Baracho M S1

Camargo GA2

Lima AM C3

M ent em JF4

M oura DJ1

M oreira J5

Nääs IA1

1 Facu ld ad e d e En g en h ar ia A g r íco la –

UNICAM P, Campinas, SP, Brazil

2 Cen t r o d e Tecn o lo g ia – UNICA M P,

Campinas, SP, Brazil

3 Faculdade de M edicina Veterinária – UFU,

Uberlândia, M G, Brazil

4 Faculdade Agronomia “ Luis de Queirós” –

USP, Piracicaba, SP, Brazil

5 Departamento de Zootecnia – FCA/UFVJM

– Campus de Diamantina, M G, Brazil

M S Baracho

Faculdade de Engenharia Agrícola – UNICAM P CxP. 6011

13.083-970. Campinas, SP, Brazil

M eat hygiene, meat qualit y, pre-processing, production chain.

Production to Pre-Slaughter: A Review

Mail Address

Keywords Author(s)

Arrived: November / 2006 Approved: December / 2006

ABSTRACT

Poultry meat quality has been w idely studied, and has become a grow ing demand of the international market. Parameters that affect meat quality are complex, and occur throughout the production chain. The constant concern w ith meat quality by the exporting sectors is a response t o consum ers’ dem ands, and is achieved by increasing ef f icien cy, an d in vest m en t s in p er so n n el t r ain in g o n q u alit y. Understanding w here critical points are in the poultry meat production chain, and investing in solving critical problems may lead to better control and management, and consequent reduction of losses. Production and management practices, from farm to processing plant, play an important role in meat quality, and the use of technologies to reduce risk factors throughout the production chain w ill allow the production of better quality poultry meat not only for exports, but also for the domestic market. This review describes the main factors that influence poultry meat quality in the production chain.

INTRODUCTION

Brazil is the w orld’s largest beef and poultry exporter, and fourth largest pork exporter, w ith total meat sales generating over USD 8 billion in 2005. Brazil achieved this position over the past decade, as Brazilian agricult ure benef it ed f rom m acroeconom ic st abilit y, high international commodity prices, currency devaluations, technological advancements, expansion in arable land area, and large capital inflow s from domestic and direct foreign investment. Domestic policies (credit and tax-exemption programs) also spurred production and processors’ incentives. Brazil’s poultry meat exports account for 41% of global trade (UBA, 2005; Valdes, 2006).

Even though the United States is the largest poultry meat producer, Brazil is the second, and this position occasionally alternates. When adding to this figures other Latin American producing countries, such as M exico, Colombia, and Argentina, the continent concentrates nearly 50% of the w orld’s poultry meat production.

important role in the increase in the productivity of the poultry industry, particularly in tropical areas, or those experiencing hot summer conditions.

A cco rd in g t o Lim a (2 0 0 5 ), su ccess in b ro iler p ro d u ct io n is d irect ly asso ciat ed t o eco n o m ical f easibilit y, qualif ied labor, int ensive use of good practices, and a close link w ith the consumer market. Each o f t h ese it em s b ears sp ecif ic im p o rt an ce; h o w ever , t h ey h ave t o b e co n si d er ed i n a multidisciplinary w ay, as these factors are overlapping. Average-size and small broiler production have met increasing difficulties to remain economically feasible in the present model of vertical structured production due t o t he necessary init ial invest ment in housing, environmental control, etc.

Heier et al. (2002) recorded high mortality rates and other economical losses during the first w eeks of broiler rearing, emphasizing that incorrect management and environmental control routines at this stage may cause significant losses.

Due to the market demand for quality, Brazilian processing plants are constantly implementing quality programs, as w ell as standards to obtain ISO 9000 cert if icat ion. In addit ion, t here is t rend t o produce broiler f ree f rom chemical, biological, and physical contaminants due to food safety concerns. This results in health and management constraints, as w ell as in l i m i t at i o n s i n t h e co n t r o l o f p ar asi t es an d microorganisms inside poultry houses, and in bird and w orker w elfare (Lima, 2005).

PRODUCTION AND MANAGEMENT

Today, the market imposes several restrictions on p o u lt ry m eat im p o rt s. Th e Eu ro p ean Un io n , f o r instance, demands that birds need to be adequately reared, and submitted to minimal w elfare standards (Blokhuis, 2004).

The follow ing five areas are crucial to success: chick quality, disease control, flock management, facilities, and feed quality. Int egrat ions f ace t he challenge of t r an sl at i n g ad van ces i n g en et i cs, n u t r i t i o n , im m unizat ion, chem ot herapy, healt h surveillance, and sim ilar t echnologies int o im proved ef f iciency in g ro w t h rat e, f eed ef f icien cy, an d livab ilit y. Th is f ier cely co m p et it ive b u sin ess r eq u ir es su p er io r m anagem ent skills t o balance decisions, such as higher f lock size and chick densit y, w it h improved housing, rapid grow th rate, shorter rearing periods, and health programs.

Rearing conditions

Poult ry m eat qualit y is pot ent ially af f ect ed by m an ag em en t t ech n iq u es, w eat h er an d r ear in g conditions, genetics, transportation, and the ability of the birds to respond to the environment, and all the variables that may interact, affecting in the production cycle (Bertol, 2004). M ost of factors influencing poultry meat quality can be controlled during the different product ion st ages, slaught er, and meat processing. Th ese f act o r s i n cl u d e ag e, g en d er , n u t r i t i o n , m an ag em en t , b ird d en sit y, h arvest in g m et h o d , environmental conditions, handling, etc. (M endes et al., 2003)

Taking into consideration the theory of M cInerney (2004), the investment related to w elfare needs to be considered as an added value by the producers, and, as pointed by Kerstin et al. (2000) and Lima (2005), the adoption of w elfare standards may influence the reduction of locomotory problems in broilers. This is consistent w ith the study of Bolis (2001), w ho verified a decline in broiler product ivit y w hen birds w ere exposed to unfavorable rearing conditions. M addocks et al. (2001), f or inst ance, assert ed t hat complet e conf inement , result ing in t he absence of access t o ultra violet radiation, may cause stress in birds due to an increase in corticosterol levels.

Although the purpose of litter is to promote bird comfort, and to improve carcass quality by decreasing breast, hock, and feet lesions, there is lack of literature information on the best material, or yet, w hich litter material needs to be used in order to reduce its possible impact on carcass quality (Oliveira & Carvalho, 2002). M oreover, high lit t er m oist ure causes f eet lesions (Julian, 2004), and increase am m onia levels inside poultry houses (M iragliotta, 2001).

t hat t he use of f orced vent ilat ion leads t o a more efficient removal of latent and sensible heat generated inside the broiler house.

Bressan & Beraquet (2002), studying broiler breast meat quality, found that birds kept under heat stress (environmental temperature around 30°C) presented higher cooking loss (28.7% in average) as compared to broilers reared submitted to comfort temperature (17 °C), w hich average cooking loss w as 27.2% .

According t o Soerensen et al. (2000), high bird density may induce to competition for space, low er feed intake, and possible feet and back lesions due to crow ding around t he f eeders. Kerst in et al. (1999) found high statistical correlation betw een locomotion abilit y and w eight gain, indicat ing t hat t here is an optimum density in w hich these problems do not occur. Garcia et al. (2001) observed t hat increase in bird densit y leads t o w orse f eat hering and consequent improvement in heat exchange efficiency; there w as also an increase in cooking loss related to high bird density. The authors also found that age influenced meat quality: from 35 to 49 days of age, cooking loss w as reduced by 32.95% .

Delazari (2001), w hen discussing w elf are and product ivit y, assert s t hat st ressed broilers are more susceptible to pathogen dissemination, compromising their health status.

In order to avoid dissemination of diseases, dead birds need to be removed from the poultry house as soon as possible, and appropriately disposed.

Genetics

Breed in g st rat eg ies h ave recen t ly t ak en in t o account m eat qualit y in order t o m eet consum ers needs (Gaya, 2006). Different genetic attributes, such as meat qualit y and carcass yield, w ere st udied by M oreira & Garcia (2003), w ho concluded that some com m ercial st rains had bet t er perf orm ance t han others, w hen bird gender is considered.

According to Julian (2004), young broilers are very susceptible to variations in environmental temperature, w hich may lead to critical changes in metabolism due to unbalanced heat exchange. The author also points that some chemical drugs such as nicarbazin, and also chlorine and nitrophenols may make the problem yet more harmful by increasing body heat production.

Resistance to heat stress has become an important issue in the last years. Silva et al. (2001a) compared tw o broiler genetic strains: one w ith the gene (Na), w hich expresses low neck feathering, and one w ith normal neck f eat hering (nana), and observed t hat ,

w h en exp o sed t o h eat st r ess (3 8 - 4 2 º C) in an environmentally-controlled chamber, the birds w ith the Na gene present ed bet t er heat st ress resist ance as compared to the others. Studies report that reduced f eat hering volum e m ay aid birds t o opt im ize heat exchange in t ropical condit ions, becom ing m ore tolerant to high temperature exposure (M arder & Arad, 1989; M acari & Gonzales, 1990; Singh et al., 2001; M oreira et al., 2006). In addit ion, non-nut rit ional factors, such as genetic inheritance and environment, play a vital role in the feathering rate, and may also contribute to poor feathering (M oreira et al., 2006).

Nutrition

Garcia et al. (2005) studied the inclusion of sorghum replacing corn in broiler feeds, and found a significant negative correlation betw een meat pH decrease and corn replacement. Sorghum inclusion also affected in meat color, promoting paler meat.

The influence of vitamin E (as all-rac-α-tocopheryl

acetate) supplementation on the sensorial quality of f r o zen ch ick en m eat w as st u d ied . Tw o d iet ar y treatments w ere compared as follow s: (1) the control group received a diet containing respectively 30, 20, and 15 mg of α-tocopheryl acetate/kg of feed from

0 - 2 0 , 2 1 - 3 8 , an d 3 8 - 4 5 d ays o f ag e; (2) t h e supplemented group received a starter diet containing 30 mg of á-tocopheryl acetate/kg of feed from 0 to 20 days of age, and a finisher diet containing 200 mg/ kg of feed from 21 to 45 days of age. HPLC analyses show ed that muscle á-tocopherol levels of the chickens fed the supplemented diet w ere 6-7-fold higher than those of the chickens fed the control diet. M eat quality w as evaluated by sensorial as w ell as by instrumental techniques, such as (G-M S) thiobarbituric acid values (TBA) and gas chromatography-mass spectrometry. It w as show n t hat vit am in E supplem ent at ion had a beneficial effect on sensorial data, and on oxidative st abilit y of t he meat , as measured by TBA. GC-M S an alyses also sh o w ed t h at t h e co n cen t rat io n o f aldehydes, w hich are considered responsible for rancid off-flavors, w as much more important in the control samples as compared to the supplemented samples.

result in higher ult imat e pH values in post mort em muscle. Therefore, dietary a-LA supplementation may be potentially reduce the incidence of pale, soft, and exudative (PSE) meat.

Health

In this text, the absence of health refer to biological abnorm alit ies, w hich result s in im paired f ert ilit y, hatchability, livability, productivity, or product quality. M any diseases cause mortality or drastic postmortem tissue alterations. The susceptibility or resistance of ch ick en s an d t u rk eys is p art ially d et erm in ed b y genetics. Few infectious agents are potent or virulent enough to overcome natural resistance in most birds. On the other hand, most infectious agents are possibly opportunistic. They have very little obvious effect on normal, healthy, w ell-cared-for birds, but may produce severe disease and drastic losses in birds stressed by rough handling, chilling during the first w eeks, poor ventilation, etc.

Some of the most common origins of diseases in broiler f locks are described below as: 1. Genet ic-determined defects; 2. M anagement related; 3. Feed and w ater related; and, 4. Infectious diseases.

1. Genetically determined defects: So m e diseases have an evident genet ic origin, and many others are suspected to have a genetic component. Anat om ic def orm it ies (f or exam ple, kinky back in broilers, w ry neck, cystic or malformed kidneys, cystic right oviduct) are included in this category, as w ell as some behavioral (hysteria) and grow th (poor feathering and tibial dyschondroplasia) problems. In general, major Brazilian breeding companies have done a good job in excluding t hese problem s, and t hey seldom cause major constraints on productivity.

2. M anagement-related disease: Unfortunately, st arvat io n , d eh yd rat io n , can n ib alism , am m o n ia blindness, and a variety of other similar diseases are uncommon. These problems can be directly related to careless or inattentive management.

3. Feed- and w ater-related diseases: Diseases in t h i s cat eg o r y i n cl u d e n u t r i t i o n al d ef i ci en ci es, intoxications, and problems associated w ith chemical residues. The best approach f or t heir prevent ion is monit oring f eed and w at er in order t o ensure t he desired quality and to decrease the risk of hazardous cont aminant s.

4. Infectious diseases: These diseases have so many possible origins that it is difficult to specifically pinpoint them. The most common diseases are derived from the breeder flock. Any infectious agent that is

transmitted from the breeder hen through the egg to the hatched chick or poult has its ultimate origin in the breeder flock. M ycoplasmosis, salmonellosis, and avian encephalomyelitis are among the diseases that can b e t ran sm it t ed f ro m b reed er f lo ck s. A t t h e h at ch ery, f au lt y san it at io n can resu lt in several d iseases, su ch as o m p h alit is, salm o n ello sis, an d aspergillosis.

Infectious agents, w hich are difficult to kill by routine cleaning and disinfection, are likely to be carried over from one flock to the next simply by survival in the cont am inat ed prem ises. In t his cat egory, diseases caused by clostridial spores, the erysipela bacterium, staphylococci, infectious bursal agent, adenoviruses, M arek’s disease, herpes-virus, etc are included.

Biological and mechanical carriers are particularly common sources of infectious diseases. Blood-sucking arthropods (mosquitoes, blackflies, mites, ticks, etc.) are know n t o be involved in t he t ransm ission of diseases, such as fow l pox and spirochetosis. Rodents and f ree-f lying birds are dangerous sources of t he causative agents of cholera and salmonellosis. Flies and beet les can be carriers of a num ber of inf ect ious agents, and are know n to be intermediate hosts of several internal parasites.

and L, lines, respectively. At seven w eeks, incidence of TD varied from 47 to 11% , and w as line-dependent. At four w eeks, incidence varied from 21.4 to 12.0% , and at seven w eeks, from 36.6 to 25.0% for males an d f em ales, resp ect ively. In cid en ce o f TD w as reduced by intermittent light only in birds from a specific line. Tibial dyschondroplasia influenced body w eights at four and seven w eeks of age, independent from lighting program and sex. At four w eeks of age, broilers w ith TD w ere 32 g heavier than broilers w ith no TD. At seven w eeks of age, broilers w ith TD w ere 47 g lighter than those w ith no TD. It is possible that the effect of TD on body w eights depends on broiler age, and on t he severit y of TD lesions. There w ere no differences in body w eight or w eight gain at four or seven w eeks bet w een t he light ing programs. Body w eights of seven-w eek-old birds submitted to constant or intermittent light w ere 2.31 and 2.32 g, respectively. Broilers under int ermit t ent light had a bet t er f eed efficiency betw een zero and four w eeks as compared to broilers exposed to constant light (1.67 and 1.71, respectively). Feed efficiency w as similar from four to seven w eeks in the tw o lighting programs (M addocks, 2001).

Focal ulcerative dermatitis (FUD) is an ulcerative skin lesion over the breast area, usually on the unfeathered skin over the keel bone. M any factors, such as type of litter, ammonia concentration, feather loss, trauma, body w eight , breast conf ormat ion, ammonia burns, and bacteria, w ere suggested as predisposing factors for both cellulitis and FUD, but t he cause of breast lesions remains unknow n (Vaillancourt & Barnes, 2003).

Cellulitis or infectious process has emerged as an economically significant disease syndrome of broiler chickens, resulting in increased condemnations and dow ngrading at processing, and costs associated w ith trimming and reprocessing affected carcasses. Cellulitis is characterized by a diffuse inflammatory reaction in the subcutaneous tissue. Escherichia coli (E. coli) is the predominant organism isolated from cellulitis lesions in a number of studies, being considered the causing agent of cellulitis. It w as show n that skin trauma or d am ag e b y scr at ch in g in cr ease cellu lit is lesio n formation by E.coli. It is believed that most cellulitis lesions observed at processing started during grow out (Schrader et al., 2004)

The impact of environment al risk f act ors on t he incidence of cellulitis has not been evaluated in the Un it ed St at es yet . Th e cau sin g ag en t , E. coli, is int roduced t hrough skin scrat ches during grow out . Previo u s w o rk su g g est ed t h at t h e lit t er w as an

important reservoir for cellulitis-associated E. coli. Julian (2006) hypot hesized t hat f act ors cont ribut ing t o a positive environment for E. coli grow th w ould increase the opportunity for the exposure of broilers to an E. coli inf ect ious dose capable of init iat ing a cellulit is lesion. A prospective study of 304 flocks in five farms from tw o integrated broiler companies w as conducted to determine the effect of environmental factors on the prevalence of cellulitis in California broiler flocks (Schrader et al., 2004). M easured lit t er variables included E. coli and total gram-negative bacteria load (colony forming units/g dry matter), w ater activity, and pH. Cellulitis ranged from 0.2% to 6.0% . Significant associat ions w ere ident if ied using linear regression among farm, litter moisture, days betw een flocks, and environmental temperature during the brooding period, gram-negative bacteria load in the litter during the brooding period, RH, grow -out, and E. coli load late in the grow out period. The significant variation in cellulitis rate among farms, combined w ith a high association o f lit t er m o ist u re an d d ays b et w een f lo cks w it h cellulites, demonstrated that management decisions strongly influenced this disease syndrome. Based on t hese dat a and in previous f indings, t he aut hores advised m anagers t o increase t he num ber of days betw een flocks, and to perform a total clean out of the house if the previous flock had a high incidence of cellulitis at processing.

Harvesting and transportation

There is evidence in t he lit erat ure t hat cat ching often results in injury, especially w hen a large number of birds are caught w it h m axim um hast e by t he catching team. Leandro et al. (2001) identified and quantified losses w hen comparing both manual and mechanized catching (16.5 to 7% , respectively). The authors found bruising in thighs, legs, and breasts of up to 25% of the harvested birds due to handling, cat ch in g , t ran sp o rt at io n , an d u n lo ad in g at t h e processing plant . How ever, m ost dam age in t he carcass w as found during catching in the breast (11% ), thighs (33% ), and w ings (38% ).

is caused by too much haste by the catchers (Gregory, 1998).

Debut et al. (2004) estimated the genetic variability betw een lines in terms of breast and thigh meat quality (pH drop, color, drip loss, and curing-cooking yield) by comparing a slow -grow ing French label-type line and a fast-grow ing standard line (SGL) of broilers exposed to different pre-slaughter stress conditions. Birds w ere slaughtered under optimal conditions or after exposure to 2h of transport or 2h of acute-heat stress (35°C). Relat io n sh ip s b et w een m eat q u alit y an d st r ess sensit ivit y w ere invest igat ed by measuring st ruggle during shackling and tonic immobility (TI) duration, one w eek before slaughter, as an indicator of the basal level of fear of the birds. Thigh meat characteristics w ere influenced by both pre-slaughter stresses, but no significant effects w ere detected on breast meat. The main effect of heat stress on thigh meat w as a decrease of the ultimate pH, leading to paler color and low er curing-cooking yield; opposit e ef f ect s w ere obtained for transport. Breast meat w as much more sensitive to physical activity of birds on the shackle line. Longer durations of w ing flapping in the shackle line produced a faster initial pH decline. Whatever the line, no relationship betw een TI duration and meat qualit y charact erist ics or act ivit y w as observed. It is suggest ed t hat SGL birds could be at disadvant age due to more intense struggle during shackling, and accel er at ed p o st m o r t em g l yco l ysi s, w h i ch i s detrimental to the quality of breast meat.

In the UK, 40% of broilers that arrive dead at the slaughterhouse may have died as a result of thermal stress and suffocation (Weeks, 2001), often due to crow ding during t ransport . UK vet erinary scient ist s commented on the modules in w hich the birds are transported: because of its compound construction, a module full of draw ers tends to be poorly ventilated, particularly w hen the vehicle stops, w hether during the journey to the processing plant or on arrival, w hen there is usually a delay before the birds are slaughtered. The modules may be unloaded and stacked in a lairage area. The authors recorded lairage times of up to seven hours. Deliveries of birds (92% ) w ere held for up to four hours before they w ere shackled and processed (Warris et al., 1999).

Pre-slaughter stress

Several studies w ere carried out to correlate pre-slaughter stress to meat quality. Fletcher (2002) asserts that poultry meat quality is highly dependent on pre-slaught er m anagem ent , and t hat losses f ound at

processing may be a direct result of inadequate rearing conditions, as discussed in the topic above.

Based on this concern, and encouraging w elfare principles, poult ry export count ries are discussing specif ic procedures in order t o ensure bet t er meat qualit y t o t he consum ers. In Brazil, t his subject is included in the agenda of the M inistry of Agriculture and Food Supply (M APA), as mentioned in Brasil (2000). A n t e m o rt em h ealt h in sp ect io n p reven t s t h e delivery of infected birds to processing plants (Delazari, 2001). Despite having applied this inspection during t he ent ire lif e of broiler f locks, som e pat hological changes can still be found at slaughter (Brasil, 1998). Losses due t o high t em perat ure at lairage, and w eight loss during transportation w ere reported by Bilgili et al. (1989) and M endes et al. (2001). These losses may range from 0.5 to 2% during transportation, and from 0.1 to 5% at the processing plant. In order to reduce carcass contamination, the gastrointestinal tract needs to be emptied, and this requires submitting birds to fasting six to eight hours prior to slaughter. When t his t ime is exceeded, t he int est ine becomes fragile, and may release the content of the gall bladder, contaminating the carcass (M endes, 2001).

According to Savenije et al. (2002), the natural time p erio d f o r ch icken b reast m u scle t o h alt en erg y consumption is 6 h. The muscle can maintain its internal energy balance for up to 2h postmortem through other means than glycolysis. Betw een 4 and 6h postmortem, rigor m ort is set s in, af t er w hich deboning can be perf orm ed w it h no risk of cold shrinking. Energy consumption in the muscle is not limited by the amount o f availab le g lyco g en , b u t rat h er b y p H an d b y availability of Adenosine Tri-Phosphate. Glycogenolysis continues after the glycolysis has stopped. It w as show n that feed w ithdraw al and transport quickly exhausts the main energy supplies of chickens (Savenije et al., 2002). Energy exhaustion compromises the w elfare of t h e an im als, an d m ak es t h em p ro g ressively less capable of coping w it h f urt her st ressors. Cat ching, crating, and transport are stressful stimuli, but it w as f ound t hat energy availabilit y is not com prom ised during the short periods of time. Also, neither feed deprivation nor transport under good conditions for short periods of time significantly affected meat quality.

POULTRY MEAT QUALITY

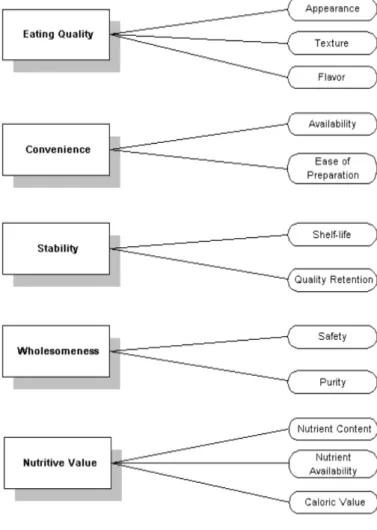

ch ar act er i st i cs d o n o t m eet t h e co n su m er ’ s expectations, the product is considered to be of inferior quality. Whether or not a poultry meat product meets t h e co n su m er’ s exp ect at io n s d ep en d s u p o n t h e condit ions surrounding various st ages in t he bird’ s d evelo p m en t , f r o m t h e f er t ilized eg g t h r o u g h production and processing to consumption. There are several charact erist ics t hat det erm ine t he overall qualit y of m eat (Figure 1), according t o Nort hcut t (1997).

Figure 1 - Schematic view of meat attributes (Adapted from Northcutt (1997).

There are many definitions of quality. Groom (1990), taking into account the need to make products meet the demands of the market place, defines quality as:

“The composite of those characteristics that differentiate individual units of a product and which have significance in determining the degree of acceptability of that unit to the user”.

The main attributes related to poultry meat that m ay det erm ine it s qualit y are color and it s w at er holding capacity, according to Gaya (2006). The ability o f p r eser vi n g f o o d i n g en er al i s r el at ed t o environmental air quality and temperature, as w ell as conditioning and packaging characteristics (Fletcher et al., 2000).

Water holding capacity (WHC) is a parameter used to describe the ability of the meat products to maintain w ater w ithin its fibers (Fennema, 1990). M endes et al. (2003) st at e t hat W HC can be m easured by t he difference in w eight of the Pectoralis muscle before and after cooking. Castellini et al. (2002) verified that organic broiler breast and t highs present ed smaller WHC values as compared to conventional broilers (53.2 and 57.5% ; and 55.3 and 60.2% , respectively).

Tw o other important attributes, appearance and texture, of poultry meat quality are pointed out by (Fletcher, 2002). Appearance is part of the consumer’s select ion of a product at t he shelf , w hile product texture is valued by sensorial perception. The selection of carcass quality is usually based on visual criteria, and does not include all the above mentioned attributes (M endes, 2001).

Poultry meat is a perishable product consisting of carbohydrat es, prot ein, lipids, and w at er. Product conservation must meet certain standards in order to preserve its quality until consumption by the final user. Shelf life is related to WHC and meat pH. Baruffaldi & Oliveira (1998) measured the influence of pH of a determined enclosed environment on the development of microorganisms. Bacteria usually grow in a pH range of 4.5 to 7.5, w hile fungi have a w ider grow th range, from 2.0 to 9.0. Fresh poultry meat has an average pH of 6.4.

M uscle hemorrhages are reported as one of the major problems in poultry carcass quality (Kranen et al., 2000).

Pr o cessed b r o iler car casses an d r aw p o u lt r y products are frequently contaminated w ith pathogenic microorganisms of public health significance. M uscle h em o rrh ag es an d p H f avo r t h e d evelo p m en t o f microorganisms.

may be more significant in determining the levels of in d icat o r o rg an ism s in p ro cessed carcasses t h an slaughter and dressing procedures (Whyte et al., 2004).

Mycotoxins

In terms of quality demanded by the international m eat m ark et , Qu eved o (2 0 0 5 ) assert s t h at it is im port ant t o invest in t he f ull cont rol of poult ry p r o d u ct i o n an d p r o cessi n g i n o r d er t o m eet international standards and regulations. Silva (2006) describes t he need of an adequat e microbiological evaluation in meat production for assurance of quality, as w el l as co n su m er ’ s saf et y. Th e am o u n t o f m icr o o r g an ism s t h at w ill d evelo p d u r in g m eat processing w ill depend on the bird’s health status, and stress conditions. When a healthy bird is assessed, few microorganisms should be found, except for those on the skin surface, and in the digestive and respiratory t ract s.

M yco t o xi n s ar e ch ar act er i zed as seco n d ar y metabolites from toxinogenic microscopic fungi, and several research studies focused on the toxins from the genus Fusarium, w hich is considered the largest contaminant of cereals and its by-products, particularly of corn (Flatscher & Willinger, 1981; Leslie et al., 1990). M ycotoxins may become a serious problem in Brazilian poultry production in the future due to their synergy w it h ot her inf ect ious agent s. A lt hough 300-400 mycotoxins are already described, those causing more concern due t o t heir incidence and t oxicit y are t he af lat oxins, zearalenone, f um onisin, as w ell as t he trichothecenes deoxynivalenol (DON or Vomitoxin) and toxin T-2 and T-2-like toxins (Alltech, 2000).

M ycotoxins are initially found in the feedstuff, and they are disseminated throughout the poultry house after contaminated feed is distributed in the feeders. Exp o su r e t o ei t h er l o w o r m o d er at e l evel s o f m ycot oxins during a considerable period of t im e reduces product ivit y, leading t o losses. M ycot oxin residues have been reported in poultry meat, stressing the need to control both fresh and processed food (Bezerra, 2005).

Brazilian legislation alerts to the presence only of aflatoxins in food for human consumption, establishing the limit of 30 µg/kg AFB1+AFG1 (ANVISA, 2001). The M inistry of Agriculture and Food Supply (M APA) limits the amount of aflatoxins in final feeds and their main feedstuffs at 20 µg/kg (Brasil, 1996). This limit is similar to those established in developed countries (Doll & Peto, 1981), as w ell as those recommended by the World Healt h Or g an izat io n (W HO) an d t h e Fo o d an d

Agriculture Organization (FAO), as mentioned in FAO/ WHO (1998).

Listeria

Listeria monocytogenes has been isolated in raw poultry meat in several countries, including Brazil.

Sites and incidence of Listeria contamination in an industrial poultry processing plant w ere investigated by sampling carcasses at different processing stages, and by testing the hands and gloves of food handlers as w ell as the chilling w ater used in the process. In the study of Barbalho et al. (2005), 66 samples representing individual carcasses w ere obtained from the processing plant and analyzed f or t he prevalence of List eria spp. The m ost f requent isolat ed species w as L. innocua, w hich account ed f or 28 out of 31 (90.3% ) isolat es. Three (9.7% ) of t he isolat es w ere L. monocyt ogenes and t w o (6.5% ) w ere L. grayi. List eria innocua w as isolat ed f rom carcass sam ples at all st eps of t he p r o cessi n g l i n e, i n cl u d i n g b l eed i n g , scal d i n g , def eat hering, beginning and end of eviscerat ion, and packaging. L. m onocyt ogenes w ere isolat ed only f rom carcasses packaging ready t o be sent t o t he m arket . No List eria sp p. w as iso lat ed f ro m p re-chilling and re-chilling w at er sam ples. Cont am inat ion sit es w ere det ect ed by sam pling of carcasses and w orkers’ hands and gloves at dif f erent product ion st ages f or List eria species by serot yping t he isolat es. Due t o t he f act t hat raw and processed poult ry m eat and w orkers’ hands and gloves harbor List eria, t he poult ry indust ry needs t o cont rol L. monocyt ogenes cont am inat ion during processing, and eventually to eliminate it from carcasses before they are sent to the market .

Salmonella

to train food handlers, and to provide information to the consumers (Savell et al., 2005; Cortez et al., 2006). Biochemical processes and structural changes that occur in muscle during the first 24 h postmortem play an important role in the ultimate quality and palatability of meat, and are influenced by the chilling processes to w hich carcasses are submitted after slaughter. Spray chilling, a system w hereby chilled w ater is applied to carcasses during the early part of postmortem cooling, is used to control carcass shrinkage, and to improve chilling rat es during evaporat ive cooling. Delayed chilling can be used t o reduce or t o prevent t he n eg at i ve ef f ect s o f co l d sh r i n k ag e; h o w ever , product ion const raint s in high-volume f acilit ies and food safety concerns make this method less useful in co m m er cial set t in g s. Elect r ical st im u lat io n an d al t er n at i ve car cass su sp en si o n p r o g r am s o f f er processors t he opport unit y t o prevent m ost of all ef f ect s of cold shrinkage w hen t radit ional chilling systems are used.

FINAL REMARKS

The development of new and efficient processing systems, the adoption of advanced technologies, and the introduction of novel products that meet the market chain requirement s and end-consumer needs have significantly contributed to increase global poultry meat consumption (Roenigk, 1998). Poultry production and p r o cessi n g t ech n o l o g i es h ave b eco m e r ead i l y accessible, and are implemented on a w orldw ide basis, t h er eb y al l o w i n g co n t i n u o u s exp an si o n an d competitiveness in this meat sector (Aho, 2001).

Processing and marketing of poultry ranges from live bird markets or very primitive on-site slaughter and sale, t o highly sophist icat ed, f ully aut om at ed and Int ernat ional St andards Organizat ion (ISO) cert if ied f acilit ies and ready-t o-eat convenience product s in many parts of the w orld. Ironically, these extremes in processing and market ing met hods are somet imes o b served w it h in t h e sam e co u n t ry. Th e lack o f inadequate refrigeration is probably the single largest obstacle to the marketing of many perishable foods, including poultry meat. In many developing countries, even minute improvements in cold storage capabilities have significantly increased trade, storage, distribution, an d co n su m p t io n o f p o u lt ry p ro d u ct s, w h et h er domestic or imported (Babji, 2001). In addition, the ad o p t io n o f m o d er n f r eezin g , p ack ag in g , an d t ran sp o rt at io n t ech n o lo g ies h ave p ro vid ed larg e poultry companies the flexibility to export their high

quality, mostly value-added premium cuts, to all corners of the w orld, especially at times of domestic surpluses and low market demands (Bilgili, 2006).

Consumers w orldw ide demand a protein supply that is saf e, w h o leso m e, n u t r it io u s, ab u n d an t , an d af f o rd ab le. Ho w ever, f o o d saf et y st an d ard s are currently not uniform, or equally enforced, around the w o rld . Dif f eren ces, f o r exam p le, in h yg ien e o r inspection regulations often lead to trade disputes and stagnation among the countries. Several international bodies, such as the Codex Alimentarius Commission of World Health Organization (WHO), the Food and Agricult ural Organizat ion (FAO), t he Int ernat ional Commission on M icrobiological Specifications for Foods (ICM SF), and t he W orld Trade Organizat ion (W TO) Agreements on Sanitary and Phytosanitary M easures (SPS) and Technical Barriers t o Trade (TBT) develop an d p r o vi d e g u i d el i n es f o r t h e eq u i val en cy i n in t ern at io n al st an d ard s t o p ro t ect t h e h ealt h o f consumers and to ensure fair practices in food trade (Bilgili, 1999).

Welfare and good production practices on the farm, during t ransport at ion, and in t he processing plant should be observed at all times, and be incorporated as part of an ef f ect ive poult ry product ion syst em . Adequat e w elf are procedures and proper hygiene must minimize dyschondroplasias, cellulitis, dermatitis, and exposure of carcasses t o f ecal m at erial and pot ent ial pat hogens, reducing t he opport unit ies of cross-contamination.

A s t he w orld m oves t ow ards a global m arket economy, poultry production w ill continue to increase in countries w ith important natural resources and that are economically competitive and politically open to business investments (Aho, 2001). M any countries or regions, on the other hand, w ill continue to struggle to compete in this market, either because of limited inf rast ruct ure (raw m at erials, land, ut ilit ies, labor, transportation) or political constraints (environmental and w elfare concerns, tax structure, trade policies).

Before poultry meat quality is addressed, it must be clearly defined how the term quality is related to poultry meat. This is a difficult task, because quality is “ in the eye of the beholder” . For example, someone trying to sell a product may consider quality in terms of how w ell the product is sold and how many people is w illing t o pay f or it . How ever, t his def init ion is incomplete, as it does not take into account product characteristics. As people only buy w hat they like, the consum er’ s percept ion of qualit y is t he ult im at e definition of quality, w hich needs to be met by poultry meat producing countries.

REFERENCES

Abu-Ruw aida AS, Saw aya WN, Dashti BH, M urad M , Al-Othman HA. M icrobiological qualit y of broilers during processing in a modern commercial slaughterhouse in Kuw ait. Journal of Food Protection 1994; 57:887–892.

Agência Nacional de Vigilância Sanit ária .Legislação. [Accessed dec. 08, 2006]. Available from: URL:http://w w w .anvisa.gov.br

Aho P. The new poultry elite. WATT Poultry USA, may, 20-24.

Alm eida Filho N, Rouquayrol M Z. Desenhos de pesquisa em epidem iologia: : : : : epidem iologia e saúde. 5. ed. Rio de Janeiro: M EDSI; 1999.

Almeida IAZC. Salmonella: sorotipos identificados na região de São José do Rio Preto/SP, no período de 1990-1999. Revista do Instituto Adolfo Lutz 2000; 59(1/2):33-37.

AL-TECH, Comércio e Importação Ltda. Compreendendo e lidando com os efeitos das micotoxinas em rações e forragens para animais domésticos. [Acesso dez. 8,. 2006]. Disponível em: URL: http:// w w w .altech.com.br/i01.htm.

Aradas M E, Nääs I, Salgado IA. Comparing the thermal environment in broiler houses using tw o bird densities under tropical conditions. Agricultural Engineering International 2005; 8:1-9.

Babji AS. Asian poult ry processing adjust s t o domest ic market demands. World Poultry 2001; 17:22-24.

Baley D. Beef and veal, pigs and poultry: meat outlook to 2009-10. Australian Commodities 2005; 12(1):65.

Barbalho TCF, Almeida PF, Almeida RCC, Hofer E. Prevalence of Listeria spp. at a poultry processing plant in Brazil and a phage test for rapid confirmation of suspect colonies. Food Control 2005; 16:211–216.

Baruffaldi R, Oliveira M N. Fatores que condicionam a estabilidade de alimentos. In: ____. Fundamentos de tecnologia de alimentos. São Paulo: Atheneu; 1998. p.13-25.

Bertol TM . Estresse pré-abate: conseqüências para a sobrevivência e a qualidade da carne em suínos. [Accessed out . 15, 2006].

Available from: URL: http://w w w .cnpsa.embrapa.br/?/artigos/2004/ art igo-2004-n004.ht m l.

Bezerra V S. [Accessed dec. 08, 2006]. Available from: URL: http:// w w w . e m b r a p a . b r / n o t i c i a s/ a r t i g o s/ f o l d e r . 2 0 0 5 0 2 -02.1550581232/art igo.2005-06-14.3711997257/.

Bilgili SF, Egbert W R, Hof f m an DL. Research not e: ef f ect of p o st m o rt em ag ein g t em p erat u re o n sarco m ere len g h an d t enderness of broiler Pect oralis m ajor. Poult ry Science 1989; 68(11):1588-1591.

Bilgili SF. Assuring the safety of poultry products in a global market: Th e US p ersp ect ive. In : Pro ceed in g s o f t h e XIV Eu ro p ean Symposium on the Quality of Poultry M eat; 1999; Bologna, Italy. p.513-519.

Bilgili SF. Poultry Products and Processing. In: The International M arket Place. Auburn: Depart ment of Poult ry Science Auburn University; 2006. p.8.

Blokhuis HJ. Recent developments in european and international w elf are reg u lat io n s. W o rld ´s Po u lt ry Scien ce Jo u rn al 2 0 0 4 ; 60(4):469-477.

Bolis DA. Biosseguridade na criação alt ernat iva de f rangos. In: Conf erência A pinco de Ciência e Tecnologia A vícola; 2001; Campinas, São Paulo. Brasil. p.223-234.

Brasil. M inistério da Agricultura, Pecuária e do Abastecimento. Regulamento técnico da Inspeção tecnológica e higiênico-sanitária de carne de aves: Portaria DAS, nº. 210, de 10 de novembro de 1998, republicada em 05.03.99. [A ccessed dec. 12, 2004]. Available f rom : URL: ht t p://w w w .agricult ura.gov.br/sda/dipoa/ republport 210.ht m l.

Brasil. M inistério da Agricultura, Pecuária e do Abastecimento. Regulamento técnico de métodos de insensibilização para o abate humanitário de animais de açougue: instrução normativa n.3, de 17 de janeiro de 2000. Brasília: [s.n]; 2000.

Brasil. Portaria M AARA No.183 de 21 de março de 1996. Diário Oficial da União, Brasília (DF); 25 de março de 1996; Seção I. p. 4929.

Bressan M C, Beraquet NJ. Ef eit o de f at ores pré-abat e sobre a qualidade da carne de peito de frango. Ciência Agrotécnica 2002; 26(5):1049-1059.

Castellini C, M ugnai C, Dal Bosco A. . . Effect of conventional versus organic method of production on the broiler carcass and meat quality. M eat Science 2002; 60:219-225.

Delazari I. Abate e processamento de carne de aves para garantia de qualidade. In: Conf erência Apinco de Ciência e Tecnologia Avícola; 2001; Campinas, São Paulo. Brasil. p.191-203.

Delazari I. Programas de segurança de alimentos na indústria da carne. Avew orld 2004; 1:44-49.

Escudero-Gilet e M L, González-M iret M L, M oreno Temprano R Heredia FJ. Application of a multivariate concentric method system f o r t h e l o cat i o n o f Li st er i a m o n o cyt o g en es i n a p o u l t r y slaughterhouse. Food Control 2007; 18(1):69-75.

FAO/WHO. Expert Committee on Food Aditives [JECFA]. Safety evaluation of certain food additives and contaminants – Aflatoxins. Geneva: World Health Organization; 1998.

Fennema OR. Comparative w ater holding properties of various muscle food. Journal of M uscle Foods 1990; 1:363-381.

Flat sch er J, W illin g er H. Bak t er ien - u n d p ilzk eim zah len in futtermitteln. w iener tierärztliche monatsschrift. In: Findlay, WPK. Fungi: folklore, fiction & fact. Surrey: Kingprint 1982; 68:282– 284.

Fletcher DL. Poultry meat quality. World’s Poultry Science Journal 2002; 58(2):131-145.

Fletcher DL, Qiao M , Smith DP. The relationship of raw broiler breast meat color and pH to cooked meat color and pH. Poultry Science 2000; 79 (5):784-788.

Garcia RG, M endes AA, Costa C, Paz ICLA, Takahashi SE, Pelícia KP, Komiyama CM , Quinteiro RR. Desempenho e qualidade da carne de frangos de corte alimentados com diferentes níveis de sorgo em substituição ao milho. Arquivo Brasileiro de M edicina Veterinária e Zootecnia 2005; 57(5):634-643.

Garcia RG, M endes AA, Garcia EA, Nääs IA, M oreira J, Almeida ICL, Takita TS. Effect of stocking density and sex on feathering, body injury and breast meat quality of broiler chikens. Brazilian Journal of Poultry Science 2001; 1(4):1-9.

Gasparetto KM PO. Sorotipos de Salmonella isolados de carcaças de f rango e avaliação da suscept ibilidade a ant im icrobianos. Revista Ciência Farmacêutica 2001; 2(2):85-199.

Gast RK. Salmonella infections. In: Saif YM editor. Diseases of poultry. 11th ed. Ames: Iow a State Press; 2003. p. 567-583.

Gaya LG, Ferraz JBS. Aspectos genético-quantitativos da qualidade da carne em frangos. Ciência Rural 2006; 36(1):349-356.

Groom GM . Factors affecting poultry meat quality. In: Options méditerranéennes Cambrigde (UK): Agricultural Development and Advisory Service (ADAS), Fisheries and Food, Cambridge (UK); 1990. (Série A-L’aviculture en M éditerranée).

Heier BT, Hogasen HR, Jarp J. Factors associated w ith mortality in Norw egian broiler flocks. Preventive Veterinary M edicine 2002; 53(1-2):147-158.

Julian RJ. Product ion and grow t h relat ed disorders and ot her metabolic diseases of poultry: a review . The Veterinary Journal (in press). [Accessed dec. 10, 2006]. Available f rom : URL: ht t p:// w w w .sciencedirect.com.

Kranen RW. Haemorrhages in muscles of broiler chickens. World´s Poultry Science Journal 2000; 56(2):93-126.

Leandro NSM . Ef eit o do t ipo de capt ura dos f rangos de cort e sobre a qualidade de carcaça. Ciência Animal Brasileira 2001; jul-dez: 97-100.

Leslie JF, Pearson CHAS, Nelson PE, Toussoun TA. Fusarium spp. from corn, sorghum and Soybean Fields in the Central and Eastern United States. Phytopathology 1987; 80:334–350.

Lima AM C. Avaliação de dois sistemas de produção de frango de co r t e: u m a vi são m u l t i d i sci p l i n ar [ t ese] . . . Cam p i n as (SP): Universidade Estadual de Campinas; 2005.

M aciorow ski KG. Incidence, sources, and control of food-borne Salmonella spp. In poultry feeds. World´s Poultry Science Journal 2004; 60(4):446-457.

M addocks SA. Behavioural and physiological effects of absence of ultraviolet w avelengths for domestic chicks. Animal Behaviour 2001; 62:1013-1019.

M atheus DP, Rudge AC, Gomes SM M . Ocorrência de Salmonella spp em carne de frango comercializada no município de Bauru (SP), Brasil. Revista do Instituto Adolfo Lutz 2003; 62(2):111-115.

M cInerney J. Animal w elfare, economics and policy: : : : report on a: study undertaken for the farm & animal health economics. Londres: Division of DEFRA; 2004.

M endes AA. Rendimento e qualidade da carcaça de frangos de corte. In: Conferência Apinco de Ciência e Tecnologia Avícolas; 2001; Campinas, São Paulo. Brasil. p.79-99.

M iragliot t a M Y. Avaliação de dois sist em as de vent ilação de densidade e sua influência sobre níveis de amônia em sistema de produção de f rangos de cort e [dissert ação]. Cam pinas (SP): Universidade Estadual de Campinas; 2001.

M oreira J, Garcia RG. Qualidade da carne de peito de frango de corte. Revista Nacional da Carne jul/2003; 317:14-19.

M oreira J, M endes AA, Garcia RG, Garcia EA, Roça RO, Nääs IA, Dalanezi JA, Pelícia K. Evaluation of strain, dietary energy level and stocking density on broiler feathering. Revista Brasileira de Ciência Avícola 2006; 8(1):15-22.

M oss M O. Fungal Biot echnology Roundup. M ycologist 1990; 21:55-58.

Northcutt JK. Factors affecting poultry meat quality. Bulletin 1157 1997. [A ccessed nov. 18, 2006]. A vailable f rom : URL:ht t p// pubs.caes.uga.edu.

Oliveira CM , Carvalho DI. Rendimento e lesões em carcaças de f rangos de cort e criados em dif erent es cam as e densidades populacionais. Ciência Agrotécnica 2002; 26(5):1076-1081.

Roenigk WP. Poultry w ill overtake pig meat consumption. World Poultry 1998; 14(12):14-16.

Sant os DM S. Salm onella em carcaças de f rango congeladas. Pesquisa Veterinária Brasileira 2000; 20(1):39-42.

Savenije B, Lambooij E, Gerritzen M A, Venema K, Korf J. Effects of Feed Deprivation and Transport on Preslaughter Blood M etabolites, Early Postmortem M uscle M etabolites, and M eat Quality. Poultry Science 2002; 81:699–708.

Sch rad er JS, Sin g er RS, A t w ill ER. A p ro sp ect ive st u d y o f m anagem ent and lit t er variables associat ed w it h cellulit is in California broiler flocks. Avian Diseases 2004; 48:522-530.

Silva M AN, Silva IJO, Piedade SM S. Resistance to heat stress of naked neck broilers. Revista Brasileira de Ciência Avícola 2001a; 3(1):27-33.

Silva N, Junqueira VCA, Silveira NFA. M anual de métodos de análise microbiológica de alimentos. 2. ed. São Paulo: Varela; 2001b.

Soerensen P, Su G, Kestin SC. Effects of age and stocking density on leg w eakness in broiler chickens. Poultry Science 2000; 79:864– 870.

Tinôco IFF. Avicult ura Indust rial: novos conceit os de mat eriais, concepções e t écnicas const rut ivas disponíveis para galpões avícolas Brasileiros. Revista Brasileira de Avicultura 2001; 3 (1):01-26.

UBA : Un ião Brasileira d e A vicu lt u ra. Relat ó rio an u al 2 0 0 3 / 2004.[A ccessed f eb. 20, 2005]. A vailable f rom : URL: ht t p:// w w w .uba.br/2005.

Valdes C. Brazil Emerges as M ajor Force in Global M eat M arkets... Livestock, Dairy, and Poultry Outlook, M ildred Haley. LDP-M -137 – LDP-M -139, USDA, Economic Research Service, January 2006. [Accessed dec. 08, 2006]. Available from: URL: w w w .ers.usda.gov/ publicat ions/ldp/.