The Ca release profile was analyzed by Atomic Absorption Spectroscopy (AAS) and found to increase with immersion time. The mechanical properties of all the examined glasses initially appeared to decrease, as expected with degradation of the composite. However, the increase in flexural strength after two weeks of immersion was unexpected, especially since shear strength did not appear to change significantly over the course of the test and requires a more in-depth analysis.

In general, 30 % of the weight of glass within the composite proved to be optimal to maintain high mechanical properties, ductility, providing a significant release of Ca, promising indicators of bioactivity.

INTRODUCTION

In this thesis an in-depth literature review has been performed, which is presented in chapter 2. Special attention has been paid to the state of the art in the field of polymer/glass composite. Influence of glass compositions and filler content on various properties of the composites are discussed.

The main results obtained during the course of the thesis are reported and discussed in Chapter 4.

LITERATURE REVIEW

- Bioactive glass

- Calcium phosphate ceramics

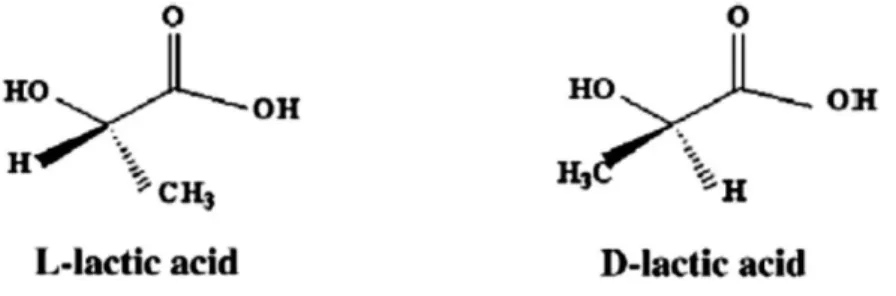

- Poly lactic Acid (PLA)

- Hydrolytic behavior of Polylactic acid (PLA)

- Porous bioactive glass/polymer composites

- Bioactive glass coated composites

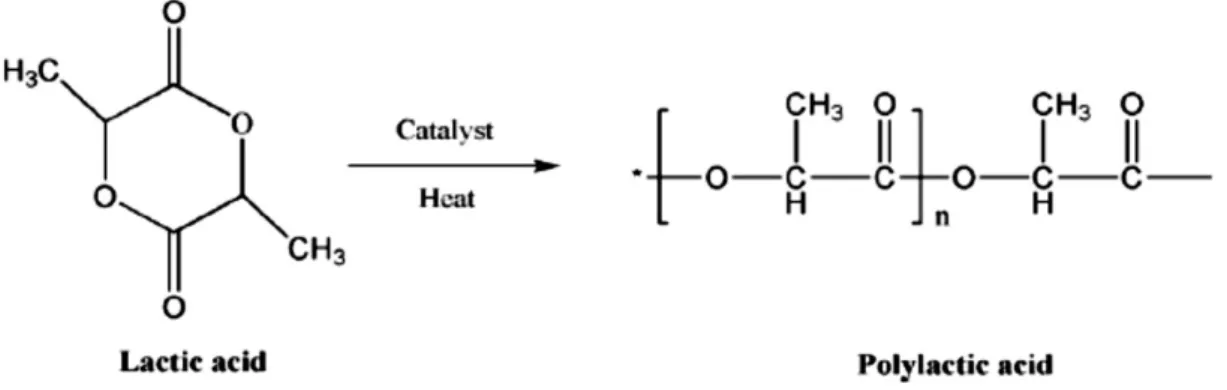

- Dense Polymer/bioactive glass composites

- β-Tricalcium Phosphate/biabsorbable polymers

The rate of degradation must be adjusted to match the rate of tissue healing. The properties of composite materials mainly depend on the properties of the matrix material. It was found that Bioglass® significantly improved the compressive modulus of the composites.

The presence of the bioactive filler was found to slow down the polymer degradation rate compared to the pure polymer foams. It was also found that the osteoblast cell was attached in the porous network over the entire depth of the foams. During the in vitro test, Ahola et al. 2013) found that the pH of the buffer was very stable in the first weeks of the test series.

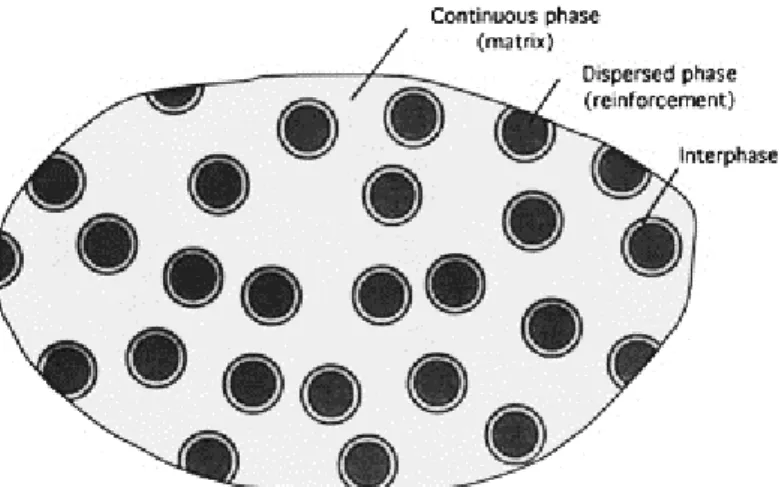

MATERIALS AND METHODS

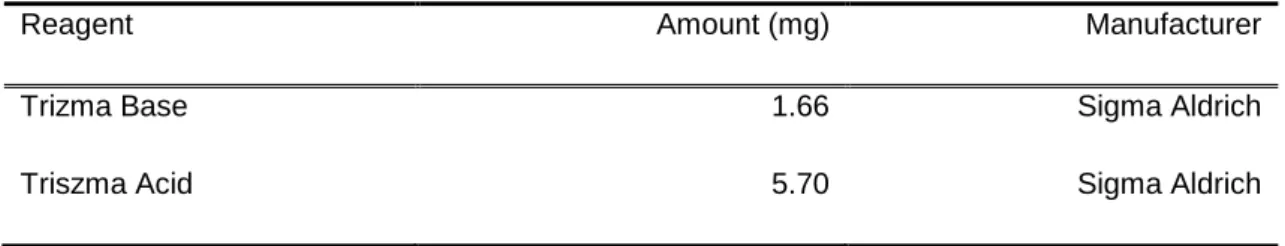

PLA and glass were fed with separate gravimetric screw feeders and mixing of the components took place in the extruder. A caterpillar track was used to guide the composite bars out of the die and the diameter of the composite bar was controlled by adjusting the speed of the belt. Subsequently, the pH of the solution was measured with a pH meter (Mettler-Toledo GmbH, Schwzebbach, Switzerland).

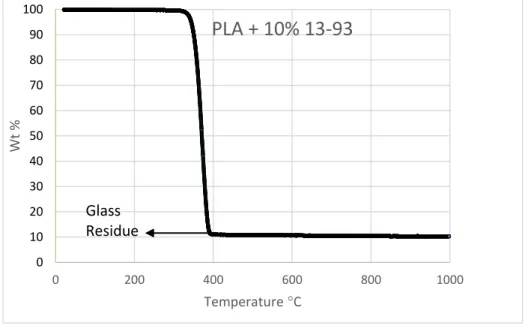

All samples were weighed before the immersion test to obtain the initial dry weight of the samples. The glass content of the test samples was measured by Differential Thermal Analysis (NETZSCH, Leading Thermal Analysis, STA 449F1). At each time point, the samples were carefully wiped with tissue to remove excess water.

The weight loss was calculated as the difference between the mass of the initial test specimen and the mass of the dried test specimen divided by the initial mass of the test specimen. Similarly, water absorption (WA) was calculated as the difference between the weight of the wet test specimen and the weight of the dried test specimen divided by the weight of the dried test specimen. The purpose of the test was to determine the initial mechanical properties of the composites depending on the composition and glass content and depending on the immersion time.

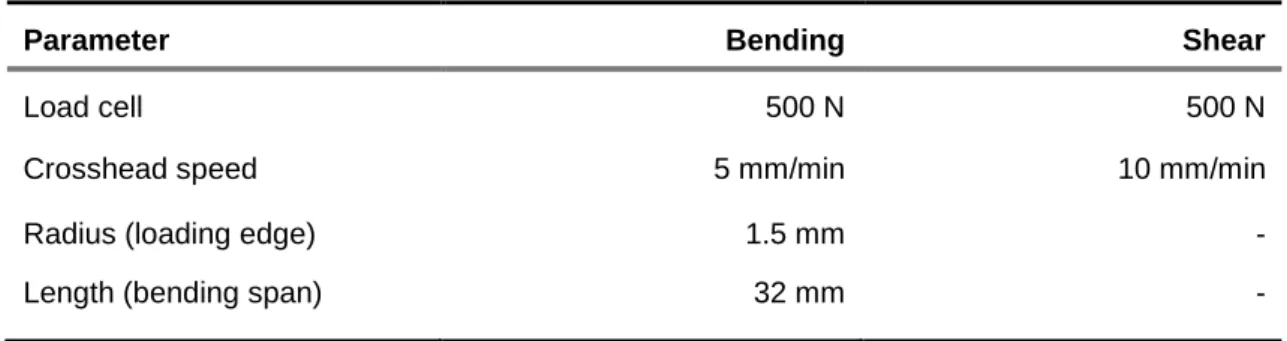

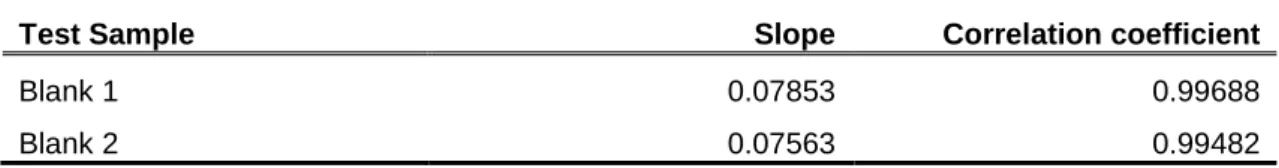

The dry samples were mechanically tested at room temperature by three-point bending and shearing using Instron 4411 mechanical testing device (Instron Ltd. High Wycombe, England). For the Atomic Absorption Spectrometry (AAS) test, 5 ml of the immersed solution was collected and diluted to 50 ml with deionized water.

RESULTS AND DISCUSSION

Bending Test (3 Point bending test)

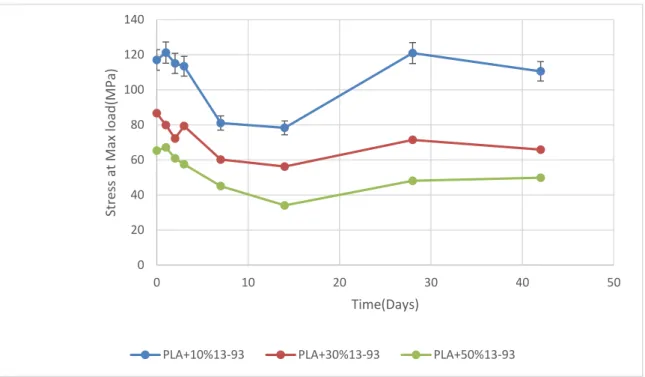

All 0-week test samples were found to be brittle, which was attributed to the brittle nature of the glass. In order to improve the initial mechanical property of the sample and to reduce the brittleness of the composites, self-reinforcement has been done. Composite samples containing silicate have the highest initial flexural strength (116 MPa) which can be observed in Figure 15.

The flexural strength decreased with in vitro test up to 2 weeks which is due to the degradation of composite especially degradation of glass for all in vitro test samples. At the same time, test sample started to become flexible from brittle which is probably due to the formation of HA layer on the surface of test samples. Longer immersion test should be performed to study the mechanical behavior of composite material in terms of flexural strength.

Niemelä, 2008) reported results for flexural strength of for similar polymer/glass composites that were different from here. Flexural strength of composites decreased gradually from 117 MPa (0 wk) to 112 MPa up to 6 weeks unlike in this study. Higher amount of filler content also resulted in faster loss of mechanical properties of sample.

However, the increase in flexural strength after 4 weeks is not as significant as for silicate-based composites.

Shear Test

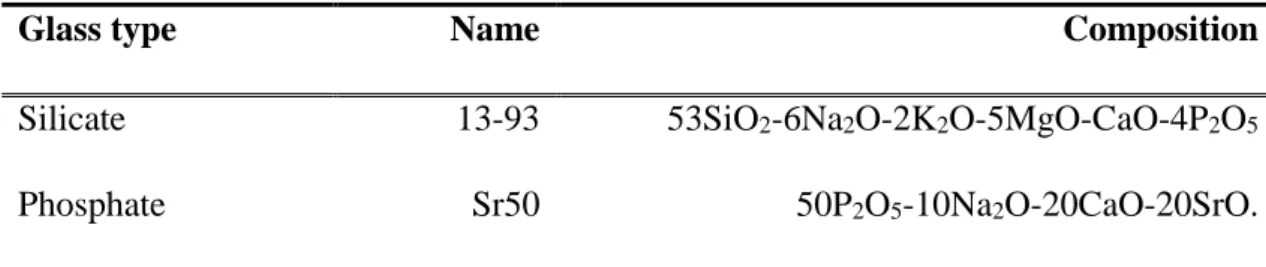

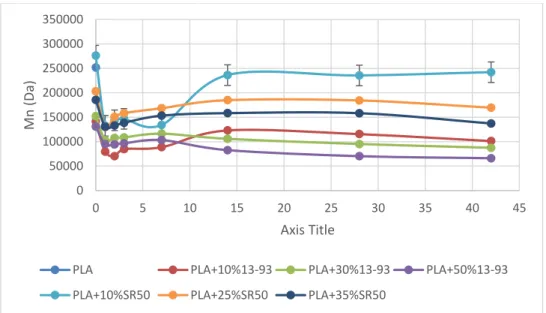

However, for phosphate-based composites, the drop in molecular weight was drastic compared to silicate-based composites. There was a dramatic increase in molecular weight in the context of the phosphate-based composition than in the silicate-based sample, which can be clearly observed from Figure 18 below. The spectrum presents a strong absorption band at 1748 cm-1 attributed to the stretching vibrations of the amorphous carbonyl groups (Furukawa et al. 2007).

The other bands observed at 1452 cm-1 and 1382 cm-1 are due to the CH3 asymmetric and symmetrical deformations. The strong absorption band at 1180 cm-1 is due to the C-O-C stretching mode, while a shoulder at 1210 cm-1 is attributed to the C-O-C stretching characteristic for the crystalline phase of PLA. With an increase in the filler content, the band attributed to the stretching vibration of the silica networks widened.

The decrease in peak intensity at 1748 cm-1, 1452 cm-1 and 1382 cm-1 band was observed with increasing filler content which may be due to Si substitution of carbonyl group of PLA. Typical FTIR of phosphate glass represents the band at 880 cm-1 attributed to the asymmetric P-O-P stretching of the bridging oxygen. The shoulder centered at 980 cm-1 and the band peaking at 1,085 cm-1 correspond to the symmetric and asymmetric stretching vibration of PO32-.

The best FTIR spectrum can be observed from a powder sample or a thin and flat surface, which was not the case with the sample used in this thesis. While addition of silicate leads to greater changes in the structure of the polymer itself.

CONCLUSIONS

2009), Structure and properties of strontium-doped phosphate-based glasses, J. 2013), Hydrolytic degradation of composites of poly (L-lactideco-epsilon-caprolactone) 70/30 and beta-tricalcium phosphate, Journal of Bioma, 28 )4, pg. 2008), Polylactic Acid: Synthesis, Properties and Applications. 2013), Current progress in bio-based polymers and their future trends, Progress in Biomaterials, p. 2003), In vitro evaluation of new bioactive composites based on Bioglass® filled polylactide foams for bone tissue engineering scaffolds; J. 2003), Bioresorbable and bioactive polymer/Bioglass®. Polymer Degradation and Stability, (95)2, p. 2008), Tissue Engineering Scaffolds from Bioactive Glass and Composite Materials, Topics in Tissue Engineering, (4), pp Progress and challenges in biomaterials used for bone tissue engineering: bioactive glasses and elastomeric composites, Advances in Biomaterials, ( 1)1.

1994), Engineering mechanics of composite material, Oxford University Press, Inc., New York p. 2001), Relating material properties to structure: Handbook and software for polymer calculations and material properties. 2013), Biodegradable Polymers and Polymer Blends, Elsevier Inc. 2007), Preparation and bioactive properties of a porous 13-93 glass and fabrication for articulating surface of a proximal tibia Article in Journal of Biomedical Materials Research Part A, 82(1) ), p Properties and medical applications of polylactic acid:A review , eEXPRESS Polymer Letters,(9)5 pp. Three-dimensional, bioactive, biodegradable, polymer-bioactive glass composite scaffolds with enhanced mechanical properties support collagen synthesis and mineralization by human osteoblast-like cells in vitro, J Biomed Mater Res A., (64)3, p. 2013), Chronology of Bioactive Glass Development and Clinical Applications, New Journal of Glass and Ceramics, (3), p. 2006), Kinetics and mechanisms of the conversion of silicate (45S5), borate and borosilicate glasses to hydroxyapatite in dilute phosphate solutions, J Mater Sci Mater Med., (17)7, pp 2012), Review of bioactive glass: From Hench to hybrids, Acta Materialia. 2010), Preparation and characterization of phosphate glass fibers and fabrication of poly(caprolactone) matrix resorbable composites, Journal of Reinforced Plastics and Composites Phosphate-based glasses for biomedical applications J. 1992), Chemical reaction of bioactive glass and glass ceramics with a simulated body fluid. 2015), Comparative evaluation of biphasic calcium phosphate and biphasic calcium phosphate collagen composite on osteoconductive strength in rabbit calvarial defect, Biomaterials Research, (19)1, p. 2013), Resorbable composites with bi- or resorbable glass fibers applications.

J Biomater Appl., 20(2), pp Processing technologies for poly(lactic acid) Progress in Polymer Science, (33), pp 2003), Three-dimensional, bioactive, biodegradable, polymer-bioactive glass composite scaffolds with improved mechanical properties support collagen synthesis and mineralization of human osteoblast-like cells in vitro;. In vitro degradation; Acta Biomaterialia, 4(1), pp. 2010), Self-Reinforced Bioceramic and Polylactide Based Composites, PhD thesis, Tampere University of Technology. 2015), Bioactive glasses beyond bone and teeth: Emerging applications in contact with soft tissues, (13), p. 2009), Study on the degradation of polylactic acid in the presence of phosphonium ionic liquids, Polym.

2011), Bioactive glass in tissue engineering, Acta Biomaterialia, (7), p. 2002), Development and in vitro characterization of new bioresorbable and bioactive composite materials based on polylactide foams and Bioglass® for tissue engineering applications; Biomaterials, 23(18), p. 2013), Mechanical properties of biomaterials based on calcium phosphates and bioinert oxides for use in biomedicine, prof. Sherwood JK, Riley SL, Palazzolo R, Brown SC, Monkhouse DC, Coates M, Griffith LG , Landeen LK, Ratcliffe A. 2002), a three-dimensional osteochondral composite scaffold for articular cartilage repair. 2002), Properties of lactic acid-based polymers and their correlation with composition Advances in Polymer Science, (27)6, p. 2001), Bioresorbable polymers: their potential as scaffolds for bioglass composites. 2004), Biological evaluation of bioceramic materials - a review, Trends Biomater. 2000), Polymer Scaffold Processing, Academic Press. 2015), Clinical Applications of S53P4 Bioactive Glass in Bone Healing and Osteomyelitic Treatment: A Literature Review, BioMed Research International pp Polymer matrix composite and technology, Woodhead publication in materials, chapter 1, p. 1990), Science and Technology of Laser glass, non-crystalline.