Emmanuel Rogdakis for his invaluable support, encouragement and advice regarding very difficult aspects of this thesis. I am grateful for all her invaluable support during my work and I also want to thank her very much for the supervision and guidance during this thesis.

1 INTRODUCTION

- BACKGROUND AND MOTIVATION

- RESEARCH OBJECTIVES AND INNOVATIONS

- THESIS STRUCTURE

- REFERENCES

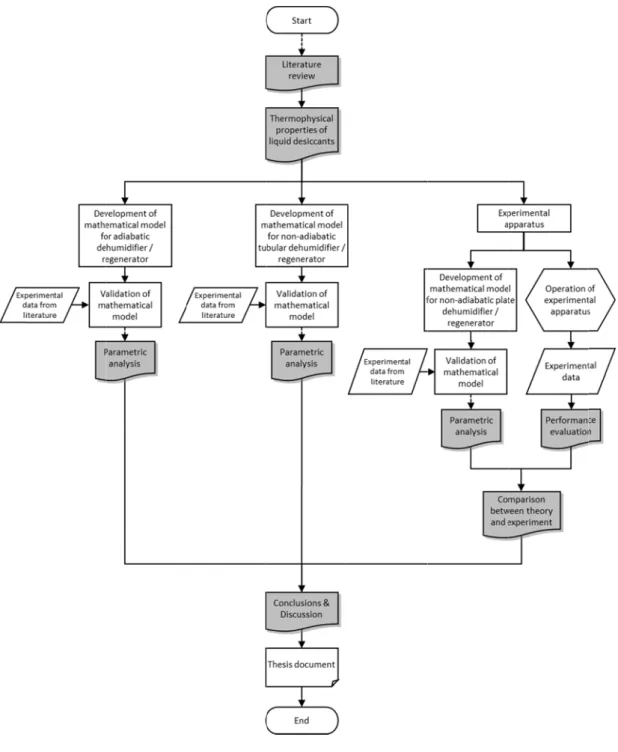

Develop mathematical models to evaluate the performance of the most commonly used liquid desiccant regenerators. The fourth chapter presents a performance study of an adiabatic liquid desiccant dehumidifier and regenerator.

2 LITERATURE REVIEW

INTRODUCTION

The performance of liquid desiccant systems is highly dependent on the heat and mass transfer characteristics of the two critical components: the dehumidifier and the regenerator. At the end of the process, find the air cooled and dehumidified and the solution diluted.

LITE Co‐flow

The authors considered the void as a crucial parameter for the evaluation of the heat and mass transfer coefficients. He therefore provided a more direct description of the relationship between the desiccant solution and the column efficiency. As in the dehumidifier [26], the regenerator's finite difference model over-predicted the actual performance, perhaps due to the assumption regarding the heat and mass transfer area and the incomplete wetting of the packing.

He also showed that the rate of water condensation decreases with the increase in cooling water inlet temperature and the decrease in desiccant-to-water heat exchanger efficiency. He found that the heat and mass transfer efficiency increased with the decrease in air flow rate and the increase in packing height, while it showed little dependence on the liquid flow rate, equilibrium humidity ratio, and intake air humidity ratio. It was found that the mass transfer coefficients for both dehumidification and regeneration increased with desiccant flow rate.

Increasing the solution temperature at the regenerator inlet increased the mass transfer coefficient and moisture removal rate, but decreased the efficiency of the regenerator.

CONCLUSIONS

Humidified air exits the top and the warm, now diluted solution leaves the bottom of the dehumidifier and is pumped for regeneration. This process has a major impact on the energy efficiency of liquid desiccant cooling systems, as heat is required here. Since the vapor pressure of the desiccant is now higher than that of the air, the moisture is evaporated from the solution and transferred to the exhaust air stream.

At the end of the process, the hot moist air is vented to the ambient air and the concentrated solution is driven to the dehumidifier. This chapter provides an overview of the available literature regarding heat and mass transfer in liquid adsorption refrigeration systems. Most of the studies reviewed focused more on countercurrent configuration and less on crosscurrent or cocurrent, due to the high effectiveness of heat and mass transfer.

However, the effects of some inlet parameters on efficiency are still uncertain; among others, the optimum air-to-desiccant flow ratio, the wetting ratio of the desiccant solution above the packing, the ratio of the heat transfer.

Experimental investigation of heat and mass transfer in a packed-bed liquid desiccant dehumidifier. Experimental and theoretical analysis of heat and mass transfer in a packed column dehumidifier/regenerator with liquid desiccant. Simplified Analysis of Coupled Heat and Mass Transfer Processes in Fluid Desiccant-Air Contact System with Packed Bed.

Air dehumidification by chemical liquid desiccant in a packed column and the effectiveness of heat and mass transfer. Experimental investigation of the heat and mass transfer between air and liquid desiccant in a cross-flow regenerator. A new method for determining coupled heat and mass transfer coefficients between air and liquid desiccant.

Experimental investigation of heat and mass transfer between air and desiccant in a cross-flow dehumidifier.

3 THERMOPHYSICAL PROPERTIES OF SALTS

INTRODUCTION

Desiccants are hygroscopic materials that absorb or release moisture into the surrounding air due to a difference between the water vapor pressure on their surface and that of the surrounding air. If it contains less moisture, it absorbs moisture from the air and releases heat equal to the latent heat released if a corresponding quality of water vapor condenses [5]. Other advantages over solids include smaller pressure drop and easy transportation to the regeneration heat source, easier integration within HVAC plants, more efficient bacteria and dust removal, and less cost [13, 21].

Moreover, energy storage is at the expense of energy and the coefficient of performance [15]. The energy storage capacity is limited because the moisture removed from the desiccant during regeneration is equal to the moisture condensed from the air during dehumidification and because of the risk of crystallization [15]. In absorption chillers, the crystallization line is usually very close to the working concentrations [25] and is activated by high ambient temperature, low ambient temperature at full load, air leakage or non-absorbable gases produced during corrosion, excessive heat input to the desorber, failed dilution after shutdown, too low.

Cyst treated soluti he salt crystallization crystal .. of system ation tempe ed up to no teristics follo .. ess steel), th on than glyc.

LITH Solubili

A Dühring chart represents the dew point temperature of the vapor phase versus the bubble temperature of the solution. Since the presence of salt in the solution hinders the evaporation of water, the saturated temperature is always higher than the temperature of saturated water vapor. The saturation point of strong solutions is determined by an empirical law, Duhring's law.

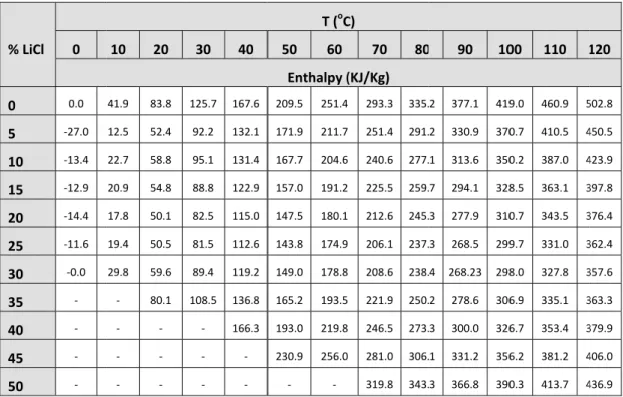

According to that, the saturation point of the solution is a linear relationship of the saturation point of the solvent of the solution under the same pressure. There is no thermodynamic expression describing this linear relationship and the definition of the coefficients is strictly experimental. The following table shows solution dew points for a mass fraction range of 0-50% and a temperature range of 0-120oC.

These data have been fitted into a linear equation relating solution dew points to solution temperature.

Thermal conductivity, λ sol(mW/mK)

O P ξ) is given fro

LiCl 0

LITH Solubili

The solution pressure depends on the dew point temperature, which is calculated by the eq.

CAL Solubili

- CONCLUSIONS

- REFERENCES

The earliest investigated liquid desiccant system may use triethylene glycol (TEG), but now glycols are used less frequently in liquid desiccant applications. A collection of equations for their most important properties needed in the design of absorption air conditioning equipment is presented. These equations are considered to be representative and provide acceptable results in engineering calculations for liquid desiccant air conditioning systems.

3] Gandhidasan, P., 1994, “Performance Analysis of an Open-Cycle Liquid Desiccant Refrigeration System Using Solar Energy for Regeneration,” International Journal of Refrigeration, 17, p. 5] Chartered Institution of Building Services Engineers, 2005, "Guide B: Heating, Ventilation, Air Conditioning and Refrigeration", CIBSE, Department of Trade and Industry, p. 23] Conde, M.R., 2004, "Properties of Aqueous Solutions of Lithium and Calcium Chlorides: formulations for use in air conditioning equipment design”, International Journal of Thermal Sciences, 43, pp.

Aqueous solutions of lithium and calcium chlorides: proprietary formulations for use in the design of air conditioning equipment.

4 ADIABATIC MODEL

INTRODUCTION

Liquid desiccant systems have been proposed as energy-saving alternatives to the conventional vapor compression systems for handling the latent load. A heat and mass transfer model of an adiabatic packed column was developed to predict the performance of the liquid desiccant dehumidifier under various operating conditions. Good agreement was found between experimental tests from the literature and the developed theoretical model, with the maximum deviation being ±2.9% in air outlet temperature, ±15.9% in air outlet humidity ratio and ±2.8% in solution outlet temperature.

The three liquid desiccant solutions, namely LiCl, LiBr and CaCl2 were evaluated against each other. The performance of the adiabatic regenerator was made possible by the development of a heat and mass transfer numerical model. Good agreement was found between the theoretical model and experimental tests of previous studies, with the deviation range being ±6.2% in air outlet temperature, ±8.1% in air outlet humidity ratio and ±1.4% in solution outlet temperature.

The three most commonly used liquid desiccant solutions, namely LiCl, LiBr and CaCl2 were evaluated against each other.

DEH Overvie

Ren et al [27] found close agreement between experimental results and finite difference model predictions when using different heat and mass transfer coefficients. During dehumidification (absorption procedure), water vapor molecules are drawn from the volume of liquid desiccant while condensation of water vapor occurs within the liquid desiccant solution. Where Wsat is the ratio of the moisture content of the saturated air that is in equilibrium with the desiccant solution at the local solution temperature and concentration.

Figure 4‐3 represents, among other things, the energy balance of the air phase in an adiabatic counterflow dehumidifier. Figure 4‐3 represents, among others, the energy balance of the liquid desiccant phase in an adiabatic counterflow dehumidifier. But as shown in Figure 4‐7, the slope of the dehumidification mass rate is greater at airflow rates less than 0.05 kg/sec.

However, it should be noted here that the difference between the outlet and inlet temperature of the desiccant is much higher than the difference between the outlet and inlet air temperatures.

REG Overvie

However, in the countercurrent configuration, the most common flow pattern for a liquid sorbent dehumidifier/regenerator, the desiccant outlet conditions are unknown. Based on the work of Factor and Grossman [22], Chengqin et al. [54] developed a control equation for the quasi-equilibrium conditions of the two fluid streams. 1] for the va uations, the ed with the. vapor moles are trained to the tra ery required by the heat. e of a high correlates directly with physical characters [43]. ecules of the ansfered to form a gd before the evaporation. pressure dr the power c cteristics, th The optimization pressure dr drop equat. humidity rat state of ai. e liquid desic the process given quantitative aporation of ions, given by. rop by consumed by he pressure. ation of the rope less than is given. h de y th trickle current n a n through. empirical correlations for the mass transfer coefficients in the gas and liquid phases, applicable to random packings with organic solvents.

The general correlation of the heat transfer is:. where raise the to the eq. mass transfer and the re. one fluid desires another in energy [60. ere Qs is the ease of air an expression he air in a a. his research serves the development of Fum me with the enerator con. rmance indic fer performa egenerator ssion:. iccant regen index to eva 0]. e total heat and desiccant for adiabatic calculation reg. Loped mathe mo and Gosw. experiment nsist of a pa pth.. ces . nce of the re efficiency.. al device acked colum king used wa . and the desorption factorspheres in the .. process driven utilization generation t .. amount of heat applied to convec .. ions of the monkey once the model is up. as a polypropylene desiccant dissolver, bee e contact co. ven by thermal efficiency thermal efficiency. devices have parametric and validated dimensions and Goswam 4m diamete ylene Rausch ion was LiCl and used in tholumn. mal energy, it ncy for the. of the aporation, ar. Since this study was conducted as an extension of the authors' previous work [33], both the geometry and the initial conditions for the parametric study should remain the same wherever possible. Uniform flooding of the regenerator and the heat transfer area equal to the mass transfer area; thus transfer area equal to the specific area of the package.

Negligible heat transfer due to radiation, due to small temperature differences of the process.. air inlet weak desiccant inlet. strong desiccant.