The subject and content of the thesis were limited to the level of sales management and the business planning process. A well-managed sales and business planning process linked to a company's strategy and business plan is recognized as a key foundation for a company's success. The aim of the thesis was to develop the sales and business planning process of the target company.

The topic and content of this thesis were limited to the management level of the sales and operational planning process.

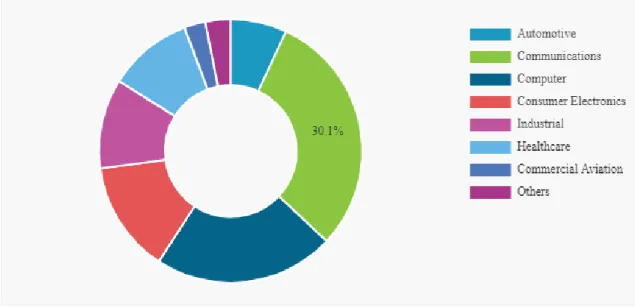

3 ELECTRONICS MANUFACTURING SERVICES

As of the first quarter of 2020, the widespread supply chain disruptions – strict shutdowns imposed in many parts of the world – caused by the pandemic have caused stoppages and delays in raw materials. Already in 2020, many major car manufacturers, including Fiat, Volkswagen, PSA Group, General Motors and BWM, had to halt production due to supply chain disruptions. One way to avoid supply chain disruptions is to be creative and smart with product design.

Another way to reduce risk in the supply chain is to increase market intelligence.

4 SALES AND OPERATIONS PLANNING

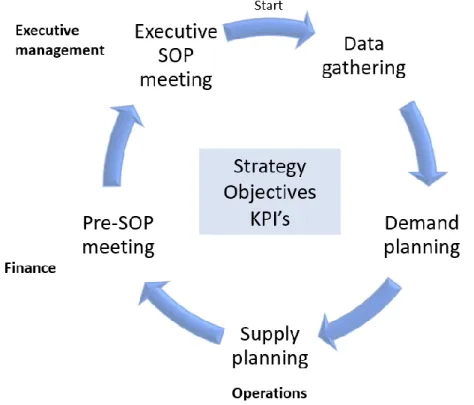

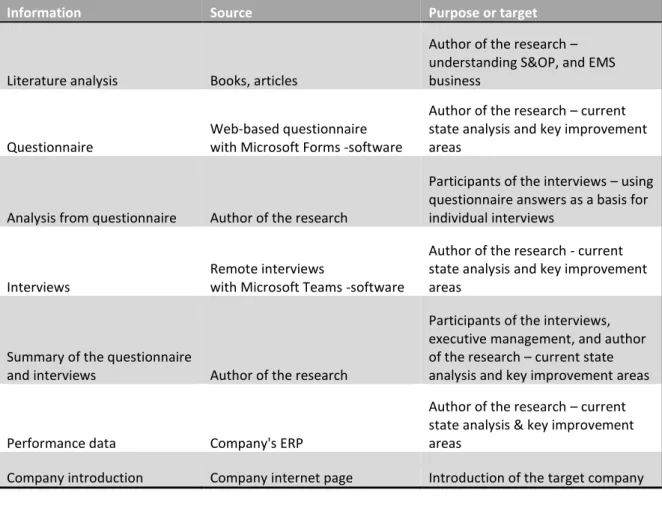

Data gathering

The process cycle begins with data collection, a step that occurs shortly after the end of the month. Often, the most recent month's up-to-date information can be easily retrieved from an enterprise resource planning or other information technology (IT) system. If the data is not easily available from an IT system, it is common for representatives of different functions to share relevant information with each other.

The demand planning phase

The pre-SOP meeting

Executive SOP meeting

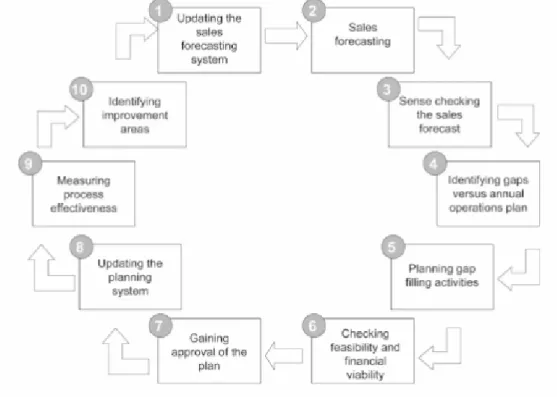

In his book "A guide to Sales Management: A Practitioner's View of Trade Sales and Organizations," Parravicini describes the sales and operations planning process as a ten-step cycle. These steps focus more on looking at and describing sales and operations planning from a sales management perspective.

Updating the sales forecasting system

Sales forecasting

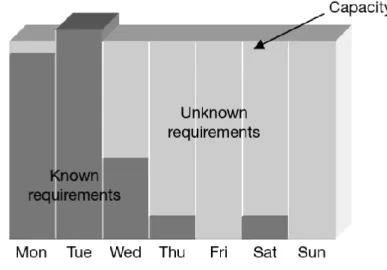

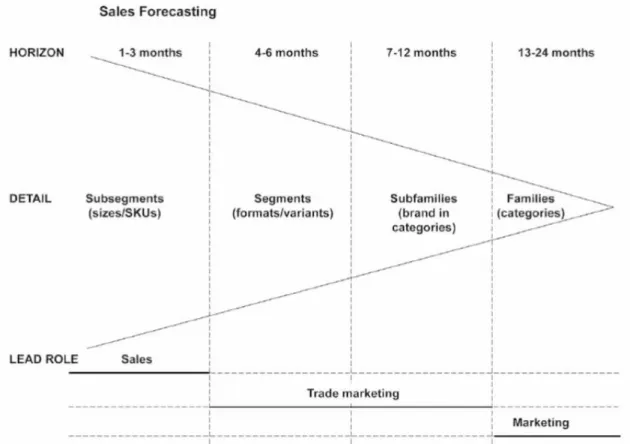

Short-term forecasting is usually one to three months, but in some companies it can be up to six months. Mid-term forecast from four or seven to 12 months and long-term is from 13 to 24 months out. Sales forecasts and the level of detail for the short, medium and long term are presented in Figure 7.

The sales and marketing team will usually prepare two different kinds of sales forecasts – a very optimistic one to pass on to the planning team and a very pessimistic forecast to plan for their line managers. The planning team makes their own forecast based on the sales forecast given to them and brings in knowledge of the supply side – production capacity, delivery times, etc. This step is completed when all the departments have prepared their forecasts and reconciled them to a consensus forecast.

In this step, all forecasts from different functions should be checked and the gap between them should be minimized. The sentence check is done by comparing the forecasts of all departments and questioning their assumptions.

Identifying gaps versus annual operations plan

Planning gap filling activities

Checking feasibility and financial viability

Gaining approval of the plan

Updating the planning system

Measuring process of effectiveness

Identifying improvement areas

This means that the top management's obligation is to commit to the process and establish a framework for the S&OP planning. One of the board members will be assigned to support the S&OP project manager and the core implementation team that includes the middle managers. Top management must include all sales and operations related formal plans – for example, not allowing budgeting to be a separate activity from the S&OP process, and leading the cultural change to make this happen.

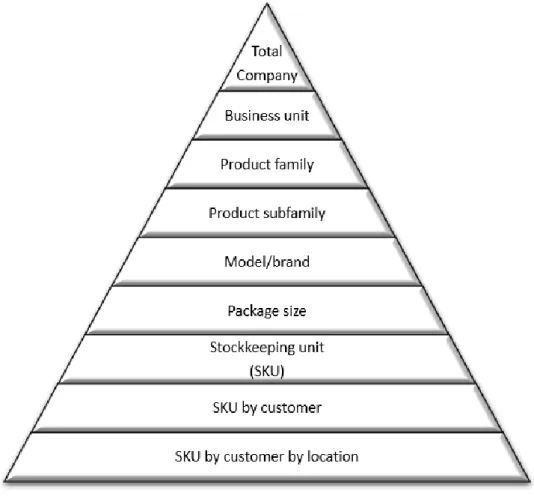

People commit their resources and prioritize S&OP related work, recognizing that S&OP is the company's most important dynamic performance management process. A cross-functional problem is related to grouping product families and determining how many of them should be when developing the S&OP process. The long-term S&OP plan can be linked to long-term financial and brand planning.

S&OP is an integrated way to run a business by balancing supply and demand. With the full support of the management team, the CEO/general manager takes responsibility for the outcome of the S&OP process. The leadership team leads by example by prioritizing the time and resources to be dedicated to the S&OP process.

From a production perspective, the S&OP as output forms the framework for developing the master production plan (MPS). One of the most important benefits of the S&OP process is to highlight the gaps between the sales forecast and the company's strategic goals in the annual operating plan.

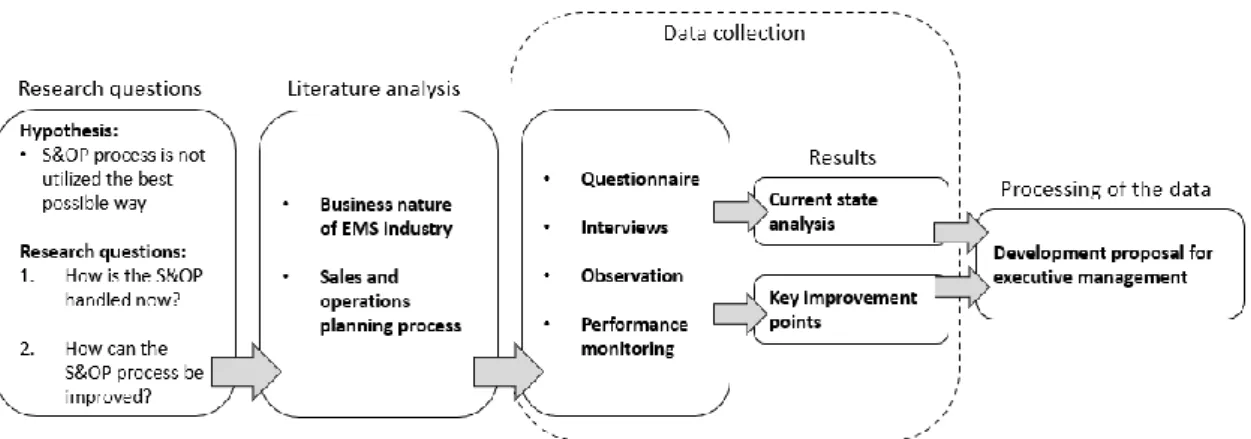

5 EXECUTION OF RESEARCH

The questionnaire was sent to people who work in different roles and parts of the organization, either in the role of management or top management, and are part of the current sales and business planning process. Before sending the questionnaire, the background and purpose of the research were clearly explained to the participants. The purpose of the questionnaire was two-fold: to get a picture of the current state of the S&OP process and to find out the things they think need to be improved.

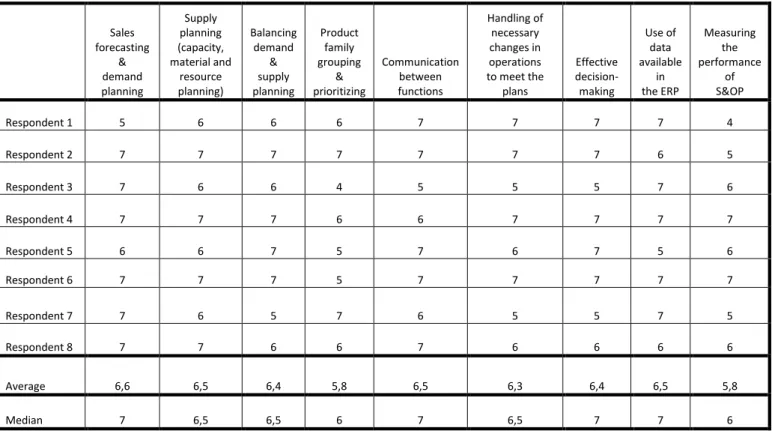

The questionnaire included an assessment of the current quality of the S&OP process, an assessment of how well key functions within the sales and operations planning process are currently performed, and how important these functions are perceived to be in the S&OP process. Next, the questionnaire included questions about which of the featured functions should be improved the most and what the current S&OP cycle is in use. The purpose of the interviews was to get a better picture of the details of the questions in the questionnaire and to get more information from the sales and business planning process than the questionnaire allowed.

All eight persons who answered the questionnaire were also interviewed, and each interview lasted 30 to 60 minutes. This was done to give as broad a picture as possible of the current process and responsibilities, and to make available deeper knowledge of certain aspects of the process. In addition, the interviewees were also asked to bring forward a wider view of different parts of the S&OP process, not just the part in which they were directly involved.

Part of the interview process was to observe the interviewer - to follow whether there were any changes in the behavior when asked or answering the questions. Some reports and measures are built outside of the ERP, but using data available in the ERP, such as on-time delivery.

6 RESEARCH RESULTS AND CURRENT STATE ANALYSIS

Handling necessary business changes to meet plans was seen as a key strength of the company. The use of data available in the ERP was widely used to support the business operations of the company. The data from the ERP is also used for measurement purposes; all the data needed for the company's key performance indicators are available in the ERP and therefore the KPIs can be tracked in real time.

It was also established that it will be necessary to improve the planning of sales and operations in the target company, which could be improved with internal actions. The table below presents the mean and median scores for each function. At the end of 2021, the book value of the company's orders is higher than it has been at any time in the company's history.

Sales and operational planning process in the target company appears to be unstructured, and the cycles and ways of working differ depending on the function or organization. Also, documentation of the sales and operations planning process, from process description, appears to be lacking. The development of some of the company's key performance indicators indicates that the current sales and operations planning process is not working in an optimal way.

Global pandemic Covid-19, global chip shortages and global supply chain disruptions are likely to have caused overall problems in the target company's business. Performance monitoring can be seen as the most reliable of the research methods used, as the performance measures or the data used for the measures were taken directly from the company's ERP system.

7 DEVELOPMENT PROPOSAL

- Data gathering

- Updating Sales and Marketing plan (Demand planning)

- Updating Operations plan (Supply planning)

- Pre-SOP meeting

- Executive SOP meeting

In the target company's case, due to the large variety of customers, products and customer-specific materials, it is extremely important that the forecast is as detailed as possible for as far into the future as possible. Some of these elements must be defined before or during the implementation of the development proposal, to ensure that the process runs smoothly and efficiently. Roles and responsibilities of the S&OP process required in the development proposal are presented in chapter 7.3.

This matrix must be documented and made available to members of the sales and operations planning process. All these should be clarified in the implementation phase of the development proposal and then modified if necessary. Product family groups and prioritization rules should be agreed upon during the implementation phase of the development proposal and then modified if necessary.

Time fences should be agreed in the implementation phase of the development proposal and adjusted as necessary. Some of these measures are influenced by other factors of the company, but still reflect the effectiveness of the S&OP process. This development proposal provides the target company with a guideline to improve the operation of the S&OP process at a higher level.

The Executive SOP team is also responsible for supporting and identifying improvements to the S&OP process. The results of the implementation of the development proposal can also be seen indirectly in all the company's key figures.

8 CONCLUSION

The aim of this thesis was to provide a development proposal for the sales and operations planning process for the target company. The development areas were identified by conducting a questionnaire and individual interviews for all the managers and executives involved in the target company's S&OP process. This, along with monitoring the company's performance indicators, provided a solid, reliable basis for making current state analyzes of the existing sales and operations planning process.

Based on the current state analysis and development areas raised by the analysis, a development proposal – in the form of a high-level process description – was created for the target company. This development proposal does not require the use of external resources, so implementation and use can be performed with only internal resources.

Sales and operations planning questionnaire