Huthaifa Issam Ashqar

Ev

aluation of P

ol

ymer Modified Asphalt Binder Aging

Universidade do Minho

Escola de Engenharia

Huthaifa Issam Ashqar

Evaluation of Polymer Modified Asphalt

Binder Aging

Master Thesis

Urban Engineering

This work was carried out under the supervision of

Doctor Hugo Manuel Ribeiro Dias da Silva

Huthaifa Issam Ashqar

Evaluation of Polymer Modified Asphalt

Binder Aging

Universidade do Minho

Escola de Engenharia

Acknowledgment

ACKNOWLEDGMENT

I am using this opportunity to express my gratitude to everyone who supported me throughout this thesis. I express my warm thanks to my supervisor Prof. Hugo Silva for his fabulous dedication.

I would also like to thank everyone in the Civil Engineering Department and in particular Prof. José Pinho and Prof. Joel Oliveira for their help and cooperation. I am grateful to everyone in the Civil Engineering Laboratory, especially Mr. Carlos Palha, Mr. Hélder Torres, and Ms. Liliana Costa for sharing their illuminating help and views.

I would like to thank Erasmus Mundus Program (Peace) for funding my master course at University of Minho.

This work is funded by FEDER funds through the Operational Competitiveness Program COMPETE and by National funds by FCT (Portuguese Foundation for Science and Technology) in the scope of Project FCOMP 01 0124 FEDER 020335 (PTDC/ECM/119179/2010).

Thanks are also due to the Companies Gintegral (for the supply of polymers) and CEPSA (for the supply of bitumen).

I dedicate this Master’s thesis to pare ts Prof. Issam and Wafaa, my sister, and my brothers. Thank you for your support.

Abstract

Evaluation of polymer modified asphalt binder aging

ABSTRACT

Asphalt binders used in road pavements basically age in two phases, the short-term aging and the long-term aging. Short-term aging occurs in binders due to mixing, transporting, placing, and compaction of asphalt mixtures, while long-term aging occurs in situ during the lifetime of the pavement. The effect of short-term and long-term aging on the binder reveals in its chemical structure, mainly by increasing the rate of oxidation, and in its physical or rheological properties by hardening.

The main aim of this work was the study of the short-term aging, especially addressing the assessment of polymer modified asphalt binders. In fact, these binders are being increasingly used, but the evolution of their properties during aging is still not well known.

A 35/50 penetration grade unmodified bitumen (B1), a 70/100 penetration grade Ethylene Vinyl Acetate (EVA)-modified bitumen (PmB1), and a 70/100 penetration grade High-Density Polyethylene (HDPE)-modified bitumen (PmB2) were aged applying two different methods.

In one method, the binders were exposed to 75-min in RTFOT testing (binder aging). In the other method, the binders were used to produce asphalt mixture samples, and the aged binders were recovered (short-term aging of the mixture and binder recovery) after mechanical testing of samples.

The rheological properties of all binders were assessed for each one of their states, namely unaged, after-RTFOT aging, and after-recovery aging. These rheological measurements after RTFOT aging o iousl i di ated a i rease i the i ders’ stiffness. However, the rheological results after-recovery appeared to be unreasonable. Hence, the binders PmB1 and PmB2 were also subjected to DSC testing trying to explain these unexpected results. DSC analysis indicated that the polymers were absent from PmBs after recovery process. Yet, the FTIR analysis had demonstrated that the recovered bituminous parts of PmBs were indeed aged chemically when the mixtures were produced and compacted.

Keywords: Short-Term Aging, Polymer Modified Bitumen, Rheological Properties, Recovered

Resumo

vi

Huthaifa Issam Ashqar

Avaliação do envelhecimento de betumes modificados com polímeros

RESUMO

Os ligantes betuminosos utilizados na pavimentação de estradas envelhecem basicamente de duas formas, a curto prazo e a longo prazo. O envelhecimento de curto prazo ocorre nos ligantes devido à produção, transporte, colocação e compactação das misturas betuminosas, enquanto o envelhecimento a longo prazo ocorre in situ durante o período de vida do pavimento. O efeito do envelhecimento do ligante a curto e a longo prazo revela-se na sua estrutura química, principalmente através do aumento da taxa de oxidação, e nas suas propriedades físicas ou reológicas pelo aumento da rigidez.

O objetivo deste trabalho foi o estudo do envelhecimento a curto prazo, e será especialmente orientado para a avaliação de ligantes betuminosos modificados com polímeros. De facto, estes ligantes têm vindo a ser cada vez mais utilizados, mas ainda não se conhece bem a evolução das suas propriedades durante o envelhecimento.

Um betume não modificado de penetração 35/50 (B1), um betume de penetração 70/100 modificado com EVA (PmB1), e um betume de penetração 70/100 modificado com PEAD (PmB2) foram envelhecidos aplicando dois procedimentos diferentes. Num dos procedimentos os ligantes foram expostos a 75-min no ensaio de RTFOT (envelhecimento do ligante). No outro método, os ligantes foram usados para a produzir amostras de mistura betuminosa, recuperando-se os ligantes envelhecidos (envelhecimento a curto prazo da mistura e recuperação do ligante) depois de realizados ensaios mecânicos.

Para todos os ligantes, foram determinadas as propriedades reológicas de cada um dos seus estados: não envelhecido, envelhecido por RTFOT e recuperado após envelhecimento. Estes ensaios reológicos indicam obviamente um aumento na rigidez devido ao envelhecimento por RTFOT. No entanto, os resultados reológicos após recuperação apresentaram-se pouco coerentes. Daí, os ligantes PmB1 e PmB2 foram também sujeitas a ensaios de DSC de modo a tentar esclarecer estes resultados inesperados. A análise dos resultados de DSC indicou a ausência dos polímeros nos ligantes betuminosos modificados com polímero após o processo de recuperação. No entanto, a análise dos resultados FTIR demonstraram que as frações betuminosas recuperadas dos ligantes modificados foram efetivamente envelhecidas quimicamente quando as misturas foram produzidas e compactadas.

Palavras-chave: Envelhecimento a Curto Prazo, Betume Modificado com Polímero,

Table of contents

TABLE OF CONTENTS

1 INTRODUCTION ... 1 1.1 Background ... 1 1.2 Objective... 2 1.3 Study Outline ... 3 2 LITERATURE REVIEW ... 5 2.1 Bitumen Aging ... 52.1.1 Bitumen Aging Process ... 5

2.1.2 Aging Factors ... 6

2.1.3 Types of Aging... 7

2.2 Short-Term Aging ... 8

2.2.1 Simulation Methods of Short-Term Aging ... 9

2.2.2 Effect of Short-Term Aging ... 9

2.3 Bitumen Modification ... 10

2.3.1 Bitumen Modification as Anti-Aging Process ... 11

2.3.2 EVA and HDPE as Asphalt Modifying Polymers ... 12

2.4 Previous Work on Aging of Modified Bitumens ... 14

2.4.1 Laboratory and In-Situ Aging ... 14

2.4.2 Previous Methods to Evaluate Aging of Different Modified Bitumens ... 15

3 MATERIALS AND METHODS ... 21

3.1 Basic Materials ... 21

1.3.3 Aggregates ... 21

3.1.2 Binders ... 22

Table of contents

viii

Huthaifa Issam Ashqar

3.3 Testing Programme ... 24

3.3.1 Specimens Preparation ... 24

3.3.2 Volumetric Properties ... 25

3.3.3 Indirect Tensile Strength (ITS) Test ... 26

3.3.4 RTFOT Aging Method ... 27

3.3.5 Binder Recovery Method ... 28

3.3.6 Dynamic Shear Rheometer (DSR) ... 29

3.3.7 Fourier Transform Infrared Spectroscopy (FTIR) ... 30

3.3.8 Differential Scanning Calorimetry (DSC) ... 30

4 TESTS RESULTS AND DISCUSSION ... 33

4.1 Mass loss in RTFOT... 33

4.2 Volumetric Properties of Studied Mixtures ... 33

4.3 Indirect Tensile Strength (ITS)... 34

4.4 Rheological Measurements ... 37

4.5 Viscosity Results ... 40

4.6 Softening point, Penetration, and Resilience Results... 43

4.7 Differential Scanning Calorimetry (DSC) Results ... 46

4.8 Fourier Transform Infrared Spectroscopy (FTIR) Results ... 49

5 CONCLUSION ... 53

5.1 Final conclusions ... 53

5.2 Future works ... 54

List of tables

LIST OF TABLES

Table 3-1 Quantities of each material or aggregate fraction used to produce the

asphalt mixtures ... 25 Table 4-1 Volumetric properties of the studied mixtures ... 33 Table 4-2 Changes of aging index before and after aging ... 51

List of figures

LIST OF FIGURES

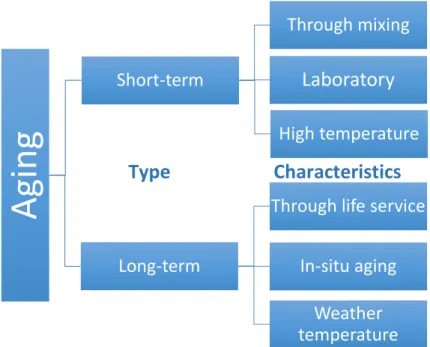

Figure 2-1 Types of aging and factors... 7

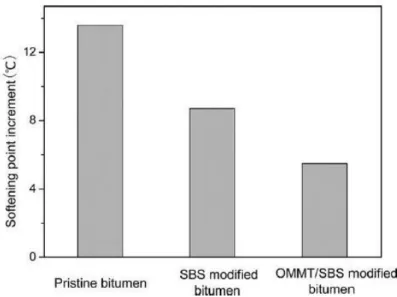

Figure 2-2 Comparison between the aging of PPA modified bitumen and pure bitumen SK70 (F. Zhang & Yu, 2010) ... 11

Figure 2-3 Softening point increment of the binders after UV aging (H. Zhang et al., 2011) ... 16

Figure 2-4 Aging indices corresponding to polymer content (B. Sengoz & G. Isikyakar, 2008) ... 16

Figure 2- MCR a d Δ“ after in situ thermal aging (Henglong Zhang, Yu, & Kuang, 2012) ... 17

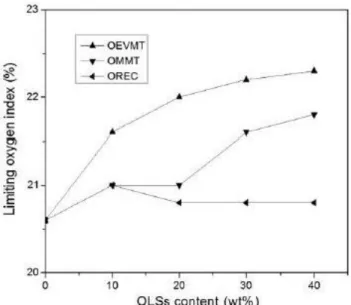

Figure 2-6 LOI variation for different flame retardants contents (Henglong Zhang, Shi, et al., 2013) ... 18

Figure 2-7 Effect of aging on the penetration ratio of bitumens with different amounts of flame retardant (Cong et al., 2010) ... 18

Figure 2-8 Viscosity ratio of three modified asphalt binders (Yin et al., 2013) ... 19

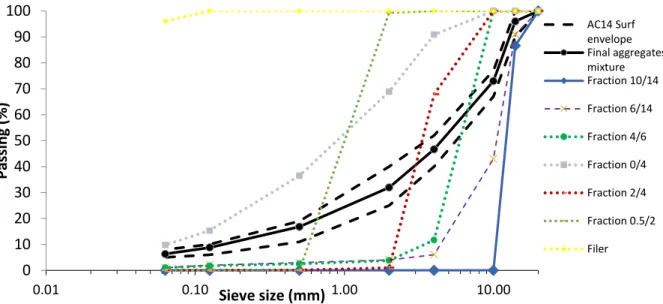

Figure 3-1 Gradation curve for AC 14 Surf mixture produced in this study ... 21

Figure 3-2 Aggregates used to produce the asphalt mixture: (a) fraction 0/4; (b) fraction 6/14 ... 21

Figure 3-3 Polymers used to modify a 70/100 bitumen: (a) EVA; (b) HDPE ... 22

Figure 3-4 High shear mixer used to produce polymer modified binders ... 22

Figure 3-5 Conventional tests specified for bitumen characterization: (a) Viscometer test; (b) Ring and Ball softening point test; (c) Penetration test; (d) Resilience test ... 23

Figure 3-6 Commercial filler used in the mixture ... 25

Figure 3-7 Indirect tensile testing frame (ITS) ... 26

Figure 3-8 Rolling thin film oven test (RTFOT) ... 27

Figure 3-9 Rotary evaporator ... 28

Figure 3-10 Dynamic shear rheometer (DSR) used in this work ... 29

Figure 3-11 Fourier transform infrared spectroscopy (FTIR) equipment ... 30

List of figures

xii

Huthaifa Issam Ashqar

Figure 4-1 Modes of failure (a) B1, single cleft failure (b) PmB1, ideal failure (c) PmB2,

localized crushing failure ... 35

Figure 4-2 Results of ITS testing of the several mixtures at 20 °C (with or without extended aging) ... 36

Figure 4-3 Results of ITS testing of the several mixtures at 40 °C (with or without extended aging) ... 36

Figure 4-4 Rheological properties of B1 bitumen (phase angle and G*) ... 38

Figure 4-5 Rheological properties of PmB1 binder (phase angle and G*) ... 38

Figure 4-6 Rheological properties of PmB2 binder (phase angle and G*) ... 39

Figure 4-7 Viscosity of B1 bitumen in the DSR and in the rotational viscometer ... 40

Figure 4-8 Viscosity of PmB1 binder in the DSR and in the rotational viscometer ... 40

Figure 4-9 Viscosity of PmB2 binder in the DSR and in the rotational viscometer ... 41

Figure 4-10 VAI values obtained with the viscosity results from DSR and from rotational viscometer ... 42

Figure 4-11 Base properties of B1 bitumen ... 43

Figure 4-12 Base properties of PmB1 binder ... 44

Figure 4-13 Base properties of PmB2 binder ... 44

Figure 4-14 SPI and PI values for B1, PmB1, and PmB2 binders ... 46

Figure 4-15 DSC curves for PmB1 and PmB2 binders ... 47

Figure 4-16 FTIR spectra analysis of B1 Binder before and after aging ... 50

Figure 4-17 FTIR spectra analysis of PmB1 Binder before and after aging ... 50

List of symbols and abbreviations

LIST OF SYMBOLS AND ABBREVIATIONS

B1 - 35/50 penetration grade binder

Def. - Indirect tensile deformation

Def.’ - Indirect tensile deformation of the mixtures with extended aging (2-hour at 163 °C) DSC - Differential scanning calorimetry

DSR - Dynamic shear Rheometer

EVA - Ethylene vinyl acetate polymer

FTIR - Fourier transform infrared spectroscopy

G* - Complex (shear) modulus

HDPE - High-density polyethylene

ITS - Indirect tensile strength

IT“’ - Indirect tensile strength of the mixtures with extended aging (2-hour at 163 °C) PI - Penetration index

PmB1 - 70/100 penetration grade EVA-modified binder

PmB2 - 70/100 penetration grade HDPE-modified binder

RTFOT - Rolling thin film oven test

SPI - Softening point index

VAI - Viscosity aging index

Vv - Void ratio

Vv’ - Void ratio of the mixtures with extended aging (2-hour at 163 °C)

ρ - Density

Introduction

1

INTRODUCTION

1.1

Background

Bitumen has recently become one of the most used materials in the worldwide industry. More than 95% is used in paving works for roads, highways, and bridges. It is used as a binder for mineral aggregate to form the asphalt mixtures. Chemically, bitumen is a complex heterogeneous mixture of hydrocarbons usually collected as a byproduct of the refining process of crude oil in petroleum refineries (Krishnan & Rajagopal, 2005).

There are various properties of the bitumen, especially rheological ones, which control the behavior of bitumen throughout mixing, construction, and in-site throughout the service life, imply the need to study the effect of aging on these properties. Like other organic substances, asphalt binder is directly affected by the presence of oxygen, ultraviolet radiation, moisture and temperature that cause aging (Araujo, Lins, Pasa, & Leite, 2013).

Thus, bitumen aging is the hardening of the material, which means changes of its chemical and/or physical characteristics. Generally, aging causes a deterioration (i.e. hardening) of asphalt binders, which leads to the decrease of its performance (especially its flexibility) and service life in road pavements. Important aging related modes of failure are traffic and thermally induced cracking, as well as raveling (X. Lu & Isacsson, 2002). Aging of the bituminous binder is manifested as an increase in its stiffness or viscosity (G. D. Airey, 2003), and this factor could be beneficial to rutting resistance of asphalt mixtures. The aging resistance of the binders is considered as one of the key factors that influence the service life of a road pavement (F. Zhang & Yu, 2010).

Thus, the aging effect on different types of asphalt binders, particularly the short-term aging effect, is an area for consideration in recent road engineering investigation. This area of research can evaluate and analyze the extent of aging effect, the behavior of different types of binder after aging, the rate of aging, the properties that could reflect this aging behavior, and the potentials of some additives to protect the asphalt binders from aging or reducing its consequences. These studies would eventually lead to a methodology of applying the

Introduction

2

Huthaifa Issam Ashqar

best production, transporting, and placing conditions to the binders, and corresponding asphalt mixtures, in order to extend their service life in roads.

In asphalt mixes for roads, most of the properties of bitumen that allow the mixtures to resist to traffic and climate actions are rheological. Bitumen is workable and homogeneous in a certain conditions. Furthermore, it should be stiff enough at high temperatures to resist rutting and remains soft enough at low temperatures to resist cracking. However, these opposite properties lead the experts to apply methods that can increase the temperature range in which the binders present adequate properties for their use in road pavements, such as using additives, namely asphalt polymer modification. The aging effect on these asphalt modified binders is less well known, and the higher complexity of these materials makes this investigation a challenge even more attractive, which should be pursued.

1.2

Objective

This study aims to investigate the short-term aging of unmodified bitumen and polymer modified bitumen. This short-term aging was evaluated on these types of binders by using two different types of aging procedures. The aging of the binders that occurs while they are exposed to the rolling thin film oven test (RTFOT), and the short-term aging of the bitumen that occurs directly in the asphalt mixture because of the mixing and compacting of the mixtures on the laboratory.

A compariso et ee the differe t i ders’ characteristics before and after aging is discussed. It is also important to determine if polymer modified bitumen has different aging processes from unmodified bitumen.

In addition, the influence of adding polymers o the i ders’ eha ior efore a d after agi g is presented, in order to assess if polymers are protecting bitumen from aging causes. Particularly, the difference between the effect of adding Ethylene Vinyl Acetate (EVA) polymer to PmB1 and High-Density Polyethylene (HDPE) polymer to PmB2 on the asphalt binder properties, before and after aging, is illustrated.

Introduction

The distinction between the RTFOT aging and the aging caused by the preparation of specimens from asphalt mixtures produced in laboratory is also a significant area of investigation in this work. Another objective of this work is to evaluate the adequacy or the extent of potential of some processes (e.g. recovery process) used during the study of asphalt aging to be used with different types of binders, while certain tests such as Fourier transform infrared spectroscopy (FTIR) are also used to complement the aging evaluation carried out.

1.3

Study Outline

This study consists of five chapters. The first chapter is the introduction, which gives a general background about the study theme and determines its objectives.

The second chapter attempts to find and present the most relevant previous-work regarding the theme of the study, namely regarding asphalt binder aging and asphalt polymer modification.

The materials used and the methods applied in this study to achieve the project's objectives are presented in the third chapter.

The fourth chapter covers the analysis and the discussion of the results obtained after the laboratorial study carried out in accordance with the methodology previously presented.

Finally, the fifth chapter reveals some essential conclusions obtained in this study and the needs of future work in this area of investigation.

Literature review

2

LITERATURE REVIEW

2.1

Bitumen Aging

2.1.1 Bitumen Aging Process

Bitumen aging is one of the principal factors causing the deterioration of asphalt pavements. In bitumen aging, two types of mechanisms are involved. The main aging mechanism is an irreversible one, characterized by chemical changes of the binder, which in turn has an impact on the rheological properties. The processes contributing to this type of aging include oxidation, loss of volatile components, and exudation migration of oily components from the bitumen into the aggregate. The second mechanism is a reversible process called physical hardening. Physical hardening may be attributed to molecular structuring, i.e. the reorganization of bitumen molecules (or bitumen microstructures) to approach an optimum thermodynamic state under a specific set of conditions (X. Lu & Isacsson, 2002).

Generally, the rheological hardening or stiffness is attributed to the asphalt compositional changes upon aging. Asphalt aging can significantly affect asphaltene and aromatic quantities, without altering saturates and resins content. Aging converts aromatic components into toluene soluble asphaltenes, which will be used as a solvent in this study. Furthermore, field aging dramatically increases total peri-condensed aromaticity as well as carbonyl and sulfoxide functional groups (X. Lu & Isacsson, 2002; Qin, Schabron, Boysen, & Farrar, 2014). This can be defined as the chemical effect of aging.

Although aging is highly studied because of its impact on the mechanical properties of the binder (hardening), it is important to continue studying this phenomenon. It was observed that all rheological indicators can be used to quantify the aging importance. In general, viscosity is mostly used as an indicator for aging, an aging index being usually defined either directly as the viscosity ratio or as the relative increase in viscosity versus time (X. Lu & Isacsson, 2002).

Bitumen structure is quite complex with slow temperature-dependent evolutions arising from molecular organization processes that are far from being fully understood. In addition

Literature review

6

Huthaifa Issam Ashqar

to that, the molecules may irreversibly evolve through chemical aging, which is generally thought to be a sum of oxidation reactions and polymerization, and to a lesser extent, lighter components evaporation. As a result, chemical aging leads to a global hardening of the material, which in turns increases the cracking probability (Lesueur, 2009).

During aging, significant decomposition of saturates and evaporation of small molecular-weight hydrocarbon were observed. Ketones and sulfoxides account for most of the oxidative reactions in the simulation of asphalt aging (Pan, Lu, & Lloyd, 2012).

2.1.2 Aging Factors

Aging leads to a hardening of asphalt, mainly due to the oxidation of the asphalt binder itself. Oxidation rate is influenced by several parameters, namely outside temperature, ultraviolet (UV) radiation and intrinsic characteristics of the mixture constituents (Lopes et

al., 2014).

One of the important and influential factors, which principally affect the in-situ aging (i.e.

long-term aging), is UV radiations. Although the influence of solar radiation on bituminous binders has been known for some considerable time, the influence of ultraviolet (UV) light on bitumen aging is often ignored in laboratory simulations of aging due to the fact that UV radiation only affects the upper layers of the pavement surfacing (Mouillet, Farcas, & Besson, 2008; Pang, Liu, Wu, Lei, & Chen; S. Wu, Pang, Liu, & Zhu, 2010; H. Zhang, Yu, Wang, & Xue, 2011). Other factors may also contribute to aging, such as molecular structuring over time (steric hardening) and actinic light (primarily ultraviolet radiation, particularly in desert conditions). Oxidation, volatile loss and thixotropic effects (steric hardening) tend to be universally accepted as the three dominant factors affecting age hardening (G. D. Airey, 2003; Lesueur, 2009).

Literature review

2.1.3 Types of Aging

There are mainly two types of aging types (Figure 2-1). The one that is primarily associated with the loss of volatile components and oxidation of the bitumen during asphalt mixture construction is called short-term aging. The other one is the long-term aging that is the progressive oxidation of the in-place material in the field. Both types cause an increase in viscosity of the bitumen and consequential stiffening of the mixture.

Figure 2-1 Types of aging and factors

Lopes et al. (2014) proposed that bitumen undergoes different types of aging, distinguished by their mechanisms, which can be classified as physical and chemical. Thus, to simulate bitumen aging, a distinction can be made between short-term aging (which occurs during asphalt mixture production and its laying down) and long-term aging (which relates to changes during the service life as a result of oxidation and UV radiation). Physical aging is a reversible phenomenon whereas chemical aging is irreversible. Chemical aging is mainly due to an oxidation process. It is generally assessed by the measurements of the sulfoxide and carbonyl chemical groups, which are created by oxidation.

Agi

ng

Short-term Through mixingLaboratory

High temperature Long-termThrough life service

In-situ aging

Weather temperature

Type

Characteristics

Literature review

8

Huthaifa Issam Ashqar

Several methods have been proposed to replicate the effect of aging and, therefore, to foresee bitumen behavior during application and service life. To simulate the age hardening occurring during plant mixing and laydown the most utilized tests are Thin Film Oven Test - TFOT (EN 12607-2 or ASTM D-1754) and Rolling Thin Film Oven Test - RTFOT (EN 12607-1 or ASTM D-2872). In both tests, the age hardening is evaluated by observing how viscosity, penetration and softening point change with aging. To simulate long-term aging during service, the Pressure Aging Test – PAV (EN 14769 or ASTM D-6521) was adopted in SHRP binder specifications, being used later transferred into other specifications. In this test, aging is evaluated by means of complex modulus (G*) and phase angle changes, determined after carrying out dynamic rheological analysis (Mastrofini & Scarsella, 2000).

However, a correlation between the short-term and long-term aging showed that the rank order of the short-term aged mixtures, in terms of their fatigue cracking resistance, did not change significantly after long-term aging. The ranking of fatigue cracking resistance of short-term aged specimens using different binders correlated well with the ranking of fatigue cracking resistance of long-term aged specimens (Arega, Bhasin, & Kesel, 2013). Nevertheless, some studies showed that reducing mixing and compaction temperatures could improve the long-term durability of the mix due to reduced short-term aging (Banerjee, de Fortier Smit, & Prozzi, 2012).

2.2

Short-Term Aging

Short-term aging is a rapid chemical aging upon mixing of the hot bitumen in a thin film around the hot aggregates. It occurs for a short time at a high temperature, typically around 160 °C, and is well simulated by the Rolling Thin Film Oven Test hi h ooks the itu e in thin moving films (1.25-mm thick) at 163 °C for 75 min. Under average processing conditions, this leads typically to a doubling of the viscosity, although the extent of hardening is bitumen-dependent and ranges typically between 1.5 and 4.0 for the viscosity at 60 °C, even though higher values are sometimes found. In the meantime, the asphaltenes content of the aged binder typically increases (Lesueur, 2009).

Literature review

2.2.1 Simulation Methods of Short-Term Aging

Tests related to the aging of bituminous materials can be divided into tests performed on the bitumen and those performed on the asphalt mixture. The most commonly used short-term binder aging tests are the high temperature TFOT and RTFOT, used to simulate the hardening that occurs during asphalt mixture production. Considerable evidence exists to indicate that the RTFOT and similar extended, high temperature, heating test methods are able to simulate short-term aging for conventional bituminous binders. However, generally, the most promising method for short-term aging of asphalt mixtures are extended heating of the loose material and extended mixing. Particularly, the RTFOT is probably the most significant modification of the TFOT involving the placing of bitumen in a glass jar (bottle) and rotating it in thinner films of bitumen than the 3.2mm film used in the TFOT. The RTFOT, therefore, simulates far better the hardening which bitumen undergoes during asphalt mixing (G. D. Airey, 2003). In addition, short-term oven aging (STOA) in the laboratory are intended to represent the aging of an asphalt binder during hot-mix asphalt (HMA) production and construction (Lee, Amirkhanian, Shatanawi, & Kim, 2008).

2.2.2 Effect of Short-Term Aging

To summarize the effect of the short-term aging, aging significantly influences bitumen chemistry and rheology. Chemical changes include the formation of carbonyl compounds and sulfoxides, transformation of generic fractions, and increases in amount of large molecules (or molecular association), molecular weight and polydispersity. As a result of those chemical changes, the mechanical properties of aged bitumens become more solid like, as indicated by increased complex modulus and decreased phase angle (Lesueur, 2009).

In addition, Lee, Amirkhanian, and Kim (2009) prepared nine asphalt mixtures (three control, three SBS-modified, and three rubber-modified) and used five short-term aging treatments in order to study the effect of short-term aging. In terms of the effects of aging on asphalt mixtures, as expected, the longer aging period and the higher aging temperature led to an increase in the large molecular size (LMS) ratios.

Literature review

10

Huthaifa Issam Ashqar

Many studies argued that short-term aging have a large effect on the rheological properties of the binders. It could lead to an increase of the viscosity, softening point, and complex modulus (G*), but on the other hand, it could decrease the phase angle and penetration (G. D. Airey, 2003; Lee et al., 2008; X. Lu & Isacsson, 2002).

2.3

Bitumen Modification

Mixing polymers into bitumen has important consequences on the engineering properties of bituminous binders. Pilot plant scale and laboratory scale mixers have been used for such unit operation. Structural and chemical changes have been observed during the processing of binders and straight bitumen. Chemical compatibility and processing conditions, such as type of mixing or dispersing device, time and temperature, are crucial to obtain the desired properties and stable compositions (García-Morales, Partal, Navarro, & Gallegos, 2006; Pérez-Lepe et al., 2003).

Yet, the mechanical properties of asphalt mixtures depend to a large extent on the type and quantity of asphalt used and hence it is imperative that a better understanding of asphalt

can be developed. Modifiers in the form of polymer, crumb tire rubber, fillers, among others, are being added to asphalt in an attempt to improve its mechanical properties. As each and every modifier can interact with asphalt in a widely different manner, the complexity in modeling the constitutive behavior of modified asphalt is increased (Krishnan & Rajagopal, 2005; Lesueur, 2009).

Generally, polymeric additives have been widely used to enhance the in-service properties of bitumen. Polymers commonly used to modify bitumen include styrene–butadiene–styrene copolymer (SBS), styrene–butadiene rubber (SBR), ethylene vinyl acetate (EVA), polyethylene (HDPE, LDPE) and waste polymers (plastics from agriculture, crumb tire rubber, among other). The characteristics of their mixing with bitumen may significantly affect the technical properties of the resulting blend, as well as the costs of the whole operation (Cuadri, Carrera, Izquierdo, García-Morales, & Navarro, 2014).

Literature review

2.3.1 Bitumen Modification as Anti-Aging Process

Most of the studies that argued the effect of bitumen modification on the short-term aging changes seem to be attempts to improve the mixtures performance in order to resist that short-term aging. They compared the characteristics, namely rheological and mechanical properties, of the modified bitumen before aging and its characteristics after aging. They also contrasted these characteristics with those of the pure bitumen. Apparently, these characteristics, such as viscosity, ductility, and softening point, are supposed to be connected to the effect of aging on asphalt materials.

Moreover, pure bitumen commonly tends to be more influenced by aging than the modified bitumen. As a case study, Zhang and Yu (2010) compared the aging of polyphosphoric acid (PPA) modified bitumen and pure bitumen (Figure 2-2).

Figure 2-2 Comparison between the aging of PPA modified bitumen and pure bitumen SK70 (F. Zhang & Yu, 2010)

The results showed that the aging reaction rate of PPA-modified asphalt was lower than that of original asphalt, the activation energy of PPA-modified asphalt was higher than that of original asphalt, and the anti-aging performance of PPA-modified asphalt was better than that of original asphalt.

Literature review

12

Huthaifa Issam Ashqar

2.3.2 EVA and HDPE as Asphalt Modifying Polymers

Many studies manifested that due to the excellent engineering property and relatively low cost, styrene–butadiene–styrene (SBS) has been widely applied in the modification of bitumen and the aging of SBS modified bitumen has also been commonly examined (Durrieu, Farcas, & Mouillet, 2007; Liu, Nielsen, Komacka, Greet, & Ven, 2014; S. p. Wu, Pang, Mo, Chen, & Zhu, 2009; H. Zhang et al., 2011). Yet, ethylene vinyl acetate (EVA) and high-density polyethylene (HDPE), which are the polymers used in this specific study, have also been used as bitumen modifiers in some studies.

Burak Sengoz and Giray Isikyakar (2008) analyzed the mechanical properties of the hot-mix asphalt (HMA) containing SBS and EVA polymer modified bitumens (PMBs) and compared them with HMA incorporating base bitumen. They found that at low polymer contents, the samples revealed the existence of dispersed polymer particles in a continuous bitumen phase, whereas at high polymer contents a continuous polymer phase has been observed. Polymer modification improved the conventional properties of the base bitumen such as penetration, softening point, temperature susceptibility, among other.

Specifically, other studies investigated the effects of both addition of commercial EVA and manufacturing mode on the performances of asphalt mixtures. Different concentrations of EVA have been incorporated either in the asphalt bitumen 80/100 or during the Hot Mix Asphalt production process. Three percentages of EVA by weight of optimum bitumen content (estimated at 6%) were considered: 3%, 5% and 7%. Softening temperature, penetration and Fraass breaking temperature tests indicate that EVA additions lead to an increase in the stiffness and thermal resistance of the binders. Moreover, it was observed that oxidative aging induces an increase in the hardness of the EVA modified bitumen (Haddadi, Ghorbel, & Laradi, 2008).

The addition of EVA to the bitumen also resulted in an increase in the zero shear viscosity and in the relaxation time of the PMB binders to be used in asphalt mixtures (Brovelli et al., 2013).

Similarly, EVA modification increases binder stiffness and elasticity at high service temperatures and low loading frequencies with the degree of modification being a function

Literature review

of bitumen source, bitumen–polymer compatibility and polymer concentration (Gordon D. Airey, 2002).

Moreover, the viscoelastic properties related to the performance of a bitumen as a binder for road pavement, are considerably improved when only 1% of recycled EVA or virgin EVA CP-636 is added to the bitumen (González et al., 2004).

In the same context, Gar ı́a-Morales et al. (2004) concluded that the viscoelastic properties of bitumen at high temperatures are improved by adding recycled EVA copolymer in amounts that depend on the bitumen penetration grade. Moreover, significant microstructural changes, related to the development of a polymer-rich phase, tend to occur in the bitumen as polymer concentration increases. These changes in microstructure have a significant influence on the flow behavior of the binder and on its in-service performance.

At the same time, Pérez-Lepe, Martínez-Boza, and Gallegos (2005) studied the influence of high-density polyethylene (HDPE) concentration on the rheological properties and microstructure of HDPE-modified binders prepared in a rotor-stator mixing device. They concluded that the addition of HDPE to bitumen enhances the mechanical properties of the binders, especially in the high-temperature region, which is mainly interesting when some pavements typically have permanent deformation problems.

Likewise, waste HDPE-modified bituminous binders provide better resistance against permanent deformations due to their high stability and high Marshall Quotient. This solution also contributes to the recirculation of plastic wastes as well as to the protection of the environment (Hı ıslıoğlu & Ağar, 200 ).

Regarding the aging effect on EVA modified bitumens, Lu and Isacsson (2000) summarized this effect using artificial aging on EVA modified bitumen and assessing the changes of its characteristics. The effect of aging on the rheology of polymer-modified binders is strongly dependent on the characteristics of polymers, and it was observed that aging increases the complex modulus and the elastic response (decreased phase angle). The temperature susceptibility is reduced by aging (Xiaohu Lu & Isacsson, 2000; Luo & Chen, 2011).

Literature review

14

Huthaifa Issam Ashqar

2.4

Previous Work on Aging of Modified Bitumens

Some significant previous attempts were made to study the aging effect on modified bitumens in different ways. In fact, various types of aging causes were analyzed, in order to understand the trends of their effect on the modified binders.

2.4.1 Laboratory and In-Situ Aging

The main concept of the laboratory and in-situ aging is the attempt to represent either the short-term or the long-term aging occurred in the field through procedures or tests in the laboratory. Various factors could affect these attempts: the different parameters of the aging process, the bitumen and aggregate type, the aging period that ought to be simulated, and the effect of the binder-aggregate interaction on the aging of the mixtures (Bell, 1989; Bell, Wieder, & Fellin, 1994; Huber & Decker, 1995; Liu et al., 2014).

In general, Bell (1989) claimed that the extended mixture heating was shown to be the most promising procedure for short-term aging, and pressure oxidation or extended mixture heating were the most promising procedures for long-term aging. He also argued that the best test methods to evaluate the effects of aging mixtures include resilient modulus, indirect tensile test, and dynamic modulus test, as well as tests on recovered asphalt.

Bell et al. (1994) demonstrated that the short-term procedure of exposing the mixtures in a forced draft oven for 4 hours at 135 °C prior to compaction is adequate for the majority of the field mixtures evaluated and conservative for some other mixtures. On the other hand, Huber and Decker (1995) claimed that curing mixtures in an oven at 85 °C for 4 days could be a procedure that represents the long-term aging occurred in projects of about 10 years old. In addition, long-term oven aging of mixtures for 2 days at 100 °C was suggested specifically for stiff mixes.

By taking into account the influence of UV radiations on the aging of SBS modified bitumen, Durrieu et al. (2007) compared between laboratory and on site aging. They concluded that the influence of UV radiation on the aging of the upper layers of surface courses of a pavement cannot be totally ignored: it occurs rapidly and after 10 h of exposure to UV

Literature review

radiation the level of oxidation is the same as that reached after an RTFOT + PAV simulation or that reached after one year of service in a pavement. Yet, another study (Liu et al., 2014) was prepared to investigate the aging properties of the SBS modified bitumen from the laboratory to the field. Results indicate that: (a) a 22-year field-aged binder had a higher viscosity than the 9-day lab-aged (short-term) binder; (b) the field-aged binder had a similar dynamic response with the 5-day lab-aged binder; (c) the Gel Permeation Chromatography (GPC) result indicated that the applied lab aging produced have originated more asphaltenes than the field aging.

2.4.2 Previous Methods to Evaluate Aging of Different Modified Bitumens

Araujo et al. (2013) studied the weathering aging of conventional asphalt binder and styrene–butadiene–styrene (SBS), hydrated lime, reactive ethylene terpolymer (RET) and polyphosphoric acid (PPA) modified asphalt binders. These modifiers represent the main compounds used to obtain improved performance from asphalt binder. The degradation of the samples was analyzed using Fourier transform infrared (FTIR) spectroscopy and thermal analysis. The styrene–butadiene–styrene, polyphosphoric acid, and hydrated lime asphalt binders showed a higher photo degradation resistance than the conventional asphalt binder for aging times up to 200 h, considering the infrared spectroscopy results.

The ultraviolet (UV) aging properties of SBS modified bitumen appears to be affected by organo-montmorillonite (OMMT). Zhang et al. (2011) observed that, as a result of UV aging, both viscosity aging index and softening point increment (Figure 2-3) of OMMT/SBS modified bitumen decrease significantly. There is a single phase trend in the morphology of the bitumen after aging, which is accelerated by the existence of SBS.

They also found in another study, as a result of UV aging, that both viscosity aging index and softening point increment of SBS modified bitumen decrease due to the introduction of another additive (Na+-MMT), which can be further reduced under the influence of OMMT. The micro-morphology of these types of binders becomes solid-like after UV aging (Henglong Zhang, Yu, & Wu, 2012).

Literature review

16

Huthaifa Issam Ashqar

Figure 2-3 Softening point increment of the binders after UV aging (H. Zhang et al., 2011)

B. Sengoz and G. Isikyakar (2008) examined the characteristics of the SBS polymer modified bitumen aging using fluorescent microscopy and conventional test methods. The results indicated that polymer modification improved the conventional properties (penetration, softening point, among other) of the base bitumen and the mechanical properties (Marshall, ITS, among other) of the corresponding mixtures. They also concluded that at low polymer contents, the samples revealed the existence of dispersed polymer particles in a continuous bitumen phase, whereas at high polymer contents a continuous polymer phase has been observed. The aging indices decrease with increasing polymer content (Figure 2-4).

Literature review

Expanded vermiculite (EVMT) clays modified bitumen can also be effectively used as a modifier to improve the aging resistance of bitumen binders. EVMT modified bitumen may form a phase-separated structure or an intercalated, and exfoliated nanostructure (Henglong Zhang, Yu, & Kuang, 2012). As a result of the thin film oven test (TFOT) and situ thermal aging, mass change rate and viscosity aging index are increased, while retained penetration and ductility of binders decreased (Henglong Zhang, Xu, Wang, & Yu, 2013). The variation of the different EVMT modified bitumen characteristics, like mass change rate (MCR) and softening point increment Δ“ after in situ thermal aging comparing with unmodified bitumen is shown in Figure 2-5.

Figure 2-5 MCR and Δ“ after in situ thermal aging (Henglong Zhang, Yu, & Kuang, 2012)

Moreover, flame retardant can also improve the aging resistance of asphalt binders (Henglong Zhang, Shi, Han, & Yu, 2013). The flame retardancy of asphalt binder increased after the RTFOT and PAV. The increasing amount of limiting oxygen index (LOI) decreased with the flame retardants contents increasing (Figure 2-6).

The softening point and viscosity of asphalt binder increased and penetration and ductility of asphalt binder decreased after two different types of aging procedures. Figure 2-7 shows the decrease of penetration after these two types of short-term and long-term aging (Cong, Chen, Yu, & Wu, 2010; Henglong Zhang, Shi, et al., 2013).

Literature review

18

Huthaifa Issam Ashqar

Figure 2-6 LOI variation for different flame retardants contents (Henglong Zhang, Shi, et al., 2013)

Figure 2-7 Effect of aging on the penetration ratio of bitumens with different amounts of flame retardant (Cong et al., 2010)

The effect of organic layered silicate on microstructures and aging properties of SBS copolymer modified bitumen have also been investigated. Organic layered silicate SBS modified bitumen shows the lower viscosity-aging index and the higher retained ductility. In addition, the influence of organic layered silicate on these physical properties of SBS modified bitumen before and after aging depends on its nature (Henglong Zhang, Zhu, Tan, & Shi, 2014).

Literature review

Finally, a study concerning the use of crumb rubber modified bitumen (CRM) is also presented. In general, the CRM binder partially loses its proportional elastic contribution at higher temperatures, but such elastic contribution remains much higher than that of unmodified binders (Mturi, O'Connell, Zoorob, & Beer, 2014). But with regard to the loss of the penetration, softening point, ductility, viscosity, and weight loss, the crumb rubber waste radiated by microwave and impregnated in epoxidized soybean oil (CRIMIESO) modified asphalt was relatively less than CRM, indicating its relatively stronger performance, namely concerning its resistance to aging (Yin, Wang, & Lv, 2013). The results of the viscosity tests of the three modified asphalts are illustrated in Figure 2-8.

Figure 2-8 Viscosity ratio of three modified asphalt binders (Yin et al., 2013)

After presenting several previous works concerning the main topics of this research, it was possible to define in more detail the materials to be studied and the test methods to be used. That information is presented in the next Chapter of this thesis.

Materials and methods

3

MATERIALS AND METHODS

3.1

Basic Materials

3.1.1 Aggregates

The type of aggregates used in this study was a natural aggregate from granite rocks, which is commonly used in the north of Portugal. Figure 3-1 shows the gradation curve of the different sizes or fractions of aggregates (Error! Reference source not found.) used to produce the studied mixture, as well as the AC 14 Surf specification envelope and the final gradation used in the mixture.

Figure 3-1 Gradation curve for AC 14 Surf mixture produced in this study

Figure 3-2 Aggregates used to produce the asphalt mixture: (a) fraction 0/4; (b) fraction 6/14 0 10 20 30 40 50 60 70 80 90 100 0.01 0.10 1.00 10.00 Pa ss in g ( %) Sieve size (mm) AC14 Surf envelope Final aggregates mixture Fraction 10/14 Fraction 6/14 Fraction 4/6 Fraction 0/4 Fraction 2/4 Fraction 0.5/2 Filer

Materials and methods

22

Huthaifa Issam Ashqar

3.1.2 Binders

In this study, the following straight bitumen (B) and polymer-modified bitumens (PmB) were used to study the short-term aging effect:

B1: a 35/50 penetration grade bitumen typically used in road construction supplied by CEPSA company in Portugal.

PmB1: a 70/100 penetration grade bitumen supplied by CEPSA company in Portugal. According to previous studies, this bitumen was modified by adding 5% of ethylene vinyl acetate (EVA) polymer with a grain size of 4 mm (Figure 3-3). This was manufactured in the laboratory by using a high shear mixer (Figure 3-4) at 7200 rpm and a temperature of 165 °C for 20 minutes.

Figure 3-3 Polymers used to modify a 70/100 bitumen: (a) EVA; (b) HDPE

Materials and methods

PmB2: a 70/100 penetration grade bitumen from CEPSA Company in Portugal. Again, and according to previous studies, this bitumen was modified by adding 5% of high-density polyethylene (HDPE) polymer with a grain size of 4 mm (Figure 3-3). This was manufactured in the laboratory by using a high shear mixer (7200 rpm) at a temperature of 170 °C for 20 minutes.

3.2

Methodology Overview

The properties of the three binders before aging (unaged binders) were characterized (B1, PmB1, and PmB2) by carrying out the conventional binder specification tests, namely penetration (EN 1426), ring and ball softening point (EN 1427), resilience (EN 13880-3), and viscosity (EN 13302) tests according to EN 12591 and/or EN 14023 specifications (Figure 3-5).

Figure 3-5 Conventional tests specified for bitumen characterization: (a) Viscometer test; (b) Ring and Ball softening point test; (c) Penetration test; (d) Resilience test

Subsequently, Rolling Thin Film Oven Test (RTFOT) was applied for 75 minutes at 163 °C to age the three binders. Yet again, penetration, resilience, ring and ball, and viscosity tests were carried out to characterize the rheological changes of the three aged bitumens.

Moreover, each one of the three different unaged bitumens (B1, PmB1, and PmB2) was used to produce hot asphalt mixtures at 165 °C temperature. Six specimens of each asphalt mixture were then compacted using the Marshall compactor (EN 12697-30), which were

Materials and methods

24

Huthaifa Issam Ashqar

later tested using the indirect tensile strength test (EN 12697-23) at 20 °C and 40 °C (three specimens at each temperature). Afterwards, each type of binder used in the three asphalt mixtures was recovered and, once again, the conventional binder specification tests were conducted to obtain the changes of the basic properties of the three recovered bitumen.

Consequently, the rheological changes for all the states (unaged, RTFOT aged, and recovered from mixtures after short-term aging) of the three studied bitumens were tested by using the Dynamic Shear Rheometer (DSR) test (EN 14770).

The aging was additionally evaluated using Fourier transform infrared spectroscopy (FTIR) for the three binders (B1, PmB1, and PmB2) for the unaged binders and after they are exposed to RTFOT, as well as after the recovery process.

The differential scanning calorimetry (DSC) was also applied to determine the thermal behavior (transition or melting temperatures) of B1, PmB1 and PmB2 in their different states: unaged, after RTFOT, and after recovery process. However, it was essentially used to determine the presence of the polymers in PmBs after the recovery process.

Finally, it is suggested to expose the same mixtures to an extended curing temperature of 163 °C for two hours (all their results are de oted ’ ). This method was recommended to roughly characterize the long-term aging changes on the exposed binders. Six specimens were compacted for B1, PmB1, and PmB2 after that curing time, following the procedures previously presented for the mixtures without extended aging time. The voids ratios of the specimens were obtained and they were also evaluated in the indirect tensile strength test.

3.3

Testing Programme

3.3.1 Specimens Preparation

A continuous grading Hot-Mix Asphalt (HMA) AC 14 Surf (Figure 3-1) was selected as being the most common mixture in Portugal, to manufacture eighteen Marshall specimens using the three different types of binders (B1, PmB1, and PmB2) mentioned previously (six samples for each binder). The HMA had a maximum aggregate size of 20 mm and 2.5% limestone commercial filler content (Figure 3-6).

Materials and methods

Figure 3-6 Commercial filler used in the mixture

Asphalt specimens of 102 mm in diameter and an average height of 60.3 mm were manufactured with binder content of 5% of the total weight of the mixture. The mixtures were produced at a mixing temperature of 165 °C, being mixed for two minutes, and compacted with a typical number of 75 blows on each side of the specimen (Table 3-1).

Table 3-1 Quantities of each material or aggregate fraction used to produce the asphalt mixtures

Fraction (mm) Material used (%) Weight (g)

10/14 10.5 × 95.0 1893 6/14 29.0 × 95.0 5227 4/6 11.0 × 95.0 1983 0/4 36.0 × 95.0 6489 2/4 8.0 × 95.0 1442 0.5/2 3.0 × 95.0 541 Commercial filler 2.5 × 95.0 451 Bitumen 5.0 949 Total 100.0% 18974 3.3.2 Volumetric Properties

The maximum theoretical density (���) and the air voids content (� ) for the all specimens were obtained to study the volumetric properties of the specimens. These values were found by using the saturated surface dry (SSD) water displacement method (EN 12697-6, 2012).

Materials and methods

26

Huthaifa Issam Ashqar

3.3.3 Indirect Tensile Strength (ITS) Test

The correlation between the deformation of the specimens and the indirect tensile strength was assessed at two temperatures: 20 °C and 40 °C (in order to evaluate the performance at medium and high in-service temperatures, at which cracking or rutting problems typically occur). These values were obtained by using the Indirect Tensile Strength test (ITS) at a loading rate of 50 mm/min since the specimens were laboratory-fabricated (Figure 3-7).

Figure 3-7 Indirect tensile testing frame (ITS)

Eighteen specimens were tested, being each six of them for one type of binder (B1, PmB1, and PmB2), and then each three of the six were tested at each test temperature. In this case, the deformation and the indirect tensile strength are denoted by def. and ITS respectively.

However, this process was then repeated in another eighteen specimens produced and compacted after the mixtures were exposed to an extended curing temperature of 163 °C for t o hours those results are de oted def.’ a d IT“’ . This ethod as re o e ded to roughly assess the mechanical changes on the exposed binders after long-term aging of the asphalt mixtures.

The reason why the ITS was carried out also at a temperature of 40 °C (not typically used in this type of test) is that it could be interesting to assess the deformation and indirect tensile strength for the mixtures with the polymer-modified binders (PmB1 and PmB2) at high

Materials and methods

temperatures, because it might be significant to evaluate the rut resistance of the corresponding HMA mixtures (HA, 2011). Furthermore, the temperature of 40 °C was selected to represent the strength of the mixtures at high temperatures and below the softening point of the conventional bitumen.

3.3.4 RTFOT Aging Method

As mentioned before, the Rolling Thin Film Oven Test (RTFOT) (Figure 3-8) was applied for 75 minutes to age the three binders, simulating the short-term aging according to the standards (EN 12607-1, 2007). Many studies have claimed the validity of using RTFOT to age unmodified bitumen. Yet, using RTFOT to age modified bitumen still open in doubt (Mouillet

et al., 2008). However, because it appears that there is no better method to simulate

short-term aging for modified binders, RTFOT was used in this study to simulate the short-short-term aging of B1, PmB1 and PmB2. The mass loss of the binder, after it is exposed to RTFOT, was determined by weighting two samples of binder before and after RTFOT.

Figure 3-8 Rolling thin film oven test (RTFOT)

The RTFOT was developed by the California Division of Highways and involves rotating eight glass bottles each containing 35 g of bitumen in a vertically rotating shelf, while blowing hot air into each sample bottle at its lowest travel position. During the test, the bitumen flows continuously around the inner surface of each container in relatively thin films of 1.25 mm at

Materials and methods

28

Huthaifa Issam Ashqar

a temperature of 163 °C for 75 min. The vertical circular carriage rotates at a rate of 15 revolutions/min and the airflow is set at a rate of 4000 ml/min. The method ensures that all the bitumen is exposed to heat and air and the continuous movement ensures that no skin develops to protect the bitumen (G. D. Airey, 2003).

3.3.5 Binder Recovery Method

According to EN 12697-3 (2013), the extraction method used in this study was the separation by centrifuge using the toluene as a solvent. Afterwards, the rotary evaporator was used in the vacuum distillation process to separate the binder from the solvent at a maximum temperature of 150 °C (Figure 3-9).

Figure 3-9 Rotary evaporator

These recovered aged binders were tested after that process to characterize viscosity, penetration, ring and ball softening point, and resilience, as well as rheology in the DSR, DSC and FTIR. These results will be used to understand the changes caused by aging in the bitumen recovered from mixtures after the short-term phase of production and compaction, which is also important for comparison with RTFOT results.

Materials and methods

3.3.6 Dynamic Shear Rheometer (DSR)

According toEN 14770 (2012), this test in the DSR (Figure 3-10) is used to compare the rheological behavior of the different binders before aging, after RTFOT aging, and after asphalt binder recovery from the short-term aged mixtures produced in laboratory. The temperature dependency (19 - 88 °C) of the phase angle, of the complex shear modulus (G*), and of the complex viscosity of the several binders under evaluation was studied in this phase of the work.

Figure 3-10 Dynamic shear rheometer (DSR) used in this work

This test applies the most commonly used method of fundamental rheological testing of bitumen, which is the means of dynamic mechanical analysis (DMA) using oscillatory-type test within the region of linear viscoelastic response (Luo & Chen, 2011). Measurements of the rheological properties were conducted in a strain controlled rotational DSR with parallel plate sample geometries of 25 mm diameter and 1 mm gap for the temperatures within the range of 46 to 88 °C, and sample geometries of 8 mm diameter and 2 mm gap for the temperatures within the range of 19 to 40 °C.

Materials and methods

30

Huthaifa Issam Ashqar

3.3.7 Fourier Transform Infrared Spectroscopy (FTIR)

FTIR is used to measure the infrared (IR) light absorbed by the material (Figure 3-11). The samples should be prepared according to EN 12594 (2007). Five percent by weight solutions of bitumens were prepared in carbon disulfide and tested in the spectral range between 4500 and 400 cm-1 with steps of approximately 1 cm-1 (BRRC, 2013).

Figure 3-11 Fourier transform infrared spectroscopy (FTIR) equipment

Results of FTIR were analyzed to evaluate the aging of the binders after RTFOT and after the recovery process. Two peaks centered around 1,700 cm-1 and 1,030 cm-1 were determined

for the oxidation of bitumen because of aging: the first peak corresponds to carbonyl functions, whereas the second one characterizes sulfoxides (Lamontagne, Dumas, Mouillet, & Kister, 2001; X. Lu & Isacsson, 2002; Mouillet et al., 2008; S. p. Wu et al., 2009; F. Zhang, Yu, & Han, 2011).

3.3.8 Differential Scanning Calorimetry (DSC)

Differential Scanning Calorimetry (Figure 3-12) is a technique used to determine the change of the difference in the heat flow rate (Höhne, Hemminger, & Flammersheim, 2003), typically associated with transition temperatures of the material. DSC can be used to characterize the thermal behavior of pure bitumen as well as the thermal behavior of

Materials and methods

modified bitumens, by indicating the presence of specific crystalline components in the PMBs (Gordon D. Airey, 2002).

Figure 3-12 Differential scanning calorimetry (DSC) equipment

However, in this study, this technique was mainly used to determine the presence or absence of polymers in the binders (EVA and HDPE, respectively in PmB1 and PmB2) after the recovery process. According to ISO 11357-4 (2014), the heating and cooling rate to apply during the test should be 10 °C/min. It is also recommended to run a sample twice in DSC. Each sample is heated and cooled, and then the sample is heated again to obtain the DSC curve for analysis (Leng, 2013). From this technique, the values of temperature (°C) and heat flow (mW) can indicate the presence of polymers in the binder after the recovery process (only if the polymer melting-point in the DSC curve of the recovered bitumen is similar to that of the polymer modified bitumen used to produce the corresponding mixture).

Tests results and discussion

4

TESTS RESULTS AND DISCUSSION

4.1

Mass loss in RTFOT

The mass loss of the binder was measured after exposing of two samples of binder to the RTFOT test. This test does not evaluate the real performance of the binder after aging, and thus it was decided to carry out this test only in binder PmB2 to have a general idea of its value for a polymer modified binder (an average value of 0.27 % was found for the mass loss). Some specifications recommended that the mass loss should not be more than 1.0 %, and thus the obtained value is not considered high (HA, 2011). This means that this binder might not be exposed to excessive age hardening, shrinkage and cracking since that a low amount of light oil is being volatized during RTFOT (HA, 2011).

4.2

Volumetric Properties of Studied Mixtures

The volumetric properties of the asphalt mixtures are vital as they are related to the mixture performance. It has been indicated that a higher air voids content lead to a higher rate of aging process and water sensitivity and, consequently, a less durable mixture (Kandhal, 1996). This implies that volumetric properties have a significant influence on the service life of asphalt mixtures.

As shown in Table 4-1, the results of the volumetric properties indicates a higher maximum theoretical density (ρth) for polymer modified binder mixtures (PmB1 and PmB2) than the

unmodified binder mixture (B1). In addition, the average air voids for PmB2 mixture is the highest in comparison to the PmB1 and B1 mixtures.

In fact, it has been presumed that a mixture of a high density implies a low air voids (Mallick & El-Korchi, 2013), and this was generally observed in this work. In the case of PmB2 mixture, the air voids values are relatively high, and this may be caused by the higher viscosity of this binder at higher temperatures due to the use of HDPE (the used polymer with higher melting temperature), which may be hampering the compaction of this mixture.

Tests results and discussion

34

Huthaifa Issam Ashqar

Asphalt mixture with binder: B1 PmB1 PmB2

ρth (kg/m3) 2501.7 2508.2 2508.5

ρ (kg/m3) 2361.6 2375.3 2342.9 ρ' (kg/m3) 2351.6 2337.6 2322.9

Average Vv (%) 5.6 5.3 6.6

Average Vv’ (%) 6.0 6.8 7.4

The density of the polymers (ρHDPE = 0.95 to 0.97 g/cm3 (Chen, Chen, & Hsu, 2006) and ρEVA =

0.90 g/cm3 (Simpson et al., 1997)) used to modify the binders have a small influence, due to

the small amount of this material in the final mixture (only 0.25 %).

The volumetric results indicate that the durability of the PmB1 mixture is expected to be the best one in comparison with B1 and PmB2 mixtures, since it has the highest density and the lowest air voids (at least before the extended curing time in the oven). In turn, the lower density of the PmB2 mixture may increase the potential of aging and hence increase the potential of fatigue deterioration, as mentioned by Mallick and El-Korchi (2013).

Table 4-1 also shows the specimens results of the voids ratio after they have been additionally hardened at a temperature of 163 °C for an extended curing time of two hours. Results show that the voids ratios were considerably increased when the mixtures become stiffer. The highest rate of increase was in PmB1, even though it has only increased to a void ratio value similar to that of PmB2 before the two-hour of hardening.

4.3

Indirect Tensile Strength (ITS)

ITS is a test that applies an axial force to characterize the stress-strain relation of an asphalt material. It is typically used to characterize the resistance of the hot mix asphalt (HMA) to the low-temperature cracking. However, it may also be used to evaluate the quality of the mixtures and assess its potential for cracking and rutting (Christensen & Bonaquist, 2004). There are some factors that may affect the test results: size and dimensions of the specimen, composition and dimensions of the loading strip, rate of loading, load-deformation characteristics of the material tested, and testing temperature. The first three factors are considered constant in this study.

Tests results and discussion

The most frequent modes of failure of each type of specimens after the two-hour hardening (used to roughly simulate the long-term aging) are given in Figure 4-1.

Figure 4-1 Modes of failure (a) B1, single cleft failure (b) PmB1, ideal failure (c) PmB2, localized crushing failure

These modes of failure indicated the way that the tensile stress distributed along the sample. The failure in B1 mixtures occurred on the bottom side of the cylinder which was the side loaded with the moving head of the machine. A shear failure is approximately intersecting the loaded diameter in PmB1 (which is the ideal failure, with an additional transversal contribution of the binder to the mixture strength), in addition to a localized crushing with ultimate failure in tension in the case of PmB2 (Hudson & Kennedy, 1968).

As Figure 4-2 and Figure 4-3 sho , the results of IT“’ after extended aging (long-term aging), either at 20 °C or 40 °C, are higher than those of ITS just after mixing (short-term aging) since the mixtures were additionally hardened when exposed to a temperature of 163 °C for two hours. When the mixtures were hardened, they become stiffer but more brittle. Consequently, at 20 °C, the results of def.’ de reased after that additional hardening except for PmB1. At 40 °C, the result of def.’ only decreased in the case of PmB2, hilst def.’ increased for B1 and PmB1. Whatever the case, it appears that the base binder used to produce the PmBs is more decisive at the temperature of 20 °C, whereas the importance of the polymer in ITS tests is mainly shown at higher temperatures (40 °C) or when the