S

olar cooking system with or without heat storage for families

and institutions

a ,

*

bˆ

Klemens Schwarzer

, Maria Eugenia Vieira da Silva

a

Solar-Institut Juelich,Ginsterweg1, 52428Juelich,Germany

b

´

Universidade Federal do Ceara,Laboratorio de Energia Solar e Gas Natural,Campus do Pici,Fortaleza,Brazil

Received 29 July 2002; received in revised form 21 May 2003; accepted 23 May 2003

Abstract

A solar cooking system, with or without temporary heat storage, has been developed and installed in different countries of the world. The two basic system components are the solar collectors with reflectors and a cooking unit. When thermal storage is needed, a tank filled with pebbles is added to the system. The working fluid, usually a vegetable oil, circulates in natural, thermo-siphon flow through a copper piping that connects the components. The system presents interesting features such as the possibility of indoor and night cooking, heat flow control in the pots, modularity, and the possibility of further adjustment to incorporate a baking oven. The first prototype of this collector–cooker system was built and installed in the city of Juelich, Germany. Further development and adjustment were performed for the next versions, which were brought to India and Mali. Other systems were installed in Africa (Burkina Faso and South Africa) and in South and Central America. About 250 systems have been built in different sizes to be used by single families or by government institutions. The excellent experimental results are presented in this article.

2003 Elsevier Ltd. All rights reserved.

1. Introduction of the energy used in some developing countries. De-forestation is an environmental problem, caused by differ-Solar cookers are heat exchangers designed to use solar ent reasons in different regions. In tropical, rain forests, energy in the process of cooking. In supplying the needed deforestation is mainly caused by agricultural expansion, energy, solar cookers can fully or partially replace the use cattle raising and wood trading. In many arid and semi-arid of firewood for cooking in many developing regions. regions, the reason is the use of firewood or charcoal as Firewood is used as fuel in family cooking and also in fuel (Martinez-Alier, 2003). In India, 47% of the energy small industrial processes, such as in brick factories and for home cooking comes from wood, and in many African bakeries. Part of the reason is the increasing price of oil countries, this value is higher than 75%, such as in Mali or caused by the high demand in industrialized countries, Burkina Faso, where it reaches 95% (Schwarzer and

leaving firewood as the only affordable alternative for Krings, 1996). Over 50% of the population in Nicaragua many families. The solution to this problem does not use wood as fuel for cooking, and over 53% of the depend only on forest cultivation, on the use of fossil country’s overall energy consumption comes from wood energy sources, and on the application of effective (GHA, 2003). Similar situation has been reported in other firewood stoves. Part of the solution is the use of an countries, such as, Ethiopia, Peru, and Indonesia. abundant and friendly to the environment energy source, The solar box cooker, or oven-type cooker, is the most such as solar energy. common and also the oldest type of solar cooker. It is Even though wood burning is not the main cause for essentially a well-insulated box with a transparent cover deforestation in areas of rain forest, it represents up to 90% and side reflectors, which result in an intensification factor

¨

of two to four (Lof, 1963). These cookers are slow to heat up, but work well even under diffuse radiation and windy

*Corresponding author.

conditions (Telkes, 1959). Experimental testing and also

E-mail addresses: schwarzer@fh-aachen.de (K. Schwarzer),

eugenia@les.ufc.br(M.E. Vieira da Silva). simulated performance have been reported in the literature

[Das et al. (1994); Funk and Larson (1998); among maintenance costs, and long lifetime. Modularity allows others]. Various models of box cookers are sold commer- manufacturing of smaller units for single-family applica-cially, using designs of different complexity. tions, as well as larger units for institutions. The system is The focusing or direct-type cooker uses a reflector to adaptable to a wide variety of local eating and cooking concentrate beam radiation onto the food or onto the habits.

cooking vessel in which the food is cooked. These cookers

use mirrors, fresnel lenses, and parabolic concentrators to 1 .1. Description of the cooking system

achieve intensification factors of 20–100, allowing high

¨

temperature cooking (Lof, 1963). Heating-up periods are The system consists of one or more flat-plate collectors small, but these cookers require adjustment to track the with a coated absorber and double glazed covering, sun. Since concentrating cookers uses direct beam radia- cooking pots, and a storage tank, if thermal storage is tion, the lack of sky clearness (dust, clouds, dust, etc) needed. Reflectors provide additional solar radiation on the reduces their performance. Oelher and Scheffler (1994) absorber surface. Oil, usually vegetable, is used as the heat have presented their experience with a community cooker transfer fluid. The oil is heated up in the collectors and that uses a tracking parabolic dish to reflect direct radiation moves by natural flow to the cooking unit, where it onto a fixed area. Over 200 community solar cookers have transfers part of its sensible energy to the cooking goods in been installed since 1986, mostly in India. double-walled pots. Manually controlled valves guide the

An indirect cooker uses a fluid to transfer heat from a oil flow-rate either to the pots or to the storage tank. solar collector to the cooking pots. This cooker has the The major system advantages are: the possibility of advantage of indoor cooking, but it is more expensive. indoors cooking, the use of a thermal storage tank to keep Getting used to operating a solar cooker is necessary, the food warm for longer periods of time or night cooking, independent of the cooker type, and cleaning fixed pots, and the high temperatures of the working fluid reached in a used frequently in indirect cookers, becomes easy with short period of time, allowing fast cooking as well as usage. A cooking system that uses vacuum-tube collectors frying and roasting. Cooking during early morning hours is has been studied at the University of Marburg in Germany possible for bigger systems (collector area greater then

2

(Balzar et al., 1996). Temperatures above 2008C were 4 m ) with storage volume greater than 100 l. Due to the measured in the pot containing edible oil. oil natural circulation, there is no need for a pump, Solar cookers of different types and models have been reducing installation and operational costs. The system tested for performance comparison (ICSC, 2000; ECSCR, runs at ambient pressure and is self regulated. The

1994). One of these technologies is the flat plate collector disadvantages are associated with the relatively high cooker, with or without temporary heat storage, presented fabrication costs and the difficulty in finding all the in this work. This indirect solar cooking system meets the required materials in nonindustrialized countries.

required thermal and technical characteristics, such as, Outdoors systems have been built in sizes that range

2 2

efficiency, easy handling, modular design, very low from 1 m of collector area to 12 m with different pot

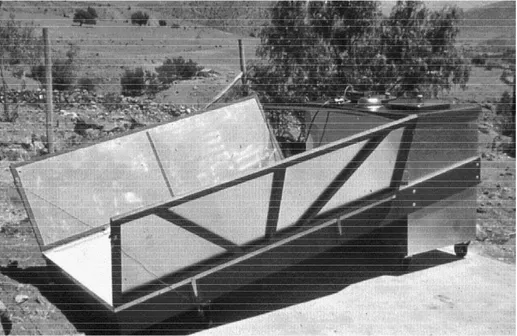

Fig. 2. Outdoor solar cooker without heat storage and a shade-roof installed in Mali, Africa.

sizes, which vary from 5 to 100 l. The standard size is presented inFig. 3.It was installed in a boarding school

2 2

(ECSCR, 1994) consists of 2 m collector area and two in Tiger Kloof, in South Africa. The system has 8 m of pots of 12–15 l capacity. The heating power per square solar collectors, eight cooking pots and no storage tanks. meter of collector area can reach values of 500 W when This kitchen is used to provide meals for 80 persons and to

2

the solar incident radiation varies from 900 to 1000 W/ m . teach cooking at the school.Fig. 4shows a bigger system,

2

If the system is hot, the boiling time for 5 l of water is with 10 m of collector area that has been installed in

2

10–12 min. Fig. 1 shows an outdoor cooker with 2 m Nicaragua to cook for 200 persons. collector area and two pots. There is also a 50-l storage

tank. This system was installed in an elementary school in

the high mountains in northern Chile (Schwarzer et al., 2. Approach 2

1996).Fig. 2 shows a 2 m collector area system without

thermal storage. This system was installed in an SOS To estimate the thermal efficiencies of the solar cooking children’s village in Mali. An example of an indoor system units, two characteristic values are used: cooking powers

Fig. 4. Indoor solar cooker with three circular pots (80, 40 and 20 l) and one rectangular 60-l flat pot installed in a school in Nicaragua, Central America.

~

and efficiency. The sensible or heating-up power repre- solar flux on the collector plane, Gt, times the collector sents the rate of sensible energy used to heat up a certain area,Ac, integrated with respect to time. It is expressed as mass of water, and the latent cooking power is the rate of

~ ~

mw,ehfg Q 2Q

energy needed to boil a certain mass of water in the pots. solarl lost

]]] ]]]]

h 5e t 5 ~ (3)

The sensible cooking power is expressed as Qsolar

~

Ac

E

Gtdtm cw wDT95 – 30 o

~ ]]]]

Qh5 Dt (1)

The rate of energy lost to the ambient can be expressed as wheremwis the mass of water in kg,cwis the specific heat

~

Q 5U sT 2T d (4)

capacity of water in J /(kg K), DT is the temperature lost system 100 amb

difference in K, andDtis the duration of the measurement

and knowledge of the experimental efficiency value, he, in seconds. To avoid uncertainty in determining the start of

allows the determination of the system overall heat transfer boiling, the heating-up power is usually estimated by

coefficient as heating the mass of water from 30 to 958C. The average

sensible efficiency is determined as the sensible energy s12hedA Gc~t

]]]]

U 5 (5)

used in heating divided by the incident solar flux on the system T 2T

100 amb

collector plane,Gt, times the collector area, Ac, integrated

with respect to time. It is expressed as The maximum temperature value is reached forh 5e 0. When the system overall heat transfer coefficient has a

m cw pDT95 – 30 small temperature dependence, the maximum temperature

¯ ]]]]

h 595 t (2)

is expressed as

~

Ac

E

Gtdt~

A Gc t

0 T 5]]1T (6)

max U amb

system

The average evaporation power is calculated as the

The system overall heat transfer coefficient can be energy to boil a mass of water in the pot divided by the

written in terms of the collector and cooking pots heat loss time interval elapsed. The latent cooking power is

esti-coefficients

~

mated as the measured rate of evaporated water, mw,e,

multiplied by the latent heat of evaporation, hfg. The G~

t

average latent efficiency is determined as the ratio of the DT 5]] (7)

rise U

system

In experiments, measurements are made with the cooking than the 0.30–0.34 values previously measured (Schwarzer

2

pots filled with 5 kg of water or oil for each m of and Krings, 1996), can be associated with the use of collector area, and with global solar radiation rate above different oil. The heating process took 32 min using energy

2

800 W/ m . Sensible or heating-powers for temperatures directly from the solar collectors and 37 min using energy above 1008C can be estimated using oil in the pot. from the storage tank.

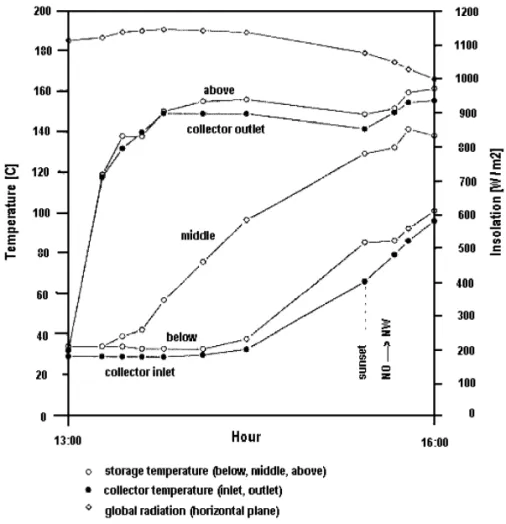

Other important information is the system heat charging The average value for the latent efficiency was about and discharging. The experimental results are the plots of 50% (Schwarzer and Krings, 1996; Schwarzer et al.,

temperature in the storage tank versus time during these 1996). This value, higher than the sensible efficiency, was processes. In the charging phase, the solar energy absorbed found because, at the start of the measurements, the whole by the working fluid is storage in the oil–pebble tank and system was already warm. The energy needed to heat up the plots show temperature measurements at the outside the system was transferred during the sensible heating part walls. The sensors are installed at the metal surface and of the experiment.

covered by the insulation, and represent an approximation Other important results were the heat lost coefficients.

2

to the working fluid temperature. In the discharging phase, For a system with 2 m collector area without heat storage when cooking is done after sunset, the heat released by the and two 10-l cooking pots, the average value for the storage is estimated by the sensible heat gained by the system heat lost coefficient, Usystem, was about 9.0–10.0 water. W/ K. In this case, only one pot with a heat lost coefficient

of 0.5 W/ Kwas used.

The average maximum temperature measured was very

3. Results and discussion close to the value estimated using Eq. (6). Using the same

2

2 m collector area system, the global solar flux of 1000

2

Measurements made with the solar cooking system W/ m and 258C ambient temperature, this maximum

2

installed in Brazil (4 m collector area, three 16-l pots, and temperature was 2358C. Values around 2208C were mea-a 16-l bmea-aking oven) presented mea-a sensible or hemea-ating-up sured. The temperature rise was 2108C.

efficiency of 0.38 (Silva et al., 2002). This value, higher Fig. 5 shows the temperature values measured in the

Fig. 6. Water and storage mean temperature during four different cooking processes with 3 l of water in the pot.

2

solar cooking system with 2 m collector area and a 50-l not cost effective and they should be made in the country stone–oil storage volume installed in Chile (Schwarzer et where the cookers are to be installed. The large-scale use

al., 1996), after a cooking period that lasted until 13:00 h. of solar cookers can only be possible through the

develop-Fig. 6 shows the water and storage mean temperature ment with financial aid. Without this financial assistance, during four different cooking processes with 3 l of water in large-scale use of solar cookers in developing countries the pot with the same system. cannot be made possible.

Under these conditions, the described solar cookers have a very good chance for large-scale use in various

applica-4. Conclusion tions, such as in large families, schools, hospital, food stations, etc.

In recent years, much experience has been acquired with the solar cooking systems described. This experience has been mostly positive. Altogether, about 250 systems were

Acknowledgements

built in various sizes and installed in different countries for many applications. Small systems with collector areas

2 The authors would like to thank all those friends and

from 1 to 2 m were installed in big family houses, while

participants in this work from various countries, especially large capacity systems in schools, feeding centers and

¨

those at the Solar-Institut Julich and at the firma IBEU in hospitals. A large system for a school with 250 students

2 Germany. Thanks also to the institutions that have given

had 12 m of collector area and pots with a volume up to

financial support and credibility to our work (GTZ and 100 l. A solar cooking system for 450 persons is currently

BMBF in Germany; CNPq in Brazil). being planned.

There have been also negative experiences. For instance, the first solar cooker had a wood structure. In general,

these cookers lasted only about 4 years and since then References

metal sheets have been used.

The solar cooker price is too high and it can only be B alzar, A., Stumpf, P., Eckhoff, S., Ackermann, H., Grupp, M.,

reduced when a large number of units are manufactured, 1996. A solar cooker using vacuum-tube collectors with

D

as, T.C.T., Karmakar, S., Rao, D.P., 1994. Solar box-cooker 2. O elher, U., Scheffler, W., 1994. The use of indigenous materials Analysis and simulation. Solar Energy 52, 273–282. for solar conversion. Solar Energy Mater. Cells 33, 379–387. E

CSCR, 1994. European Committee for Solar Cooking Research. S chwarzer, K., von Meer, A., Siggelkow, P., 1996. Entwicklung Second International Solar Cooker Test. Summary of Results. und Erprobung von kleinen regenerativen Energiesystemen fur¨ F

unk, P.A., Larson, D.L., 1998. Parametric model of solar cooker den landlichen Raum in Chile. Shaker, Aachen, ISBN 3-8265-¨

performance. Solar Energy 62, 63–68. 2112-9.

G

HA, 2003. Global Health Alliance. Improving human and S chwarzer, K., Krings, T., 1996. Demonstration und Feldtest von environmental health. http: / / www.glbhealth.org / solarcooking- Solarkochern mit temporare Speicher Indien und Mali. Shaker,¨

.htm 13 / Feb / 2003. Aachen, ISBN 3-8265-1981-7.

I CSC, 2000. Conference Proceedings of the International Confer- S ilva, M.E.V., Schwarzer, K., Medeiros, M.R.Q., 2002. Ex-ence on Solar on Solar Cooking, Kimberley, South Africa. perimental results of a solar cooker with heat storage. In: ¨

L

of, G.O.G., 1963. Recent investigation in the use of solar energy Krauter, S.C.W. (Ed.), Proceedings of Rio 02 World Climate for cooking. Solar Energy 7, 125–133. and Energy Event, Rio de Janeiro, Brazil, pp. 89–93. M