INSTRUCTIONS & PARTS CATALOG

Cat. No. 9A2520zSi February, 1989.W500/UT

Thread Trimming Mechanism for

Flat Bed Interlock Stitch Machine

5 -> •; mm

First edition: issued in February. 1985 (1985^ 2

UjiLiLiCOX B^giBBS, Ltd.

-- SPRIMGWOOD DRIVE . SFRiMG'A-CCC NDLSTRlil E5TA"= . BRAi:^"r,EE , ESSEX. CM7 7YN

From the library of: Superior Sewing Machine & Supply LLC

W500/UT

m #

W542-01,03,08 (W541-01,03,08)

/ U T I O I

• • •

HH

im m)

W542-01,03,08 (W541-01,03,08)

/ U T 1 0 2

• •

W562-01,03,08,21 (W561-01,03,08,21)

/ U T 1 0 3

• •

W562-01,03,08,21 (W561-01,03,08,21)

/ U T 1 0 4

• 1

W542-01,03,08 (W541-01,03,08)

/ U T 3 0 1

• • •

W542-01,03,08 (W541-01,03,08)

/ U T 3 0 2

• •

W562-01,03,08,21 (W561-01,03,08,21)

/ U T 3 0 3

• •

W562-01,03,08,21 (W561-01,03,08,21)

/ U T 3 0 4

•

From the library of: Superior Sewing Machine & Supply LLC

aufelz

CC0OT*(±, W500/UT«a»mT-1-o

<

m ^

SEH 1

-co^^T 1

b A>fc — ^ ~ 1

T-zf)W0Mxtmft^<o&^x:t 2-3

^-9-zf-U — ^3

fitSttiBSffl® y #1^5^ 4

^ 5

3- K®g!«si • 6~®

Biyav>±®a® ®

#ilttaiS®&BSilii 9

10 10 10

x»yx.i' y 9 —

Sf'®<itjhfiB®«iy®?L-^-i'-®Siaj®ffiSiJ5i

vi/y-f K(ifi)®®y#w-:3^

(ifi)®® y ii~i2

V l/y-f K(«)i::*X^(ffi)®jtiS- 13

amss 1^

®Hiffi- —15

i^m^aim<»ms6

xT-^uTiiB®^® — 1®

XT-5SUTSB®ffiB ""11

11

K1^ V ® as — ^11

u I) (B)®® y —— 1®

•> y vi^- («) t («)® itB 18

W5 0 0/UT-t-ii -tt«— 19

W5 0 oyur/^-y y x i ^ — 43—58

English edition starts from page 21,

From the library of: Superior Sewing Machine & Supply LLC

W500/UT^M#= vXi.

^ i"o

t t o (fTlf-C'l' t t .

imRU'E-Sf-lZ'DlM:

r ^ ± tA V^ - J: o T M $ i-L r ^ ^ 1" 0

^lC^t^c€«l±^5:C/'tBI5[C J:

oTH^'i = X h vrZ^-^-^f^-fflL^i-o

€ E m wl p"o # ^

lOOV 1 802044-91

200 V 3 802045-91

220V 3 802046-91

240V 3 802047-91

380V 3 802048-91

MmCDU'^lz 415V 3 802049-91

W500/UT^Eft= i-Xi, i

1: •"/j T-E-^J o T L ^ 1", f^^ij : W500-01CAX232/UT103

220V i 1 802050-91

240V { 1 1 802051-91

lOjTj #!!«

— I —

From the library of: Superior Sewing Machine & Supply LLC

mi

4-«513

019.5 4-025.5

2 8 4 -

— 2 —

From the library of: Superior Sewing Machine & Supply LLC

W500/UT^mft = V > c7)$gft(i.

•fo

n-oX<

l.mi^^X. r--r;v^mxix <

2M2^^X. 0~®<7)liiC|gftia ftttt:

[—/i

• WSOO/UT^M# = V > {c (i, tSIf 50^IIn(7)T- 7*;^^i5i!)^6L^i•o

• l^)?50inm«7)T—•7'/Uc7)^|F'^(i, X'to

• W7i»H7mmJ.:JlT<7)T-r;K7)J-i'^{±,

9

9

m2

2.'<>'uh(i. M5yv-<;uh

X:— 9 —X— 0 —C7)^r|.g(niin)

6 0 Hz 5 0 Hz

6 , 0 0 0 1 0 5 1 2 5

5,500 9 5 1 1 5

5 , 0 0 0 8 5 1 0 5

4,500 8 0 9 5

4 , 0 0 0 7 0 8 5

(—•/£•

• ^—9 — T—^}—ii. l-

*CI1!') ±ih^LX^^<l^idbX </"::'$ ''^(H 3 ) h^O-IM-tKi, 9K1112#Mo

h JU:?

T=W X L(200-250kg-cm)

US

— 3 —

From the library of: Superior Sewing Machine & Supply LLC

—A=28mm

••4el n;>4M-cn X4<•4 -rr-7-✓N v» AfvenP^v V1to oo4OJf a

f

3 3>i

<- m/is (1a--T-

o -t:arA eciff1

' ^SUj4 en0 1 r~i_

O

9

rAn© /N.r~1 owr\® nve>»/s.3 <- •/9xriam oo< n'Vc <rr) W

H m m H 0 S G M-

U.1^ n: V > v;' 5+I 4® ^3 ri

sm (I ±a rA ✓%

V; O is c-c r\r\ /N. n OJt

n

M

K [MP qra 0 m G M-From the library of: Superior Sewing Machine & Supply LLC

1117

5

— 5 —

From the library of: Superior Sewing Machine & Supply LLC

(IPOS.

(2P0S.

LOW HIGH

yu-dr Ifxjgy jfxjgy ••

y L'/ 'T K p - K

•-KCD^iu

(—/3E

• :^>-®'j K®(i.

<n±riiLW. ^'SiiUbht t V^r- < ?

• h a-7-coPOS. X-f yf-fi, 2P0S.

(r-*)(C-fev h LX <

HP

\.X:-9-\,zH^^X^^h^^-^9 9 - 0 . 0, 0$:

u > h n — y — iz^^LX < /:f$

2.'S?®X'f •y^C0:7 4;

LX<

3.fS:ic#il±i^<7)=? > h a —7—(C .^iS^LX</c'^v^,

K^on ;f> ^ rJ'—0^ 3 > h C7 —7

X<

— 6 —

From the library of: Superior Sewing Machine & Supply LLC

^r\15? m fOcfV

7104 m» D8» % IVVi

•n

II0003I QQQ OOOO OOOOHI>^ «

From the library of: Superior Sewing Machine & Supply LLC

(011)

2m±n^.<Dmm

^>f&<D^04''C.^tC'^h-^. M-±.W.,^.X'±!ibX < f::

Z<X>t^. K'i-^^—>'K7)P-^— ^ t T —A

^^> K'tN^—-'u^lllL'CP-^—^7 t •EP

3mTWMo)mm nm^ihUibimL

4 ) M x ^ " " O N j l z LT,

^ ^ 4"21(5:^(- Mi" t $-\-^'TW.AX^^± L

±Lt'tc K'i-x^—;uc7)prp—7

>:T-A!7)»ep7:?>'^o-cv^^ :: t ^mULXi

$ V ,

7 u / /f KiO't'Tl^ =J— K^0:3 4 y —

®^;2> ha —y ——i7<7)r?

vu KHJd^lifLLr <

S,W^^%x'7^y{ -/^(^(Try'i^ 3 >

r? 4 y : 7 — r ? > h n —7—

r <

9.-^-^ 'J Jfiyjrj— Y{^)<r>zi y ^7 > h n —7 —(C, —:4<7)7 4> i7 ;J^—©^4'li='—K (M)fiij(c^i^^uLr <

• :^- = X l^lHljl^#M

LT < (010)

— 8 —

From the library of: Superior Sewing Machine & Supply LLC

m2.i3) h (7)^:b(ijEL < mmiX<

'<>'U h

») t t o

2. ^ c^iiSS

$:l^|p-C'l' t t o

i&f^<50)f>S{z4-') ^1"o

-f- y ,i<;u hOt!ilLt:^<?>/±^i^

lnL-C< r::^^\

mmmx-y ho^msbxm^ix < r::^^\

• :3>hn —7 —, —

*\ ioaK<^ *v

(11114)

W.tx^\z%\^x.

(i'>><x>m\m^hmBix< /::•^v^J

m

— 9 —

From the library of: Superior Sewing Machine & Supply LLC

(1315)

mmx'^ti-o LX^^lz^jttto

iz^< ®-t-^^7!?^'-C"#^i-o

i^(±. j^xtfrx^ L-t < /"C'? v^

(7M. miomm

• wC7)X ^ •/tTi^B>XXo

%f(DW'±^m(DWD1^^ (1^16)

a> Vv-y-^-i^-^Jvco x^ -y^oxmrKx^tto

(—) jpjj7&^' 1 .t°y X 3 > , (—•)1PJJ:^?^' 2 .t: X 3 > T- to(^3#m)

^-57-( (1116)

'/•7 = @T-|^ln-C'^^1-o

• ^: —:7 — T ' — " J — < LT^>6,000

LOW HIGH

IPOS.(-) if<wn

2P0S.(r-*) thT51:i;f?il: UTW.A-^±9^.^A'i^} 0

IPOS

(2P0S

— 10 —

From the library of: Superior Sewing Machine & Supply LLC

Vby-f K(m)0TO1tl:)-73 (BI17.18)

K±ffi7:>^'l^—l^?-r'7K¥{::=5.-^ J:

Oftttr <

2.y uy-f K3ii&a<?5iilis

•y-'--@-CJli&l;^17.9ram(C-b-/ h L-C< /-w'^

• "f" -y h O ^ ^{ki''!) i> i ^ (i, X h ••/ '' —©{C HI') 3 mm) ^ XHX < ^

7'7 y -y h h9y> 90<^®M t X^n7.5mmlZ^h-±X <

• 9y>90^'

IK j)!)< zt^mm^ix<rz^^\

(^19-22)

± / X^©3^®^±9 X ® « t T"167niinH,

± / X ^ i ± / f c 1 "

-2) J:^C|z')ft(t'C<

Ty'X^©j^®7!?^:^Ty'X ® « ^ -C163. SmtnC Ty'X^tTy'X(±mj®©7:?'-iJc1--i) J:

©

r

167mm

•163.5mm

— 11 —

•v

5 '>

rl7.9mm 117.5mm

©

From the library of: Superior Sewing Machine & Supply LLC

12 L -C < /Jf $ V^(D T'1^500 g X'to)

^ I XJ.— XlZ-\il]itlh Z t

L T < /"si'^ I'^ h L-9Ji'L;!?^'Sv> (J:

^mmLX<

12 —

r a

From the library of: Superior Sewing Machine & Supply LLC

(1^23-27)

m2Z^^mLX. 9y>

X'M^LX<

— 7T'lTo-t <

l.fzo 1 mraT'i-o

fz')it{t-C<

3.T/ X@<50thfi(i.T^ x^^AXC-t^X-to (^24#HB)

@C7) If <7) (153:43 ^-et'o

5.T^ X(7)^^il$i±y X®60^^jC7)$M1-^ D^

^(i0.5min,T/Xc7)7 y t ±^ X E "tiS 1 mm-ei"o

T/xx>^2 7 y 7Tffi F^^fiOT'i-o

• 11. 12KXI

') i t ( t ^ ^ I X

16mm

— 13 —

B = 2mm

SI

^y.r|n '4l

—A=1mm

|+rtl(mm) C"4'iS(nim) 2.4-4.8

5.6, 6.4

E = 1 mm

F = 0(mm)

From the library of: Superior Sewing Machine & Supply LLC

±:7^^Sit^CDiiiE5 (1328)

1.Ty'ry X<DT1S

±tbLX<r::^^^o

2.u^<—®(±. 7K¥*C7'7^-y h®<J:±/lra®^0 0 ~0.3tnm, Gi-ife7&>'5.5mra{C^ J: i C

3.l4®(i. HTrfcfeA^'6[nin(Z5i:^ J:

tbX <

(itf'tS_hffi>i'* »^6.5ram{zJ:") v€)^

-C<

6.5mm

— 14 —

0 ~ 0.3mm

®

yy///.^//////A

14mm

From the library of: Superior Sewing Machine & Supply LLC

©CdP 01

nro C;lD^ Pli3 3n M

S? tj-

W- r\ to jmHr*: ov is r- /s. rt rVcV: T?"

i:

Ee iMp ® rv > 0 3 ^2?ttTnmh w K dig qra 0

1 ©

(g r>- rt^ rVc•!>

V ® k 5+ )J>' »-> <-^ «/ (1

W'(t<}W^5- ^44

V ^ 3 ^

wt-ft s^m'vc ^w-S-"S n>4Mb°4 9t- <r- ii- r* r\ rt av

f

as- UOs=nra f'ndt %

r^rA m a •<A. o-» 5+✓S n fVc

tJJ a> 3 3 O -j 3 3 CJI 3 3 m CO

9+ e rv V e 3

0v» 94-® 'f^ >s 45- ^0 ^4 4 1 nrj: 9->av d-»i: <hr° O- n -^' v: O k"

0-4^<.- 9-r11 *4 n^V rvv:s r (i! V. 0 3 m3.

^ ^ i^

1—5rO 0 r« > v; OI 0 4

^ ?

-vjlo V 0 3cn 3 3_ r• »->

4 xs. n av

S ^Jla(g VW-V rAV» ®3 34V >^ V: e m

wrr CO9+ I (» 3^- n^-r;

^ 4 s

Pro-va 44^ '0"' Vf4 ).OJfvjl r-sV o°A

CJM C5 y 0

From the library of: Superior Sewing Machine & Supply LLC

ooooooo

n

¥WmGmm%CO^I®CDMl's•.mWai

V^mw^^-5ISGG4WGm1m®Gn H»VG12,Ki.•WlEgWs1^1$.H^

N•odfl®DHs4a'WV CO

From the library of: Superior Sewing Machine & Supply LLC

xT-^UT^®0@21f

©

'X 7 - 3 V L/ -y-9'- IC jgig^

^-To ^0iKmX'^^Zt: 5~7kg/arflc!g|lSU X <tz^\i^.

#x7-£E$:±ij's [ULr

• xT-ffiS:Ttf'2>i:Sli, :^^[Rltc|sILT < fc'

$ v^.

—a

-yp«3lCX7-?!>^J^ori>-5i; tt±, J<>)VX7

®'ec:ras< v^o

KU V®#{ii

- U=arjL b-3i -OtcfctofcKbvti,

LT#ai

1135

— 17 —

From the library of: Superior Sewing Machine & Supply LLC

1.036$:#BaLT, O, O(0MlZ^'p>^O(D±

mt^'yh^±m d if ^ t-tk^ ic -s j; •? ic m)

2.t/U IS.Omn -e-T.

^V(D-ti&it 89.0mm ViTa

m t r . uvi'©,

l.Omm T'f o

^0m(Dmm:&mit. i3m (mm^) MbT<

— 18 —

18.0mm 89.0mm

=1.Omn

From the library of: Superior Sewing Machine & Supply LLC

t o

I

W500/UTffl —f±«—'

m E (V) m ^

— rPpb#"^ H ^ m E (V) ^ =E-'^-

IS %

m 40 (Hz) # 40 H m (Hz) m 40 = 40

0 ^ 100 200 50/60 802044-91 802045-91

• ^ U ^ no 60 802044A91 x ^ 7 KJU

m n $

-f 7 > p o >t:*7 110 220 60 802044A91 802046-91

^ m

-f > K h 'j x y - K h/\'x

iJ'' 7 -f 7^') ti^^m

110-120 220 60 802044B91 802046A91

X5^:t t°T 802044C91 802046B91

^rxT 7-r ') t:> 220 220 60 802050-91 802046-91

V i i 77H2>5^>

^ >-9-'—7'

220 50 802050-91 ^ -f 220 220/380 50 802050-91 802048B91

h 7UZI /N°7 :J''7 -f

V I U 7 — 7 > K

'< h i-lx 7 'j

+''J v 7 4^ H 220 380 50 802050-91 802048-91

;^^-f > h :#3'7U

^ • -y • W 200 346 50 802050A91 802048C91

;»3y7U—>

60

^ 7 > y

220 380 50 802050B91 802048A91

7 -f > 7 > K

(^•1' 7U— h ) 802050-91 ^ 7 7 'j 240 380 50 802051-91 802048-91

'r>K^^v7 -r 4^'U 7 240 415 50 802051-91 802049-91

v ' J 7 7 7 > 7 230 380 50 802051B91 802048A91

5^ a X V 7 110/220 50 802050C91 K 5 x:^ 220 60 802046-91

yH 'J t ' 7 v>^\'7'x

lx/\V > 7^:71—7-'> 802048-91

X v y h 7-f 7 380 50

'J 7 > ^

230 50 802051A 91

yf - 7 MJ 7

802048A91

X ZL — V — 7 > K X > 7 — 7

7 'j 7 + 7*p:^

i ? ' ! ? ! - h 240 50 802051-91

7 -f - i ^ -

From the library of: Superior Sewing Machine & Supply LLC

W500/UT Organaization chart

Machine Qodels

Thread trimminng mechanism

Electoric foot l i f t e r

Pneumatic foot l i f t e r

Thread wiper

(Erectoric type) A note

Erectoric type

Pneumatic type W542-01,03,08

(W541-01,03,08) ,

/ U T I O I

• • •

HITSUBISI "I"

Motor (standard ) Top cover thread trimmer : No W542-01,03,08

(W541-01,03,08)

/ U T 1 0 2

• •

W562-01,03,08,21 (W561-01,03,08,21)

/ U T 1 0 3

•

W562-01,03,08,21 (W561-01,03,08,21)

/ U T 1 0 4

• W542-01,03,08

(W541-01.03,08) / U T 3 0 1

• • •

W542-01,03,08 (W541-01,03,08)

/ U T 3 0 2

• •

W562-01,03,08,21 (W561-01,03,08,21)

/ U T 3 0 3

• •

W562-01,03,08,21 (W561-01,03,08,21)

/ U T 3 0 4

•

= Y e s

— 21 —

From the library of: Superior Sewing Machine & Supply LLC

INTRODUCTION

This manual contains the operating and servicing instructions of the Thread Trimming Mechanism used on the W500/UT machine.

For other instructions, refer to the W500/UT instruction manual.

TABLE OF CONTENTS Page

GENERAL DESCRIPTION 23

COMPONENTS AND MOTOR^ 23

IDENTIFICATION^ 23

TABLE CUTTING AND MACHINE REST BOARD ASSEMBLY 24~25

DRIVING MOTOR PULLEY AND BELTING^ 25

POSITION DETECTOR — 26

SOLENOID OPERATED FOOT LIFTER — —26

THREADING "27

CORD CONNECTION,CONNECTING STEPS— 28-30

CAUTION 31

ADJUSTING POSITION OF OPERATION DETECTOR 31

PEDAL ACTION^ — 32

PRESSER FOOT LIFT SWITCH — —^32

SELECTING NEEDLE STOP POSITION • TOP SPEED OF MOTOR 32

SOLENOID (UNIT) SETTING ^33

KNIFE HOLDER (UNIT) SETTING 33-34

CONNECTION OF SOLENOID (UNIT) WITH KNIFE HOLDER (UNIT) 35

THREAD WIPER ADJUSTMENT -36

THREAD RELEASER ADJUSTMENT 37

OPERATION DETECTOR ADJUSTMENT 37

CONNECTING FOR THE PNEUMATIC UT DEVICE 38

PIPING FOR THE PNEUMATIC UT DEVICE 39

ADJUSTING AIR PRESSURE — 39

REMOVING DRAIN — 39

INSTALLING CYLINDER(UNIT) 40

CONNECTION OF CYLINDER (UNIT) WITH KNIFE HOLDER (UNIT) ^ 40

W500/UT (UNDER THREAD TRIMMER) MOTOR SPECIFICATIONS ^41

W500/UT PARTS LIST — ^43—58

— 22—

From the library of: Superior Sewing Machine & Supply LLC

GENERAL DESCRIPTION

The W500/UT machine is driven by an electromagnetic clutch type needle positioning motor. The micro processor based precision controller controls needle positioning, thread trimming, thread wiping and foot lifting.

Pressing the pedal backward at the end of sewing causes the looper thread to be cut off under the needle plate. Then, the wiper takes out the needle threads from the presser foot, and the presser foot lifts. The presser foot can be moved up or down by pedal action at the start of sewing.

COMPONENTS AND MOTOR

The W500/UT machine consists of a foot lifter, motor and W500/UT machine equipped with the thread trimming mechanism. The standard motor is

MITSUBISHI LIMI-STOPZ. Various motors suitable

for the voltage and phase are provided for use as

listed in Table 1.

IDENTIFICATION

The machine is shown by the machine type, gauge and the UT device type number. Between them is a slash /.

Example: W500-01CA x 232/UT103

Table 1

VOLTAGE PHASE PART NO.

lOOV 1 802044-91

200V 3 802045 -91

220V 3 802046 -91

240V 3 802047 - 91

380V 3 802048-91

415V 3 802049 -91

220V 1 802050-91

240V

1 ! 802051 -91

See page 41.

— 23 —

From the library of: Superior Sewing Machine & Supply LLC

Fig.1

4-013

— 50

362

— 24—

From the library of: Superior Sewing Machine & Supply LLC

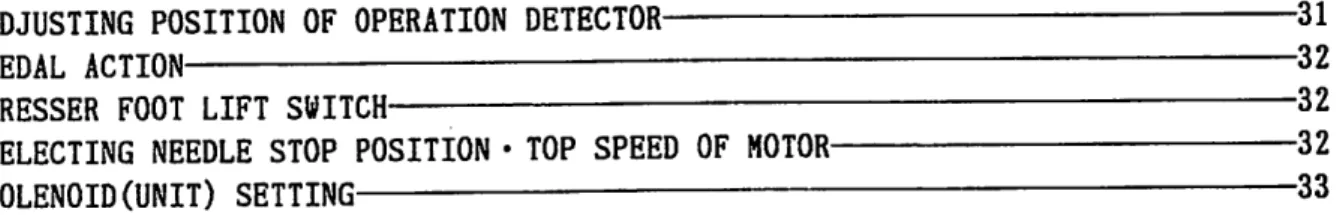

TABLE CUTTING AND MACHINE REST

BOARD ASSEMBLY

For W500/UT machine, semi-submerged installation is adopted.

1. Refer to Fig. 1 and cut the table.

2. Refer to Fig. 2 and assemble the machine rest

board O ^ ® in sequence.

^NOTE:

• For W500/UT machine, a table of thickness 50mm is recommended.

• For the table of thickness 50mm, Washer 0is

unnecessary.

• For the table of thickness 47mm or smaller, use Washer 0 .

©-tvAi

DRIVING MOTOR PULLERY AND BELTING

The machine should use a motor and belt of the following specifications.

1. Motor: Clutch motor, 2 pole, 550 watts.

2. BELT: V belt. Type M

3. Motor pulley: Select an appropriate pulley referring to Table 2.

Fig. 2

Relation between Machine Speed and Motor Pulley Table 2 Machine speed (s. p. m.) Motor pulley diameter (mm)

60 Hz 50 Hz

6,000 105 125

5,500 95 115

5,000 85 105

4,500 80 95

4,000 70 85

I-NOTE

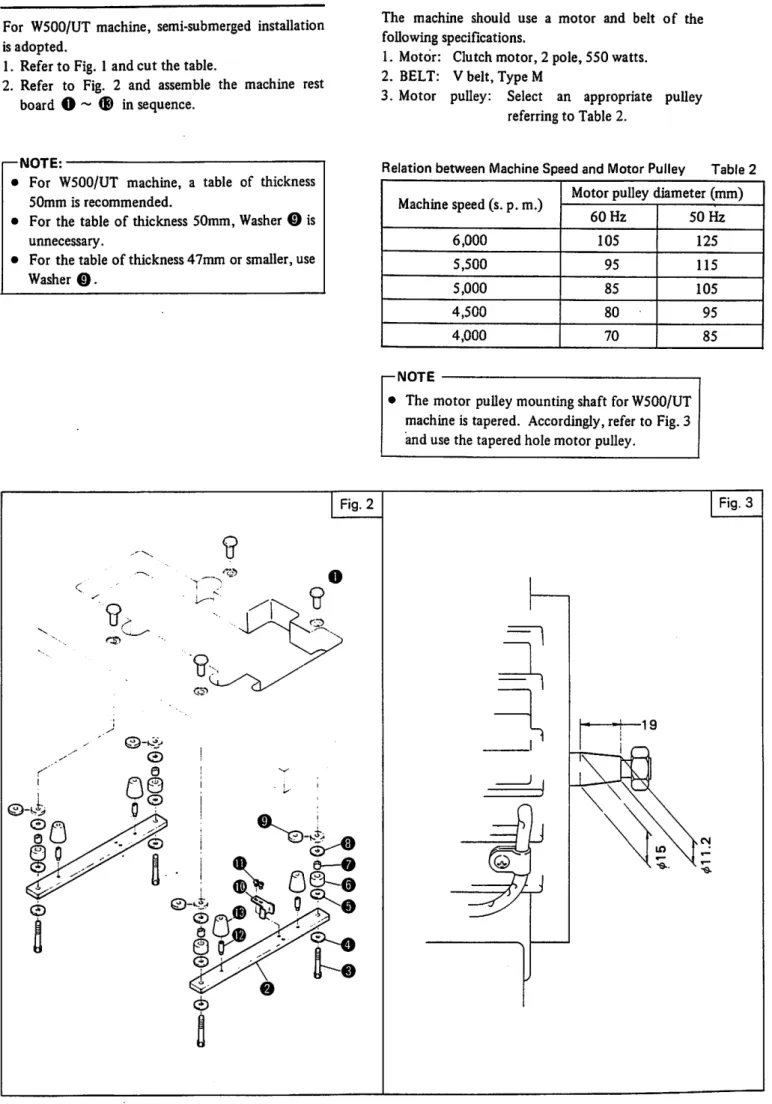

• The motor pulley mounting shaft for W500/UT machine is tapered. Accordingly, refer to Fig. 3 and use the tapered hole motor pulley.

\

Fig. 3

0 0—O

— 25—

From the library of: Superior Sewing Machine & Supply LLC

POSITION DETECTOR (Fig. 4) 1. Remove Screw O-

2. Refer to Fig. 4, and install 0 and 0 in sequence.

(Fix Screwwith Pin 0 with Nut 0 .)

SOLENOID OPERATED FOOT LIFTER (Figs. 5,6) Refer to Figs. 5, and 6, and install parts 0 to 0 ,and

to 0 in sequence.

• Loosen Nut 0 and adjust the stroke S.

Setting distance "A" to 28 mm provides standard

stroke.

• Adjust Pitman Rod 0 so that Foot Lift Lever 0

has a little play.

— 26—

From the library of: Superior Sewing Machine & Supply LLC

THREADING

Fig. 7

y j

5 u

From the library of: Superior Sewing Machine & Supply LLC

—11—CONTROL PANEL

Power source connector

CORD CONNECTION I— NOTE

LOW HIGH

Brake Clutch

Be sure to extend earth (ground) wire from the motor and machine to a good ground.

Do not connect Thread Trimming Junction Cord ® until the highest/lowest needle stop positions have been set by the synchronizer.

Set the PCS switch on the controller to

"2P0S" (.—•).

Position detector

(IPOS.)

(2P0S.)

Presser foot lifter switch

Needle position

Operation detector

Presser foot lifter solenoid

Thread trimming ..junction cord

connector

CONNECTING STEPS (Figs. 8 ~ 10)

1. Insert Connectors and of the motor into

the controller. '

2. Insert Power Switch Connector O into the motor.

3. Insert Synchronizer Connector 0 into the

controller.

4. Insert Safety Detector Junction Cord Connector into the controller, and Connector © into the synchronizer.

— 28—

From the library of: Superior Sewing Machine & Supply LLC

Connect to the bed the earth(ground)sire(yellow

& green storipes) (E) coning out of the terminal box shown in Figure 10. Use the cord crip See Figure 10—1.

5. Turn the power switch on. Press the pedal a little

and check the direction of rotation of the machine. If the machine runs in reverse, re-insert Power Connector O upside down.

Turn the power switch off.

Z

— 29—

Yellov &

sreen stripes

earth(ground)(o^Os3

Vhxte

DOO cr ?oo

Thread wiper solenoid

1

Thread trimmer solenoidGreen

Junction cord (short)

7

Black

From the library of: Superior Sewing Machine & Supply LLC

6. To set the needle stop position (Fig. 11)

1) Remove Cover O and loosen Screw 0 .

2) To set the upper dead point of needle:Line up the part ® of Upper Position Detecting Plate 0 (inside, black color) with the center of

Sensor Baseplate 0, and stop it at the upper dead point of the needle.If the P mark of the hand wheel and the • mark of the arm do not agree, fix the upper position

detecting plate, turn the handwheel to lineup the

P mark with the • mark, and tighten Screw 0, 3) To set the lower dead point of needle:Line up the part (§) of Lower Position Detecting Plate 0 (outside, red color) with the center of

Sensor Baseplate ®.• In this case. Screw 0 need not be loosened.

Adjust first from the upper dead point of needle.

4) Turn the power switch on, and press down the pedal. Return the pedal to the neutral position,

and the needle stops at its lower dead point. Byfurther pressing down the pedal, the needle stops at its upper dead point. Then, check that the P

mark on the handwheel is lined up with the • mark on the arm.

7. Insert Connector 0 of Presser Foot Lift Junction Cord into the controller. Insert the other Connector 0 into the solenoid.

8. When using Presser Foot Lift Switch 0 (option),

insert Connector 0 into the controller.9. Insert Connector 0 of the thread trimming

junction (long) into the controller and the other

Connector 0 into the relay cord (short) side.

• For connection inside the terminal box, refer to the detailed drawing. (Fig. 10)

— 30—

From the library of: Superior Sewing Machine & Supply LLC

CAUTION (Figs. 12.13)

1. Keep the belt tension correct. Adjust it so that a 1 kg force on the center of the belt allows a

deflection of about 15 mm.

• Excessive belt tension may overload the machine

and motor.

• Insufficient belt tension may cause the belt to slip, and the needle may not stop correctly.

2.. To adjust pedal pressing force:

Pedal pressing weight can be adjusted by changing the position of hooking Tension Lever Q on Lever o

• Insufficient spring tension may cause the lever stopping position unstable and lead to malfunction.

3. To adjust pedal pressing forward force:

Loosen Nut and turn Bolt O to adjust the spring pressure.

Then, tighten Nut 0 to fix.

• Read well the guide book enclosed in the controller

and motor.

ADJUSTING POSITION OF OPERATION

DETECTOR (Fig. 14)

Press the pedal backward under the energized state, and the presser foot lifts up.

Loosen Screw 0> and slide slowly ' righfward

Operation Detector 0, and the presser foot will

drop. Turn 0 back leftward to the position for the presser foot to lift up, and tighten Screw 0.(Adjust from the rear side of the machine.)

Fig. 13

— 31 —

From the library of: Superior Sewing Machine & Supply LLC

PEDAL ACTION (Fig. 15)

Press the pedal forward and themachine runs.

• Machine speed can be freely adjusted by thepedal

pressing amount.

• After the thread has been trimmed, the presser foot can be lifted up or down by pedal action.

• Whde the machine is stopped, the handwheel can be turned freely by hand.

PRESSER FOOT LIFT SWITCH

To lift the pressr foot without trimming the thread while the machine is stopped, press Presser Foot Lift Switch (Refer to page 23, Fig. 10)

• This switch is available as option.

SELECTING NEEDLE STOP POSITION (Fig. 16)

The needle stop position can be selected by the

switch e on the controller panel.

(u.) side is Position 1, and (.—) side is Position 2.

(Refer to Table 3)

TOP SPEED OF MOTOR (Fig. 16)

The top speed of the motor is adjustable by the knob

Oon the controller panel.

• The motor speed is so set as not to rotate beyond 6,000 r.p.m. however large the motor pulley

diameter is made.

LOW HIGH

Table 3

\ PEDAL

\^ION

NEEDLE^

POSITION \

PRESS PEDAL FORWARD

4 NEUTRAL

NEUTRAL PRESS PEDAL

BACKWARD

IPOS(-) Needle stops at highest position.

Thread trimmed, then presser foot lifted.

2 PCS (.—•) Needle stops at lowest position.

Needle stops at lowest position, thread is trimmed at highest needle position, and then presser foot lifts

up.

Pressing backward

• •

(IPOS.)

(2P0S.)

Needle position

— 32 —

Fig. 15

Neutral

Fig. 16

From the library of: Superior Sewing Machine & Supply LLC

SOLENOID (UNIT) SETTING (Figs. 17,18)

1. Refer to Fig. 17 and set O and O in sequence so that the upper face of Crank O should level with the upper face of the bed horizontally. (*)

2. Solenoid stroke adjustment:

Remove Rubber Cover loosen Nut and set the

stroke to 17.9mm with Stopper 0 ,

• When loosening Nut 0, insert a round stopper bar (about 3 mm in diameter) into Stopper 0.

3. Crank position adjustment:

Set the distance between the right end face of Bracket 0 and the face ® of Crank 0 to 117.5

mm.

• Make sure that Crank 0 lightly moves when Compression Spring 0 is not fixed.

a\A'3\

See from the rear side of the machine

KNIFE HOLDER (UNIT) SETTING (Figs. 19~22) 1. Setting Upper Knife (Unit):

Set the distance between the end face of Upper Knife Holder 0 and the edge of Upper Knife 0 to 167 mm, and the gap between the end face of Upper Knife and the end face of Plate Spring to 0.3 mm, and yet set so that the upper knife holder agrees with the upper knife at their front faces (@).

2. Setting Lower Knife (Unit):

Set the distance between the end face of Lower

Knife Holder and the edge of Lower Knife 0 to 163.5 mm, and that the lower knife holder agrees with the lower knife at their front faces

0 // ^

1

•167mm-

/ © 0 I

J

<

\

©•183.5mm-

— 33—

117.5mm

Fig. 18

17.9mm

Fig. 19

>©

Fig. 20

From the library of: Superior Sewing Machine & Supply LLC

3. Setting Knife Holder (Unit):

Refer to Fig. 21 and set (f) and is sequence.

After setting, make sure that Lever ® lightly moves, (about 500 g load at Point (D) )

• Checking Knife Cutting:

Check that a piece of woollie thread is smoothly trimmed. It not, adjust Plate Spring (p.

- 3 4 -

Fig. 22

From the library of: Superior Sewing Machine & Supply LLC

CONiSIECTION OF SOLENOID (UNIT) WITH

KNIFE HOLDER (UNIT) (Figs. 23 ~ 27)

Refer to Fig. 23 and connect Link O ^nd Crank O

with Screw

Check the dimensions of respective parts so that the upper dead point of the needle bar agrees with P

mark on the handwheel.

1. Gap A should be 1 mm under the set condition.

2. To adjust the return spring pressure, set CollarO so as to make Gap B 2 mm.

3. Set the projection of Lower Knife 0 to Size C at the left dead point of the lower knife. (Refer to Fig. 24)

4. Set the positions of advance and return of Lower Knife 0 so that the tip of the lower knife is approximately at the middle of the thickness of Looper 0 .

Adjustment should be made with Screw 0.

5. The clearance D at the cross of the blade of the

lower knife with the blade of Upper Knife 0 should be 0.5 mm, and the clearance E between the tip of the hook of the lower knife and the upper knife should be about 1 mm.

6. The clearance F between the rear end face of Plate

Spring 0 and the lower face of the second hook

of the lower knife should be zero.

• When the above parts are not exactly set at the sizes as specified, re-check the setting dimensions given on pages 33 and 34

-35-

8 = 2mm

16mm

I \\\

Fig. 23

—A=1mm

Fig. 24

Needle bar center

Needle gauge (mm)

Dimension C (mm) 00

I

CM

9.4 5.6, 6.4 8.6

Fig. 25

Fig. 26

E = 1mm

F = 0(mm) Fig. 27

From the library of: Superior Sewing Machine & Supply LLC

THREAD WIPER ADJUSTMENT (Fig. 28)

1. Temporarily fix Bracket <E) horizontally to the middle part of the elongated hole with Screw 0.

2. Lever 0 should be horizontal. Tighten so that the gap between Bracket 0 and Stopper Ring 0 is

0 ~0.3 mm, and the size G is 5.5 mm.

3. Shaft 0 should be stopped with Screw 0 so that

the size H becomes 6 mm.

4. Thread Wiper 0 should be stopped with Screws 0 and 0 so that it is 14 mm from the center of

the needle bar at the left dead point and its height is 6.5 mm from the upper face of the needle plate.

5. Set Thread Wiper 0 and Plate Spring 0 with

their tips aligned.

6.5mm

36 —

Fig. 28

0 ~ 0.3mm

14mm

From the library of: Superior Sewing Machine & Supply LLC

THREAD RELEASER ADJUSTMEIMT (Figs. 29, 30) 1. Set ThreacJ Releaser Crank O so that the gap

between the side of the bed and the side of the crank should be 33 mm.

2. With Screw 0 of Crank 0 loosened, connect Lever O and Cranks O and with Screw 0 3. Adjust Lever Shaft 0 so that the gap between the

thread tension disk and the. claw of the thread releaser should be 0 ~ 0.5 mm. Then, tighten Screw 0 on Crank

4. Shaft 0 should be stopped with Screw 0 so that

the size A should be 37 mm.

• The thread releasing for each thread depends on the positional relation between Thread Guide 0

and Thread Releaser For cotton thread:

B = 6 mm, C = 7 mm, D = 8.5 mm, E = 6.5 mm, F = 9 mm

For elastic thread such as woollie threads, reduce the clearances slightly.

- NOTE;

Thread Releaser 0 (for upper spreader thread) should be set to such a position that should not be affected even when the needle thread and the looper thread are loosened.

OPERATION DETECTOR ADJUSTMENT (Fig. 31) Loosen Screw 0 and set the gap between Operation Detector 0 and Magnet 0 to 0.5 mm.

(For adjusting the right and left positions, refer to page 31-)

0.5mm

©

Fig. 29

J 33mm

Fig. 30

0

— 37—

From the library of: Superior Sewing Machine & Supply LLC

Connecting for the pneumatic UT device

Hake connecting as shovn.

Refer to the connecting steps,cord connection of the electrical UT device the note,adjustment of the other.

Yelloe &

green stripes earth(ground)

38—

Thread trimmer solenoid

Black Yelloe

Black Vhite M

Thread wiper solenoid

n

Junction cord (short)

Red Black

Vhite

From the library of: Superior Sewing Machine & Supply LLC

Piping for the pneumatic UT device Make piping as shown.

Refer to Figure 32

Connected to the air compresser.

Adjusting air pressure

Pull knob®on filter regulator o. It should pop up a little with a click. Then adjust the air pressuer for 5—7kg/a^.

#To increase the air pressure, turn knob ®

clockwise.

•To decrease the air pressure, turn knob ®

counter clockwise.

—Note-

(Note that even after the air supply is shut off from the compresser, the cutter can operate with a push of the valve actuator if air is left enough in the tube to actuate the

cutter.

Removing drain

Drain collected in filter regulator O ®ust be draind out by pushing the drain hose O of the bottom to right or left before it reaches buffle

'h

— 39 —

From the library of: Superior Sewing Machine & Supply LLC

Installing cylinder(unit)

1. Refer to fig.36,and set Oand ©in sequence

so that the upper face of crank© shouldlevel with the upper face of the bed horizontally.(5K)

2. Air cylinder stroke is IS.Omm.

3. Trun the surface of right .edge of bracket O

to dimention of surface ® of crank © is89.0mm.

Connection of cylinder(unit) with knife holder(unit)

Refer to fig. 38, connect link ©and crank © with screw©.

1. Gap A should be l.Ontm under the set condition, Refer to P.13(Electrical type)the note and how to adjustment of the other.

18.0mm 89.0mm

=1.Omn

— 40 —

From the library of: Superior Sewing Machine & Supply LLC

W500/UT (UNDER THREAD TRIMMER) MOTOR SPECIFICATIONS

Nation

Voltage (V)

Frequency (Hz)

Part nunber of the motor

Nation

Voltage (V)

Frequency (Hz)

Part number of the motor

1-phase 1-phase 3-phase 1-phase 3-phase

GUATEMALA

no 60 802044A91

JAPAN 100 200 50/80 802044-81 802045-91

COSTA RICA ECUADOR

110 220 80 802044A91 802048-91

VENEZUELA KOREA

IRAN

220 50 802050-81

COLOMBIA

IRAQ TAIWAN

INDIA TRINIDAD AND TOBAGO

URUGUAY UNITED STATES OF AMERICA

no ~ 120 220 80 802044B8I 802048A9I

ETHIOPIA CANADA 802044C81 802048691

KENYA PHILIPPINES 220 220 80 802050-91 802048-81

UNION OF SOVIET SOCIALIST ARGENTINA

220 220/380 50 802050-81 802048B8I

TANZANIA THAILAND

TURKEY PARAGUAY

NIGERIA POLAND

VIET-NAM CHILE

220 380 50 802050-91 802048-91

GRECE CHINA

SPAIN PORTUGAL

MOROCCO HONG KONG 200 348 50 802050A8I 802048C8I

CAMEROON

60 NETHERLANDS

220 380 50 802050B8I 802048A9I

PERU FINLAND

( BEIRUT )

110/220 50

802050-81 SOUTH AFRICA 240 380 50 802051-81 802048-81

INDONESIA

802050C81

ENGLAND 240 415 50 802051-81 802048-81

SYRIA FRANCE 230 380 50 80205IB8I 802048A8I

TUNISIA DOMINICAN REPUBLIC 220 80 802046-81

BOLIVIA ZIMBABWE

380 50

802048-81

LEBANON SWEDEN

EGYPT SWITZERLAIO

ST.LUCIA

230 50 80205IA9I AUSTRIA

802048A9I

NEW ZEALAND DENMARK

AUSTRALIA

240 50 802051-81

CYPRUS KUWAIT SINGAPORE FIJI

From the library of: Superior Sewing Machine & Supply LLC

PARTS CATALOG

W500/ UT

x T - ^ # x ^ ^ ^ ^ | -

T A B L E O F C O N T E N T S

COVERS

THREAD WIPER MECHANISM • KNIFE MECHANISM THREAD TENSION MECHANISM

ELECTRIC THREAD TRIMMING MECHANISM ELECTRIC FOOT LIFTER

PNEUMATIC THREAD TRIMMING MECHANISM PNEUMATIC FOOT LIFTER

PART NUMBER INDEX

— 43—

44-45 46-47 48-49 50-51 52-53

-54-55 -56-57 58

-44-45 -46-47 -48—49 -50-51 -52-53

-54-55 -56-57 58

From the library of: Superior Sewing Machine & Supply LLC

— 44—

From the library of: Superior Sewing Machine & Supply LLC

@2t

1122

REF- PART NO.

NO. 9" j r -j NAI1E

1 350003 Djr- COVER

2 7043 (n4) SCREW

3 350004 •n\Y- COVER

4 7096 (114) SCREW

5 240104 WASHER

6 211301 SPRING WASHER

7 4803 NUT

8 250010 FLAT SPRING

9 7078 b5;<ci;MI12.5) SCREW

10 202588 WASHER

From the library of: Superior Sewing Machine & Supply LLC

—45-From the library of: Superior Sewing Machine & Supply LLC

—46—THREAD WIPER MECHANISM-KNIFE MECHANISM

REF. PART NO.

NO. 9" j r :'j NAME

1 811045--91 SOLENOID

2 748005 CLANP

3 7019 (n4) SCREU

h 350031 9^5T9h BRACKET

5 306553 GUIDE

6 202522 RING

7 7019 fDZV"" (N4) SCREU

8 350026--92 9599(9^) CRANK ASSEMBLY

9 350026 9599 CRANK

10 4500 b5^^9^ (P15) SCREU

11 350027 9^99Tb®9 PIN

12 200555 RETAINING RING

13 7009 b5T9^ (113) SCREU

14 350028--91 BRACKET ASSEMBLY

15 350032 •<hn5-< THREAD UIPER

16 350033 FLAT SPRING

17 350034 UASHER

18 7008 b5T9" (113) SCREU

19 350053--91 (9^) KNIFE HOLDER ASSEMBLY

20 350000--91 9^599h BRACKET ASSEMBLY

21 350014 b j r - LEVER

22 350013 U99 LINK

23 240132 UASHER

24 7094 9^99TT9^ (n5) SCREU

25 350015 79tT GUIDE

26 7095 b5T9^ (115) SCREU

27 350023 LOUER KNIFE HOLDER

28 7097

b5T9'^ •(I13)

SCREU29 350024 u9:^2 LOUER KNIFE

30 350025 UASHER

31 7031 b5T9^ (n2.5) SCREU

32 350016 UPPER KNIFE HOLDER

33 350021--91 9^5T9h BRACKET ASSEMBLY

34 7031 b5T9^ (112.5) SCREU

35 240131 799l9jrT SPRING

36 350018--91 UPPER KNIFE

37 350017 UASHER

38 350019 FLAT SPRING

39 350020 9'^599h BRACKET

40 7098 tr5T9'' (112.5) SCREU

- 4 7 -

QT 1 2 2

From the library of: Superior Sewing Machine & Supply LLC

48) @~<S),@-®X3

@X2,®

24ctf-fiB 0 : m 2-Needle

Without top cover thread.

49)@~(i),®)~®X3

•) : t 2-Needle

With top cover thread.

- 4 8 -

50)®-®

@X3,i

)~®X4

0 : M 3-Needle

Without top cover thread.

51)®-®.®- _

@X3,®,®

3-NeedIe

With top cover thread X5

From the library of: Superior Sewing Machine & Supply LLC

THREAD TENSION MECHANISM

REF, NO.

PART NO.

7^ W 'j NANE QT

1 350036-92 9579(9=) CRANK ASSEI1BLY

2 350036 9579 CRANK

3 4531 t5:j:7^ (N5) SCREU

4 350037 b i ^ - LEVER

5 7027 t5:?:7'' (115) SCREU

6 350038-92 9579(9=) CRANK ASSEMBLY

7 350038 9579 CRANK

8 4531 (n5) SCREU

9 7066 SCREU

10 202868 UASHER

11 350039-91 bjr-7^9 LEVER-SHAFT ASSEMBLY

12 5382 794^^7 VC5 SCREU

13 350043 HOLDER

14 200983 RING

15 4554 (113) SCREU

16 350042 7^9 SHAFT

17 350047 HOLDER

18 350045 THREAD RELEASER

19 4554 h;>t47^ (113) SCREU

20 350046 4jb9^- HOLDER

21 350045 TMJb;^ THREAD RELEASER

22 4554 h;>t47'' (113) SCREU

23 254005 9^5r2h BRACKET

24 254006 THREAD RELEASER

25 350044 777T GUIDE

26 7019 b547'' (114) SCREU

27 306301 tV]Y Uir4 SPRING

28 5447 594 LATCH

29 254010A91 •<h4397(9=)U30) TENSION NUT ASSEMBLY (HEAVY)

30 208447 439779h POST NUT

31 208448 hMV T r SPRING BUSHING

32 201037 797l9jr4(439) TENSION SPRING (HEAVY)

33 208450 W 5 CAP

34 210319 43977^5 DISC

35 1817-2A 43974"9 SCREU STUD

36 254010B91 -rh4397(9=)(439) TENSION NUT ASSEMBLY (MEDIUM) 37 201086 797290"4(429) TENSION SPRING (MEDIUM)

38 254010C91 -rh4397(9=)(7"1'9) TENSION NUT ASSEMBLY (LIGHT) 39 201068 79729n"4(7"1'9) TENSION SPRING (LIGHT)

40 206203 -rh=4 THREAD LEAD-IN GUIDE

41 350048 4K43979"T THREAD TENSION GUIDE

42 206202 2^®-9- TENSION POST COLLAR

43 350049 -rh=4 THREAD GUIDE

44 7019 b547" (114) SCREU

45 167079 EYELET

46 7019 b547" (114) SCREU

47 7019 b547" (114) SCREU

48 350054B91 T>ya> (75) TENSION CONTROL MECHANISM

49 350054C91 T»3> (75)

TENSION CONTROL MECHANISM 34^^88

50 350054D91 T>y3> (75)

TENSION CONTROL MECHANISM see pl'ge 34

51 350054E91 T>y3> (75) TENSION CONTROL MECHANISM

— 49-

2 3 4 4 8 1 1 1 2 1 1 3 3 3 3 3 6 3 1 1 1 1 5 5 5 1 1 1 1 2 1 1 1

From the library of: Superior Sewing Machine & Supply LLC

From the library of: Superior Sewing Machine & Supply LLC

50—THREAD TRIMMING MECHANISM

REF. PART NO.

NO. 9" i r -j NAUE QT

1 811044-91 SOLENOID ASSEI1BLY 1

2 750014-91 TERI1INAL BOX ASSEMBLY 1

3 760149 TERMINAL BOX 1

4 760150 5-^711/1^^ V02~)9 COVER 1

5 7018 b5aL'^ (114) SCREU 2

6 750015 TERMINAL BRACKET 1

7 4020 SCREU 2

8 9A2519 INDICATION PALTE 1

9 747005 CORD BUSHING 3

10 7019 (n4) SCREU 2

11 350050 BRACKET 1

12 7009 (113) SCREU 2

13 350005-RA BRACKET ASSEMBLY 1

14 4518 SCREU 3

15 811048-91 SOLENOID 1

16 4531 (115) SCREU 3

17 350008-91 BRACKET ASSEMBLY 1

18 4500 (n5) SCREU 3

19 350011 SHAFT 1

20 240130 ?Tu20\VZ SPRING 2

21 201665 1)5- COLLAR 1

22 5084 Qyi}0ZV'^/C3 SCREU 2

23 350012 03-j0 CRANK 1

24 4808 DVUOfVh NUT 1

25 201665 1)5- COLLAR 1

26 5084 •91l97'Vh SCREU 2

27 7094 (n5) SCREU 1

28 240062 UASHER 1

29 4820 •!VD979h NUT 1

30 7088 U79I- (115) NUT 1

— 51 —

From the library of: Superior Sewing Machine & Supply LLC

— 52 —

From the library of: Superior Sewing Machine & Supply LLC

ELECTRIC FOOT LIFTER

REF. PART NO.NO. 9^^ IV 'j NAI1E QT

1 306566-91 FOOT LIFTER 1

2 4751 BOLT 2

3 206337 UASHER 2

4 4808 NUT 2

5 306334-FD BRACKET 1

6 4515 (116) SCREU 4

7 748006 9U'V9°(3A) CLAnP 1

8 4009-1 b5;iCL'VC5 SCREW 1

9 303335 UASHER 1

10 306339 yyviowz SPRING 2

11 811017 SOLENOID/FOOT LIFTING 1

12 306335 BRACKET 1

13 4515 t'DZV'' (116) SCREW 4

14 306338 KNUCKLE 2

15 306337 b":; PIN 2

16 4808 oynoty^ NUT 1

17 306336 b j r - LEOER 1

18 742092 JUNCTION CORD 1

19 306791 PITHAN ROD ASSENBLY 1

20 306793 ROD (SHORT) 1

21 306792 CONNECTOR 1

22 2022-4 ovwru^'/cio SCREW 1

23 306795 PITHAN ROD (hediuh) 1

24 201166 oub" :> COTTER PIN

25 802044-91 Lt-Slb/l 000,53/90 L-nOTOR/1000,1-PHASE

26 802045-91 Lf-Mb/2000,390 L-nOTOR/2000,3-PHASE 1

27 802046-91 Lt-hJb/2200,390 L-I10T0R/2200,3-PHASE 1

28 802047-91 Lt-Mb/2400j390 L-nOTOR/2400,3-PHASE 1

29 802048-91 Lt-Mb/3800,390 L-NOTOR/2800,3-PHASE See pages 41 1

30 802049-91 Lt-Mb/4150,390 L-I10T0R/4150,3-PHASE 1

31 802050-91 Lt-Mb/2200,53/90 L-I10T0R/2200,1 -PHASE 1

32 802051-91 Lt-Mb/2400,53/90 L-I10T0R/2400,1-PHASE 1

33 742272-91 ^200-1'3-hVl'h1^U(53/) JUNCTION CORD/THREAD TRIimiNG 1

34 742089 003/3/94: r-lOO-TD-h" JUNCTION CORD 1

35 742227-91 ^lOOl'D-KV-rh4:"J(?lO) JUNCTION CORD/THREAD TRIimiNG 1

36 748002 95123/ ir3/h^ BAND

37 716014-91 003/3/194: DETECTOR 1

38 350051 0^509h BRACKET 1

39 2905 b54^3/''/C5 SCREW 1

40 7019 b54^3/^ (114) SCREW

41 201185 WASHER

42 748005 t-r03/ 5iJ90°(2A) CLAnP 1

43 7018 (114) SCREW 1

44 201185 'V7}''Z WASHER 1

45 810010-91 lO^'ZVhiO^) HAGNET ASSEHBLY 1

46 7027 b54^3/^ (n5) SCREW

47 240062 'V1}''Z WASHER 1

48 350035 b® DyZZV PIN-SCREW 1

49 107723-05 7 h 9 i r - STOPPER 1

50 4818 •9JJ509h NUT 1