Original scientific paper

PROTOCOL FOR USING PROTEIN SOLUBILITY AS AN INDICATOR OF FULL-FAT SOYBEAN HEAT TREATMENT

Dragan V. Palić and Sophia E. Coetzee

When the degree of full-fat soybean (FFSB) processing is determined using protein solubility as an indicator of heat treatment extent, a problem represents the lack of a standard with known value of protein solubility, against which the protein solubility of heat treated FFSB would be determined. Also, a special practical problem imposes the fact that universal ranges of units for describing the degree of FFSB processing are used globally, without taking into consideration specific regional differences. In this paper, a

protocol was proposed for establishing unit ranges for defining under-, adequately- and over-processed FFSB when protein solubility is used as an indicator of the extent of heat treatment.

KEY WORDS: Full-fat soybeans, degree of processing, extent of heat treatment, protein solubility

INTRODUCTION

The use of full-fat soybeans (FFSB) in animal feeds has been limited because of the uncertainty of the exact availability of the amino acids. This arises due to both the presence of biologically active substances with an anti-nutrient action, which are con-tained in raw soybean, as well as the effect that processing has on the availability of the amino acids contained therein. Processing of the raw FFSB by means of heat destroys the anti-nutrients, thus making them fit for use in monogastric diets. The problem relating to the availability of the amino acids in the heat-treated soybeans arises due to the fact that only an optimum level of heat treatment will produce maximal availability of the amino acids to the animal. Both under- and over-processing result in decreased availability of amino acids (4).

Amongst other authors, Holmes (1), Ruiz et al. (2) and Zarkadas et al.(3) showed that moderate heating is necessary to increase the digestibility of soybean protein for non-ruminants. A comparatively mild heating leads to partial protein degradation (denatura-tion of tertiary and quaternary structures), allowing more effective penetra(denatura-tion by diges-tion enzymes.

One of the major concerns is: what happens when FFSB is under- or over-processed? Is the one more detrimental than the other? To define under- and over-processing is easy

Original scientific paper in theoretical terms, but is it easy to define it in practice? The following mechanisms are involved in under- and over-processing:

Under-processing: Residual trypsin inhibitor mediates its effects via the digestive

processes, affecting both endogenous and exogenous amino acid losses. It also binds and inactivates the pancreatic enzyme trypsin (4). The result is that protein digestibility is re-duced and swelling of the pancreas occurs, caused by the production of additional trypsin and chymotrypsin.

Over-processing: In this process, proteins are more than partially denaturated and

amino acid availability is reduced. This is because the Maillard reaction takes place, i.e. reducing sugars react with the epsilon-amino group of lysine (4).

As a consequence, the objective of heating processes for full-fat soybeans, intended for inclusion in diets for poultry and pigs, is to maintain optimum balance between de-gradation of anti-nutrients on the one hand and maintenance of protein digestibility on the other.

Commonly used methods for assessing the processed FFSB quality are those for the determination of:

1. Urease Activity Index (UAI) 2. Trypsin Inhibitor Activity (TIA) 3. Protein Solubility in KOH (PSKOH) 4. Nitrogen Solubility Index (NSI) 5. Protein Dispersibility Index (PDI) 6. Lysine availability

In a critical assessments of methods, Palic et al. (5, 6), established that some of com-monly used methods, e.g. UAI, have limitations, as they can be used only to determine the under-processed FFSB, that some of the methods are very complicated to perform, such as TIA and Lysine availability, and concluded that protein solubility is the best indicator for FFSB quality control and that therefore PSKOH, NSI and PDI methods would be the prefferd choice. A problem represents the fact that there is a lack of a stan-dard with known protein solubility, against which the protein solubility of processed FFSB would be determined.

Special practical problem imposes the fact that universal ranges of units for PSKOH, PDI and NSI methods, for describing the under-, adequately- and over-processed FFSB, are used globally, without taking into consideration specific regional differences (7).

The aim of this study was to develop a protocol for establishing unit ranges for defi-ning under-, well- and over processed FFSB, when protein solubility is used as an indica-tor of the extent of heat treatment.

EXPERIMENTAL

In the absence of a standard with known value of protein solubility, the solution is to use an “indirect” standard, which can be obtained through in vivo trial with animals.

Original scientific paper Step 1. Raw soybeans processing

A number, but not less than five, samples of FFSB processed at different temperatu-res, i.e. exposed to different extents of heat, is produced. In this study, raw soybeans, with moisture of 10-11%, were processed by dry extrusion, using industrial „Insta-Pro 2000R“ single screw extruder at 8 temperatures: 110, 120, 127, 136, 140, 145, 151 and 165°C, with the processing time ranging between 30 and 40 seconds.

Step 2. In vivo trial

Samples of FFSB produced in Step 1 are fed to animals and their performance is mo-nitored. In the work presented, atotal of 384 male Ross broilers were randomly allocated to 48 pens, each containing 8 birds. On arrival, all broilers were sorted into equal weight groups, and assigned at random to the different treatment pens, such that initial average weight and weight distribution were similar for all pens. They were allocated to one of eight dietary treatments containing the processed FFSB. The average body weight gain (ADWG), in the period from 0 to 14 days of age, and feed conversion ratio (FCR), on day 14, were monitored as production parameters.

Step 3. Choice of laboratory method

A laboratory method for determining protein solubility is chosen. In this study, as a model-method for determining protein solubility as an indicator of the extent of soybean processing, the Protein solubility in potassium hydroxide (PSKOH), as described by Palic (8), has been chosen. Eight samples of FFSB processed in Step 1 were analysed for PSKOH in duplicates by five laboratories.

Step 4. Establishing ranges of units for chosen method for describing the degree of FFSB processing

Original scientific paper 80 85 90 95 100 105 110 115 120

115 125 135 145 165

Temperatures (°C) A ver ag e d ai ly w ei g h t g ai n ( g ) 40 50 60 70 80 90 100 KO H ( % ) AWG KOH X Y

Fig 1. Illustration of the relation between in vivo animal performance, measured by average daily weight gain (g), and the KOH protein solubility (%) for FFSB samples

processed at different temperatures

Statistical analysis. Data were analyzed using the statistical program SAS/STAT (9). The experiment was designed as a randomized complete block with five replicates per treatment. Analysis of variance (ANOVA) was used to test for differences between treat-ments. Treatment means were separated using Fishers' protected t-test least significant difference (LSD) at the 5 % level of significance.

RESULTS AND DISCUSSION

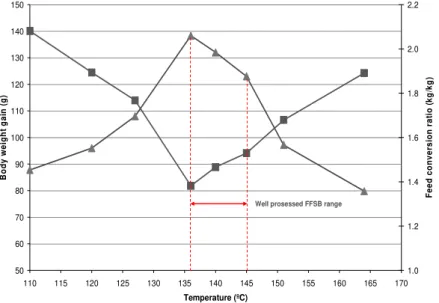

The results of the in vivo trial are shown in Table 1 and Figure 2.

Table 1. Average body weight gain (ABWG) and feed conversion ratio (FCR) for chickens fed FFSB processed at different temperatures in the period

from 0 to 14 days of age

Temperature (oC) ABWG (g) FCR (kg/kg) 110°C 120°C 127°C 136°C 140°C 145°C 151°C 164°C 87.8bc 96.0bc 108.0bc 138.3a 132.0a 123.0a 97.2b 79.8c 2.081d 1.893cd 1.768c 1.382a 1.466a 1.529a 1.679c 1.891cd SEM1 LSD2 CV%3 7.94 22.81 19.1 0.081 0.232 11.5 a,b,c,d

Original scientific paper

50 60 70 80 90 100 110 120 130 140 150

110 115 120 125 130 135 140 145 150 155 160 165 170

Temperature (ºC)

Bod

y

w

e

ig

ht

ga

in

(

g

)

1.0 1.2 1.4 1.6 1.8 2.0 2.2

F

eed

co

n

ver

si

o

n

r

at

io

(

kg

/kg

)

In-vivo body weight gain In-vivo FCR Well prosessed FFSB range

Fig. 2. Average daily body weight gain in the period from 0 to 14 days of age, and feed conversion ratio on day 14, of broiler chickens fed FFSB processed at different

temperatures

Statistical analysis of the results showed that the best performance was achieved by chickens that were fed the FFSB processed at 136oC, 140oC and 145oC and that there was no significant difference between them (P>0.05). However, the difference between the groups that received the FFSB processed at 1270C and 136oC, as well as at 145oC and 151oC, were significant (P<0.05). Based on these parameters, a relation between the tem-perature of extruding and the in vivo assessment of the degree of FFSB processing has been derived and is shown in Table 2.

Table 2. Relation between the temperature of extruding and the in vivo assessment of the degree of FFSB processing

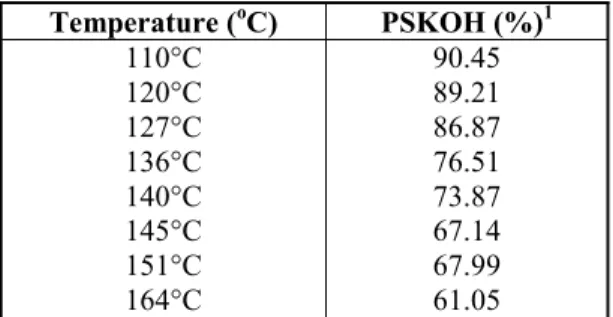

The results of the protein solubility in potassium hydroxide (PSKOH) are shown in Table 3.

Degree of FFSB processing Temperature of extrusion (oC)

Under-processed < 136

Adequately - processed 136 – 145

Original scientific paper Table 3. Results of the determination of protein solubility in potassium hydroxide

(PSKOH) in FFSB samples processed by dry extrusion at different temperatures

Temperature (oC) PSKOH (%)1 110°C

120°C 127°C 136°C 140°C 145°C 151°C 164°C

90.45 89.21 86.87 76.51 73.87 67.14 67.99 61.05 1 Mean values of the results obtained in five laboratories

FFBS samples processed at temperatures between 136oC and 145oC, represented ade-quately-processed FFSB (Table 1). The mean values for PSKOH for these two samples, obtained at five laboratories (Table 3), were 76.51 % and 67.14%, or for the practical ap-plication, 77 % and 67% respectively. Therefore, the following ranges, shown in Table 4, for describing the degree of FFSB processing when PSKOH method is used, have been established.

Table 4. Ranges for describing the degree of FFSB processing using PSKOH method

Degree of FFSB processing PSKOH (%)

Under-processed >77%

Adequately- processed 67% - 77%

Over-processed <67%

CONCLUSION

Using the protocol described in this study, the ranges for any laboratory method which uses protein solubility as an indicator of the extent of FFSB heat treatment, can be established. The numerical value of the units for the method(s) established by using the proposed protocol, take into consideration regional differences such as soybean quality and may be safely applied for FFSB quality control, regardless of what the globally ac-cepted unit ranges for the specific method(s) are.

ACKNOWLEGMENT

This study has been supported by the Protein Research Foundation of South Africa.

REFERENCES

Original scientific paper 2.Ruiz, N., F. de Belalcazar and G. J. Diaz: Quality Control Parameters for Commercial Full-Fat Soybeans Processed by Two Different Methods and Fed to Broilers. J. Appl. Poult. Res.13 (2004) 443-450.

3.Zarkadas, L. N. and J. Wiseman: Influence of processing of full fat soya beans inclu-ded in diet for piglets. 1. Performance. Animal Feed Science and Technology 118 (2005) 109-119.

4.Monary, S.: Fullfat Soya Handbook, American Soybean Association, Brussels (1989) p.6.

5.Palic, D., K. Moloto, E. S. Coetzee and O. Djuragic, O: Critical assessment of labora-tory methods for full-fat soybean quality control. 1st International Congress on Food Technology, Quality and Safety, Novi Sad, 13-15 November 2007, Proceedings p. 197. 6.Palic, D., J. Levic, S. Sredanovic, O. Djuragic: Quality control of full-fat soybeans

using urease activity: critical assessment of the method. Acta Periodica Technologica, 39 (2008) 47-53.

7.Palic, D: Quality control of processed full-fat soybeans: Choice of method. XI Inter-national Feed Technology Symposium, Vrnjacka Banja, 30 March–3 June 2005, Pro-ceedings p. 96.

8.Palic, D: Quality control of processed full-fat soybeans using protein solubility in KOH: Critical review and modification of the method. 11th International Feed Tech-nology Symposium, Vrnjacka Banja, 30 March – 3 June 2005, Proceedings p.106. 9.SAS/STAT User's Guide, Version 8, SAS Institute Inc., Cary, NC:SAS Institute

(1999).

ɉɈɋɌɍɉȺɄɁȺɄɈɊɂɒȶȿȵȿɊȺɋɌȼɈɊȴɂȼɈɋɌɂɉɊɈɌȿɂɇȺɄȺɈ

ɂɇȾɂɄȺɌɈɊȺɌȿɊɆɂɑɄɈȽɌɊȿɌɆȺɇȺɉɍɇɈɆȺɋɇȿɋɈȳȿ

. Sophia E. Coetzee

-,

ђ ђ .

, ,

.

ђ ,

ђ ,

.