Availableonlineatwww.sciencedirect.com

w w w . j m r t . c o m . b r

Original

Article

The

variant

selection

in

the

transformation

from

austenite

to

martensite

in

samples

of

maraging-350

steel

Neuman

Fontenele

Viana

∗,

Cristiana

dos

Santos

Nunes,

Hamilton

Ferreira

Gomes

de

Abreu

UniversidadeFederaldoCeará,Fortaleza,CE,Brazil

a

r

t

i

c

l

e

i

n

f

o

Articlehistory:

Received19February2013 Accepted25March2013 Availableonline17October2013

Keywords:

Maragingsteel

Martensitetransformation Variantselection

a

b

s

t

r

a

c

t

Experimentshave been conducted to study the variant selection phenomenon in the transformationfromaustenitetomartensiteinmaraging-350steel.Thetransformationof austenitetomartensiteinmaragingsteelsoccursattemperaturesbelow300◦Cdepending onthealloychemicalcomposition.Thetransformationtomartensiteinthesesteelsoccurs regardlessofthecoolingrate.Inthesesteels,therevertedaustenitepresentsthesame crys-tallographictextureofthemotheraustenite.Samplesofmaraging-350wereaustenitizedat 860◦Cinsideafurnaceattachedtoatensiontestmachineandthencooledinthefurnace untilthetemperatureof600◦Cand400◦C.Atthesetemperaturessamplesweredeformedby compressionwith10%reductioninheight.Afterdeformationtheappliedforcewasremoved andsampleswerecooledtoroomtemperatureinair.Asecondgroupofsampleswas sub-jectedtothesameaustenitizationandcooleduntil300◦Cwhenitwasappliedacompressive stresswithmagnitudebelowtheyieldstrength.Withtheforceapplied,thesampleswere aircooledtoroomtemperature.EBSDanalysiswasperformedincross-sectionofsamples todeterminetheinfluenceofplasticdeformationbeforethetransformationandalsothe influenceofastressintheelasticregimeintheselectionofvariantsofmartensite.Measured polefigureswerecomparedwithcalculatedonesusingthephenomenologicalmartensite transformationconceptassociatedwithPatel–Cohenmodel.

©2013BrazilianMetallurgical,MaterialsandMiningAssociation.PublishedbyElsevier EditoraLtda.

1.

Introduction

Maragingsteelsbelongtoafamilyofcarbonfreeiron–nickel alloyswithadditions ofcobalt, molybdenum,titanium and aluminum.Thetermmaragingisderivedfromthe strengthen-ingmechanism.Marfrommartensite+agingmeansthatthe

∗ Correspondingauthor.

E-mail:neumanfv@gmail.com(N.F.Viana).

alloytransformstomartensitewithsubsequentage harden-ing.Thisfamilyofsteelsfindsimportantapplicationswhere ultra-highstrengthisrequired,alongwithgooddimensional stabilityduringheattreatment[1].

Thetransformationofaustenitetomartensitein marag-ing steelsoccurs regardlessofthecoolingrate. TheAs, Af,

MsandMftemperaturesweremeasuredfortheMAR350cold

2238-7854 ©2013BrazilianMetallurgical,MaterialsandMiningAssociation.PublishedbyElsevierEditoraLtda.

http://dx.doi.org/10.1016/j.jmrt.2013.03.017

Este é um artigo Open Access sob a licença de CC BY-NC-ND

(111) Cube texture

ϕ1

φ

40 50 60 70 80 90 100 2θ (º)

110 650˚C

600˚C

500˚C

480˚C

450˚C

α

α γ α γ

Fig.1–(a)ϕ2=45◦odfsections;(b)X-raydiffractogramsforthemartensitephaseofsamplesagedat450◦C,480◦C,500◦C

and650◦C.

deformed80%usingthermo-magneticanalysis.The temper-atures were found to be 690◦C, 800◦C, 175◦C and 130◦C,

respectively[1].

Nakadaetal.havestudiedthe reversionofaustenite in a martensitic stainless steel and concluded that most of revertedaustenitehadthesame orientationastheoriginal austenitematrixbeforemartensitictransformation.Theyalso suggestedthatrevertedausteniteretainedaKurdjmov–Sachs relationshiptomartensite[2].

Thetheoryconcernedwithmartensitetransformationis wellestablished.Thecrystallographyofeachplateof martens-itecanbedescribedintermsofamathematicallyconnected setconsistingofthehabitplane,orientationrelationshipwith theaustenite,andtheshapedeformation[3–7].

ThePatelandCohenmodelforpredictingthevariant selec-tion phenomenon isbased in the energyof appliedstress duringtransformation.Theinteractionenergythatprovides themechanicaldrivingforce fortransformationisgivenby Eq.(1)[8]:

U=N+s (1)

whereNisthestresscomponentnormaltothehabitplane, istheshearstressresolvedonthehabitplaneinthedirection ofshearan,andsarerespectivelynormalandshearstrains associatedwithtransformation[3].Thetotalfreeenergy avail-ablefortransformationisthesumofchemicalandmechanical components,accordingtoEq.(2);thelatteronebeingzeroin theabsenceofanappliedstressduringtransformation[4]:

G=GCHEM+GMECH (2)

whereGMECH≡U. It would bereasonable to assume that thereisstrongvariantselectionwhentheratioofGMECH/G

islarge[4].

Inthiswork,samplesofmaraging350wereaustenitized at860◦Cinsideafurnaceattachedtoatensiontestmachine

andthencooledinthefurnaceuntilthetemperatureof600◦C

and400◦C.Atthistemperaturethesamplesweredeformed

bycompression withreductionsinheightbelow10%.After deformationtheforcewasremovedandsampleswerecooled toroomtemperature.Asecond groupofsampleswas sub-jectedtothesameaustenitizationandcooledto300◦Cwhen

it was appliedacompressive stress withmagnitudebelow theyieldstrength.Withtheforceapplied,thesampleswere air cooled to room temperature. Pole figures obtained by EBSDwerecomparedwithcalculatedpolefigures basedon thephenomenologicalmartensitetransformation crystallog-raphy(PMTC)associatedtothePatel–Cohenmodel.

2.

Experimental

SamplesofforgedMAR350steelwiththecomposition19.77 Ni,10.74 Co, 4.70 Mo,1.4 Ti,0.10 Al, 0.0073C and balance ofFewereaustenitizedat860◦Cfor1handcooledinsidea

furnaceassembledtoaUniversaltestingmachine.Whenthe temperaturereached600◦Cand400◦Csampleswerepressed

resultingina10%ofplasticdeformation.Anothersamplewas cooledto300◦Cwhenacompressivestressof200MPa–below

theyieldingofMar350atthistemperature–wasappliedand keptuntiltheendoftransformation.Tofindtheorientation ofthepreviousaustenite,sampleswereagedat550◦Cfor1h

toprecipitaterevertedaustenite.

The EBSD study was performed in an Oxford Channel 5-EBSDsystemattachedtoaSEMPhilipsXL-30.Sample prepa-rationsequencewasapre-grindto600SiCandpolishto3-m diamond.Thefinalpolishingwasdoneusingacolloidalsilica suspensionofparticlesizeof0.05mduringlongperiodsof time.X-raydiffractionwasperformedinaPhilips diffractome-termodelX’PertProusingCoK␣radiationwithanattached monochromator.

To reproduce the phenomenological theory of mar-tensite transformation crystallography the software crys-talhabitpoly.f.Detailsofuseofthissoftwareareavailablein Ref.[9].

3.

Results

Thefirst taskofthis work wastoassure that thereverted andtheparentaustenitepresentedthesamecrystallographic texture. Fig. 1a shows ϕ2=45◦ odf (orientation distribution functions)sectionsforthemartensitephaseofsamplesaged at450◦C,480◦C,500◦C and650◦C.Comparing odf’s,it can

conditionsareacubecomponent(001)[100]and the(111) fibermoreintensein{111}112.Samplesagedat500◦Cand

650◦Cshowspeaksofrevertedausteniteonthediffractogram

presentedinFig. 1band no changein the crystallographic textureofthemartensitephase.

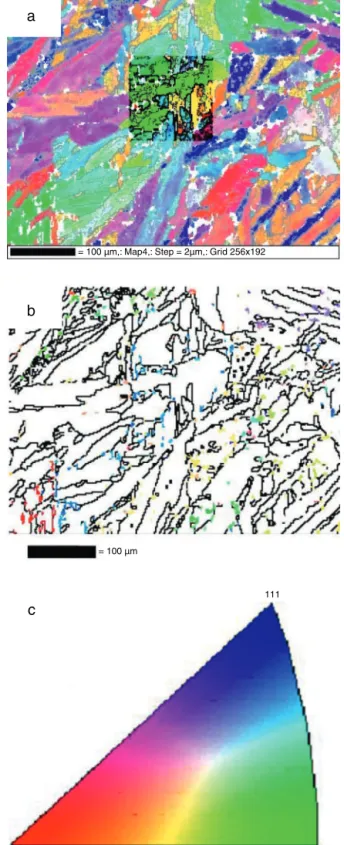

Fig.2showsEBSDmapsformartensiteandaustenitefor asampleofmaragingagedfor1hat550◦Candcooledinair

withoutstressorpriordeformationbeforemartensite trans-formation.Thecolorofeachpointisassociatedtothelocal orientation,asshownintheorientationstandardtriangle.The selectedgrainforstudyistheoneinblueinthecentralpart ofFig.2b.

Theorientationofausteniteintheselectedgrainwas deter-minedbytheEBSDChannel5softwareandisrepresentedby the setofEuler angles– ϕ1=334.3◦, =47.9◦ and ϕ2=60.3◦. Toperformthecalculationoforientationofthemartensite resulting from the transformation, a complete set of crys-tallographicdataisnecessary. Unfortunately,such datafor maragingsteelisnotavailable.Adata thatcorresponds to thetraditionaltwinned{259}␥transformationfoundinhigh

carbonsteels,Fe–NiandFe–Ni–Cwillbeused[10–12]. The choice of lattice invariant shear (LIS) was the (112)[111]␣ twinning system inthe bcc phase, that

corre-spondsto(111)[101]␥inthefccphase.

Thefollowingdatawasobtained: MagnitudeofLIS‘g’=0.272602.

Magnitudeoftheshapestrain‘m’=0.219957.

Habitplane:

(−0.4167810.5886170.694388)␣

or

(0.1850640.594242−0.782705)␥

Shapestraindirection:

[0.628457−0.4784560.613288]␣

or

[0.2095360.6728230.709509]␥

Orientationrelationship:

[100]␥=[0.7239850.6777400.128506]␣

[010]␥=[−0.018574−0.1670690.985770]␣

[001]␥=[0.689565−0.716070−0.108367]␣

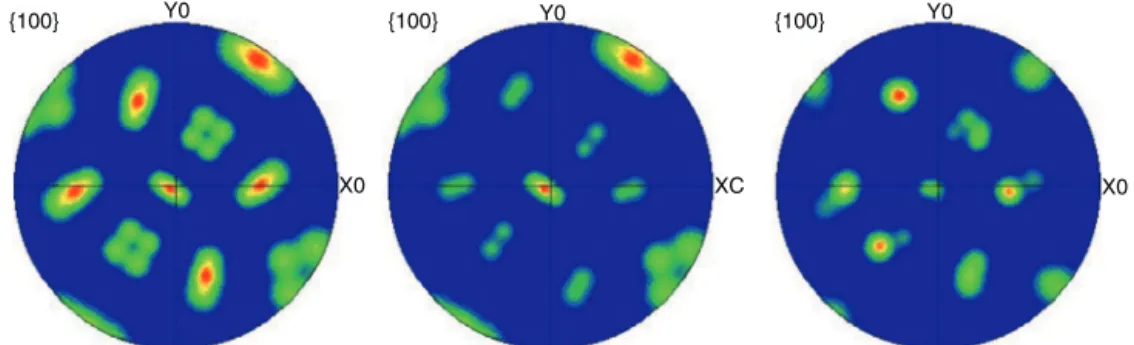

Fig. 3a shows (100) calculated pole figure for martens-ite using the phenomenological martensite transformation crystallographytheoryandassumingthatall24variantsare present,i.e.,novariantselectionisacting.Itwascompared withmeasured(100)bccpolefigureforthesameregionand ispresentedinFig.3b.Thereisaverygoodmatchbetween cal-culatedandmeasuredpolefigures.Theseresultpointstothe factthatrevertedandparentaustenitehavethesame crys-tallographictexture.Itisalsoevidentthatthereisnovariant selectioninthistransformation.

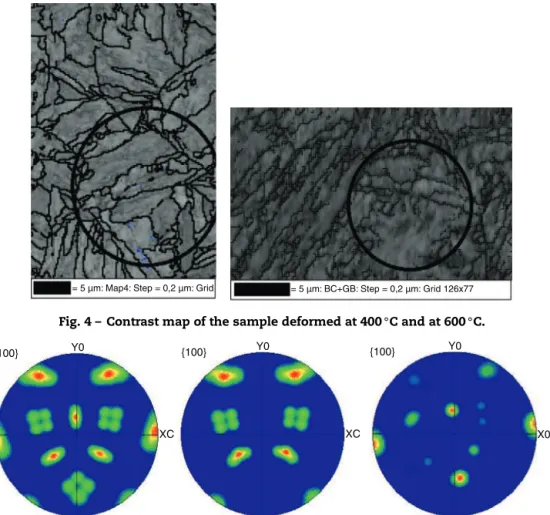

Fig.4showsthecontrastmapofacross-sectionalareaof thespecimendeformed10%atitsheightinacompressiontest performedat400◦C.Thecirclemarkedinthefigureindicates

theaustenitegrainusedtostudythecrystallographyofthe transformation.

Fig.5compares(100)calculatedpolefigurein(a)and(b) withonemeasuredbyEBSDinonegrainthatbelongs toa sampledeformed10% inits heightbythe application ofa compressiveforceat400◦C,i.e.,beforemartensite

transfor-mation.InFig.5aitwasassumedthattherewasnovariant selection. In Fig. 5b, it was assumed that some vestige of

= 100 µm,: Map4,: Step = 2µm,: Grid 256x192

a

b

= 100 µm

111

101 01

c

Fig.2–(a)EBSDmapformartensite;(b)EBSDmapfor austenite;(c)standardtriangle.(Forinterpretationofcolor inthetext,thereaderisreferredtothewebversionofthe article.)

{100} Y0 {100} Y0

X0 X0

a

b

Fig.3–Calculated(a)andmeasured(b)(100)polefigures forbccphaseinareashowninFig.2c.

comparison with the pole figure calculated assuming the modelofPatel–Cohenonerealizesthatvariantsnotpredicted bythemodelappearedaswellasvariantspredictedbythe modelarenotpresent.Theprobablereasonforthedivergence isthatafterwithdrawing theforcethatmadeplastic defor-mation inthe sample,it was placedinairfor coolingand duringcoolingthermalstressesaroseinfluencingthevariant selectionprocess.

Forthesampledeformedat600◦Cthesamephenomenon

happened. All variants predicted by the PMTC assuming 24variantsarepresentinFig.6c.Somevariantswithpositive mechanicalenergypredictedbythePatel–Cohenmodelare presentandsomenot.Therearealsovariantsnotpredicted bythemodelthatprecipitated.

= 5 µm: Map4: Step = 0,2 µm: Grid = 5 µm: BC+GB: Step = 0,2 µm: Grid 126x77

Fig.4–Contrastmapofthesampledeformedat400◦Candat600◦C.

{100} Y0 {100} Y0 {100} Y0

XC XC X0

Fig.5–(100)polefiguresforasampledeformedat400◦Cbeforetransformation:(a)calculated24variants;(b)calculated 9variants;(c)measured.

{100} Y0 {100} {100}

XC XC XC

Y0

Y0

{100} Y0 {100} {100}

X0 XC X0

Y0 Y0

Fig.7–(100)polefiguresforasamplewithelasticappliedstressduringtransformation:(a)calculated24variants; (b)calculated12variants;(c)measured.

Finallythelastsamplewasnotplasticallydeformedbefore martensitictransformationisshown inFig.7. Thissample showedaverygoodmatchbetweencalculatedpolefigureand measuredpolefigure.ThePatelandCohenmodelwas devel-opedtoanalyzetheinfluenceofstressduringtransformation. Thissamplewasnotsubjecttoanyplasticdeformationbefore martensitictransformationonlyelasticcompressivestressat thetransformationtemperature.

4.

Summary

Thephenomenologicaltheoryofmartensitecrystallography (PMTC)showedtobeveryaccuratetosimulatetransformation textureinmaraging-350steel.ThePatelandCohencriterion was very precise for predicting variant selection in sam-pleswheretransformationtookplaceundertheactionofan externalstress.Samplesplasticallydeformedintemperatures aboveMspresentedavariantselectiondifferentthanthe pre-dictedbythemodel.

Conflicts

of

interest

Theauthorsdeclarenoconflictsofinterest.

Acknowledgements

The authors are grateful to the support from CNPq (National CouncilforScientific and Technological Develop-ment)projects304503/2011-8and475825/2011-0.

r

e

f

e

r

e

n

c

e

s

[1]TavaresSSM,AbreuHFG,NetoJM,daSilvaMR,PopaI.A thermomagneticstudyofthemartensite–austenitephase transitioninthemaraging350steel.JAlloysCompd 2003;358:152–6.

[2]NakadaN,TsuchiyamaT,TakakiS,HashizumeS.Variant selectionofreversedausteniteinlathmartensite.ISIJInt 2007;47:1527–32.

[3]KunduS,BhadeshiaHKDK.Crystallographictextureand interveningtransformations.ScrMater2007;57: 869–72.

[4]KunduS,BhadeshiaHKDK.Transformationtexturein deformedstainlesssteel.ScrMater2006;55:

779–81.

[5]BowlesJS,MacKenzieJK.Thecrystallographyofmartensite transformations.ActaMetall1954;2:129–37.

[6]MacKenzieJK,BowlesJS.Thecrystallographyofmartensite transformationsII.ActaMetall1954;2:138–47.

[7]BhadeshiaHKDH.Geometryofcrystals.2nded.London: InstituteofMaterials;2001.

[8]PatelJR,CohenM.Criterionfortheactionofappliedstressin themartensitictransformation.ActaMater1953;1:

531–8.

[9]KunduS.UniversityofCambridge;2007.Availablefrom: www.msm.cam.ac.uk/phasetrans/[PhDthesis].

[10]BowdenHG,KellyPM.Thecrystallographyofthepressure inducedphasetransformationsinironalloys.ActaMetall 1967;15:1489–500.

[11]KellyPM.ISISpecialRep1964;86:146. [12]KellyPM.Themartensitetransformationin