The theoretical basis for this research lies in Supply Chain Management and in more detail in transportation management. These results show that it is possible to create new ways of logistics operation in the Pirkanmaa region and that organizations are ready for a change.

Thesis outline

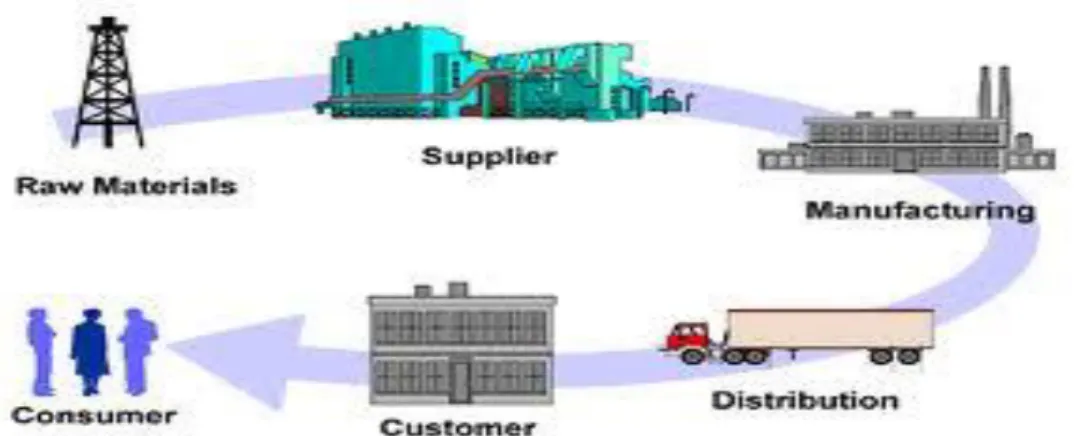

It takes a lot of planning and management to reach the end goal; fulfilling the customer's order. In supply chain management (SCM) finding the most efficient ways to manage and control the flow of goods is at the heart of the whole process.

Research background

Tapaaminen järjestettiin Tampereen Logistiikka Liikelaitoksen toimitusjohtajan Rek Martin, logistiikkajohtaja Erkki Harjun, Anasse Bouhlalin ja opinnäytetyön tekijöiden välillä. Samana päivänä pidettiin informatiivisempi tapaaminen opinnäytetyön tekijöiden ja Tampereen Logistiikka Liikelaitoksen edustajien välillä.

Research objectives

Members of these organizations were invited to a meeting to explain the topic of the research and its goals and objectives. At the meeting, it appeared that representatives of these four organizations were enthusiastic about this research, although the potential change to the current system was a little scary for some.

Research methods

Discussions with companies

This gave them more insight into the research, but also opened up the topic for detailed questions. Most of the information for the theory part was found from books and only a small amount of internet research was needed.

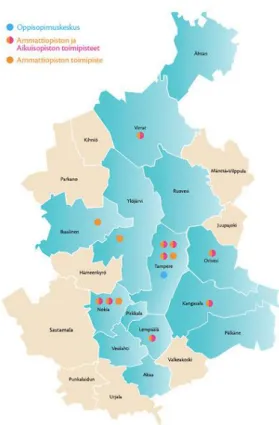

PIKI

PIKI libraries

Tampereen aluepelastuslaitos (ALPE)

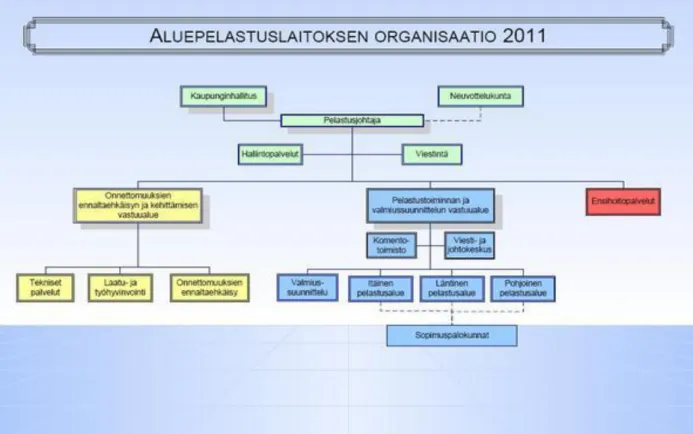

The organization

Their main tasks are accident prevention, actual rescue work and emergency forecasting. These plans cover all actions that can take place on land, water, anywhere, anytime.

Rescue work

The rationalization of the rescue activity is based on knowledge, awareness and dimensioning of the risks in the intervention area. The improvement of the safety culture is one of the core ideas of ALPE's functions.

Voluntary fire department

The proposed alerting proposals, which enable the best possible outcome of the rescue operations, are based on the mapping of the risks. One of the most important future goals for ALPE is to direct more momentum into accident prevention.

PIRKO

FIMLAB Laboratoriot Oy

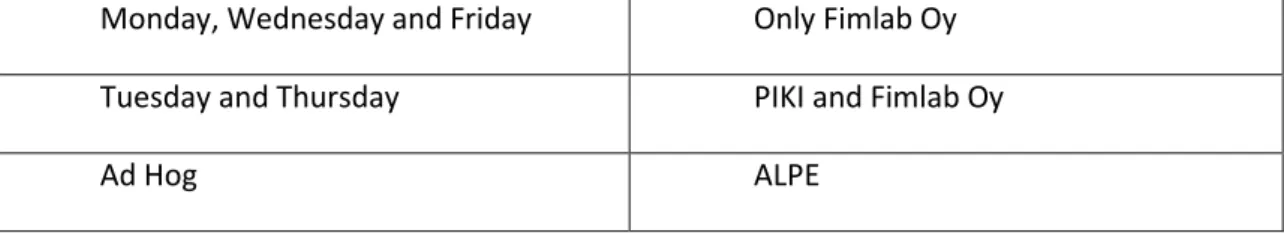

Current situation

This means that if the samples are not tested within 4 hours, the sample will be unusable. The time window is important because if samples are not tested within four (4) hours, they will spoil and become unusable.

Tampereen Logistiikka Liikelaitos

The time the sample needs to be sent to the laboratory varies because samples are not treated with chemicals in the Tampere and Nokia region. If we were to add for example some libraries to the route that could compromise the four hour time window that is crucial for samples.

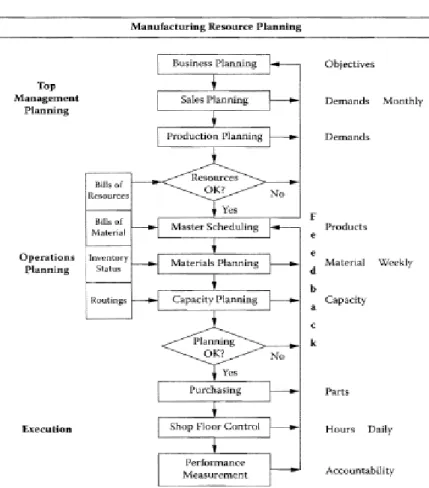

Supply Chain Management (SCM)

The key objectives of SCM

The flows of the SCM

Physical flow

Information flow

Financial flow

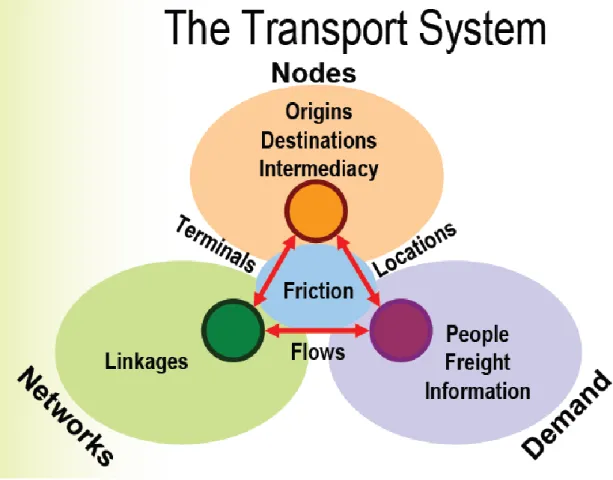

Transportation management

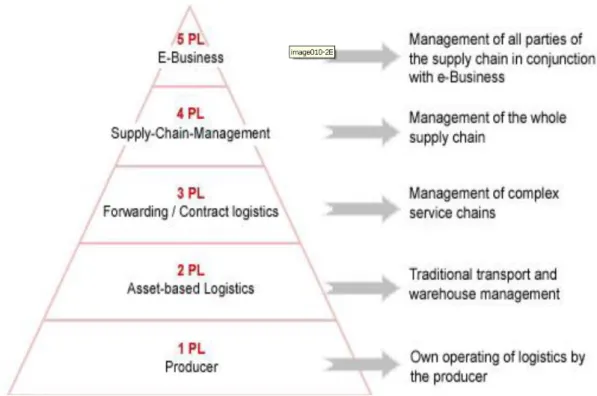

The rental business is booming and there are big and small actors in the Tampere region in this industry. The for-hire trend arose when logistics managers noticed that it was more efficient to order the transport service for goods from a company specialized in this type of function, rather than having large, heavy and expensive cars and drivers for them for sale.

Economic drivers in transportation

Road has been chosen because freight transport will be inland, and there are neither reasonable waterways nor railways to be used. Also, the distances are not that long, and the deliveries must be delivered to the customers' door, so the truck is the best solution.

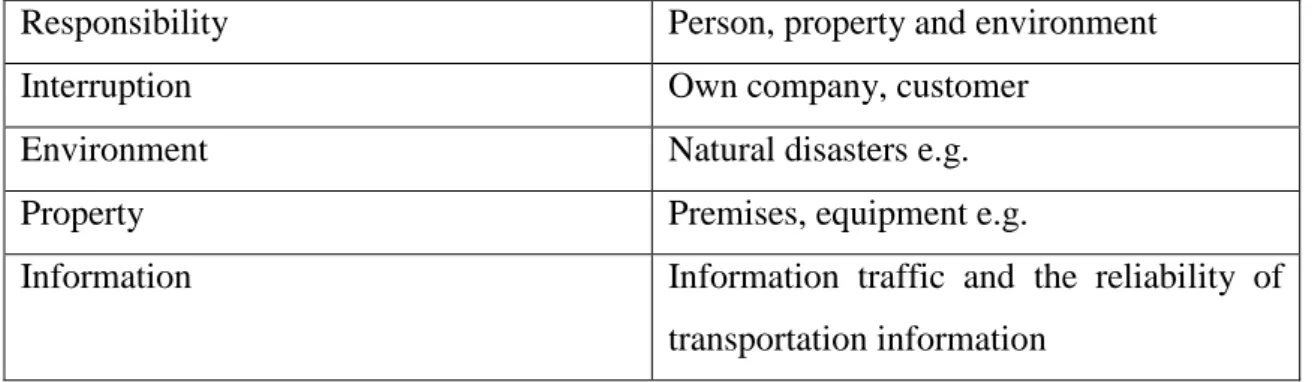

Transportation risk

This means that if the liability is bad, it will lead to customer dissatisfaction and damage claims. Handling is one of the lesser factors in this research as the goods do not require any special handling devices compared to, for example, heavy items.

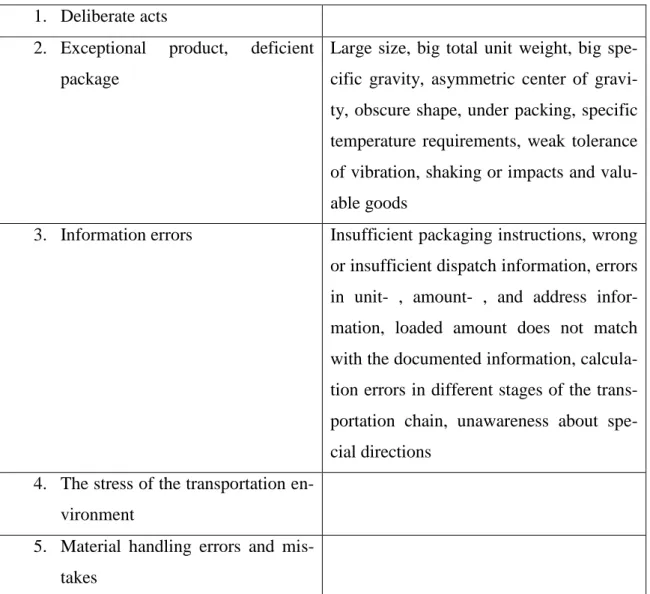

Transportation damages

There are many risks in the transport system and the probability of damage also varies between goods, transport routes and means of transport.

Transportation planning

Selecting the transportation route

Traffic Traffic flow can affect the route due to congestion.

Selecting the transportation method

PL’s

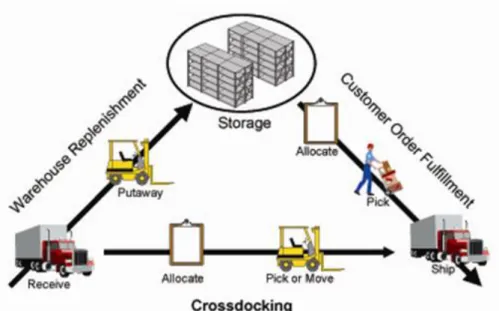

Cross docking

Push and pull strategy in logistics

What is push strategy?

In today's market it is sometimes difficult to know what will happen in the coming months. If the company fails to sell the manufactured and manufactured products, they will certainly remain in the inventory.

What is pull strategy?

The push-pull system

Lean logistics

What is lean logistics?

Speaking of lean logistics, nothing is more important than minimizing waste. This way of thinking and acting in the supply chain focuses on the flow of value to the end user, the elimination of waste from all processes, the tailoring of the resources (machinery, material, people, time, etc.) and the providing the tools to help people continuously improve their work.

The advantages of lean logistics

Five lean principles

It starts when a customer places an order for a desired product until the customer receives that same product. When mapping the value stream used to perform this step, you create a “one-sided picture”. For this second principle, managers really need to think about the whole picture and define all the steps. In this third principle of lean, the ultimate goal is a one-piece flow that eliminates all non-value-added activities, which is the whole idea of lean logistics.

After removing a few layers of waste, companies tend to slow down in terms of improvement.

Purchasing

- The purchasing cycle

- The main objectives of purchasing

- The change in purchasing

- The strategical role of purchasing

Nowadays, the purchasing department can also be responsible for establishing long-term relationships with customers, questioning their needs, but also the needs of suppliers. The purchasing department can also contribute a lot to the strategic success of the company. If the company was successful in this development project, it could lead to a reduction in development times for new products, because suppliers were already involved in the earlier stages.

Because procurement has taken place in many different areas, it can be helpful in making important business decisions.

Quality management

The Baldrige criteria

Effective strategic and business planning and deployment of plans, with a strong focus on customer requirements and operational performance. How the company determines customer and market requirements. and expectations enhance customer relationships and determine customer satisfaction.

Total Quality Management (TQM)

They are the ones who work on the production line, which means they are the first to notice if something goes wrong and the product is defective.

Quality inspections in the supply chain

In this way, the company can save money on raw materials and reduce the total downtime of the production process. When the products come off the production line, i.e. they run out, they must be inspected again. The company has its own quality standards, which the customers are sure to know about, so no goods can be transported without quality control.

In this way, the company can ensure that the finished goods can still be sent to the customer.

Logistics tools for transportation purposes

- Process for using logistics tools (example ArcLogistics)

- Why ArcLogistics?

- Meetings and discussions

- With PIKI

- With ALPE

- The 20 th of April 2012, Nokia

- The 4 th of May 2012, Hämeenkyrö

- With Fimlab Oy

- With PIRKO

The system requires constant maintenance, and it must have a centralized unit of responsibility - the host of the contract. This part of the research analyzes the organizations logistics needs and current systems they use. Plus, sorting the items into the locations this way would take much longer, and it wouldn't work with the tight schedule.

At the start of the meeting, they were asked how they deliver their house mail.

Findings

- Fimlab

- PIKI

- The new, combined route

- Tendering

- Allocation of the costs

There are several organizations in the operational district of Kuopio, and this should also be the goal in Pirkanmaa. If necessary, Tampereen Logistiikka will adjust the previously mentioned matters in a form that will satisfy both parties. The proposal is for Tampereen Logistiikka to take control of those matters and become the principal settler of the carrier's transport agreement.

Agreement will be made on how the costs of the regular transport will be allocated, and how the irregular posts affect the allocation.

Routing requirements

Demands for the delivery vehicle

The Fimlab representative informed us that the delivery vehicle must maintain room temperature at the loading location. They also want to have surveillance equipment in the cargo hold so they and the driver can monitor temperature changes in the "tagon." They said the luggage or container should be dry and dust-free because the goods being transported can easily collect moisture or dust that can affect the air conditioning systems in the destination libraries.

Later on, the moisture and dust could also form mold that would further damage the goods.

Planning the new routes

Talks were held with PIKI and ALPE representatives and the only real request came from PIKI. The biggest transport risk in the routing system is ensuring that the samples arrive at the main Fimlab laboratory within a 24-hour time window. This is not a problem in the routing system, as the longest driving path was clearly faster than the largest time window.

The best possible direction would have been completely different and the roads would have been very different from the old ones.

New routes

Model for the new operation structure

Pricing

Pricing by the distance travelled

Fixed cost per drop-off

The prices for deliveries in the area are different from those for transport to the further regions of Pirkanmaa. However, this is a fair way of thinking because fuel costs are naturally higher as the distance increases.

Figure 25. SWOT-analysis of fixed cost per drop-off

Routing scheduling using ArcLogistics

Using ArcLogistics

Right click on “vehicles” Open “new vehicle” Vehicle Properties box opens Add the information you need for your project. Right click on “Routing folders” from main menu Open “New routing folder” Add necessary information Click “Next”. In the other box we don't have to change anything because the settings are correct and suitable for us.

Also, check that all the fields from the used excel file are in the box.

Result meeting 11.9.2012

Recently, it was discussed what the management structure of this system should be. This is due to the fact that none of the organizations wanted the responsibility of handling all operations including this system. Of course this means added expenses for this system, but the representatives were not worried about that.

Erkki Harju also mentioned that the transport company will ultimately decide how they will drive the given route. They may have other interruptions along the route that they would also handle for the other companies outside of this system. As a result, it was proven that with careful and professional planning, the help of logistics software and evaluating the needs of the organizations, it is possible to create well-functioning synergies.