This thesis focuses on the new product process, information created in it and its flow. With the help of literature review, company's internal documents and organized workshops, the current state of the new product process is described and a data flow diagram is drawn.

INTRODUCTION

During the first three years after the merger, the plan was to reduce approximately 5% of employees (SSAB 2014). In this thesis, the theoretical part consists of a literature review on learning organization and how to control tacit knowledge.

DESCRIPTION OF THE PROBLEM AND OBJECTIVES

Objectives and research questions

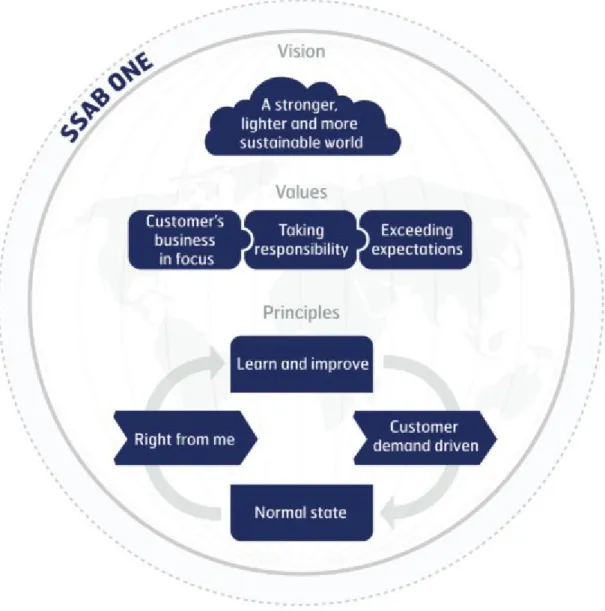

- SSAB One

In short, SSAB One is about improving the workflow based on the customers' needs and, above all, that the employees share in the improvements. SSAB One has much in common with Toyota's management philosophy, but it is based on SSAB's own history and views.

Research scope

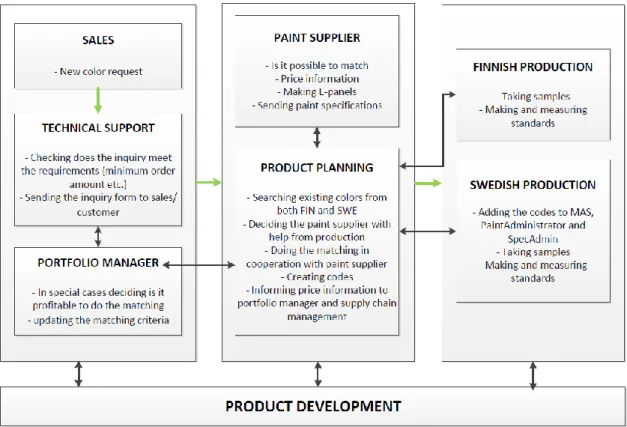

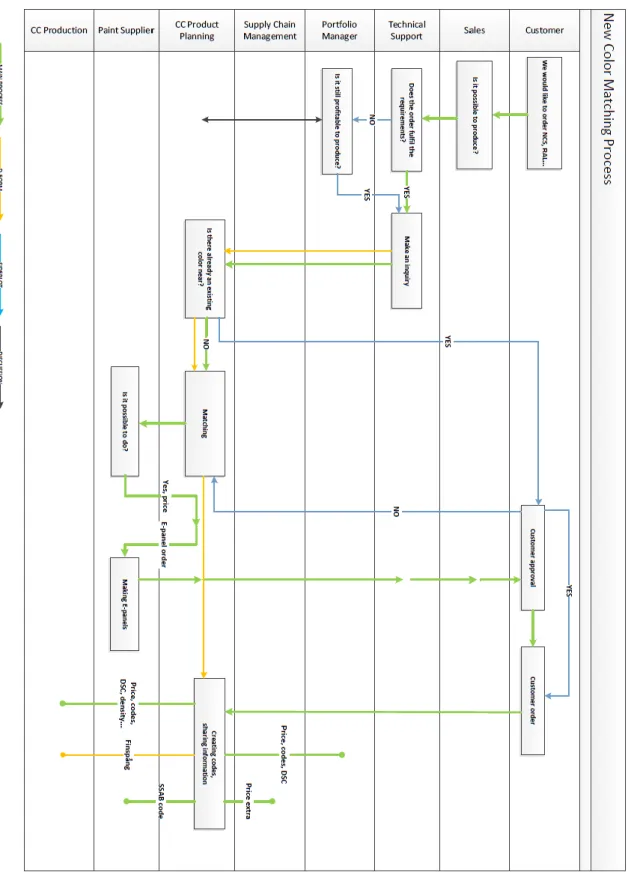

The process map in figure 3 does not represent the current state, but the insights from two years ago. The process starts at the sales or from the customer with a request of a new color and ends either with decision not to do the new product or when the order is in the factory systems.

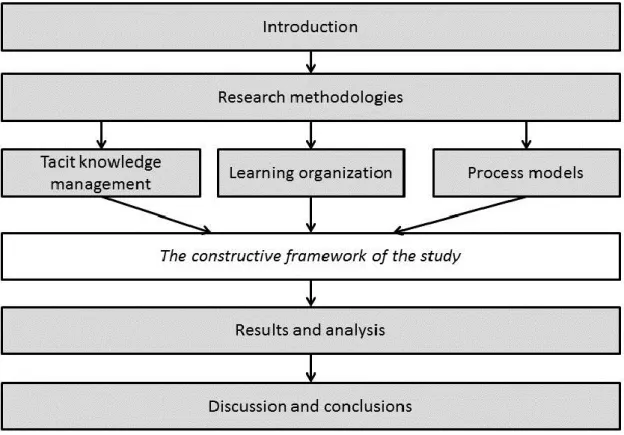

Structure of the study

Then, in the sixth chapter, the collected data is analyzed, followed by the results of the analysis. Appendix A provides a complete data flow diagram of the new product process, and Appendix B provides a complete data and work flow diagram.

RESEARCH METHODOLOGY

Research philosophy and approach

Inductive research usually collects qualitative data, and the main goal is to understand the object of the research. As presented in the previous chapter, the approach of this study is to observe the process and try to represent it in as much detail and realistically as possible.

Research purpose, strategy, choices and time horizon

Lukka (2001), on the other hand, is of the opinion that case study is more of an umbrella term that includes several different strategies instead of one research strategy. This study belongs to the first; the study is a cross-sectional view of the current state of the process.

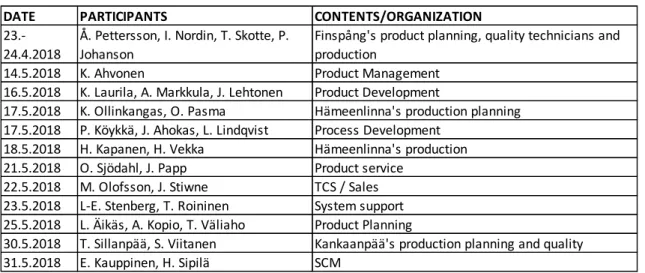

Research material collecting and analysing methods

One challenge of having an observer-researcher role is how much of the research the researcher has to reveal to the research subjects. Practitioner-researcher (Saunders et al. 2009) is common when the researcher works in the research organization.

LITERATURE REVIEW

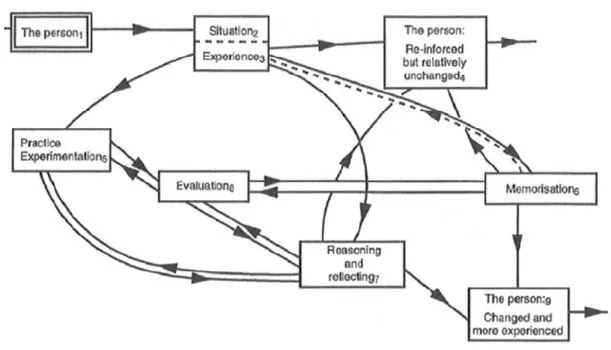

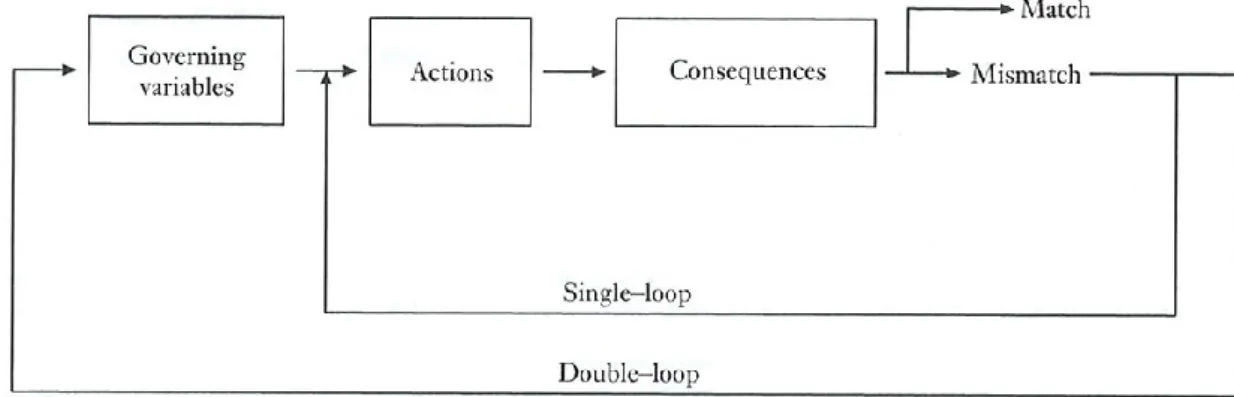

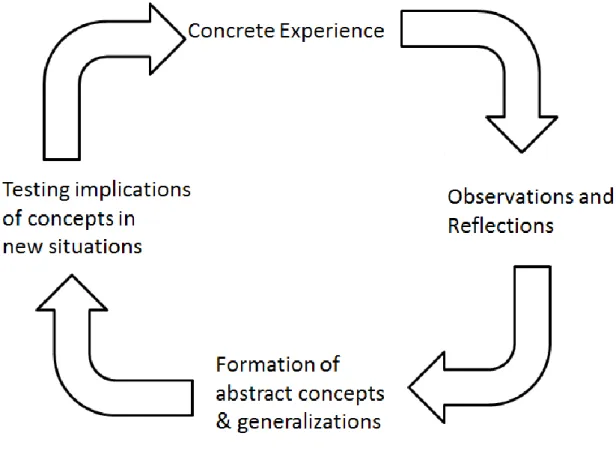

Learning theories

This type of learning usually occurs in the early years of a human being's life. Functional learning is the most common interpretation of learning and occurs as a change in behavior.

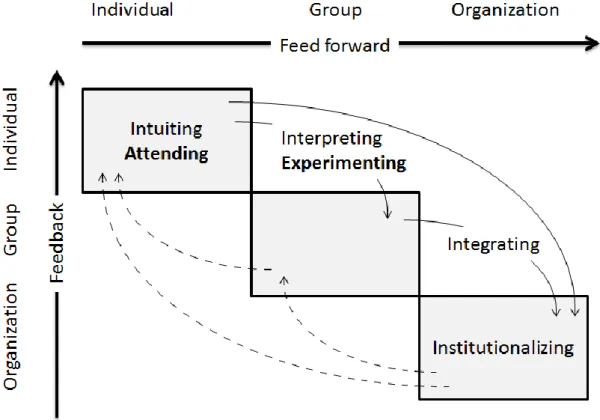

Learning organization

- Organizational forgetting

According to the visionaries, the learning organization is flexible, adaptable and in this way brings a competitive advantage. Despite the flat structure and orientation of the learning organization, management still has a responsibility to the organization and should be accountable to the management team and stakeholders or the company. Knowledge and skills learned by an organization should be present in the organization even if the person who originally learned the skill is no longer a member of the organization (Attewell and Hislop (2005) both make a distinction between organizational learning and a learning organization .

Garvin in Harvard Business Review (1998) states that the key to a learning organization is the translation of knowledge into ways of behaving.

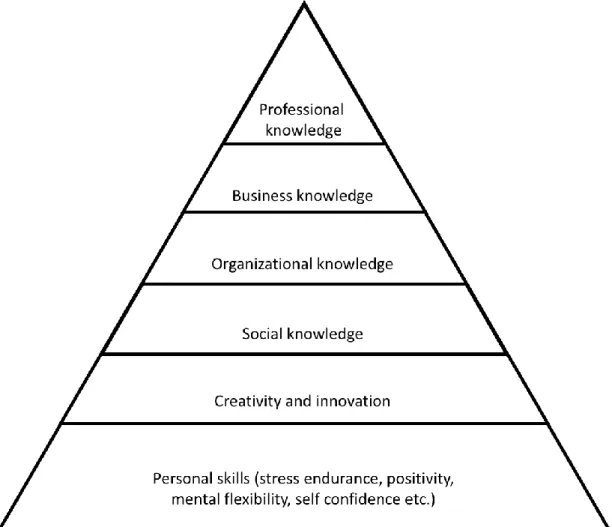

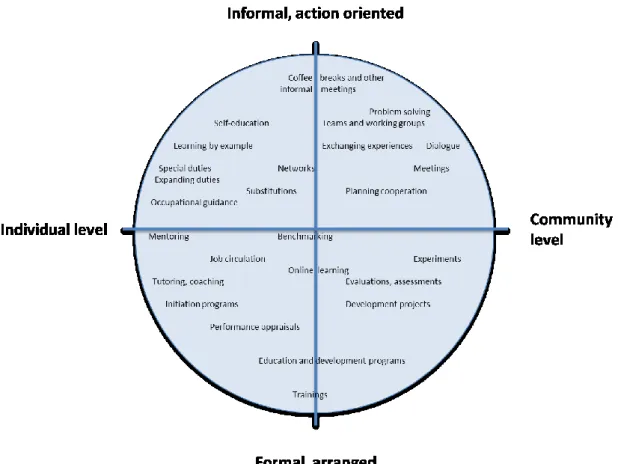

Tacit knowledge management

Awad & Ghaziri (2004) summarize that the purpose of saving tacit knowledge is to extract individual's problem solving knowledge to build a knowledge management system. It is important that the management respects the tacit knowledge, but also that the employees value their knowledge. Literature gives many examples of how to start moving in the direction of adequate tacit knowledge management.

Recognizing tacit knowledge influences the actions of an organization by changing the culture and appreciation of knowledge.

Process models

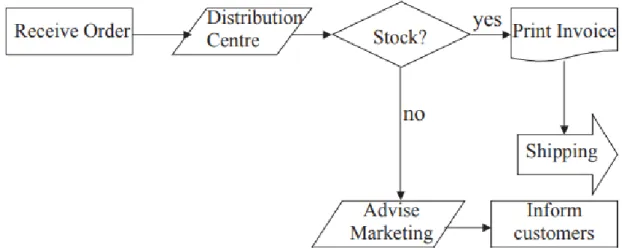

- Process flow models

- Systems thinking

The starting point of the flow would be a goal, where it is understood what features the new product should have. The flow model helps to identify the process steps that add value to the final product. Activities related to timing or product inspection belong to the control flow.

Millet & Nelson 2007) DFD describes the information or data that the previous part of the process has brought in and that the next part must use.

COMPANY INTRODUCTION

Company and organization introduction

Of all the responsibilities, the new product process was chosen to be the object of this study, since it was the most affected by the merger and since it creates the largest part of the daily workload in product planning. If counted by the organizations involved in the process, new color process is certainly the broadest of product planning's processes. The two former companies, SSAB and Rautaruukki, had a very different way of handling new product requests and now those ways have been compressed into one way of working.

New product process

- Product commercialization process

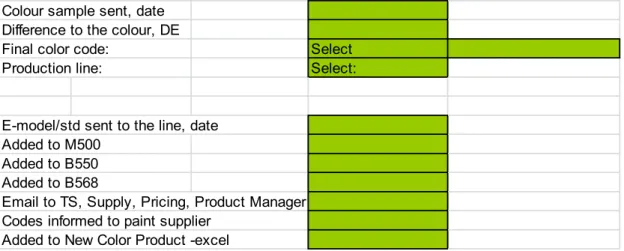

Basically, there are three phases in the phases of the process: evaluation, paint supplier collaboration and IT system updates. In the first phase, either TCS, product planning or product management, as the case may be, defines whether the product is profitable and feasible to manufacture. The process is designed so that all the organizations participating in the process have as comprehensive initial data as possible from the start of the process.

The PCP brings together all the different tasks carried out by different organizations and in this way increases the transparency of the process for all its participants.

Challenges in the process’ present state

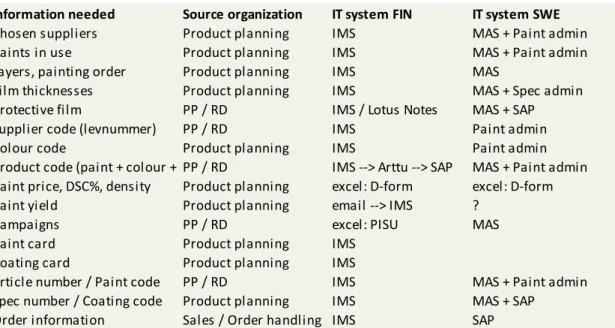

On the other hand, production planning does not have access to many of the IT systems used to control the process. In short, the price information goes very differently from the rest of the process and was found to be inappropriate. After the closure of the product planning tasks from Sweden, practically all personnel knowledge was lost.

This chapter contributes to the first research question by revealing the background and current state of the process.

DEVELOPING THE NEW PRODUCT PROCESS

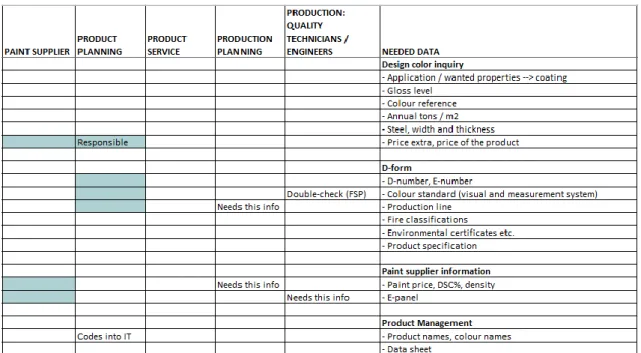

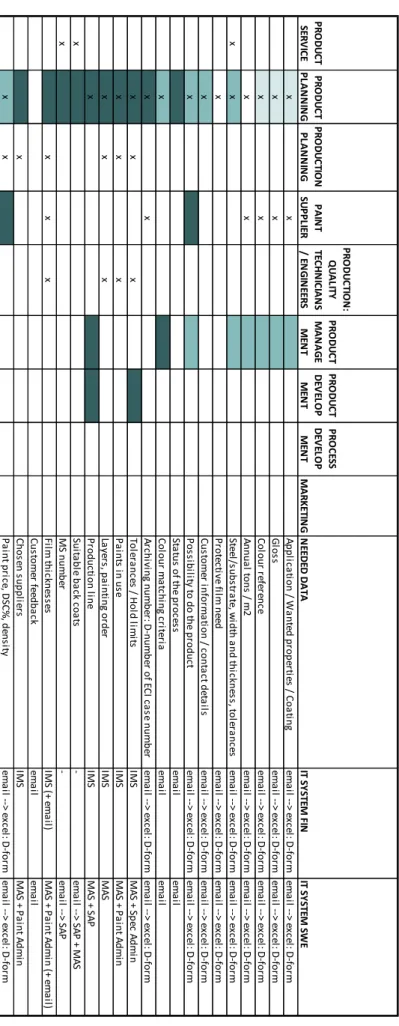

Data flow diagram

After that it was time to focus on the new product process and the role of the organization was revised. A portion of the completed DFD is shown in Figure 21 and the full DFD can be found in Appendix A. The column headings are the organizations involved in the process and below them are the information needs marked with an x.

As can be seen, most of the information present in the process is also created during the process.

Suggestions for development in the new product process

- Design customer inquiry and exceptional customer inquiry tool

Another suggestion to share the experience of the mode-experienced employees is a common workspace for the product planning team. In this way, the IT system structures will generally be the same between the two countries and the administration of the codes can be easier. In one of the countries there was quite a wide range of products that could have the same color code and in the other it was much narrower so that the colors did not match one to one.

The goal of the second stage of the joint production program tool is to generate an update file ready to be downloaded for the SC, but which is still under development.

DISCUSSION AND CONCLUSIONS

Answers to the problem setting

In particular, the knowledge flow indicates where the information emerges, where it is used, where it accumulates and what the route of the information is (Fujimoto 2007, Lehtonen et al. 2012). When the knowledge flow is recognized in the process, it is easier to also identify the implicit sources of knowledge and to determine whether or not it is critical. A list has been edited from DFD to visualize both existing information and information created in the process. In addition, some tacit knowledge could be recognized regarding the process and also its critical parts.

The goal of ECI is to collect color matching and new product process data in the same place, reduce the amount of emails and increase the transparency of the process.

Evaluation of the results and implementation of the study

It is therefore suggested to add automation to the use of the text document. As mentioned at the end of chapter 6.2, the most important thing for the realization of projects is the motivation and interest of employees. Finalizing the DFD also took several iterations to get it to the form it is now.

Research questions were reached and research into the implementation of the proposed developments will continue from here.

Continuation of research

Challenges of knowledge and information management during new product launch: Experiences from a Finnish multinational company. Available in [view https://www.ssab.com/globaldata/news-center/2014/1/22/ssab-and- rautaruukki-to-combine-through-ssab-making-a-recommended-share-exchange- offer-to- rautaruukkis shareholders. CUSTOMER SALES PRODUCT PLANNING PRODUCT SERVICE PRODUCTION PLANNING PAINT SUPPLIER PRODUCTION:QUALITY TECHNICIAN/ENGINEERS DELIVERY SUPPORT SUPPLY CHAIN MANAGEMENT PRODUCT MANAGEMENT PRODUCT DEVELOPMENT PROCESS DEVELOPMENT MARKETING NEEDED DATAIT SYSTEM /WExxA features Visit SYSTEM FINIT / excl. mail --> Excel: D-formxxxxGlossemail -- > excel: D-formemail --> excel: D-formxxxx Color references mail --> excel: D-formemail --> excel: D-formxxxxAnnual ton / m2e-mail -- > excel: D-formemail --> excel: D-formxxxxSteel /substrate, width and thickness, tolerancesemail --> excel: D-formemail --> excel: D-formxx Protective film required email --> excel: D -formemail --> excel: D-formxxxCustomer information / contact details email --> excel : D-formemail --> excel: D-formxxUrgent email e-posxxxxxPossibility to email the product --> excel: D-formemail --> excel: D-formxxxx Status of the process e-mail e-posxx Color matching criteria e-mail e-posxx Archiving number: D-number of ECI case number e-mail --> excel : D-formemail --> excel: D-formxLine specificationsexcelexcelxxxTolerances / Holding limitsIMSMAS + Specification AdminxxxPaint in useIMSMAS + Paint AdminxxxLay, paint orderIMSMASxProduction lineIMSMAS + SAPxSuitable backcoats email --> SAP +mail email -->SAP + MASxMS number SAPxxx email+MS number email )MAS + Paint Admin (+ email)xxCustomer feedback email emailxSelected suppliersIMSMAS + Paint AdminxxxPaint price, DSC%, densities email --> excel: D-formemail --> excel: D-formxxxxColor extra email -- > Sales Configurator --> SAP (by MDM Team) Email --> Sales Configurator --> SAP (by MDM Team)xxxPrice of the Products Mail + Sales Configurator Email + Sales ConfiguratorxE- number emailxxxxE panel / Color model--xxxE panel acceptance email --> excel: D-forms mail -> excel: D-formxxInformation for production program & Sales ConfiguratorRemaster + Sales ConfiguratorRemaster + Sales ConfiguratorxxProduct names, color names mail -- > IMSe mail --> SAPxxxMarkingLotus Note mail --> SAPxxProduction level / releaseIMSemail --> SAPxxxxxxxx Specification number / Coverage codeIMS (+ email )email --> MAS + SAPxxxProduct code (paint + color + supplier combination)IMS -- > Arttu --> SAPMAS + Paint AdminxxArticle number / Paint codeIMSMAS + Paint AdminxxSupplier code (lev number)IMSPaint AdminxxxxxxxxxColor codeIMSemail --> SAP + Paint AdminxxxCorresponding color FIN/SWEIMse-post --> SAPxTests to be doneIMSSpec AdminxxColor standard: visual and on spectrophotometryColourColibrixxxPaint cardIMS-xxCovering cardIMS-xxxProtective film typeIMS / Lotus Note mail --> MAS + SAPxxxxx Order info mail --> IMSe mail:PexPaxepos:SAPxpos:SAPxepos:SAPxepos:SPAxpos deliver mail -- > IMSMASxSafety data sheetsChemsoftChemsoftxBatch certificates: infinite value e-mail-posxPaint batch number mail --> IMS -xRaw material informationIMSMAS --> TVBxSettings from previous runs (roll speed, roll pressure, oven temperatures)IMSTVBxWork instructionsLotus NotesAPH.