CONTINUOUS ETHANOL PRODUCTION USING IMMOBILIZED YEAST CELLS ENTRAPPED IN LOOFA-REINFORCED ALGINATE CARRIERS

Phoowit Bangrak1, Savitree Limtong2, Muenduen Phisalaphong1*

1

Department of Chemical Engineering, Faculty of Engineering, Chulalongkorn University, Bangkok 10330, Thailand;

2

Department of Microbiology, Faculty of Science, Kasetsart University, Bangkok 10900, Thailand.

Submitted: February 22, 2010; Approved: January 13, 2011.

ABSTRACT

A culture of Saccharomyces cerevisiae M30 entrapped in loofa-reinforced alginate was used for continuous

ethanol fermentation in a packed-bed reactor with initial sugar concentrations of 200-248 g/L. Maximum

ethanol productivity of 11.5 g/(L·h) was obtained at an ethanol concentration of 57.4 g/L, an initial sugar

concentration of 220 g/L and a dilution rate (D) of 0.2 h-1. However, a maximum ethanol concentration of

82.1 g/L (productivity of 9.0 g/(L·h)) was obtained at a D of 0.11 h-1. Ethanol productivity in the continuous

culture was 6-8-fold higher than that in the batch culture. Due to the developed carrier’s high

biocompatibility, high porosity, and good mechanical strength, advantages such as cell regeneration,

reusability, altered mechanical strength, and high capacity to trap active cells in the reactor were achieved in

this study. The immobilized cell reactor was successfully operated for 30 days without any loss in ethanol

productivity. The average conversion yield was 0.43-0.45 throughout the entire operation, with an

immobilization yield of 47.5%. The final total cell concentration in the reactor was 37.3 g/L (17.7 g/L

immobilized cells and 19.6 g/L suspended cells). The concentration of suspended cells in the effluent was

0.8 g/L.

Key words: ethanol, loofa, alginate, immobilization, continuous

INTRODUCTION

Ethanol demand has continued to grow, both as an

alternative fuel and as a petroleum fuel extender because of

gasoline shortages. Ethanol production from renewable

carbohydrate materials has attracted worldwide interest, and

much research has focused on ethanol production using

immobilized viable microbial cells in continuous systems.

Continuous fermentation using immobilized cell (IC) carriers

offers many advantages, such as higher productivity, relative

ease of product separation, biocatalyst reuse, and high

productivity. The immobilization of yeast cells inside the

porous support material enhances cell stability (5).

Fermentative ethanol production by S. cerevisiae

immobilized within alginate beads has been found to have a

higher productivity than in a batch system (8). However, some

limitations, such as gel degradation, low physical strength and

severe mass transfer restrictions, were often observed when

using alginate-based carriers. Dias et al. (3) reported a lower

specific growth rate of immobilized yeast cells due to oxygen

diffusion problems caused by entrapment in a Ba-alginate gel.

In contrast, the loofa sponge was shown to be an excellent cell

carrier for ethanol fermentation by flocculating the cells in a

bubble column with an external loop for the recirculation of the

fermentation broth (11). Its strength, abundance, low price,

biodegradability, and natural origin are of great interest.

However, a low-shear environment and a large aggregate of

cells were required during the application of the loofa sponge

to prevent excessive cell sloughing from the carrier (9, 10). In

our previous study, immobilized yeast cells entrapped in

loofa-reinforced alginate matrix (ALM) carriers were successfully

developed for repeated batch ethanol fermentations in a

500-mL shake flask system (13). The carriers were simply

fabricated by gelating a peripheral loofa sponge that had been

previously dipped in an alginate/cell mixture. An ALM with

dimensions of 9×9×3 mm3, which was comparable to a

2-mm-diameter alginate bead, was found to be effective for yeast

immobilization. Moreover, after storage for 4 months, the

ALM-immobilized cell culture was still active, and the stability

of IC cultures in the ALM was higher than that of the

suspended culture (13). The ALM structure proved to be more

porous and less dense than a typical alginate bead, allowing for

better internal mass-transfer diffusion. The aim of present

investigation is to use an ALM carrier with dimensions of

20×20×3 mm3 for continuous ethanol fermentation in a

packed-bed reactor (PBR) and evaluate its performance for long-term

operation.

MATERIALS AND METHODS

Microorganisms and media

Saccharomyces cerevisiae M30 was selected for this study because of its high efficiency in ethanol production from

molasses at high temperatures. Starter cultures were prepared

by transferring cells from stock PDA slants to 150 mL of

sterilized medium followed by incubation at 33°C at 150 rpm

for 20 h. The medium for the starter culture contained 0.05%

ammonium sulfate and 5% inverse sugar from palm sugar at

pH 5.0. Subsequently, the resulting cell suspension was

concentrated by decantation and then transferred to the main

culture.

Cell immobilization

Sodium alginate (3% w/v) solution was formulated by

dissolving Na-alginate powder in 0.9% (w/v) NaCl solution. It

was autoclaved for 5 min at 121°C and stored overnight at 4°C

to facilitate deaeration. To form an alginate-cell mixture, 5 mL

of cell suspension was added to 50 mL of 3% (w/v) alginate

solution. Loofa sponges were cut into small thin square pieces

with dimensions of 19 x 19 x 2 mm3 using scissors. To form

ALMs, 2 g of sterilized thin square loofa sponges were dipped

into the alginate/cell mixture. The gel carriers were transferred

to 1.5 % (w/v) CaCl2 solution and left to harden in this solution

with mild stirring for 15 min. The carriers were then rinsed 3

times with 0.9% (w/v) NaCl solution. The carriers were

prepared under aseptic conditions, and the average ALM

dimensions were 20 x 20 x 3 mm3.

Fermentations

A 1-L (Ø= 5.7 cm; height= 43.4 cm) reactor column

containing an immobilized cell bed of ALM carriers was used

for the study. The experimental setup for the PBR with a

packed volume of 32% (v/v) of the total bed volume is shown

in Fig. 1. The temperature of the system was controlled at 32 ±

1°C by passing 28°C cooling water inside the reactor jacket.

Initial sugar concentrations of 200, 220, and 240 g/L were

continuously fed into the bottom of the reactor at dilution rates

of 0.11, 0.16, 0.20, and 0.30 h-1. Samples (5 mL) were

collected every 8 hours. The samples were frozen before

determining the sugar, ethanol, and cell concentrations to

enable simultaneous analysis of all samples.

Analytical methods

Free cell dry weight was determined from the absorbance

measured at 660 nm by a UV-2450 UV-visible

using a corresponding standard curve. For immobilized cells, a

known mass of cell carriers was dissolved in 0.05 M sodium

citrate. After the sponge was removed, immobilized cell

concentrations were determined in a manner similar to that

used for the free cells. Yeast cell viability was determined

using methylene blue staining (2). The concentration of ethanol

was determined using a gas chromatograph (model GC-7AG;

Shimadzu, Kyoto, Japan) equipped with a flame ionization

detector. To measure reducing sugar concentration, the sample

solution was hydrolyzed in 33% HCl at 100ºC for 10 min and

neutralized with NaOH solution. Reducing sugar content was

then determined using the dinitrosalicylic acid method (6).

Figure 1. Schematic diagram of the immobilized-cell PBR.

RESULTS

Batch fermentation

The purpose of this work was to expand upon our previous

work (13) and develop an efficient, continuous process for

producing ethanol from sugarcane molasses using an

immobilized S. cerevisiae M30 culture. ALM was chosen

based on its strong potential as a cell carrier. The ALM carrier

has many advantages, including high regeneration ability,

reusability, altered mechanical strength, and high ethanol

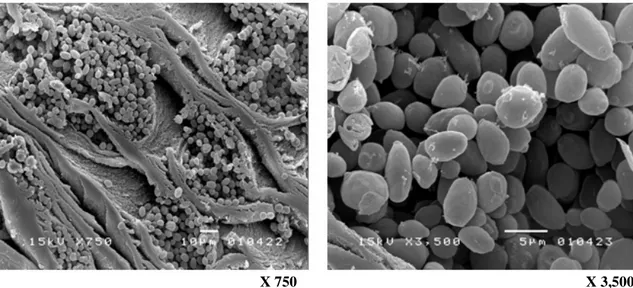

productivity. Inspection of the cross section of the ALM carrier

(Fig. 2) reveals the carrier’s structure, which is composed of

loofa fiber, a layer of alginate gel, and a hollow space between

the loofa fiber and alginate gel. The hollow space between the

alginate and loofa fiber was found to be an ideal space for cell

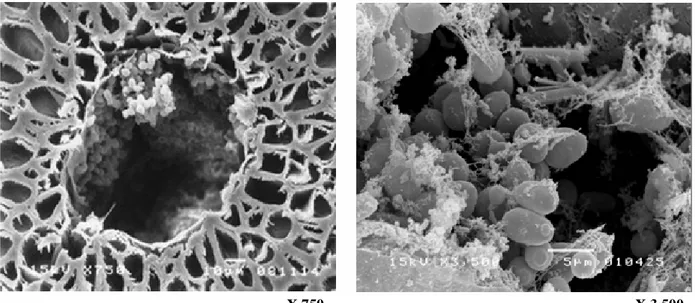

growth (13). Fig. 3 and 4 reveals that yeasts can also grow well

in the alginate layer and in the hollow space of the core fiber.

The cells had a normal oval shape, and filaments were

Feed pump

Feed tank

Product pump

Water cooler tank

Water cooler pump

Product tank

Sampling valve Carbon dioxide

vent

Immobilized cell reactor

Jacket

Sampling ports

Cotton filter

Vent

Cotton filter

Vent

Sampling ports

(5th)

5th

3rd

4th

2nd

observed connecting cells both to other cells and to cellulose

fibers (Fig. 4). This filamentous structure likely promoted firm

attachment of the cells both to the carrier and to cell

aggregations.

For more convenient preparation, the ALM carrier used in

the PBR was modified into a square with dimensions of 20 x

20 x 3 mm3. Pre-examination was performed in 500-mL

Erlenmeyer flasks containing 250 mL sterilized medium under

controlled conditions of 220 g/L of initial sugar, initial pH of

5.0, 150 rpm, and 33°C. Ethanol production, growth rate, and

immobilized yield (YI) using the squares with dimensions of 20

x 20 x 3 mm3 and 9 x 9 x 3 mm3 were comparable (Fig. 5). An

ethanol concentration of 89-90 g/L was produced within 60

hours of batch fermentation, whereas the IC and free-cell

concentrations were about 4.0 g/L and 1.0 g/L, respectively.

No significant differences were observed in the data obtained

from the ALM carriers of the two different sizes.

(A) (B)

Figure 2. (A) Cross-section of the ALM after 72 h of ethanol fermentation. The ALM consisted of loofa fiber (I), a hollow space between the loofa fiber and alginate gel (II), and alginate gel (III). (B) A higher-magnification view of the hollow space.

X 750 X 3,500

X 750 X 3,500 Figure 4. Yeast cells in the hollow core fibers of the ALM after 72 h of ethanol fermentation.

0 50 100 150 200 250

0 8 16 24 32 40 48 56 64 72

Time (hour) S u g a r c o n c e n tr a ti o n ( g /l ) 0 20 40 60 80 100 E th a n o l c o n c e n tr a ti o n (g /l )

Time (h)

S

u

g

a

r

c

o

n

c

en

tr

a

ti

o

n

(

g

/l

)

E

th

a

n

o

l

c

o

n

c

en

tr

a

ti

o

n

(

g

/l

)

Figure 5. Batch fermentations using ALM carriers with dimensions of 9 x 9 x 3 mm3 (open symbols) and 20 x 20 x 3 mm3 (filled

symbols); , = sugar: , = ethanol.

Continuous fermentation

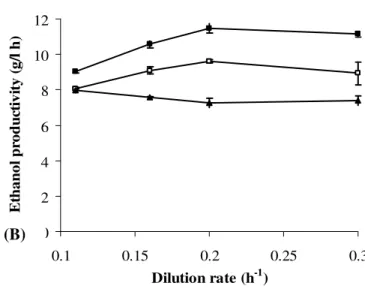

Effect of dilution rate and initial sugar concentration:

Continuous ethanol fermentations using cane molasses in a 1-L

packed-bed reactor were performed at a temperature of 32 ±

1°C and an initial pH of 5.0. The initial reducing sugar

concentrations were 202, 222, and 248 g/L at dilution rates

ranging from 0.11-0.30 h-1. The effects of dilution rate on

ethanol concentration and ethanol productivity are presented in

Fig. 6 and Fig. 7, respectively. The ethanol concentration

commonly observed. When the initial sugar concentration (S0)

was at 200–220 g/L, the ethanol productivity increased linearly

with the dilution rate, from 0.1 to 0.2 h-1, and then remained

nearly constant. However, at the very high initial sugar

concentration of 248 g/L, the ethanol productivity was limited

to 8.0 g/(L·h). The optimal S0 for ethanol productivity was 220

g/L. Under steady-state conditions and at varying dilution rates

of 0.11, 0.16, 0.20 and 0.30 h-1, the average ethanol

concentrations in the effluent were 82.1, 66.1, 57.4 and 37.2

g/L, respectively, corresponding to ethanol productivities (PE)

of 9.0, 10.6, 11.5 and 11.2 g/(L·h), respectively. The ethanol

conversion yield (YE/S) was almost constant at 0.45±0.02. An

optimal ethanol productivity of 11.5 g/(L·h) was obtained at an

ethanol concentration of 57.4 g/L, an initial sugar concentration

of 220 g/L, and D of 0.2 h-1, whereas the maximum ethanol

concentration of 82.1 g/L (PE = 9.0 g/(L·h)) was obtained at a

D of 0.11 h-1. At the end of the procedure (360 h), the

concentrations of immobilized cells, suspended cells in the

reactor, and suspended cells in the effluent were 16.0±0.4,

12.3±0.5 and 0.6±0.1 g/L, respectively, with an average

immobilized yield of 56.5%.

0 10 20 30 40 50 60 70 80 90 100

0.1 0.15 0.2 0.25 0.3

Dilution rate (h-1)

E th a n o l co n ce n tr a ti o n ( g /l )

Figure 6. Ethanol concentration at dilution rates of 0.1-0.3 h-1 and initial sugar concentrations of 200 g/L ( ), 220 g/L ( ), and 248

g/L ( ).

0 2 4 6 8 10 12

0.1 0.15 0.2 0.25 0.3

Dilution rate (h-1)

E th a n o l p ro d u ct iv it y ( g /l h )

Figure 7. Ethanol productivity at dilution rates of 0.1-0.3 h-1 and initial sugar concentrations of 200 g/L ( ), 220 g/L ( ),

and 248 g/L ( ).

Effect of superficial velocity: The design of packing materials that achieve ideal conditions, which correspond to

plug flow and a uniform distribution of fluid across the

cross-section of the column, is important for a PBR. The ethanol and

reducing sugar concentrations measured from the five sampling

ports on both sides of the PBR after the system reached steady

state revealed a satisfactorily uniform distribution of the fluid.

The ethanol concentration profiles in a plug-flow reactor

packed with immobilized cells entrapped in ALM are shown in

Fig. 6. Usually, for anaerobic ethanol fermentation with high

substrate concentrations, it is likely that external mass transfer

is not limiting, at least for a large portion of the packed bed

(15). The external mass transfer coefficient can be enhanced by

increasing the liquid superficial velocity. In this study, the

effect of liquid superficial velocity was examined. Liquid

superficial velocity (VS, cm/h)) was calculated from:

A

Q

V

Sϕ

=

,where Q is the volumetric flow rate of the fluid (cm3/h), A is

the cross-sectional area of the bed (cm2), and is the

packed-bed porosity (the volume of voids per volume of reactor).

Based on the results, the effect of superficial velocity on

ethanol concentration profile can be divided into two

sub-effects, one with S0 of 200-220 g/L and the other with S0 of

248 g/L. Fig. 8(A) and Fig. 8(B) depict the results with S0 at

200 g/L and 220 g/L, respectively. The results revealed an

increase in ethanol concentration as the liquid superficial

velocity was increased from 4.8 cm/h to 6.9 cm/h. However, no

significant enhancement in ethanol production was observed

when the liquid superficial velocity was further increased to

8.7-13.0 cm/h. Based on the result with S0 at 200-220 g/L, the

external mass transfer resistance exhibited some negative

effects on the overall fermentation rate of the packed bed

reactor when the liquid creeping over the static solid particles

had a velocity of less than about 7 cm/h. However, at a high

initial sugar concentration at S0 of 248 g/L, decreases in sugar

consumption and ethanol production were observed as the

liquid superficial velocity increased (Fig. 8(C)). The inhibitory

effects of high initial sugar and high ethanol concentrations

have been previously reported (12). Therefore, mass transfer

resistance had a positive effect on ethanol fermentation at very

high sugar concentrations due to a reduction of sugar-induced

inhibition.

0

20

40

60

80

100

0

2

4

6

8

10

Retention time (h)

E

th

a

n

o

l

co

n

ce

n

tr

a

ti

o

n

(

g

/L

).

0

20

40

60

80

100

0

2

4

6

8

10

Retention time (h)

E

th

a

n

o

l

co

n

ce

n

tr

a

ti

o

n

(

g

/L

).

0 20 40 60 80 1000 4 8 12 16 20

Retention time (h)

E th a n o l co n ce n tr a ti o n ( g /L ).

Figure 8. The steady-state ethanol concentration profiles at initial sugar concentrations of 200 g/L (A), 220 g/L (B), and

248 g/L (C) and at superficial velocities of 4.8 cm/h ( ), 6.9

cm/h ( ), 8.7 cm/h ( ), and 13.0 cm/h( ).

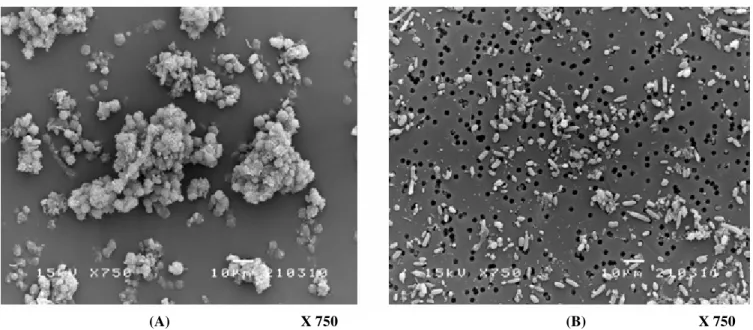

Stability test: The long-term stability of the immobilized yeast cells entrapped in ALM carriers during continuous

ethanol fermentation was examined using an initial sugar

concentration of 220 g/L at a constant D of 0.11 h-1. After 30

days of operation, the degradation of alginate films due to cell

growth and CO2 production was observed and resulted in cell

leakage. Such leaks could also be observed from the cell

suspensions in the reactor and in the effluent. Fig. 9(A) and

Fig. 9(B) depict the suspended yeasts in the reactor and in the

(A)

(B)

effluent, respectively. The suspended cells in the reactor

appeared healthy and retained their normal oval shape. In

addition, aggregations of yeast cells with filamentous

connections were observed. These cell filaments were barely

observed in the alginate gel layer. Therefore, it is possible that

the formation of these filaments may be activated by the

cellulose fibers of the loofa sponge. It was found that almost all

of the aggregated cells were trapped in the packed bed.

However, the suspended cells in the effluent were thinner,

much smaller, and non-aggregated. The use of a

hemacytometer and methylene blue staining to discriminate

between dead and live cells revealed that almost all of the cells

(>95%) in the reactor were alive, but more than 70% of cells in

the effluent were dead.

The robust performance of the immobilized cells in the

alginate-loofa cube during continuous ethanol fermentation in

the PBR was confirmed by satisfactory operational stability

during 30-day fermentation at a D of 0.11 h-1. There was no

significant decline in productivity during continuous operation,

and an average ethanol productivity of 8.7 g/ (L·h) was

achieved at an average ethanol concentration of 79.3 g/L. The

average conversion yield was 0.43-0.45 throughout the entire

operation, with an immobilization yield of 47.5%. The final

total cell concentration in the reactor was 37.3 g/L (17.7 g/L

immobilized cells and 19.6 g/L suspended cells). The

concentration of suspended cells in the effluent was 0.8 g/L.

(A) X 750 (B) X 750

Figure 9. Suspended cells in the PBR (A) and in the effluent (B) after 30 days of continuous fermentation.

DISCUSSION

The data presented in this work demonstrate that

continuous ethanol production from molasses using

immobilized S. cerevisiae M30 cells entrapped in ALM (20 x 20 x 3 mm3) is promising. Compared to the batch fermentation,

higher ethanol productivity (6-8-fold) was obtained by

continuous fermentation in the PBR. A maximum productivity

of 11.5 g/L h at an ethanol concentration of 57.4 g/L was

obtained using an initial sugar concentration of 220 g/L at a D

of 0.20 h-1, whereas a maximum ethanol concentration of 82.1

concentration in the effluent of the packed-bed column

obtained in this work was reasonably high compared to those

described in previous reports (1, 4, 7, 8, 14, 16). The

experimental results revealed that the ALM was suitable for

yeast immobilization in a continuous PBR. With its favorable

mechanical properties, high biocompatibility, and superior

porous structure, the ALM is a system with high cell density,

high ethanol production, and high stability. Furthermore, the

ALM should be applied as a cell carrier for efficient production

in other fermentation systems.

ACKNOWLEDGEMENTS

This work was supported by the Thailand Research Fund

(TRF) and Chulalongkorn University (contract grant number

RSA5080011).

REFERENCES

1. Amutha, R.; Gunasekaran, P. (2001). Production of ethanol from liquefied cassava starch using co-immobilized cells of Zymomonas mobilis and Saccharomyces diastatcus. J. Biosci. Bioeng. 92, 560-564. 2. Bai, F. W.; Chena, L. J.; Zhangc, Z.; Andersona, W. A.; Moo-Young, M.

(2004). Continuous ethanol production and evaluation of yeast cell lysis and viability loss under very high gravity medium conditions. J. Biotechnol. 110, 287-293.

3. Dias, J.C.T.; Rezende, R.P.; Linardi, V.R. (2001). Effects of immobilization in Ba-alginate on nitrile-dependent oxygen uptake rates of Candida guilliermondii. Braz. J. Microbiol. 32, 221-224.

4. Goksungur, Y.; Zorlu, N. (2001). Production of ethanol from beet molasses by Ca-alginate immobilized yeast cell in a packed-bed reactor. Turk. J. Biol. 25, 265-275.

5. Kiyohara, P.K.; Lima, U.A.; Santos, H.S.; Santos, P.S. (2003). Comparative study between yeasts immobilized on alumina beads and on membranes prepared by two routes. Braz. J. Microbiol. 34, 129-137. 6. Miller, G.L. (1959). Use of dinitrosalicylic acid reagent for

determination reducing sugar. Anal. Chem., 31, 426–428.

7. Monte Alegre, R.; Rigo, M.; Joekes, I. (2003). Ethanol fermentation of a diluted molasses medium by Saccharomyces cerevisiae immobilized on chrysotile. Braz. Arch. Biol. Technol. 46, 751-757.

8. Najafpour, G.; Younesi, H.; Syahidah, K.; Ismail, K. (2004). Ethanol fermentation in an immobilized cell reactor using Saccharomyces cerevisiae. Bioresour. Technol. 92, 251-260.

9. Ogbonna, J.C.; Tomiyama, S.; Tanaka, H. (1996). Development of a method for immobilization of non-flocculating cells in loofa (luffa cylindrical) sponge. Process. Biochem. 31, 737-744.

10. Ogbonna, J.C.; Tomiyama, S.; Liu, Y.C.; Tanaka, H. (1997). Efficient Production of ethanol by cells immobilized in loofa (Luffa cylindrical) sponge. J. Ferment. Bioeng. 84, 271-274.

11. Ogbonna, J.C.; Mashima, H.; Tanaka, H. (2001). Scale up of fuel ethanol production from sugar beet juice using loofa sponge immobilized bioreactor. Bioresour. Technol. 76, 1-8.

12. Phisalaphong, M.; Srirattana, N.; Tanthapanichakoon, W. (2006). Mathematical modeling to investigate temperature effect on kinetic parameters of ethanol fermentation. Biochem. Eng. J. 28, 36-43. 13. Phisalaphong, M.; Bundiraharijo, R.; Bangrak, P.; Mongkolkajit, J.;

Limtong, S. (2007). Alginate-Loofa as carrier matrix for ethanol production. J. Biosci. Bioeng. 104, 214-217.

14. Valach, M.; Navratil, M.; Horvathova, V.; Zigova, J.; Sturdik, E.; Hrabarova, E.; Gemeiner, P. (2006). Efficiency of a fixed-bed and gas-lift three-column reactor for continuous production of ethanol by pectate and alginate immobilized Saccharomyces cerevisiae cells. Chem. Pap. 60, 154-159.

15. Vega, J.L.; Clausen, E.C.; Gaddy, J.L. (1988). Biofilm reactors for ethanol production. Enzyme Microb. Technol. 10, 390-402.

16. Wang, B.; Ge, X.M.; Li, N.; Bai, F.W. (2006). Continuous ethanol fermentation coupled with recycling of yeast flocs. Chin. J. Biotechnol. 22, 816-821.