ORIGINAL PAPER

Cupuassu (

Theobroma grandiflorum

) Peel as Potential Source

of Dietary Fiber and Phytochemicals in Whole-Bread

Preparations

Jocelem Mastrodi Salgado&Bruno Sanches Rodrigues&

Carlos Mario Donado-Pestana&Carlos Tadeu dos Santos Dias& Maressa Caldeira Morzelle

Published online: 24 September 2011

#Springer Science+Business Media, LLC 2011

Abstract Cupuassu (Theobroma grandiflorum) is a fruit tree native to the Brazilian Amazon. Cupuassu beans are extensively used in the Brazilian food industry. Fat from cupuassu beans, which are a rich source of triacylglycerols and fatty acids, is used extensively in the production of candies and confectionery in the northern and northeastern regions of Brazil. The potential use of the agro-industrial by-products of cupuassu has only slightly been addressed by the scientific community. Often, such by-products are sources of bioactive compounds with functional properties. Thus, the aims of this study were to characterize the use of cupuassu peel flour (CPF) and to examine the potential of CPF as a partial replacement in the preparation of breads through various means: chemical analyses, determination of protein digestibility, tannins, phytic acid and phenolic contents, pH, color, volume, and acceptance tests. The results show that CPF is a potential source of dietary fiber (79.81%), mainly insoluble fiber (78.29%), and breads made with added CPF present high dietary fiber content (5.40 and 6.15 g/100 g for

inclusions with 6 and 9% CPF, respectively) and phytochem-ical values. The use of this by-product did not produce substantial changes in the physical, chemical or rheological characteristics of breads. Therefore, breads enhanced with CPF may be a convenient functional food, offering a good source of dietary fiber and phytochemicals. Breads prepared with 6% added CPF presented an acceptable overall quality to consumers.

Keywords Cupuassu peel . Functional ingredient . Dietary fiber . Whole bread

Abbreviations

CPF Cupuassu peel flour

Introduction

Cupuassu (Theobroma grandiflorum) is a fruit tree native to the Brazilian Amazon, a diploid species, member of the Sterculiaceae and is commonly related to cacao (Theobroma cacaoL.) [1]. The fruit has the form of a drupe with a strong and pleasant smell; the endocarp contains 25–50 superposed seeds in five rows. The seeds are fermented, roasted, milled, and pressed to obtain the fat in yields of approximately 60% [2]. Fat from cupuassu beans is extensively used in the production of candies and confectionery in the northern and northeastern regions of Brazil, where theTheobromaspecies was originally found and is considered an excellent raw material for use in the food industry [3].

The production of cupuassu has increased from 10 million metric tons in 1998 to 21.4 million metric tons in 2000 [2], arousing interest due to its variety of attractive

J. M. Salgado (*)

:

B. S. Rodrigues:

C. M. Donado-Pestana:

M. C. Morzelle

Departamento de Agroindústria, Alimentos e Nutrição, Escola Superior de Agricultura Luiz de Queiroz, Universidade de São Paulo,

Av. Pádua Dias, 11,

CEP 13418-900 Piracicaba, São Paulo, Brasil e-mail: jmsalgad@esalq.usp.br

C. T. dos Santos Dias

Departamento de Ciências Exatas, Escola Superior de Agricultura Luiz de Queiroz, Universidade de São Paulo,

Av. Pádua Dias, 11, Piracicaba CEP 13418-900, São Paulo, Brasil

chemical and sensory characteristics. In 2006, cupuassu showed a production of 39,045 tons solely in the State of Pará, Northeastern Brazil [4]. Cupuassu pulp, which surrounds the seeds, is used in juices, ice creams, jams, candies, desserts, liquors and a product similar to cocoa powder (called“cupulate” in Brazil) that can be obtained from fermented seeds [1].

Very few studies have emphasized the potential use of agro-industrial by-products of cupuassu in the development of new functional ingredients for food enrichment to provide an economic alternative for industries and sustainability for the environment. Some by-products such as peels and pulps have been processed into food ingredients. A funcional food is a food, either natural or formulated, that enhances humans’

physiological performance or prevents or treats diseases and disorders [5]. Often, such by-products are sources of bioactive compounds with functional properties, such as fiber, which undergoes fermentation in the digestive tract and accelerate bowel movements, reduce cholesterol synthesis and absorption, increase mineral absorption, improving the antioxidative defense system, and help to prevent some diseases or disorders such as constipation and colorectal cancer [6]. These bioactive compounds, which are natural components of foods or other ingestible forms that have been determined to be beneficial for the human body in preventing or treating one or more diseases or improving physiological performance, have been named nutraceuticals [5].

Based on these concepts, this study evaluated the potential use of cupuassu peel in the preparation of a flour and consequently in the development of whole-grain breads enriched with fiber from this by-product in sufficient quantity to be considered functional. Bread was the product chosen because it has been one of the most important foods and energy sources throughout human history. Moreover, the majority of breads produced in Brazil depend largely on imported wheat, which raises the final price of bread. Thus, the partial replacement of wheat flour in bread formulations with alternative flours that are rich in fiber reduces the cost and adds value to the product.

Materials and Methods

Fruit Collection and Peel Flour Preparation

Cupuassu fruits used in this experiment were purchased from a market in the city of Palmas in the State of Tocantins, Brazil. The peel was separated from the pulp and seeds, selected manually, cleaned for 15 min in 200 ppm hypochlorite solution and then freeze-dried. Grinding was performed using a knife mill, and the powder obtained was stored in laminated polyethylene bags at 4°C until use.

Bread Preparation Procedures

The bread ingredients were obtained from retail stores in the city of Piracicaba, State of São Paulo, Brazil. The breads were developed by replacing conventional wheat flour with 3, 6, and 9% CPF. A sample without the addition of cupuassu flour (0%) was used as the control. The bread was prepared according to the method described by Giami et al. [7], with minor modifications. In the first stage of bread preparation, all ingredients were weighed. For each group, a mixed flour containing regular wheat flour and CPF was prepared according to each proposed substitution. All ingredients were mixed in a mixer (40 rpm), after which the dough was rapped (120 rpm). The doughs were fermented for 90 min at 28± 1°C, then punched, scaled to 250 g dough pieces, proofed for 90 min at 37°C, and 90% relative humidity and baked for 15 min at 145 °C.

Chemical Composition of CPF and Whole Breads

The crude protein content was determined from the nitrogen content by the Kjeldahl method [8] using a conversion factor of 6.25 [9]. Total lipids were extracted (ethyl ether) and analyzed as described by Bligh and Dyer [10]. The fiber content was determined through a method described by Asp et al. [11]. Samples were suspended in buffer and enzymes such as α-amylase were used to

hydrolyze starch, and pepsin followed by the use of pancreatin to break down proteins. Enzyme digestates were filtered through fritted glass crucibles. Crucibles containing insoluble dietary fiber (IDF) were rinsed with dilute alcohol, followed by water and acetone. In the soluble dietary fiber (SDF), the filtrates were mixed with 95% ethanol to precipitate materials that were soluble in the digestates. The precipitates were then filtered through fritted glass crucibles. The residue was measured gravimet-rically and corresponded to the dietary fiber fraction. One of each set of duplicate insoluble fiber residues and soluble fiber residues was ashed in a muffle furnace at 550 °C for 5 h. Another set of residues was used to determine protein as Kjeldahl nitrogen. The percentage of ash and crude protein found in the residues was discounted from the values for the respective dietary fiber fraction in the samples. This method is based on the isolation of dietary fiber by enzymatic digestion of the rest of the constituents of the material using enzymes.

In VitroProtein Digestibility of Whole Breads

Thein vitroprotein digestibility of breads was determined according to the method described by Akeson and Stahmann [13] using acidic solutions of pepsin, pancreatin solution, and 1% picric acid for protein digestion. The total protein was considered for calculation of the final protein digestibility in %.

Determination of Tannins, Phytic Acid, and Phenolic Compounds of Whole Breads

The determination of the total content of phenolic compounds in the samples was performed by spectrophotometry accord-ing to the colorimetric method of Folin-Ciocalteu usaccord-ing catechin as a standard [14]. The concentration of tannins was determined through the protocol described by Price et al. [15]. Tannins were extracted with methanol followed by colorimetric reactions using a solution of 1% vanillin in methanol and 8% methanolic HCl (1:1). The solution was incubated at 30 °C for 20 min and the absorbance read at 500 nm. The concentration of phytic acid was determined using Wade reagent, readings were conducted at 500 nm, and the standard curve was obtained using phytic acid [16]; the results are expressed in mg phytate/g sample.

pH Values, Volume and Color Measurements of Whole Breads

The pH was determined directly from samples using a potentiometer (Oakton pH 300 series 35618, Vemon Hills, IL.) with automatic temperature compensation and a glass penetration electrode (Digimed, São Paulo, Brazil). The volume of the breads was measured with the rapeseed displacement method. The color measure-ments were performed with the aid of a Minolta colorimeter model CR-400 (Minolta Co., Osaka, Japan), and the results are expressed in accordance with the CIELAB system. The parameters L*, a* and b* were determined by reflectance.

Acceptance Test of Whole Breads

The breads produced were subjected to sensory evalu-ation. This test was designed to evaluate the acceptance of the breads by consumers. The experimental design included 40 panelists and untrained volunteers, all consumers of bread, aged between 18 and 50 years. The participants were provided four sample replicates, i.e., breads containing 0%, 3%, 6%, and 9% CPF instead of regular wheat flour. The breads were presented in a randomized order in their molds on plastic trays, with randomly assigned three-digit codes,

and each subject assessed four samples per session. Water was provided for rinsing the mouth between each sample [17]. The model used was the multiple comparison test proposed by Moraes [18], which adopted an accept-ability scale ranging from “dislike extremely” to “like extremely”to assess the acceptance of the products by the panelists with regard to color, aroma, texture, and flavor differences between the standard bread and featuring cupuassu flour.

Statistical Analysis

In the experiments conducted, the effects of different amounts of added CPF on the bread characteristics were examined. All the results are reported as the averages of four replicates to enhance better reliability of the data, which were analyzed using the analysis of variance technique (ANOVA) and Tukey’s studentized range test (statistical significance was determined at p<0.05). All statistical analysis were carried out using SAS software (Version 9.0, SAS Institute, Inc., Cary, NC).

Results and Discussion

Chemical Composition of CPF and Whole Breads

The following values were obtained for CPF: 1.45% moisture, 2.45% ash, 1.91% lipids, 2.84% protein, and considerable dietary fiber content (79.81%), mainly insol-uble fiber (78.29%), which has been associated with many health benefits, including a reduction in the risk factors of cardiovascular diseases and prevention of weight gain, cancer, and diabetes [6]. A previous study measured the dietary fiber fractions in cocoa (Theobroma cacao) peel using the gravimetric AOAC method and determined the total polysaccharide content by GLC analysis of the monosaccharides. The results reported values of 63.6, 51.9 and 11.7% of total, insoluble and soluble fiber, respectively, by the AOAC method, and the total polysac-charide level by GLC analysis was approximately 40%, which was composed of a heterogeneous mixture of several types of pectic and hemicellulosic polymers such as pectin (40–45%), galactoglucomannan (7–10%), xyloglucan (5–

7%), glucuronoarabinoxylan (4%), and cellulose (34%) [19]. A fiber-rich product obtained from cocoa commer-cialized in Europe contains 60.54% of dietary fiber, mainly insoluble fiber (50.42%) [20]. Therefore, the enrichment of bread with CPF, which is rich in dietary fiber, should enhance the health benefits of the product.

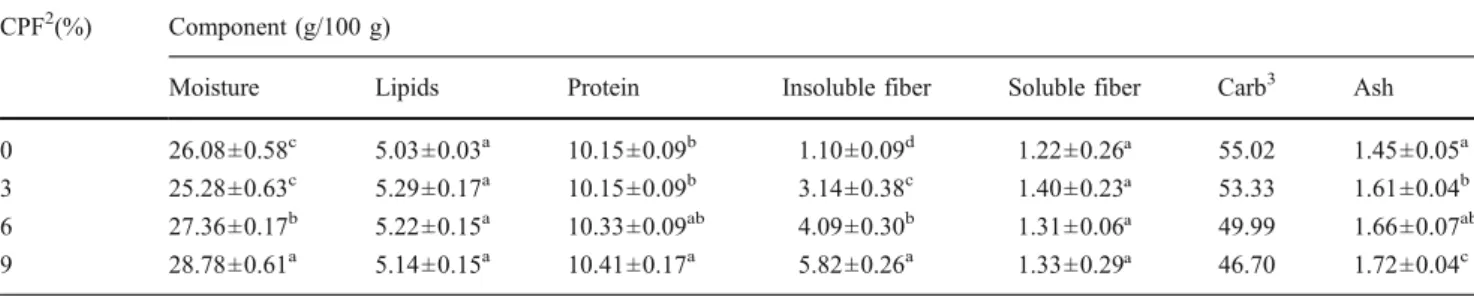

values recorded for the bread with 9% CPF. The samples with 6 and 9% CPF were major sources of protein and ash. With regard to the lipids and soluble fiber contents, all samples yielded similar results, with contents ranging from 5.03 to 5.29% and from 1.22 to 1.40%, respectively. The bread with 9% cupuassu peel exhibited the highest insoluble fiber and total fiber contents, followed by the breads containing 6, 3, and 0% CPF, which were significantly different (p<0.05).

According to the Brazilian Food Composition Database [21], the bread known as French bread, which is widely consumed in Brazil, possesses the following contents on average: 20.76% moisture, 1.78% ash, 2.22% lipid, 12.08% protein, 3.15% total dietary fiber, and 63.16% carbohy-drate. On the other hand, a loaf of whole-wheat bread has 32.63% moisture, 2.30% ash, 3.31% lipids, 11.27% protein, 4.32% dietary fiber, and 40.49% carbohydrate. A study by the same authors who assessed the dietary fiber in Brazilian foods reported total dietary fiber contents ranging from 3.92 to 5.03% [22]. These values are close to those obtained in the analysis of the breads produced in this research, except for the lipid content and dietary fiber, which were higher for the bread with cupuassu peel. Such differences are mainly due to the raw materials used to manufacture the bread as well as the different quantities of ingredients used in each formulation, which are responsible for the unique character-istics of each product.

Breads with 9% added CPF exhibited the lowest calorie factor (272.4 kcal/100 g) compared with breads produced with 6, 3, and 0% CPF (288.6, 301.0 and 305.9, respectively). These results are similar to those observed for French and whole-wheat breads (308 and 260 kcal, respectively) [21]. The lower calorie factor may be associated with the replacement of carbohydrates from wheat flour by the complex polysaccharide fiber in the fruit peels of theTheobromaspecies [19].

In VitroProtein Digestibility and Phytochemicals in Whole Breads

The in vitro protein digestibility tannins, phytic acid and phenolic compounds contents of breads with different concentrations of CPF are shown in Table 2. The in vitro protein digestibility of the breads varied from 73.51 to 79.66%, and the sample with 9% CPF showed the lowest digestibility. Protein digestibility tended to decrease with CPF addition. Angioloni & Collar [23] showed that the addtition of dietary fiber decreased protein digestibility in whole breads. This may result from the possible formation of a complex between the added fiber components and the protein fraction of the samples [24]. Whole-wheat bread products showed protein digestibility values ranging from 83.3 to 85.9% [25]. The protein digestibility of bread depends on the type of flour used, the baking conditions,

Table 1 Approximate composition of breads with different concentrations of cupuassu peel flour (fresh weight basis)1 CPF2(%) Component (g/100 g)

Moisture Lipids Protein Insoluble fiber Soluble fiber Carb3 Ash

0 26.08±0.58c 5.03±0.03a 10.15±0.09b 1.10±0.09d 1.22±0.26ª 55.02 1.45±0.05a 3 25.28±0.63c 5.29±0.17a 10.15±0.09b 3.14±0.38c 1.40±0.23ª 53.33 1.61±0.04b 6 27.36±0.17b 5.22±0.15a 10.33±0.09ab 4.09±0.30b 1.31±0.06ª 49.99 1.66±0.07ab 9 28.78±0.61a 5.14±0.15a 10.41±0.17a 5.82±0.26a 1.33±0.29ª 46.70 1.72±0.04c

1 Data are the means ± standard deviation. Means with the same letter in a column are not significantly different (Tukey test,p<0.05). 2

Cupuassu peel flour

3

Carbohydrates is calculated by difference

Table 2 In vitroprotein digestibility and tannins, phytic acid and phenolic compounds contents in breads with different concentrations of CPF (fresh weight basis)1

CPF2(%) Protein digestibility (%) Tannins (mg/g) Phytic acid (mg/g) Total phenolics (mg/g) 0 79.66±0.84a 0.84±0.03c 1.19±0.08c 3.32±0.07d 3 77.32±0.88b 0.91±0.03b 1.98±0.06b 3.57±0.08c 6 75.86±0.95b 0.94±0.04b 2.10±0.16b 3.83±0.03b 9 73.51±0.88c 1.08±0.02a 2.62±0.11a 3.98±0.07a

1

Data are the means ± standard deviation. Means with the same letter in a column are not significantly different (Tukey test,p<0.05).

2

the phytic acid content and other antiproteolytic compo-nents of breads. The leavening and fermentation of breads resulted in an increase in protein digestibility and the availability of amino acids [26]. Fibers derived from apple, lemon, and wheat have been added to cookies to replace wheat flour at different levels; such replacement has shown in vitro protein digestibility to reduction with increasing fiber content [24].

The results obtained from the analysis of the phytochem-ical compound contents show a tendency for the levels of tannins, phytic acid and phenolic compounds to increase in correspondence with the amount of CPF added to the breads. Similarly, the addition of apple pomace does not change the physical properties of cake to undesirable levels and can be used as a source of dietary fiber [27]. Furthermore, the incorporation of cashew apple and guava residues from the fruit juice industry as ingredients in cookie formulations has been shown to significantly improve the total fiber and protein contents of modified products with respect to those of control products. The supplementation seems to be suited for wheat flour substitution, and it is possible to obtain cookies with value-added food ingredients within the proposed standards [28]. Studies have shown that bioactive phytochemicals may have beneficial effects against several types of human cardiovascular diseases [29], and cancers and may also possess anti-aging properties [30].

pH Values, Coloration and Volume of Whole Breads

In the analysis performed to determine the pH of the breads, no significant difference was detected at a 5% probability level of the average values. The pH values of the breads, in terms of the replacement of wheat flour by CPF, varied from 5.26 to 5.5 (data not shown), though they remained similar for all treatments, indicating that there is no relationship between the addition of the peel flour and the average pH values. Similarly, yellow noodles prepared by the partial substitution of wheat flour with banana pulp flour as a functional ingredient showed pH values that were slightly different between controls (7.64) and test samples

(7.27) [31]. The pH level is important in bread making because it influences the growth and activity of yeast and controls the growth of many other microorganisms.

Hunter color values indicating breads containing CPF and did not differ regarding the value of L* for the crust, except for breads with 3% CPF (Table 3). The color of bread crust with 6% added CPF was the most yellow (b* 35.4). The breads with 0, 6 and 9% of CPF presented the highest values of a*, indicating a darker crust. With regard to the bread crumbs, the L* values were higher for the samples with 3% CPF, followed by the sample with 6% CPF and the control sample. Breads with 9% CPF showed a darker color. In addition, breads with added CPF featured crumbs that were more yellow compared to those of the control. In general, the observed Hunter L*, a*, b* color values suggest that the addition of CPF did not cause extra browning, and the resultant breads presented a good appearance. Soulski and Wu [32] found that the crust color in breads became lighter and more yellow as the level of added pea fiber increased. On the other hand, the presence of apple fiber in a snack bar base caused a reduction in the yellow in color of the bar filling [33]. The color character-istics of ingredients, mainly lightness, play an important role in bakery products, strongly influencing the consumer acceptability of wheat breads [23]. Flour color is of importance because it determines to a large extent the

Table 4 Effect of CPF addition in sensory panel score of breads. A nine-point hedonic scale ranging from 1 (dislike extremely) to 9 (like extremely) was used1

CPF2(%) Color Aroma Texture Flavor 0 7.48¹a² 7.65ª 7.58ª 7.70ª

3 7.18ab 7.33ab 7.28ª 7.50ª

6 7.38a 7.15ab 7.10ab 7.33ª

9 6.70b 6.73b 6.58b 6.00b 1

Data are the means ± standard deviation. Means with the same letter in a column are not significantly different (Tukey test,p<0.05).

2

Cupuassu peel flour

Table 3 Mean color values for the crust and crumb of breads with different concentrations of cupuassu peel flour1

CPF2(%) Crust Crumb

L* a* b* L* a* b*

0 64.5±1.6b 10.1±0.8a 34.9±1.5ª 66.7±3.1ª −2.0±0.2ª 16.2±0.4b

3 71.9±0.8ª 6.9±0.6b 30.5±1.7b 72.3±2.0ª −1.3±0.5ª 21.2±1.0a

6 63.5±0.2b 9.1±0.5a 35.4±0.3ª 67.0±0.9ª 0.9±0.2b 21.8±0.8a 9 63.1±1.0b 9.4±0.3a 31.4±0.7b 60.1±2.6b 1.4±0.2b 23.1±0.8a

1 Data are the means ± standard deviation. Means with the same letter in a column are not significantly different (Tukey test,p<0.05). 2

subsequent color of the bread crumb. Flour color can either be natural (e.g., presence of bran and germ) or artificially induced by a processing method. Generally, the color of flour is affected by particle size, extraction rate, flour treatment, temperature and time of drying [35].

There was a steady reduction in the specific volume of breads with added CPF. The sample that had the highest volume-to-mass ratio (6.86 mL/g) was that without CPF. It is likely that the addition of CPF to the dough resulted in a reduced amount of gluten and a lower growth rate of the bread (6.27 mL/g for breads with 9% CPF). Similar results were found when peach and cocoa dietary fibers were used in a muffin formulation: high consistency impeded volume development [35,36].The presence of fiber in flour could puncture expanding gas cells during fermentation, thus producing a reduced loaf volume [37]. In addition, a number of interrelated factors account for the final volume in baking, such as the batter’s rheological properties, the level of air incorporation and the mixing and homogeniza-tion time and speed [38].

Acceptance Test of the Whole Breads

The panel of untrained volunteers suggested and assessed the following descriptors: color, aroma, texture and flavor of the breads (Table 4). All attributes varied significantly with the addition of 9% CPF. Breads with 0, 3 and 6% of CPF were perceived as having been unaltered with respect to the descriptors; these results suggest that bread with added CPF did not affect consumer perception. It can also be inferred that there was a decrease in the acceptance rate with the increase in CPF addition. The bread with 9% CPF had the overall lowest acceptance rate because according to the panelists, it presented perceptible granules and had a less smooth and more pungent flavor compared to the other breads. Considering the color, aroma, texture and flavor attributes, it could be inferred that the 6% level of incorporation of CPF was optimal. Therefore, breads of acceptable overall quality may be prepared using 6% CPF formulations. Finally, with regard to the consumption and purchasing intent, 92.5% (data not shown) of the respond-ents claimed that they would buy/consume the bread prepared with CPF.

Conclusions

CPF is a rich source of dietary fiber and phytochemicals, which makes it suitable as an added ingredient in breads and/or various dietetic, low-calorie, high-fiber and phyto-chemical based foods to enhance their nutraceutical properties. The substantial dietary fiber content of cupuassu peel as a by-product, should attract the interest of dietitians.

Apart from its basic nutritional elements, CPF also adds economic value to secondary products from the cupuassu processing agro-industry. Additionally, the use of this solid waste could reduce environmental impacts due to the liberation of an enormous amount of residues. The criteria for the incorporation of additives in foods should be related to the desired physical, chemical or sensory characteristics of the given food.

References

1. Alves RM, Sebbenn AM, Artero AS, Clement C, Figueira A (2007) High levels of genetic divergence and inbreeding in populations of cupuassu (Theobroma grandiflorum). Tree Genet Genomes 3:289–298

2. Kamel BS, Kakuda Y (2008) Fatty acids in fruits and fruit products. In: Chow CK (ed), Fatty acids in foods and their health implications. CRC Press, Florida, pp 263–301

3. Silva JC, Plivelic TS, Herrera ML, Ruscheinsky N, Kieckbusch TG, Luccas V, Torriani IL (2009) Polymorphic phases of natural fat from cupuassu (Theobroma grandiflorum) beans: A WAXS/ SAXS/DSC study. Cryst Growth Des 9:5155–5163

4. Silva AE da, Silva LHM da, Pena RS (2008) Comportamento higroscópico do açaí e cupuaçu em pó. Ciênc Tecnol Aliment 28:895–901

5. Wildman REC (2001) Nutraceuticals: A brief review of historical and teleological aspects. In: Wildman REC (ed), Handbook of nutraceuticals and functional foods. CRC Press, Florida, pp.2-12 6. Anderson JW, Baird P, Davis RH Jr, Ferreri S, Knudtson M,

Koraym A, Waters V, Williams CL (2009) Health benefits of dietary fiber. Nutr Rev 67(4):188–205

7. Giami SY, Mepba HD, Kiin-Kabari DB, Achinewhu SC (2003) Evaluation of the nutritional quality of breads prepared from wheat-fluted pumpkin (Telfairia occidentalis Hook) seed flour blends. Plant Foods Hum Nutr 58:1–8

8. AOAC (1995) Official methods of analysis, 16th edn. Association of Official Analytical Chemists, Washington, DC

9. Food and Agriculture Organization of the United Nations (1970) Amino acid content of foods and biological data on proteins. FAO, Rome

10. Bligh EG, Dyer WJ (1959) A rapid method of total lipid extraction and purification. Can J Biochem Physiol 37:911–917 11. Asp NG, Johansson CG, Hallmer H, Siljestron M (1983) Rapid

enzymatic assay of insoluble and soluble dietary fiber. J Agric Food Chem 31:476–482

12. Merill AL, Watt BK (1973) Energy value of foods: Basis and derivation. United States Department of Agriculture, Washington, DC 13. Akeson WR, Stahmann MA (1964) A pepsin pancreatin digest

index of protein quality evaluation. J Nutr 83:257–261

14. Swain T, Hillis WE (1959) The phenolic constituents ofPrunus domesticaI.- The quantitative analysis of phenolic constituents. J Sci Food Agric 10:63–68

15. Price ML, Hagerman AE, Butler LG (1980) Tannin content of cowpeas, chickpeas, pigeon peas and mung beans. J Agric Food Chem 28:459–461

16. Grynspan F, Cheryan M (1989) Phytate-calcium interaction with soy protein. J Am Oil Chem Soc 66:93–97

17. ISO (1988) Sensory analysis: General guidance for the design of test rooms. The International Organization for Standardization, Geneva

19. Redgwell R, Trovato V, Merinat S, Curti D, Hediger S, Manez A (2003) Dietary fibre in cocoa shell: Characterisation of component polysaccharides. Food Chem 81:103–112

20. Lecumberri E, Mateos R, Izquierdo-Pulido M, Rupérez P, Goya L, Bravo L (2007) Dietary fibre composition, antioxidant capacity and physico-chemical properties of a fibre-rich product from cocoa (Theobroma cacaoL.). Food Chem 104:948–954 21. Menezes EW, Giuntini EB, Dan MCT, Lajolo FM (2009) New

information on carbohydrates in the Brazilian Food Composition Database. J Food Compost Anal 22:446–452

22. Menezes EW, Caruso L, Lajolo FM (2000) An application of criteria to evaluate quality of dietary fibre data in Brazilian foods. J Food Compost Anal 13:455–473

23. Angioloni A, Collar C (2011) Physicochemical and nutritional properties of reduced-caloric density high-fibre breads. Lebenson Wiss Technol 44:747–758

24. Bilgiçli N, Ibanoglu S, Herken EN (2007) Effect of dietary fibre addition on the selected nutritional properties of cookies. J Food Eng 78:86–89

25. Abdel-Aal ESM (2008) Effects of baking on protein digestibility of organic spelt products determined by two in vitro digestion methods. Lebenson Wiss Technol 41:1282–1288

26. Lathia DN, Koch M (1989) Comparative study of phytic acid content,in-vitroprotein digestibility and amino acid composition of different types of flat breads. J Sci Food Agric 47:353–364 27. Masoodi FA, Bhawana S, Chauhan GS (2002) Use of apple pomace as

a source of dietary fiber in cakes. Plant Foods Hum Nutr 57:121–128 28. Uchoa AMA, Costa JMC, Maia GA, Meira TR, Sousa PHM, Brasil IM (2009) Formulation and physicochemical and sensorial evaluation of biscuit-type cookies supplemented with fruit powders. Plants Food Hum Nutr 64:153–159

29. Salgado JM, Oliveira AG, Mansi DN, Donado-Pestana CM, Bastos CR, Marcondes FK (2010) The role of black rice (Oryza sativaL.) in the control of hypercholesterolemia in rats. J Med Food 13:1355–1362

30. Yin X, Quan J, Kanazawa T (2008) Banana prevents plasma oxidative stress in healthy individuals. Plant Foods Hum Nutr 63:71–76

31. Saifullah R, Abbas FMA, Yeoh SY, Azhar ME (2009) Utilization of green banana flour as a functional ingredient in yellow noodle. Int Food Res J 16:373–379

32. Sosulski FW, Wu KK (1988) High-fiber breads containing field pea hulls, wheat, corn, and wild oat brans. Cereal Chem 65:186–

191

33. Sun-Waterhouse D, Teoh A, Massarotto C, Wibisono R, Wadhwa S (2010) Comparative analysis of fruit functional snack bars. Food Chem 119:1369–1379

34. Priestley RJ (1979) Effects of heating on foodstuffs. Applied Science Publishers, London

35. Martínez-Cervera S, Salvador A, Muguerza B, Moulay L, Fiszman SM (2011) Cocoa fibre and its application as a fat replacer in chocolate muffins. Lebenson Wiss Technol 44:729–736

36. Grigelmo-Miguel N, Carreras-Boladeras E, Martín-Belloso O (2001) Influence of the addition of peach dietary fiber in composition, physical properties and acceptability of reduced-fat muffins. Food Sci Technol Int 7:425–431

37. Crabtree J, James AW (1982) Composite flour technology TPI’s experience and opinions on the planning and implementation of national programmes. Trop Sci 24:77–84