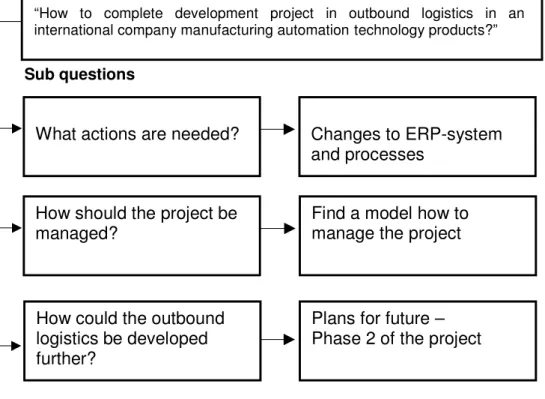

Another goal was to plan what could be done in the future to further develop outbound logistics. This thesis also provides suggestions for what could be done in the future to develop outbound logistics processes in the company.

Background

The power of logistics in achieving an organization's customer service goals and supporting customer satisfaction has received increased attention in the press. The development project has not proceeded as planned, and there have been many problems and errors that must be corrected before implementation.

The objectives and limitations of the study

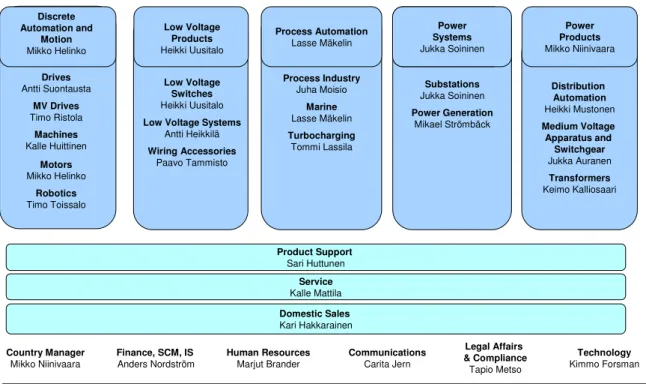

This thesis was commissioned by ABB's System Modules unit, but the development project is common to all ABB Drives' units. This thesis will deal with the development project as a whole and also the issues that are specific to System Modules unit.

Research questions of the study

The measures for further development are proposals that could be investigated further after the first phase of the project has been successfully completed. In this thesis, reference to ABB means ABB Drives unit in Helsinki, not the entire ABB group.

Research methods

Case study

In a case study, the subject of research is usually practical actions, a process in certain circumstances, for example in an organization. Typical characteristics of a case study are data collection in natural settings, data collection methods are humane, such as interviews, observations and various written documents, the research is descriptive and does not aim to quantify the data collected, the research focuses on processes.

Quantitative analysis

The results of the research process are the finding of connections between different phenomena, or the development of new concepts or deeper understanding of the research object.

Theoretical framework of the study

ABB

Drives

Due to growth in recent years, Drives has become more global and has established manufacturing facilities around the world.

System Modules

The structure of the study

Logistics is not just a "money saving" operation; it is an important part of the customer-oriented service strategy. Communication problems and IT opportunities are also often taken into account when aiming for more accurate planning and control at different stages of the order-delivery chain.

Developing logistics processes

Developing logistics is mainly about developing cooperation both within the company and with suppliers and customers. The ways associated with process control to achieve the goals differ significantly from previously used ways.

ICT systems in logistics

Outsourcing logistics

Staffing issues if staff are moving to an external contractor. companies, poor communication and lack of control are other typical problems. Outsourcing cannot be left to the responsibility of an external company; the external contractor must be actively involved in the project.

RFID Technology

Utilization of RFID Technology

Capturing and integrating data about an item's location and history in the supply chain can help create a more efficient workflow and error-free processes. The more processes in the supply chain that can be integrated through RFID-collected data, the greater the potential for efficiency improvement. Connecting these to all business and integrating all processes in the supply chain is the challenge for the coming decade.

Implementing RFID technology

Most of the current RFID enabled supply chain solutions look at applying RFID between only two points (just one link) in the chain, recognizing the full integration of the links in the supply chain as the true value liberator. While RFID is a natural enabler for supply chain integration, several intermediate issues must be addressed before RFID can realize its full potential in the supply chain: (Bhuptani & Moradpour 2005, pp.21-22). Serialization Most supply chain processes and applications today are designed to work with barcode technology.

Benefits of RFID

It should be understood that the business benefits promised by RFID technology do not manifest immediately. Project management can be defined as planning, scheduling and controlling a set of integrated tasks so that project objectives are achieved successfully and in the best interest of the project stakeholders. Project work includes project meetings, ongoing communication with stakeholders, milestones and checkpoints that help the project manager keep the project within scope, action plans that show what needs to be done in.

Project organization

The most common tasks of a project manager are: dividing and directing the work, inviting the project and reference group to meetings, making the project plan, taking responsibility for achieving the goals, reporting to the steering group and monitoring and controlling procedures between project meetings. The project group is the “motor” of the project that ensures that the project achieves its goal and goals. The most important task is sticking to the plans and reporting to the project manager if there are any problems.

Factors affecting success or failure of a project

The project group must be able to work as a team efficiently to achieve the goals assigned to the team. It is not wise to choose the best person for a particular task in the project organization, the most suitable person should be chosen. If there are conflicts between members of the project team, it can reflect on the action of the whole group.

Project management systems

A simple and effective thing that management in a company can do to improve and support projects is to set the company's project management policy. In this way, there is a clear vision of how the company can utilize project management concepts. A company cannot get maximum value out of project management unless it concentrates on the big picture.

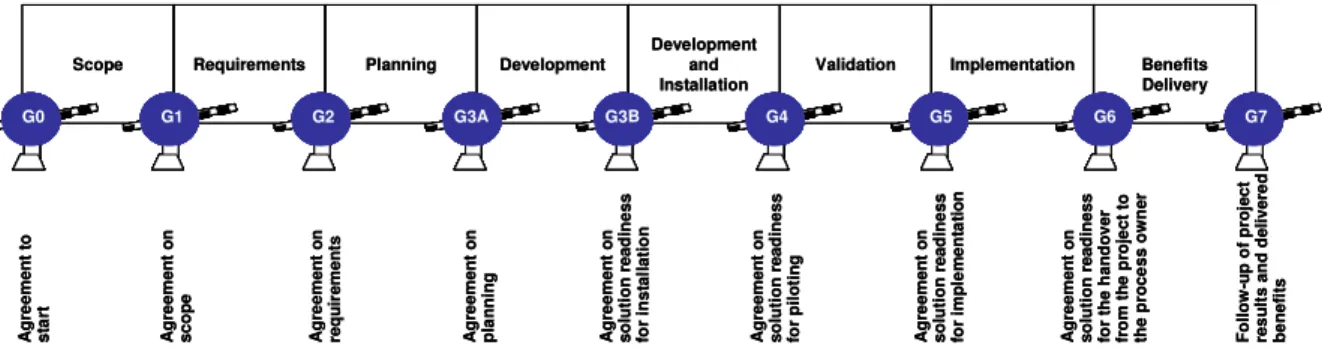

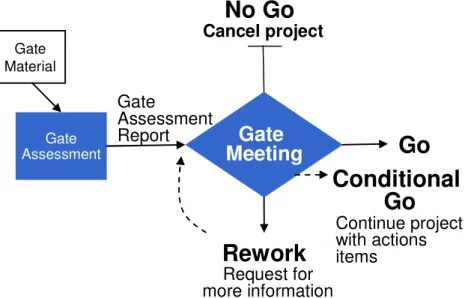

Gate Model for process development projects

At step 5 (G5), it is necessary to obtain consensus on the readiness to publish the results of the project and hand over the project to the recipient. The main goal of the project is to free up space from the factory by transforming outbound logistics. After that, the project team started planning the future processes by creating a process flow diagram.

Starting point

Starting point in System Modules unit

There are certain modules that are sold as a package containing 2-12 modules or packages containing modules and filters. That problem must be resolved before the modules can be packaged with the new system.

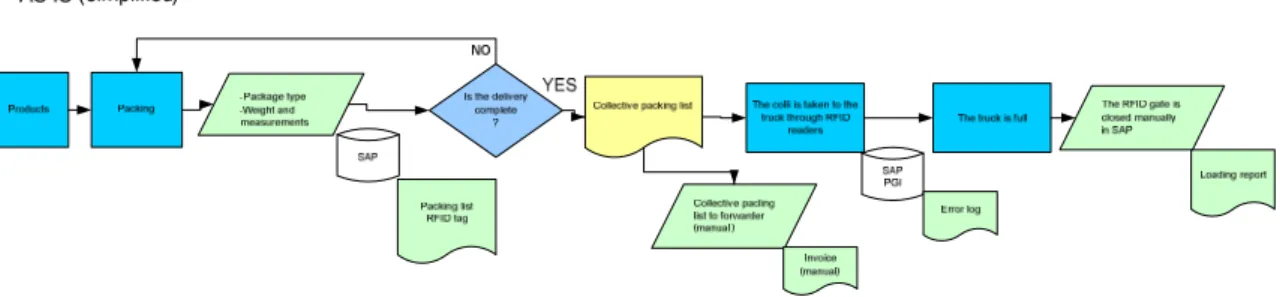

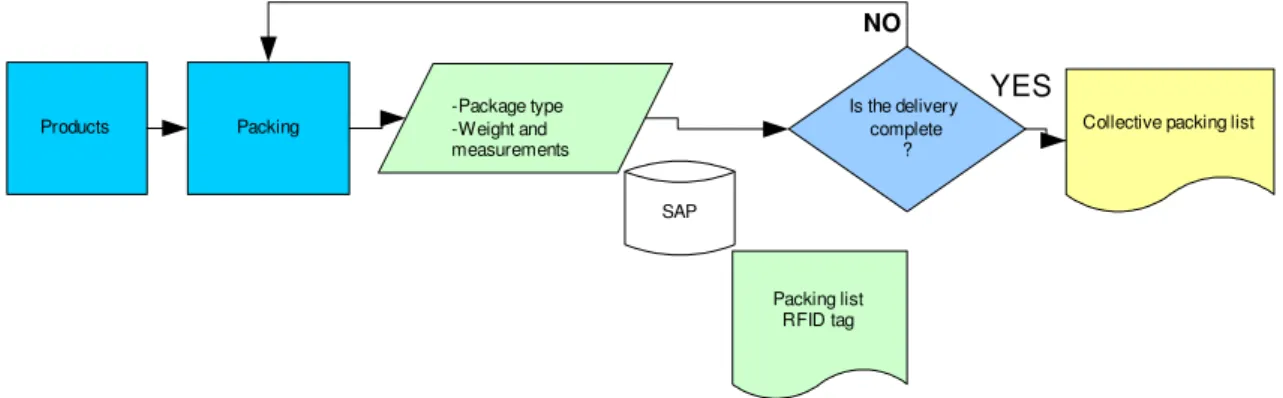

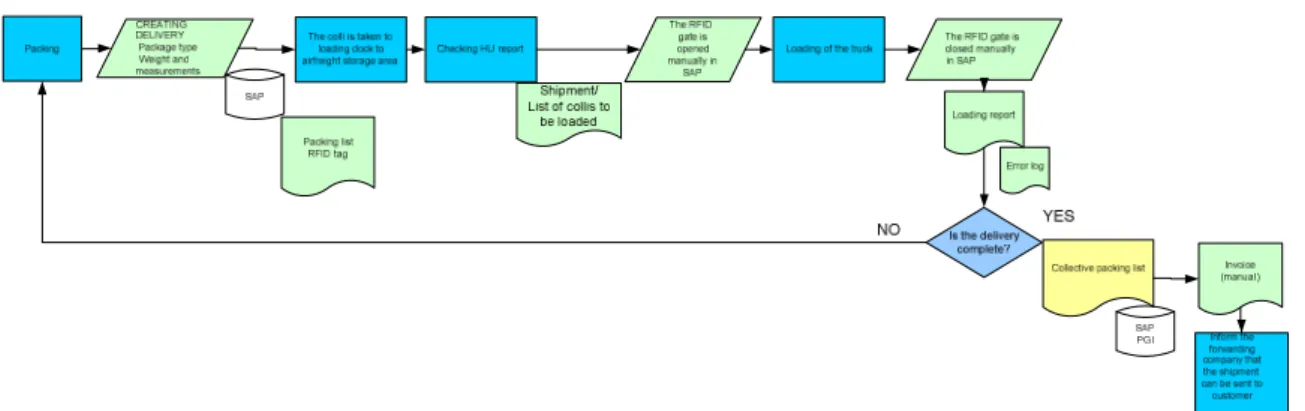

The process AS IS

The errors must be cleared before the RFID reader can be closed and the load report printed. System modules cannot use the RFID readers and the PGI must be created manually. The RFID reader also reads the package to the load report, even though a manual shipment has already been made.

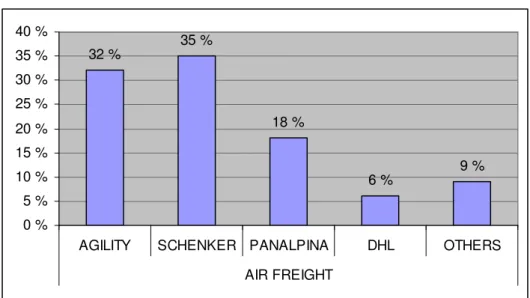

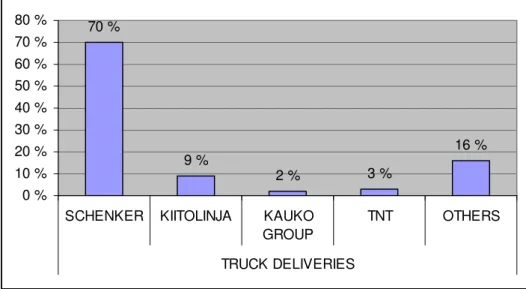

Analysis of deliveries

The reason for this is that when the delivery term is FCA, the customer chooses the forwarding company. These data support the suggestion that the process for air shipments should be further developed. These data justify the suggestion that the process for air shipments should be developed further.

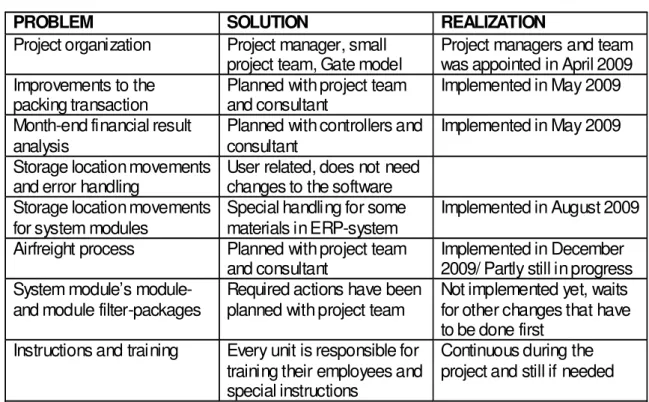

Project organization

The consultant who is selected for the project should also be committed to the project and thoroughly familiar with the project. The Gate Model provides clear instructions to the project manager on how the project should be planned and executed. When the project manager, project team and consultant are selected, they must solve the most pressing problems with the software.

Sub-project

Most acute problems

Changes to packing transaction

There are changes that need to be made to the package transaction to work properly. There are also smaller changes that will make the packaging transaction easier and more convenient to use. There is also a new feature that prevents the use of the packing transaction if someone else is handling the same sales document at the same time.

Result analysis

This change was made because when the goods are received on the trailer and the PGI is automatic, at the end of the month there would be situations where the night shift would have received the packages on the trailer and the RFID gate would have released the PGI, but no one would have done it invoice within the same month. This would have caused incorrect financial data in the ERP system and that is why it was important to make this change before increasing the volume of finished goods handled with RFID readers. The consultant made the technical specification and then the results analysis process was tested by the project team and ABB business controllers.

Storage location movements and error handling

It spent more time and money than budgeted, but because the outcome analysis is a critical issue, it had to be done properly before proceeding with other changes. The implementation will take place in August 2009 due to the freeze of development on the ERP system during the summer of 2009. After the implementation this still needs to be tested in practice and ensure that there are no more problems that could cause incorrect material movements.

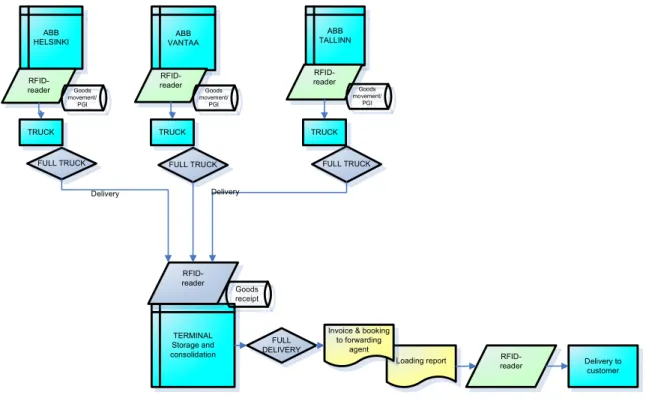

Short term activities for System Modules unit

Currently, all modules from Vantaa and Tallinn are sent to the Helsinki factory for consolidation. System modules should begin to consider how the new system should also be implemented at these two other production facilities. Implementation of the new system to other production units requires the system to be tested and working well at the factory in Helsinki.

Handling of air shipments

Air freight process

When the truck arrives, the RFID reader is opened and the packages are loaded into the truck according to the shipping document. With this process, RFID readers can be used and the packages will be moved to the forwarding company's terminal faster. This process requires more work from the forwarding department compared to a process where packages can be transferred to a trailer without creating a shipment and storing the packages at a loading station for a short period of time.

Restrictions and limitations for implementation

It must be ensured that the beginning of the sales process is handled correctly. The sales administrators who book the orders in the ERP system must keep the customers' information and delivery instructions in the system up to date. It is important that the employees understand and accept that when the processes are changed, the procedures must also be revised.

Realization of planned actions

Holding the hold prevents the shipment or invoice from being made and forces the packing or shipping department employees to check either from the system or from the sales administrator why the order is blocked and if there are some special requirements that need to be considered before proceeding. Employees should be properly trained and there should be someone who can support them if something is unclear or if there are problems. There is already a workaround for this, but the system modules wanted to change the entire package handling process starting from production planning, and those changes need to be implemented first.

Consolidation of shipments outside the factory

- Consolidation model

- Advantages and disadvantages of consolidation model

- Costs and operation of the consolidation terminal

- Benefits of consolidation

All the finished products from the factory could be driven to the terminal with one van. The terminal must be located near the airport, preferably somewhere between ABB's factory and the airport. The risk of damage would also be reduced because there would be more space to operate in the terminal than in the factory area, and a system could be created.

Reporting and traceability

The operating partner specializes in these types of functions and is likely to have more modern and efficient ways of working than ABB. The personnel costs for ABB would also be lower and the implementing partner would probably be able to deploy its personnel more flexibly and respond to high and low peaks.

Utilizing RFID-technology

XML messages between ABB and forwarding agencies

The aim of this thesis was to document and analyze what has been done in the development project and to define the actions to complete the project. The empirical part of this thesis consisted of an analysis of the deliveries, a plan of actions to complete the project and suggestions for the further development of the outbound logistics. The actions for phase 1 described in this thesis have been implemented and the project has been successfully completed.