Mat. Res. vol.9 número3

Texto

Imagem

Documentos relacionados

According to Table 4 the values of the electrochemical parameters found for the samples with different tempering temperatures were very close, so that the variation of the

PLUS™ and 904L super austenitic stainless steels showed again a good corrosion resistance. in the aqueous medium of synthetic oil field formation

Assim, através do papel do animador, a Animação Sociocultural, na sua forma mais participativa, é fulcral para a investigação social, não só para o

On both steels and after oxidation for 50 hours at all temperatures, a continuous oxide film is formed on the 430A and 430E stainless steels. In the temperature range and

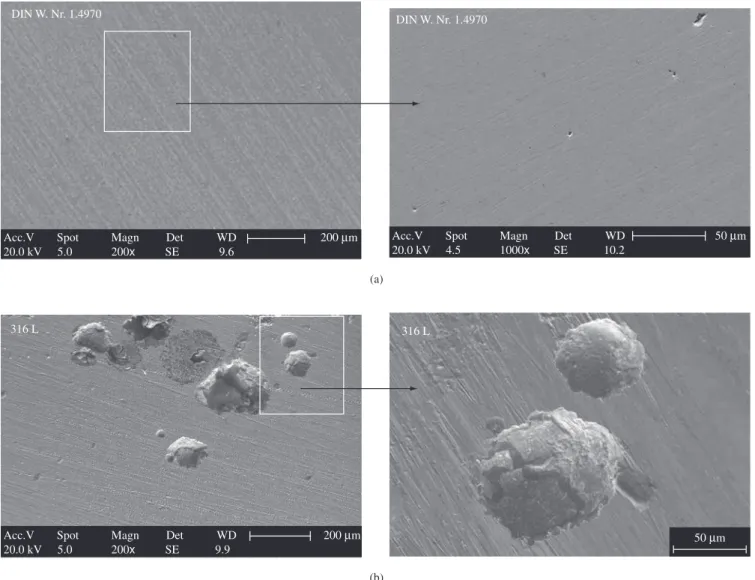

The green samples of the supersaturated alloy which showed a shift of the pitting potential were examined by scanning electron microscopy after the corrosion tests. The

The potentiodynamic polarization curves obtained for both studied alloys shown in Figure 3 reveal that lower current densities, nobler corrosion potentials and higher film

In the mechanism of synergy of erosion corrosion showed that the AFe3 and AFe3 steels have increased activity, especially the corrosion current density when they are subjected

For carbon steels immersed in CO2 saturated solutions at different temperatures, the structure and the composition of corrosion product film formed on the steel surface were studied