*e-mail: moises_parucker@hotmail.com

Development of Self-lubricating Composite Materials of Nickel with Molybdenum

Disulfide, Graphite and Hexagonal Boron Nitride Processed by Powder Metallurgy:

Preliminary Study

Moisés Luiz Parucker*, Aloisio Nelmo Klein, Cristiano Binder, Walter Ristow Junior, Roberto Binder

Department of Mechanical Engineering, Technological Center, Federal University of Santa Catarina – UFSC, University Campus, CP 476, CEP 88040-900, Trindade, Florianópolis, SC, Brazil

Received: June 20, 2013; Revised: October 15, 2013

The purpose of this work was to develop nickel self-lubricating composites using solid lubricant as second phase and obtained by powder metallurgy. The work involved the study of chemical stability and chemical interaction between the nickel alloy matrix and solid lubricating additives (molybdenum disulfide, graphite and hexagonal boron nitride). The results showed a thermodynamic stability during sintering for the composites containing the phases of graphite and hexagonal boron nitride. The presence of molybdenum disulfide phase permits a reaction with the matrix, the formation of a liquid phase of nickel sulfide and the solubilization of molybdenum in the matrix.

Keywords: composites, powder metallurgy, solid lubricants

1. Introduction

This work is part of a set of themes which aim to develop materials of low friction coefficient and high mechanical resistance in order to open the application fields for self-lubricating materials. Dry self-self-lubricating bearings have been used for decades in household equipments and in office slight equipments (printers, electric shavers, drills, blenders, among others). Usually these materials have a high content of solid lubricant (15 to 35 vol.%) and this results in a high degree of discontinuity of the metallic matrix leading to poor mechanical strength of composite. Thus, these materials cannot be used for many typical mechanical applications where it is necessary higher mechanical and wear resistance of the self-lubricating sintered material. In this direction, the development of dry bulk self-lubricating materials combines a low friction coefficient with high mechanical strength, tuned for each particular application.

A solid lubricant can be applied to components of a tribological pair in the form of films/layers deposited or generated on its surface and incorporated into the volume of the material in dispersed particle form in the matrix, generating self-lubricating composite materials.

Lubricating composites are used to increase the service life of machinery and equipment where oil and grease cannot be used. For example, metal matrix composites which contain solid lubricants for high temperature applications and vacuum conditions are produced by powder metallurgy1.

To obtain a composite which can conciliate a low friction coefficient of and high mechanical strength it is necessary that the composite matrix has a high degree of continuity and the additive (solid lubricant) is not soluble and do not react with the matrix.

Graphite (C) and molybdenum disulfide (MoS2) are the most commonly used solid lubricants. Molybdenum disulfide is attractive due to its extremely low friction coefficient in the presence of different materials, operating rates, temperatures and pressures. However, its performance decreases in the presence of humidity and that is the reason it has been used as solid lubricant to vacuum work and space applications2. Graphite has better properties as solid lubricant when in the presence of humidity. Hexagonal boron nitride (h-BN) is a soft, white, lubricant powder with unique features which makes it attractive in place of graphite, molybdenum disulfide and other inorganic solid lubricants. With its superior adhesion property and thermal stability, BN presents an opportunity for the formulation of new solid lubricants for applications where conventional solid lubricants are inefficient or do not exhibit the expected performance3.

2. Literature Review

The term composite material refers to material having at least two chemically distinct and insoluble phases, three-dimensionally combined, with clearly defined interface. These materials belong to the group called “materials of low friction coefficient”.

Wang et al.1 studied the effect of MoS

2 solid lubricant in the tribological properties of Ni/MoS2 self-lubricating composites depending on the temperature (23-550 °C) and various compositions (20, 40, 60 and 80 wt.%) and identified that the friction coefficient and wear decrease until the percentage of 60 wt.%.

the surface lubricating film formation resulting in a linear decrease of the friction coefficient and wear up to 60% m/m depending on the integrity of the film formed.

Ni-Cr alloys with MoS2 (0, 2, 4, 6, 10, 15 and 20 wt.%) and hardener elements (Al, Mo, Ti, B) under temperatures of 20 to 600 °C were also studied. Regarding the effect of MoS2 addition to the alloy the decrease in density and hardness was observed. Regarding the friction and wear properties there was a tendency to decrease the friction coefficient close to 0.1 with the increase of MoS2 quantity up to 10 wt.%. The results show that the addition of 10 wt.% of MoS2 provides excellent lubrication and wear resistance properties under extreme temperature conditions (400 °C) and loads (196 N). The addition of Mo, Al, Ti and B allows the alloy hardening by solid solution and the formation of Ni3Al and Ni3(Al, Ti)[5].

Other works have reported the study of nickel composite layers. The deposition of fine particles of h-BN (combined with other components) without the aid of an external potential (electroless) has been used as coating on metallic substrates from parts of mechanical structures to form a self-lubricating and high wear resistance surface. Léon et al.6-8 while studying composite layers of Ni-P-(h-BN) obtained by electroless deposited on AISI 316L steel presents a promising future of these types of self-lubricating composites.

In other research, sintered bearings were produced using solid lubricants: C, MoS2 and BN. Considering the C and MoS2 lubricants did not meet the needs of application on ferrous alloys due to lubricant reactions with the matrix and its decomposition at elevated temperatures, the authors suggested the use of BN due to its chemical inertness and thermal stability9.

The aim of this study was to evaluate the thermodynamic stability/compatibility between solid lubricants with a nickel matrix during sintering heat treatment.

3. Experimental Procedures

To develop the study pure nickel carbonyl (INCO 123) powders and solid lubricant powders of graphite, molybdenum disulfide and hexagonal boron nitride were used. The physicochemical characteristics of the powders are shown in Table 1.

Mixtures of nickel carbonyl powders with solid lubricant powders in 10 vol.% of types of MoS2, h-BN and C to evaluate the reactivity of the lubricant with the nickel matrix were made. The mixtures were carried out in Y-type mixer for 60 minutes and the samples were compacted in a uniaxial double-action matrix under 600 MPa using a laboratory press.

After compaction, the samples were sintered using plasma process (90% Ar-10% H2), with resistive heating, in a voltage of 400 V with pulse time on (ton) of 50 µs and pressure of 1 torr. The heating rate was 10 °C/min up to 1150 °C under isotherm at the same temperature for 60 minutes. The time and sintering temperature were experimentally determined.

Microstructural characterization was performed by scanning electron microscopy and X-ray energy dispersive

spectroscopy (EDS) coupled with SEM and the X-ray diffraction technique. The density of the sintered samples was measured using the geometric method.

4. Results and Discussion

This section presents the results for the study that aimed to define the type of solid lubricant phase more suitable to be used in a nickel matrix. For this purpose sinterability tests were performed to evaluate the stability of the phases (reactions between solid lubricant additives and nickel matrix) during the sintering heat treatment and the microstructural changes between the matrix and the solid lubricant as well, i.e., the composite microstructure.

The morphology of the nickel powder utilized is presented in Figure 1.

4.1.

Nickel + Molybdenum disulfide

To assess the stability of MoS2 phase in the nickel matrix and microstructural changes during sintering at 1150 °C some sintering tests of Ni + MoS2 (10 vol.%) compacted powder mixtures were carried out.

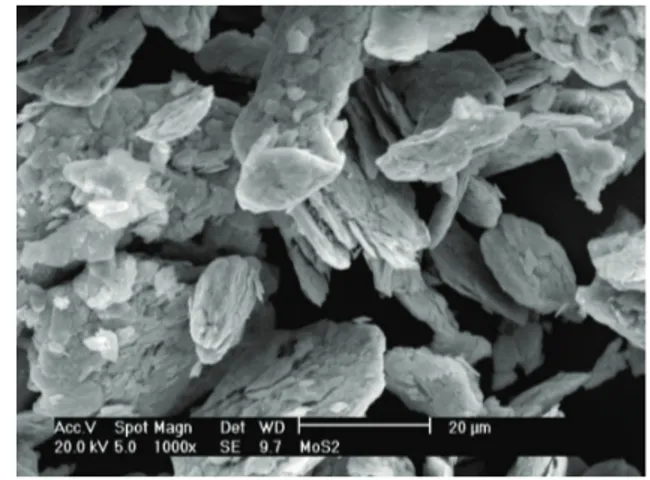

The MoS2 powder used for the present study has irregular morphology in the form of platelets, as showed in Figure 2.

The sintering test results of compacted mixtures of MoS2 + Ni powders show that during sintering at 1150 °C, MoS2 reacts with the nickel matrix favoring the formation of a new sulfide phase, Ni3S2 in this case. The molybdenum

Table 1. Characteristics of nickel and solid lubricant powders.

Characteristics Nickel

Supplier INCO123

Chemical composition (%) 99

Particle size (µm) D50(3,9)

Particle morphology Spike

Density (g/cm3) 8.9

Characteristics Solid lubricant (h-BN)

Supplier GE AC6004

type

GE HCPH type

Particle size (µm) 6-9 12-14

Crystal size (µm) 3 >10

Surface area (m2/g) 17 2

Particle morphology Platelets Spherical pellets

Density (g/cm3) 2.25

Characteristics Solid lubricant (Graphite)

Supplier Höganäs

Particle size (µm) 10-12

Density (g/cm3) 2.27

Characteristics Solid lubricant (MoS2)

Supplier GKN

Particle size (µm) 10-12

and a mean free path between them as proposed in the design of composite material.

4.2.

Nickel + Hexagonal Boron Nitride

According to Kimura et al.10, the h-BN has gained attention in recent years due to its tribological properties besides its similar or superior properties related to MoS2 and graphite in certain conditions.

To evaluate the stability and microstructural evolution of the composite the mixtures of Ni + h-BN (10 vol.%) were produced. The mixtures were compacted and sintered at a temperature of 1150 °C in isotherm for 60 min. Figure 5 shows the morphology of h-BN particles used.

After sintering, the presence of h-BN was observed homogeneously distributed in the nickel matrix the same way it was in the mixture before sintering. Figure 6 shows the micrograph and EDS (detail A) and Figure 7 shows the X-ray diffractogram of the composite obtained.

Figure 8 shows the topography and microstructure of the composite respectively containing 10 and 30 vol.% of h-BN. The composite showed good sinterability and it was

Figure 1. Morphology of powders of INCO123 nickel. Figure 2. Morphology of MoS2 particles.

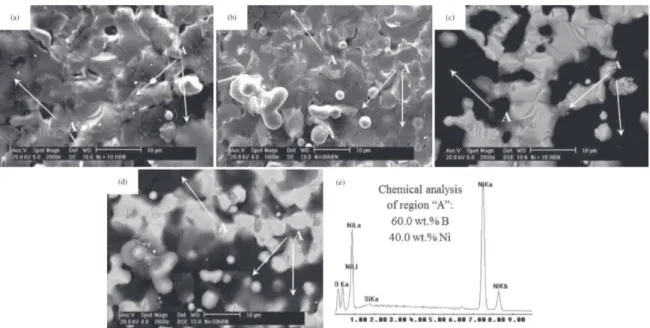

Figure 3. (a) Microstructure of the Ni/MoS2 composite showing the formation of liquid phase during sintering (detail A). (b) EDS of Ni3S2 phase (region A in the figure).

released by dissociation of MoS2 enters into solid solution in the nickel matrix.

Figure 3 shows the microstructure obtained indicating the formation of a liquid phase during sintering (step identified by the letter A in the figure). On solidification of the liquid phase the Ni3S2 phase crystallizes. This compound was identified via X-ray diffraction (Figure 4). Analysis of the chemical composition of the phase formed via EDS showed the presence of 76.0 wt.% of nickel, 22 wt.% of sulfur and 1.43 wt.% of molybdenum, confirming the presence of the Ni3S2 compound which has already been identified by X-ray diffraction.

Figure 6. (a) Microstructure of the Ni/h-BN composite. The dark regions indicated by the letter “A” contain the dispersed particles of h-BN. (b) EDS of dispersed phase (h-BN).

Figure 7. X-ray diffractometry of the Ni/h-BN composite.

found that increasing the content of solid lubricant tends to decrease the density and hardness of the sintered material. The image analysis showed 15 and 31% of porosity and the presence of h-BN phase in composites in which were added 10 and 30 vol.% of h-BN, respectively, i.e., the h-BN added did not react with the matrix.

Figure 9 shows the presence of h-BN dispersed on the surface of the nickel/h-BN composite.

4.3.

Nickel + Graphite (C)

To assess the stability of the graphite phase in the nickel matrix and microstructural evolution during sintering some sintering tests of Ni + C (10 vol.%) compacted powder mixtures were carried out. The graphite powder used for the present study shows a morphology of platelets, as seen in Figure 10.

After sinteringat 1150 °C, though the carbon has low solubility in nickel we observed the presence of homogeneously distributed graphite in the matrix. Figure 11 shows the micrograph and the EDS (detail A) of the composite obtained.

5. Conclusion

As for the preliminary study of the chemical stability and chemical interaction between matrix and solid lubricant additivesit may be concluded:

• Themolybdenumdisulphidereactswiththenickel matrix hindering the development of Ni/MoS2 composites. During sintering, there is the formation

Figure 4. X-ray diffraction of sample obtained by sintering of compacted powder mixture of Ni + MoS2 powder, showing the

Figure 8. (a) Topography of Ni/h-BN (10 vol.%) composite, (b) Microstructure of Ni/h-BN (10 vol.%) composite, (c) Topography of Ni/h-BN (30 vol.%) composite, (d) Microstructure of Ni/h-BN (30 vol.%) composite.

of a new phase of nickel disulfide (Ni3S2) and molybdenum enters into solution in the nickel matrix. The results suggest not using MoS2 as solid lubricant in sinterings at 1150 °C;

• IntheNi/h-BNcompositesthesolidlubricantphase was inert and homogeneously distributed in the matrix after sintering. The stability of h-BN particles in the composite was confirmed by X-ray diffractometry; • ThepresenceofgraphiteintheNi/Ccompositealso

provided the graphite phase stability after sintering due to the low solubility of carbon in nickel.

Acknowledgements

The authors are thankful to EMBRACO and to STEELINJET – LUPATECH Division.

Figure 10. Morphology of the graphite particles.

References

1. Wang F, Wu Y and Cheng Y. Effects of solid lubricant MoS2 on the tribological behavior of hot-pressed Ni/

MoS2 self-lubricating composites at elevated temperatures.

Tribology Transactions. 1996; 39:392-397. http://dx.doi.

org/10.1080/10402009608983544

2. Sliney H. Solid lubricants. NASA Technical Memorandum. April 1991.

3. Lu J, Yang S, Wang J and Xue Q. Comparison on the microstructure and mechanical strength of a Ni-based alloy with and without 3wt.% CeF3 addition. Materials Science and

Engineering. 1998; 268-272.

4. Wu Y, Wang F, Cheng Y and Chen N. A study of the optimization mechanism of solid lubricant concentration in Ni/ MoS2 self-lubricating composites. Wear. 1997; 64-70.

5. Dangsheng X. Lubrication behavior of Ni-Cr-based alloys containing MoS2 at high temperature. Wear. 2001;

25(1-2):1094-1099. http://dx.doi.org/10.1016/S0043-1648(01)00803-1

6. León OA, Staia MH and Hintermann HE. High temperature wear of an electroless Ni-P-BN(h) composite coating. Surface

Coating and Technology. 2003; 163-164:578-584. http://dx.doi.

org/10.1016/S0257-8972(02)00663-1

7. León OA, Staia MH and Hintermann HE. Deposition of Ni-P-BN(h) composite autocatalytic coating. Surface Coating and

Technology. 1998; 108-109:461-465. http://dx.doi.org/10.1016/

S0257-8972(98)00595-7

8. León OA, Staia MH and Hintermann HE. Wear mechanism of Ni-P-BN(h) composite autocatalytic coatings. Surface

Coating and Technology. 2005; 200:1825-1829. http://dx.doi.

org/10.1016/j.surfcoat.2005.08.061

9. Gallo A and Jorio I. Bearing produced by sintering metal powders with solid lubricants. Powder Metallurgy. 1970; 13(25).

10. Kimura Y, Wakabayashi T, Okada K, Wada T and Nishikawa H. Boron Nitride as a lubricant additive. Wear. 1999; 232:199-206. http://dx.doi.org/10.1016/S0043-1648(99)00146-5