GENETIC ALGORITHM BASED

PARAMETER TUNING OF PID

CONTROLLER FOR COMPOSITION

CONTROL SYSTEM

Bhawna Tandon Asstt. Prof., EIE Deptt., M.M.Engineering College,

Mullana.

Randeep Kaur Lecturer., EIE Deptt., M.M.Engineering College,

Mullana

Abstract- A Composition control system is discussed in this paper in which the PID controller is tuned using Genetic Algorithm & Ziegler-Nichols Tuning Criteria. Tuning methods for PID controllers are very important for the process industries. Traditional methods such as Ziegler-Nichols method often do not provide adequate tuning. Genetic Algorithm (GA) as an intelligent approach has also been widely used to tune the parameters of PID. Genetic algorithms are used to create an objective function that can evaluate the optimum PID gains based on the controlled systems overall error.

I. Introduction

In a Composition control system, represented by Fig. 1, a concentrated stream of control reagent containing water and solute is used to control the concentration of the stream leaving a three-tank system. The stream to be processed passes through a preconditioning stirred tank where composition fluctuations are smoothed out before the outlet stream is mixed with control reagent.

Fig. 1 Composition Control system

The measurement of composition in the third tank is sent to the controller, which generates a signal that opens or closes the control valve, which in turn supplies concentrated reagent to the first tank.

+ + + C

R _

Fig. 2 Block diagram of Composition control system

Where R is the set-point, C is the concentration of output stream and is the concentration input from the control reagent tank.

The Transfer function of the Process shown in Fig. 2 is

(1)

Many PID tuning methods are introduced. The Ziegler-Nichols method is widely used for Controller Tuning. One of the disadvantage of this method is prior knowledge regarding plant model. Once tuned the controller by Ziegler Nichols method, a good but not optimum system response will be reached. The Transient response can be even worse if the plant dynamics change. To assure an environmentally independent good performance, the controller must be able to adapt the changes of the plant dynamic characteristics. For these reasons, it is highly desirable to increase the capabilities of PID controllers by adding new features. Many random search methods, such as Genetic Algorithm (GA) have received much interest for achieving high efficiency and searching global optimal solution in the problem space.

II. PID Controller

The PID controller, represented by Fig.3, is well known and widely use to improve the dynamic response as well as to reduce or eliminate the steady state error. The Derivative controller adds a finite zero to the open loop plant Transfer function and improves the transient response. The Integral controller adds a pole at the origin, thus increasing system type by one and reducing the steady state error due to a step function to zero. PID controller consists of three types of control Proportional, Integral and Derivative control.

Fig.3 Schematic diagram of Conventional PID controller

PID control consists of three types of control, Proportional, Integral and Derivative control.

A. Proportional Control

The proportional controller output uses a ‘proportion’ of the system error to control the system.

= Error (2)

B. Integral Control

1

5 1

1 1

1 1 1

The Integral controller output is proportional to the amount of time there is an error present in the system. The Integral action removes the offset introduced by the proportional control but introduces a phase lag into the system.

(3)

C. Derivative Control

The Derivative controller output is proportional to the rate of change of the error. Derivative control is used to reduce overshoot and introduces a phase lead action that removes the phase lag introduced by the integral action.

(4)

III. GENETIC ALGORITHM

The basic principles of GA were first proposed by Holland. The technique was inspired by the mechanism of natural selection, a biological process in which stronger indivisual is likely to be the winners in a competing environment. GA uses a direct analogy of such natural evolution to do global optimization in order to solve highly complex problems. It presumes that the potential solution of a problem is an indivisual and can be represented by a set of parameters. These parameters are regarded as genes of a chromosome and can be structured by a string of concatenated values. The form of variables representation is defined by the encoding scheme. The variables can be represented by binary, real numbers or other forms, depending on the application data. Its range, the search space, is usually defined by the problem. An illustrative flowchart of the GA algorithm implementation is shown in the Fig. . In the beginning an initial chromosome is randomly generated. The chromosomes are

Fig.4 Flow Chart of Genetic Algorithm

IV. EVALUATE THE PROCESS USING FITNESS FUNCTION A. Objective Function

The most crucial step in applying GA is to choose the objective functions that are used to evaluate fitness of each chromosome. Some works use performance indices as the objective functions. The objective functions are Mean of the Squared error (MSE). Integral of Time multiplied by absolute Error (ITAE), Integral of Absolute Magnitude of the error (IAE) and the Integral of the Squared Error (ISE).

(5)

= | | (6)

| | 7

∑ (8)

B. The Fitness Values

The PID controller is used to minimize the error signals, or we can define in term of error criteria: to minimize the value of performance indices. And because the smaller the value of performance indiced of the corresponding chromosomes the fitter the chromosomes will be, and vice versa, we define the fitness of the chromosomes as

1

V. SIMULATION RESULTS

The Concentration control system is simulated using SIMULINK in MATLAB as shown in Fig. The values of KP, KI and KD are selected as 3.7, 1.8 & 1.8 as obtained from Ziegler-Nichols Tuning criteria.

Fig. 5 Simulation of Concentration Control System using PID

Table I

GAs PARAMETER SETTING

PARAMETERS VALUE

Fig. 6 Response Curves for Objective function ITAE

Table II

Comparative Analysis for Objective Function ITAE

ITEM GA

Zeigler-Nichols

%age Overshoot 40.4 29.6 Rise time(sec) 0.1 1.5 Peak Time(sec) 0.15 2.5 Settling Time(sec) 3 10

KP 54.96323 3.7

Ki 8.51 1.8

Kd 99.1578 1.8

Fig. 7 Response Curves for Objective function IAE

Table III

Comparative Analysis for Objective Function IAE

ITEM GA

Zeigler-Nichols

%age Overshoot 38.2 29.6 Rise time(sec) 0.1 1.5 Peak Time(sec) 0.35 2.5 Settling Time(sec) 2.9 9.8

KP 31.16428 3.7

Ki 9.0578 1.8

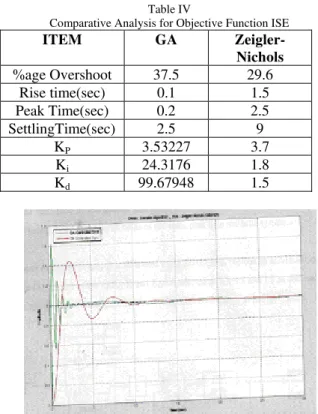

Fig. 8 Response Curves for Objective function ISE

Table IV

Comparative Analysis for Objective Function ISE

ITEM GA

Zeigler-Nichols

%age Overshoot 37.5 29.6 Rise time(sec) 0.1 1.5 Peak Time(sec) 0.2 2.5 SettlingTime(sec) 2.5 9

KP 3.53227 3.7

Ki 24.3176 1.8

Kd 99.67948 1.5

Fig. 9 Response Curves for Objective function MSE

Table V

Comparative Analysis for Objective Function MSE

ITEM GA

Zeigler-Nichols

%age Overshoot 37.5 29.6 Rise time(sec) 0.1 1.5 Peak Time(sec) 0.12 2.5 SettlingTime(sec) 2.5 8

KP 54.96323 3.7

Ki 8.5105 1.8

Kd 99.15787 1.8

VI CONCLUSION

VII REFRENCES

[1] Chia-Ju Wu, “Genetic Tuning of PID controllers using a Neural Network model: A seesaw example”, Journal of Robotics and Intelligent systems, Vol. 25, Issue 1, 1999.

[2] T. K. Teng, J. S. Shieh, C. S. Chen, “Genetic Algorithms applied in on-line autotuning PID parameters of a liquid control system,” Transactions of Institute of Measurement and Control, Vol. 25, pp. 433-450, 2003.

[3] Pereira, D.S., Pinto, “Genetic Algorithm based system identification and PID tuning for adaptive control”, Advanced Intelligent Mechatronics, Proceedings, IEEE/ASME International Confrence, July 2005.

[4] Ismail K. Bouserhane, Rahli Mostefa, “Optimal Fuzzy self tuning of PI Controller using Genetic Algorithm for Induction motor speed control” University of Sciences and Technology of Oran, Algeria, August 2007.

[5] J. G. Ziegler, N. B. Nichols, “Optimum settings for Automatic controllers”, Transactions of American Society of Mechanical Engineers, Vol. 64, pp. 759-768, 1942.

[6] M. Zhuang, D. P. Atherton, “Automatic Tuning of Optimum PID Controllers,” IEE Proceedings on Control and Applications, Vol. 140, pp. 216-224, 1993.