, irrespective of the restorative system used, all of the restored groups should present higher resistance to fracture when compared to the

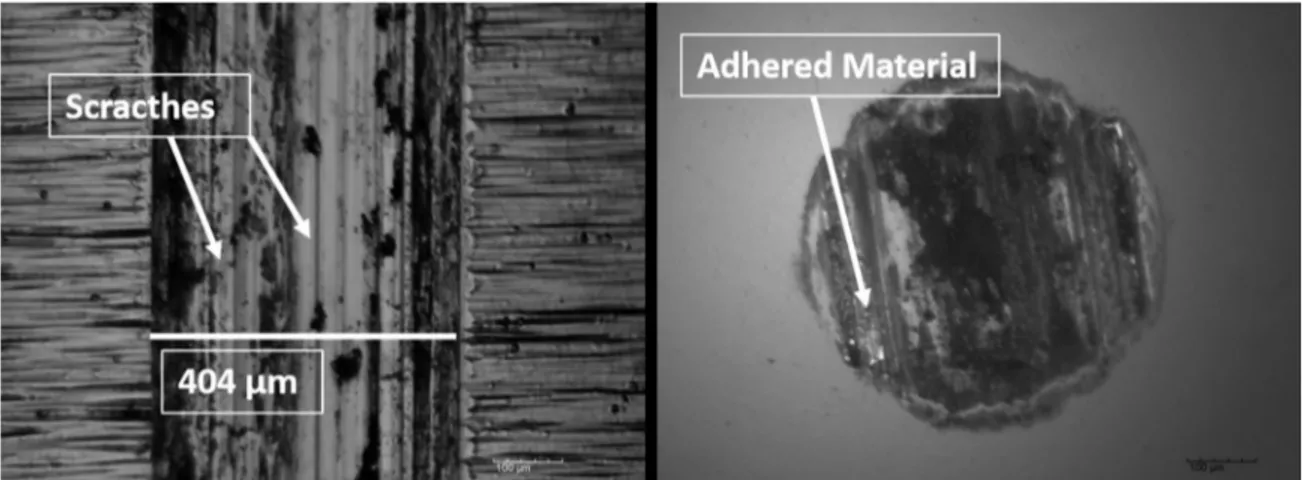

It is shown in this paper that the observed wear rate was higher for the unreinforced aluminium alloy when compared to the Al/TiB 2 reinforced composites.. Wear rate was decreased

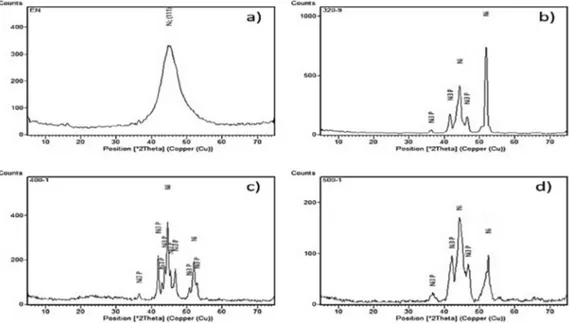

When aluminum is added to the coatings, the hardness of the coatings is improved due to the formation of a composite material, and a ternary phase appears at the higher

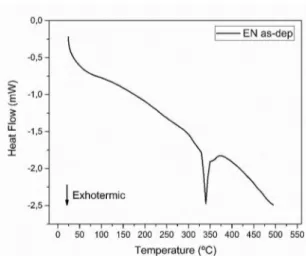

From the X-ray analyses, the behaviour of the microhardness with the annealing temperature for the Ni-Mo coatings is explained due to the fact that with the increase