w w w . s b f g n o s i a . o r g . b r / r e v i s t a

Original

Article

In

vivo

potential

hypoglycemic

and

in

vitro

vasorelaxant

effects

of

Cecropia

glaziovii

standardized

extracts

Daniela

Paula

Arend

a,

Talitha

Caldas

dos

Santos

a,

Luisa

Helena

Cazarolli

d,

Mariana

Appel

Hort

c,

Diva

Sonaglio

a,

Ana

Lúcia

Gomes

dos

Santos

a,

Rosa

Maria

Ribeiro-do-Valle

c,

Fátima

Regina

Mena

Barreto

Silva

b,

Angela

Machado

de

Campos

a,∗aDepartamentodeCiênciasFarmacêuticas,LaboratóriodeFarmacotécnica,CentrodeCiênciasdaSaúde,UniversidadeFederaldeSantaCatarina,Florianópolis,SC,Brazil bDepartamentodeBioquímica,LaboratóriodeHormônioseTransduc¸ãodeSinais,CentrodeCiênciasBiológicas,UniversidadeFederaldeSantaCatarina,Florianópolis,SC,Brazil cLaboratóriodeFarmacologiadeProdutosNaturais,DepartamentodeFarmacologiaCentrodeCiênciasBiológicas,UniversidadeFederaldeSantaCatarina,Florianópolis,SC,Brazil dUniversidadeFederaldaFronteiraSul,CampusUniversitárioLaranjeirasdoSul,LaranjeirasdoSul,PR,Brazil

a

r

t

i

c

l

e

i

n

f

o

Articlehistory:

Received19November2014 Accepted25May2015 Availableonline3July2015

Keywords: Cecropiaglaziovii Decoction Maceration Totalphenolic

Antihyperglycemicactivity Vasorelaxantactivity

a

b

s

t

r

a

c

t

TheaimofthisstudyistoinvestigatetheeffectofCecropiaglazioviiSnethl,Urticaceae,extractsonthe

oralglucosetolerancecurve,onglycemiainalloxan-induceddiabeticratsandvasorelaxanteffectafter

theextractionprocess,andtostandardizetheextractivesolutions.Theeffectsoftheprocessvariables

andtheirinteractionswerecalculatedinrelationtodryresidue,pH,totalphenolicresultsandchemical

markercontent.Furthermore,theeffectoftheextracts(400mg/kg),chlorogenic(2or15mg/kg)and

caffeicacids(2mg/kg)wereinvestigatedontheoralglucosetolerancecurveandonglycemiain

alloxan-induceddiabeticrats.Oraladministrationofethanolextracts4d20and8d20significantlyimproved

glucosetoleranceinthehyperglycemicrats.Chlorogenicandcaffeicacids,aswellastheassociationof

thecompoundswereabletosignificantlyreduceglycemiaafteroralgavagetreatments.Ontheother

hand,theaqueousextractsdidnotaltertheglycemia.Theaqueousextracts(8020and9030)andonly

thehigherdoseofchlorogenicacidpresentedasignificanteffectonserumglucoseloweringindiabetic

rats.Additionally,theIC50revealsthattheethanolextractspresentedmorepotentvasodilatoreffects

thantheaqueousextractsinaorticrings.ThisstudyshowsthatC.glazioviistandardizedextractsexhibits

antihyperglycemicaction,isabletoimproveglucosetoleranceandhasapotentvascularrelaxingeffect.

Theseresultsareprobablylinkedtoconcentrationsofthemainphenoliccompoundsoftheextracts.

©2015SociedadeBrasileiradeFarmacognosia.PublishedbyElsevierEditoraLtda.Allrightsreserved.

Introduction

LeavesofCecropiaglazioviiSnethl,Urticaceae,areusedinthe

traditionalmedicine,mainlyintheformoftea.Pharmacological

studieshaveshownthatextractivesolutionsofthisspeciesproduce

anxiolytic(Rochaetal.,2002),hypotensive(Lima-Landmanetal.,

2007),antiasthmatic(Delarcinaetal.,2007),antidepressant(Rocha

etal.,2007),antacid,antiulcer(Souccaretal.,2008)effects,aswell

asinvitroantiviraleffectsagainsthumanherpesvirustypes1and

2(Silvaetal.,2010).

SomeCecropiaspeciesare usedinpopularmedicinetotreat

diabetes and hypoglycemic effects have been reported for the

extractive solutions of Cecropia obtusifolia Bertol., Urticaceaae,

Cecropia peltata L., Urticaceae (Andrade-Cetto and Wiedenfeld,

∗ Correspondingauthor.

E-mail:angela.campos@ufsc.br(A.M.deCampos).

2001;Nicasioetal.,2005;Andrade-Cettoetal.,2007;Alonso-Castro etal.,2008;Andrade-CettoandVázquez,2010)andalsoCecropia pachystachyaTrécul.,Urticaceae(Aragãoetal.,2010).Basedonthe

hypoglycemicpotentialdescribedtoCecropiaspeciesand

consid-eringthattherearenostudiesonthehypoglycemiceffectofC.

glaziovii,thepresentstudysoughttoevaluatetheeffectofextracts

preparedfromC.glazioviileavesonoralglucosetolerancecurve

andonglycemiainalloxan-induceddiabeticrats.

Inthepreparationoftheextractivesolutions,theapplicability

ofthemacerationanddecoctionmethodswasdeterminedfor

opti-mizingtheextractionconditionsofphenolicacidssubstancesfrom

C.glazioviileaves.Someextractionparameterswereanalyzedusing

anexperimentaldesign.Thisworkthereforedeterminesthemost

appropriateextractionmethod,andthebestconditionsfor

pro-motinganextractionwiththehighestcontentsofchemicalmarkers

(chlorogenicandcaffeicacids).Chlorogenic(CGA)andcaffeic(CFA)

acidswereusedaschemicalmarkersforstandardizationdueto

highconcentrationpresentintheextractsandalsotoberelatedto

http://dx.doi.org/10.1016/j.bjp.2015.05.010

thehypoglycemic/antihyperglycemiceffectsintheliterature(Hsu etal.,2000;RodriguezdeSotilloandHadley,2002;Jungetal.,2006; Gentaetal.,2010).Theseinitialresultscanbeusedtoguidefurther

standardizationand applicationofC.glazioviileafextractinthe

developmentofphytopharmaceuticalpreparations.

Materialsandmethods

Materials

Chemicalsandreagentswereobtainedfromthefollowing

com-mercialsources:chlorogenicacidandcaffeicacid(Sigma–Aldrich,

St.Louis,MO,USA),Folin–Ciocalteu(Fluka,Sigma–Aldrich,St.Louis,

MO,USA),methanolandacetonitrile(HPLCgrade)werepurchased

fromJ.T.Baker (Phillipsburg, NJ,USA), aceticacid(Qhemis, São

Paulo,Brazil),LC-gradewaterobtainedinMilli-Qsystem(Millipore,

Bedford,MA,USA).Allsamplesandsolutionswerepreparedfrom

bidistilledwater.Allotherreagentsandsolventswereofanalytical

grade.

Rawmaterialcharacterization:plantmaterial

TheleavesofCecropiaglazioviiSnethl,Urticaceae,werecollected

bytheÍlioMontanariJr.researcheratPluridisciplinaryCenterof

Chemical,BiologicalandAgronomicStudies(CPQBA)ofthe

Uni-versityofCampinas,SP,Brazil.Aspecimenvoucherisdeposited

attheCPQBAherbarium(number78).Thedryleaveswereground

inaknifemill(Macmont)usinga3mmmesh.Themilledvegetal

materialwascharacterizedbytotalashcontent,lossondrying,

par-ticlesizedistributionandmicrobiologicalqualityoftherawplant,

asdescribedbelow.

Totalashcontent(TA)

Thetotalashcontentwasdeterminedafterbummingthemilled

leaves.Theprocedurewasdonegravimetricallybyweighing3.0g

ofmilledleavesinaporcelaincrucible.Thesampleswere

submit-tedtocalcinationinanovenat600◦C for2h. Theresultswere

expressedaspercentageofremainingweight(w/w)bythemean

ofthreemeasurements(FarmacopéiaBrasileira,2010).

Lossondrying(LOD)

Thelossondryinganalysiswascarriedouttodeterminethe

amountofwaterandvolatilematterintheplantdrugmaterial.The

LODwasdeterminedgravimetricallybyweighing2.0gofmilled

leavesinaweighingbottleandsubmittingthesamplestoaheated

stoveat105◦Cfor2h.Theprocedurewasrepeateduntilconstant

weightwasachieved(variation<5mg).Theresultswereexpressed

aspercentageofweightlost(w/w)bythemeanofthree

measure-ments(FarmacopéiaBrasileira,2010).

Particlesizedistribution

Particlesizedistributionwasevaluatedbyastandardsieving

method,fora periodof15min(SieveShakerBertel1400),with

30gof thedried milledplantmaterial, usinga series ofsieves

withscreensizescorrespondingto180,355,500,710,1000and

1700m. Theaverageparticlesizewascalculated bymeansof

Probito’sevaluation(Vila-Jato,1997;Pasqualotoetal.,2005).

Assessmentofmicrobiologicalqualityofrawplant

Thetotalviableaerobiccountoftheplantmaterialwas

deter-mined,asspecifiedinthetestprocedurebelow,usingtheplate

countmethod.Aerobicbacteriaandfungi(moldsandyeasts)were

determinedinthistest.

Pretreatmentofthetestplantmaterial

Plantmaterial(10g)wasdilutedinphosphatebufferpH7.2,

totalvolumeadjustedto100ml.Thetreatedsampleresultedina

dilutionof10−1.

Totalviableaerobiccount

Todeterminethetotalbacteria,thepre-treatedherbal

mate-rialwaspreparedinduplicateusingdecimaldilutionuntil10−9

dilution.Sampleswereincubatedat30–35◦Cfor7daysinnutrient

agar.Similarly,forfungi,pre-treatedplantmaterialwaspreparedin

duplicateusingdecimaldilutionuntil10−9dilution.Sampleswere

incubatedat20–25◦Cfor7daysinSabouraudagar(WHO,1998).

Extractpreparation:experimentaldesign

Twofullfactorialscreeningdesigns(22)waschosento

investi-gatetheeffectsoftheextractionconditionsinthetwoextraction

methods:macerationand decoction. Inthe case ofmaceration,

theindependentvariableswereethanolconcentration(20,50and

80%;v/v)(factorA)andextractiontime(4,6and8days)(factor

B),whileforthedecoctionmethodthevariableswere

tempera-ture(70,80and90◦C)(factorA)andextractiontime(10,20and

30min)(factorB).Alldataaregivenasmeans±standard

devia-tionsoftwoindependentbatches.Onecentralpointwasproposed

ineachdesignandtheseexperimentswereperformedin

dupli-cate. The effects ofthe process variables and theirinteractions

onthedryresidue,pH,totalphenolicandchemicalmarker

con-tent(CGA andCFA)werecalculatedasthedifferences between

themeansonthehighandthelowlevels,respectively.The

sig-nificanceoftheeffectswasevaluatedbycomparingtheirvalues

totheconfidence intervals basedonthe meanstandard

devia-tionfor the respectiveresponse variables (Montgomery,2005).

Theexperimentswerecarriedoutrandomlyandtheeffectswere

calculatedpresumingalinearmodelwithinteractionamongthe

factors.Theestablishedscreeningdesignandtheresultswere

ana-lyzed by Design-Expert® software (Version 8.0.6, StatEase, and

Minneapolis,MN).Theeffectsofeachfactortestedinthese

exper-imentsweredemonstratedusinganalysisofvariance(regression

coefficientsandsignificantpvalues)andParetochart,whichwere

ausefultoolforshowingthestatisticallysignificanteffects

eval-uatedinstudy.ThefunctionoftheParetochartistoprovidean

additionalchartusedtodisplaythet-valuesoftheeffects.Another

useoftheParetochartis tocheck“onemoresignificanteffect”

thatwasnoteasilyvisibleintheotherchart.Analysisofvariance

(ANOVA)wasperformedtoidentifythesignificanceofsingle

fac-torsand theirbinaryinteractionsin termsoftheirinfluenceon

theresponsesanalyzed(significantwhenthepvalue<0.05).The

interactiontermsthatwerenotsignificantwereremovedfromthe

model.

Characterizationoftheextractivesolutions(ethanolandaqueous extracts)

Determinationofdryresidue

Thedryresiduewasdeterminedbydrying20gofeach

extrac-tivesolutioninanovenat105◦Cfor2h.Aftercompletedrying,

theresidualsolidmatterwasweighedandthedryresidue was

expressedasapercentage(w/w)bythemeanofthree

Totalphenoliccontent(TPC)

Percentages of total phenolic of the ethanol and aqueous

extractsweredeterminedaccordingtothemethodreportedbyYu

etal.(2002).Briefly,thereactionmixturecontainedextractive

solu-tion(10lofethanolextractor20laqueousextract),500lofthe

Folin–Ciocalteureagent,and1.5mlof20%sodiumcarbonate.The

finalvolumewasmadeupto10mlwithpurifiedwater.After2hof

reaction,theabsorbanceat765nmwasmeasuredandusedto

cal-culatethephenoliccontentsusinggallicacidasstandard.Triplicate

reactionswereconducted.

QuantitativeanalysisofCGAandCFA(HPLC)

Thechlorogenic(CGA)and caffeic(CFA)acidscontentinthe

extractivesolutionsweredeterminedbyHPLCanalysisusinga

pre-viouslyvalidatedmethod(Arendetal.,2011)onaPerkin-Elmer

apparatusequippedwithanautosamplerSeries200,interface600

SeriesLINK,binarypumpSeries200,UV-VisdetectorSeries200,

andvacuumdegasserSeries200.AZorbaxCHPC18column(5mm,

150mm×4.6mm,AgilentTechnologies)wasused.Thegradientof

elutionconsistedofacetonitrile(A)1.0%aceticacid(B)withaflow

rateof1ml/min,andwasprogrammedasfollows:0–15min,87%

B;15–25min,87–60%B;25–34min,60%B.Detectionwassetat

330nm.Theinjectionvolumewas20l.

Thequantificationofchemicalmarkers,CGAandCFAwas

car-riedoutbycomparisonoftheirretentiontimesandco-injectionof

standardsolutions.Twostandardcurveswereplotted:chlorogenic

acid(2.5–200g/ml)andcaffeicacid(2.5–100g/ml).

Quantifica-tionoftheindividualcompoundswasperformedusingavalidated

regressioncurve(r>0.9999).Threemillilitersofeach extractive

solutionsweredilutedto10mlusingamethanol:watersolution

(50:50;v/v).Thesampleswerefilteredthrougha0.45mmHVLP

membrane(Millipore)beforeinjection.

Vascularreactivityinthoracicrataorta

Pharmacological studiesrelatedtohypotensive activityhave

alreadybeendescribedforthisplant(Lima-Landmanetal.,2007;

Ninahuamanetal.,2007).Inanattempttoevaluatethepotency

ofthese extractivesolutions, thepotentialcardiovasculareffect

wasdemonstratedthroughvascularreactivityinthoracicrataorta

followingthestepsbelow.

Animals

Male Wistar rats (250–300g) were maintained in a 12h

light/darkcyclewithfreeaccesstowaterandstandardratchow.On

thedayoftheexperiments,ratswereeuthanizedunder

anesthe-siawithamixtureofketamine(80mg/kg)andxylasine(15mg/kg)

given intraperitoniallyand theaortawasremoved.The

experi-mentswereperformedafterapprovaloftheprotocolbythelocal

ethicalcommitteeforanimaluse(ProtocolCEUA/UFSCPP00482).

Tissuepreparation

The thoracic aorta was isolated as described previously by

Andriambelosonetal.(1999).Inbrief,afterremovaloffatand

con-nectivetissue,aorticrings(3–4mminlength)weremountedinan

isolatedorganbathonisometricforcetransducersconnectedtoan

amplifierandchartrecorder(SoftandSolutions/KITCAD8,Brazil)

forisometrictensionrecordingsasdescribedelsewhere.Therings

werebathedwithphysiologicalsalt solutionwiththefollowing

compositioninmM:130.0NaCl,4.7KCl,1.2KH2PO4,1.2MgSO4,1.6

CaCl2,14.9NaHCO3,0.03EDTAand5.5glucose,maintainedat37◦C

andbubbledwith95%O2–5%CO2.Theaorticringswerestretched

applyingtensionof1gappliedfor1hwithperiodicalwashesevery

15min.Afterthisperiod,theringswerecontractedwith

phenyle-phrine(1M)andchallengedwithacetylcholine(1M)totestthe

tissueviabilityandintegrityoftheendothelium,respectively.

Evaluationofthevasorelaxanteffect

Endothelium-intactaorticringswerecontractedwith

phenyle-phrine(1M)untilthe plateauofthecontractionwasreached

(around15min)andthenexposedtoincreasingconcentrationsof

theextractivesolutions(0.1–100g/ml)givenat5minintervals.A

concentration–responsecurveofacetylcholine-induced

vasodila-tation(1nMto3M)wasusedasapositivecontrol.Theresults

wereexpressedasmean±standard errorof themean (SEM)of

percentageofrelaxation.Statisticalcomparisonsbetweengroups

werecarriedoutusingone-wayanalysisofvariance(ANOVA)

fol-lowedbytheTukeytest.Theresultswerealsoexpressedasthe

geometricmean(IC50)values,accompaniedbytheirrespective95%

confidencelimits.

Antihyperglycemicactivity

Fastedratsforantihyperglycemicactivitymeasurements,from

thesameanimal facility,weredeprivedoffoodforatleast16h

butallowedfreeaccesstowater.Alltheanimalsweremonitored

andmaintainedinaccordancewiththelocalethicalcommitteefor

animaluse(ProtocolCEUA/UFSCPP00223).

Oralglucosetolerancecurve

Animals were divided into groups of five animals for each

treatment: hyperglycemic group: fasted rats that received

glu-cose(4g/kg;8.9M);hyperglycemictreatedgroup:fastedratsthat

receivedglucose(4g/kg)plusdifferentethanoloraqueousextracts

(400mg/kg)ortolbutamide(100mg/kg)orchemicalmarkeralone,

chlorogenicacid(CGA2or15mg/kg)orcaffeicacid(CFAatadoseof

2mg/kg)orincombination(CGAplusCFAatadoseof2mg/kg).All

treatmentswerecarriedoutbyoralgavage.Bloodsampleswere

collectedjustpriortoandat0,15,30,60and180minafterthe

glucose loading.Aftercentrifugation, serum wasusedto

deter-minetheglycemiabytheglucoseoxidasemethod(Foladoretal.,

2010).Datawereexpressedasmean±S.E.M.One-wayanalysisof

variance(ANOVA),followedbytheBonferronipost-testor

non-pairedStudent’sttest,wasusedtoidentifysignificantlydifferent

groups.Differenceswereconsideredtobesignificantatthep≤0.05

level.

Diabeticanimals

Ratsweremadediabeticbya singleintravenousinjectionof

alloxanmonohydrate5%(w/v) ina salinesolutionat adoseof

40mg/kgbodyweight.Bloodsampleswerecollected3dayslater,

andglucoselevelsweredeterminedasindicativeofthe

develop-mentofdiabetes.Diabeticratsreceivedethanoloraqueousextracts

(400mg/kg)orchemicalmarkeralone,chlorogenicacid(CGA2or

15mg/kg)orcaffeicacid(CFAatdose2mg/kg)orincombination

(CGAplusCFAatdose2mg/kg).Bloodsamplesfromthetailvein

werecollectedandcentrifugedandtheserumwasusedto

deter-minetheglycemiabytheglucoseoxidasemethod.Aserumglucose

rangeof22–29mmol/lwasusedfortheexperiment(Foladoretal.,

2010).

Determinationoftheserumglucoseconcentration

Bloodsampleswerecollectedandcentrifuged,andtheblood

glucoselevelsweredetermined bytheglucoseoxidasemethod

Table1

Dryresidue,pH,totalphenoliccontent,andCGAandCFAcontentsforthemacerationextractionmethod.

Extractivesolution Ethanol(%) Time(days) Dryresidue(%) pH Totalphenolic(mg/ml) CGA(g/ml) CFA(g/ml)

4d20 20 4 1.06 5.78 3.64 131.09 36.93

4d20 20 4 1.05 5.81 3.96 128.81 36.67

4d80 80 4 1.02 5.88 3.48 150.99 3.25

4d80 80 4 1.01 5.88 3.37 150.69 3.27

8d20 20 8 1.14 5.79 3.95 73.36 58.35

8d20 20 8 1.10 5.83 3.69 75.62 57.61

8d80 80 8 1.06 5.90 3.47 154.80 3.78

8d80 80 8 1.05 5.93 3.43 153.99 3.67

6d50 50 6 1.08 5.92 3.88 167.11 11.94

6d50 50 6 1.07 5.96 3.89 167.65 12.18

Resultsanddiscussion

Rawmaterialcharacterization

Plantsarecomplexmixturesthatpresentaprobleminterms ofstandardizationandqualitycontrol.Therefore,protocolswere developedfromtherawmaterialtoestablishtheirprevious treat-mentandqualitycontrolinordertocharacterizethemproperly. Determinationofthetotal ashcontentisparticularlyimportant forevaluatingthecleanlinessoftheplantmaterial,forexample, thepresenceorabsenceofinorganicmattersuchassandanddirt adheredtothesurfaceofthedrug(Jainetal.,2010).Similarly,the

presenceofwatercanpromotedegradationreactionsand

prolif-erationofmicroorganisms.Thiscontaminationcompromisesthe

integrityofpharmacologicallyactivesubstances.Totalashcontent

andlossondryingoftheplantdrugweredeterminedbythe

pro-ceduresgivenintheBrazilianPharmacopoeia(2010).Theresults

were7.92±0.03%and13.10±0.06%,respectively.Themean

diam-eterofthecrushedleaveswasdeterminedas0.78±0.41mm.This

informationisimportantforstandardizingthereproducibilityof

theextractionprocess,a homogenoussamplemighttoimprove

thekineticsofthechemicalcompoundextraction.

Thepresenceofmicroorganismscanbeanaturalconsequenceof

theagriculturalpracticesandprocessingconditionsofplant

mate-rials(Kolb,1999).Thus,rawmaterialplantmaybeassociatedwith

abroadvarietyofmicrobialcontaminants,andthismicrobiological

backgroundhasanimportantimpactontheresultsofqualitative

andquantitativeanalysescarriedoutforqualitycontrol(Wolfgang

etal.,2002;Kosalecetal.,2009).Theresultsofthestandard

aer-obicbacteriacountwere1.04×103UFC/ml,moreover,themean

valuesformoldandyeastwerefrom8.25×104UFC/ml.Therefore,

therawmaterialdidnotexceedthevaluerecommendedbythe

WHO(1998).Thedataobtainedsuggestthattherawmaterialwas

characterizedanddeemedappropriateforcontinuingstudies.

Preparationandstandardizationofextractivesolutions

Inthestandardizationofherbalpreparationsvariousaspectsof

analysismustbeperformed,requiringtheuseofscientificproof

and clinicalvalidationwithchemical standardization,biological

assaysandclinicaltrials(Ong,2004).Thechoiceofthetechnique

for theextractionplantmaterial is themost importantstep in

thedevelopmentofanalyticalmethods(Benthinetal.,1999;Ong,

2004),particularlyconsideringthat herbalextractsarecomplex

mixtures,andappropriatetechniquesareneededtoallowa

bet-terextractionoftheirconstituentsofinterest(Jacquesetal.,2007).

Decoctionandmacerationmethodswereinvestigatedasan

alter-nativetotraditionalextractionmethodsusedintheextractionof

chemicalmarkers(CGAandCFA),searchingforimproved

extrac-tionefficiency.TheconditionsfortheextractionofC.glazioviiusing

macerationanddecoctionmethodswereevaluatedondryresidue,

totalphenolicvaluesandCGAandCFAacidscontent.Tables1and2

showtheresultsoftheexperimentaldesignsusedforthe

macera-tionanddecoctiontechniques,respectively.

Dryresidue

Intheethanol extractsobtainedbymaceration, bothfactors

–ethanolconcentration(factorA)andextractiontime(factorB)

–weresignificant(Table3;Fig.1c).Increasingthepercentageof

ethanolcausesadecreaseofdryresidue.Ontheotherhand,the

increaseinextractiontimeresultedinanincreasedamountofdry

residue(Fig.1a).

In the case of the aqueous extracts obtained by decoction,

onlythefactortemperaturewassignificant(Table4;Fig.1d).The

increaseintemperaturecausedanincreaseindryresidue.Inthe

decoctionmethod,significantcurvaturewasobserved,indicating

thereisnolinearityforthedryresidueresponse,asshowninFig.1b.

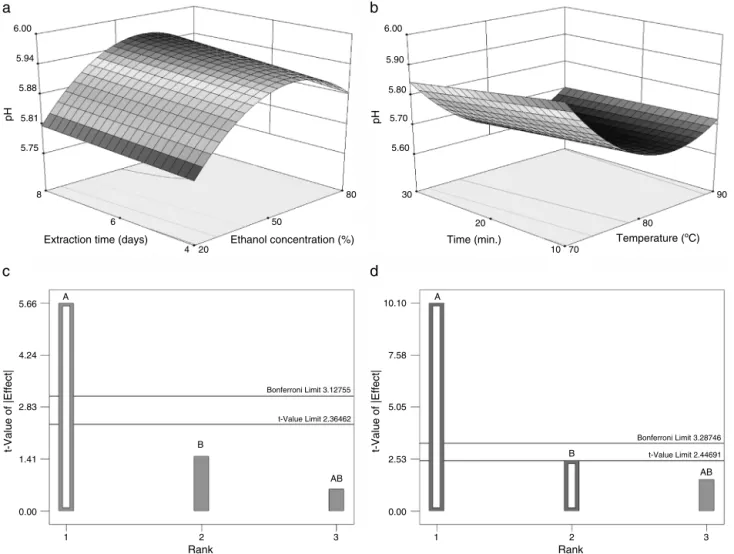

pH

The pH values for the ethanol extracts were in the range

5.78–5.96.Intheextractsobtainedbymaceration,onlythefactor

ethanolconcentrationwassignificant(Table3;Fig.2c).Lowering

theethanol concentrationalsoloweredthepH values(Fig.2a).

Thesameoccurredwithincreasingtemperaturefortheaqueous

extracts(Table4;Fig.2bandd),whichseemstoindicatethe

extrac-tionofsubstanceswithacidiccharacterinthoseconditions.The

Table2

Dryresidue,pH,totalphenoliccontent,andCGAandCFAcontentsforthedecoctionextractionmethod.

Extractivesolution Temperature(◦C) Time(min) Dryresidue(%) pH Totalphenolic(mg/ml) CGA(

g/ml) CFA(g/ml)

7010 70 10 0.82 5.88 2.09 179.09 7.75

7010 70 10 0.76 5.94 1.65 177.67 7.72

9010 90 10 0.91 5.72 2.19 190.17 7.59

9010 90 10 0.93 5.72 2.15 192.99 8.02

7030 70 30 0.87 5.85 2.21 185.41 8.06

7030 70 30 0.83 5.84 2.13 186.65 8.18

9030 90 30 0.91 5.70 2.19 191.55 8.70

9030 90 30 0.95 5.71 2.35 193.04 8.63

8020 80 20 0.77 5.65 2.15 220.87 4.86

Table3

Analysisofvariance(regressioncoefficientsandsignificantpvalues)fordryresidue,totalphenolic,CGAandCFAresponsesformacerationextractionmethod.

Polynomialterm Dryresidue(%) pH Totalphenolic CGA(g/ml) CFA(g/ml)

Coefficient pvalue Coefficient pvalue Coefficient pvalue Coefficient pvalue Coefficient pvalue

Model – 0.0023 – 0.0018 – 0.0153 – <0.0001 – <0.0001

Intercept +1.06 – 5.85 – 3.62 127.42 – 25.44 –

(A)Ethanol(%) −0.026 0.0024 0.048 0.0007 −0.19 0.0053 +25.20 <0.0001 −21.95 <0.0001 (B)Time(days) +0.026 0.0024 0.013 0.1466(NS) 0.011 0.8057(NS) −12.98 <0.0001 +5.41 <0.0001

(AB)Interaction – NS – NS NS +14.75 <0.0001 −5.18 <0.0001

Curvature – NS – 0.0017 0.0370 – <0.0001 <0.0001

NS,notsignificant.

Ethanol concentration (%)

Extraction time (days) Time (min.) Temperature (ºC)

Bonferroni Limit 3.28746

t-Value Limit 2.44691 t-Value Limit 2.36462 Bonferroni Limit 3.12755

B

AB A

4.58

3.44

2.29

1.15

0.00 AB

B A

5.02

4.02

3.01

2.01

1.00

0.00

0.95

0.89

0.82

0.76

0.70

30 80

50

20 4 6

8 1.14

1.11

1.07

1.03

1.00 Dey residue (%)

Dey residue (%)

70 10

80

90

20

t-Value of

|Effect

|

t-Value of

|Effect

|

1 2 3

Rank

1 2 3

Rank

a

b

c

d

Fig.1.Graphofethanolconcentration(A)andextractiontime(B)versusdryresidueformaceration(a);andtemperature(A)andtime(B)fordecoction(b),andsignificance oftheeffects(*)onParetochart:Maceration(c)Decoction(d);positiveeffects(#);negativeeffects(##).

Table4

Analysisofvariance(regressioncoefficientsandsignificantpvalues)fordryresidue,pH,CGAandCFAresponsesfordecoctionextractionmethod.

Polynomialterm Dryresidue(%) pH CGA(g/ml) CFA(g/ml)

Coefficient pvalue Coefficient pvalue Coefficient pvalue Coefficient pvalue

Model – 0.0046 – 0.0001 – 0.0002 – 0.0044

Intercept +0.85 – 5.79 – +13.91 – +7.44 –

(A)Temperature(◦C) +0.053 0.0020

−0.082 <0.0001 +0.18 <0.0001 +0.15 0.0289

(B)Time(min.) +0.017 0.1340(NS) −0.020 0.0498 +0.077 0.0038 +0.31 0.0017

(AB)Interaction – NS – NS −0.064 0.0081 – NS

Curvature – 0.0031 – 0.0003 – <0.0001 <0.0001

Ethanol concentration (%)

Extraction time (days) Time (min.) Temperature (ºC)

t-Value of

|Effect

|

t-Value of

|Effect

|

6.00

5.94

5.88

5.81

5.75

8

6

4 20

50

80 30

20

10 70

80

90 5.60

5.70 5.80 5.90 6.00

pH

10.10

7.58

5.05

2.53

0.00 AB

B A

5.66

4.24

2.83

1.41

0.00

Bonferroni Limit 3.12755

t-Value Limit 2.36462

t-Value Limit 2.44691 Bonferroni Limit 3.28746 B

AB A

1 2 3

Rank

1 2 3

Rank

pH

a

b

c

d

Fig.2.Graphofethanolconcentration(A)andextractiontime(B)versuspHforMaceration(a)andtemperature(A)andextractiontime(B)fordecoction(b),andsignificance oftheeffects(*)onParetochart:Maceration(c);Decoction(d);positiveeffects(#);negativeeffects(##).

significantcurvaturevaluesforbothextractionmethodsshowthat thisincreaseisnotlinear,abehavioralsoshowninFig.2aandb.

ThepHvaluesappeartoreachasteadystateatahigherethanol

concentrationfortheethanolextractsandatahighertemperature

fortheaqueousextracts.However,althoughtherearestatistical

differences,thesmallvariationbetweenthepHvalues(5.78–5.96)

maynotberelevantfromtechnologicalstandpoint.

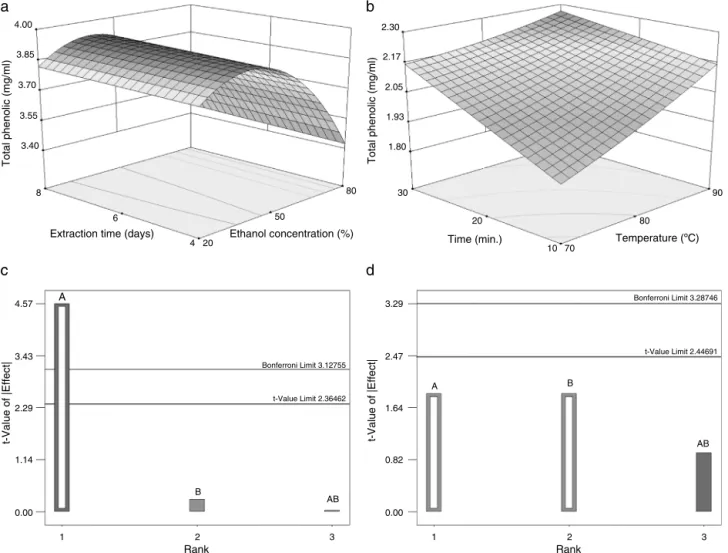

Totalphenoliccontent

Severalresearchershaveinvestigatedtheabilityofsome

phe-noliccompoundspresentinplantmaterialtoactasantioxidants

(Seerametal.,2006;Zhangetal.,2008;Is¸ıketal.,2011).This

activ-itymaybecorrelatedwiththecontentoftheirphenoliccompounds

(Veliogluetal.,1998;Cheungetal.,2003).Determinationoftotal

phenoliccontenthasbeenachievedusingtheFolin–Ciocalteu

pro-cedure(Yuetal.,2002).Thiscolorimetricmethodisbasedonthe

extractionofphenoliccompounds(acidicsolution)afteroxidation

ofthereduced molecules bya mixtureof thetwostrong

inor-ganicoxidantphosphotungsticandphosphomolybdicacids(Is¸ık

etal.,2011).TheFolinmethodhaspoorspecificity,asitcangive

anoverestimatedvaluefortotal phenolcontentinextracts.For

example,betweensomenon-phenolicsubstancesthismethodcan

potentiallyinterfereinthedeterminationoftotal phenolic

con-tentbyincreasingtheabsorbancevalueofthephenoliccompounds

(Stevanatoetal.,2004;Is¸ıketal.,2011).Evenwiththispotential

interference,duetothecomplexityofthesample,thistechnique

iseasyandfasttouse,andisconvenientforroutineuseforquality

controltestsontheplantmaterial.

Totalphenoliccontentwasexpressedasgallicacidequivalents.

Acalibrationcurvewasconstructedwithdifferentconcentrations

ofgallicacidasstandard.Theamountofphenoliccompoundsin

theethanolextractswashigherthanthatoftheaqueousextracts

(Table 1).Thetotal phenoliccontent ofethanol extracts

gradu-allydecreasedwithincreasingethanolconcentration,andwasnot

influencedbyextractiontime(Table3;Fig.3aandc).Thisindicates

thatat4daysofmaceration,asteadystatemayhavealreadybeen

reachedintheextractionofthesecompounds.Thehighertotal

phe-noliccontentintheethanolextractsthanintheaqueousextracts

mightbeexplainedbythedifferentextractorliquid usedinthe

extraction.Inaddition,theextractionmethodmaycontributeto

thedifferenceincontent(Yuetal.,2002).Normally,theefficiency

oftheextractionofpolyphenolicscompoundsislowerusingpure

solutionslikewater,ethanolormethanol.Theyieldoftotal

pheno-liccompoundsextractedfromtheseextractscanbehigherwhen

solventscontainingsomewaterareusedintheextractionprocess

(Katsubeetal.,2009).

AsobservedinFig.3b,theincreasesintemperatureand

extrac-tion time tend to increase the total phenolic concentration in

theaqueousextracts,althoughnostatisticalsignificancehasbeen

observed in the factors evaluated for these extracts (Fig. 3d).

The yield of phenolic compounds may dependsignificantly on

extractiontemperature andtime (Herreraand LuquedeCastro,

4.00

3.85

3.70

3.55

3.40

8

6

4 20

50

80

Ethanol concentration (%) Extraction time (days)

A

2.30

2.17

2.05

1.93

1.80

30

20

10 70

80

90

Time (min.) Temperature (ºC)

Bonferroni Limit 3.28746

t-Value Limit 2.44691

B A

AB

1 2 3

Rank

1 2 3

Rank B

AB

0.00 0.82 1.64 2.47 3.29

t-Value of

|Effect

|

t-Value of

|Effect

|

0.00 1.14 2.29 3.43 4.57

Bonferroni Limit 3.12755

t-Value Limit 2.36462

Total phenolic (mg/ml) Total phenolic (mg/ml)

a

b

c

d

Fig.3. Graphofethanolconcentration(A)andextractiontime(B)versustotalphenolicforMacerationmethod(a)andtemperature(A)andtime(B)fordecoctionmethod (b),andsignificanceoftheeffects(*)onParetochart:Maceration(c);Decoction(d);positiveeffects(#);negativeeffects(##).

integrity, hydrolyze the bonds of bound phenolic compounds

(phenol–proteinorphenol–polysaccharide)andenhancephenolic

solubility.Asaresult,phenoliccompoundswoulddisperseinthe

solvent(Juntachoteetal.,2006;Lietal.,2006;Spignoetal.,2007;

Chanetal.,2009).However,eventhoughincreasedtemperatures

increasethesolubilityofthechlorogenicandcaffeicacids,itshould

betakenintoaccountthathighertemperaturespromote

instabil-ityofthephenoliccompounds(HerreraandLuquedeCastro,2005;

Maetal.,2009).Thismayindicateadegradationofsomephenolic

acids(Maetal.,2009)whichisacrucialinfluenceintheextraction

ofphenolicacidyields.

CGAandCFAcontent

Accordingtotheexperimentaldesign, theextractionof CGA

frommacerationhadasignificantinfluenceonethanol

concentra-tionand time.However,aninteractionbetweenthefactorswas

observed.Significantcurvaturewasalsoobserved,indicatingthere

isnolinearityforthisresponse(Table3;Fig.4aandc).

Ethanolextractscontaining80%ethanolshowedthesame

con-centrationoftheCGAforallextractiontimes(4,6and8days).

Thesedatasuggestthatthesteadystatebetweendrugandsolvent

occurredfromthefourthday.Ontheotherhand,extractsprepared

with20%ethanolpresentedsignificantlylowerlevelsofCGAover

time(Fig.4a).TheCFAcontentinextractscontaining20%ethanol

wasdifferentaccordingtotheextractiontime(Table3;Fig.4band

d).Betweenthefourthandeighthdays,anincreasewasobserved

in theamountof this compound,from 36to 58g/ml,

respec-tively.Inthesameperiod,CGAconcentrationdecreasedfrom130to

75g/ml.ThisdecreaseinCGAcontentwaspreviouslyinvestigated

byourgroup(Arendetal.,2011).Inordertochecktheoccurrence

ofthermalorenzymaticdegradationofCGAduringthemaceration

time,theinfluenceoftemperatureandthepresenceofa

preser-vativeonthecontentofthisacidintheextractivesolutionswere

evaluated.TheseresultsshowedthatCGAconcentrationdoesnot

alterinpresenceof apreservative,suggestingthatthedecrease

inCGAcontentinextractivesolutionsisnotdueto

microbiologi-caldegradationduringtheextractionperiod.Thiseffectmightbe

relatedtoachemicaldegradation,consideringthatchlorogenicacid

isanesterofcaffeicacidandquinicacid(Olthofetal.,2001;Arend

etal.,2011).AhigherCGAconcentrationwasobservedinextracts

containing50%ethanol,followedbywith80%ethanol

(indepen-dentof extractiontime)and 20%ethanol, 4daysand 8daysof

extractiontime,respectively.

CGAextractiononaqueousextractsappearstobeinfluenced

bytimeandtemperatureandaninteractionbetweenthefactors

wasobserved(Table4;Fig.5aandc).MaximumCGAcontentwas

observedat30minandanextractiontemperatureofabout80◦C,

showingnon-linearityinthisresponse(Table4).Thesameoccurs

for the amountof CFA,but inthe opposite direction,with the

smallestamountoccurringataround80◦C(Table4;Fig.5band

d).However,CFAcontentintheaqueousextractswasverylow,

particularlywhencomparedCGAcontentintheseextractive

Ethanol concentration (%)

Extraction time (days) Extraction time (days) Ethanol concentration (%)

CFA (

μ

g/ml)

CGA (

μ

g/ml)

200

165

130

95

60

8

6

80

50

20 4

6

4 20

50

80 8

0 15 30 45 60

66.92

57.36

47.80

38.24

28.68

19.12

9.56

0.00

t-Value of

|Effect

|

AB

B A

237.15

177.86

118.57

59.29

0.00

B A

AB

1 2 3

Rank

1 2 3

Rank

t-Value of

|Effect

|

a

b

c

d

Bonferroni Limit 3.53411

t-Value Limit 2.57058 Bonferroni Limit 3.53411 t-Value Limit 2.57058

Fig.4. Graphofethanolconcentration(A)andextractiontime(B)versusCGA(a)andCFA(b)inthemacerationmethod,andsignificanceoftheeffects(*)onParetochart: CGA(c);CFA(d);positiveeffects(#);negativeeffects(##).

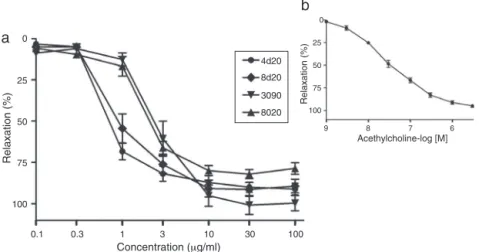

Vascularreactivityinvitrointhoracicrataorta

Infusion of C. glaziovii leaves has been used in traditional

medicineas anantihypertensive, cardiotonicand antiasthmatic

(Rochaetal.,2002).Lima-Landmanetal.(2007)describedan

anti-hypertensiveeffectforaqueousextractandbutanolicfractionofC.

glaziovii,withsatisfactoryresults.Basedontheseresults,thiswork

providesevidenceoftheabilityoftheextractivesolutionsprepared

bymaceration(4d20,8d20)anddecoction(9030and8020)torelax

rataorta,andevaluatethepotencyoftheextractsforthispurpose.

Fig.6showstheconcentration–effectcurvestosamplesinrataortic

ringspre-contractedwithphenylephrine(1M).Cumulative

dos-ingofextractsproducedaconcentration-dependentrelaxationof

aorticrings.TheIC50 valueswiththe95%respectiveconfidence

intervalsfortheextractivesolutionswere:4d20,0.85(0.74–0.96);

8d20,1.48 (1.01–1.89); 9030,2.62 (2.26–2.98);and 8020,2.41

(1.99–2.81)g/ml.AnalyzingtheIC50values,weverifiedthatthe

ethanolextractspresentedmorepotentvasodilatoreffectsthanthe

aqueousextractsinaorticrings.

Antihyperglycemicactivity

AcuteantihyperglycemiceffectofC.glaziovii

Fig.7aandbshowstheeffectofdifferentethanoland

aque-ousextractsfromC.glazioviiontheglucosetolerancecurve.The

extractswereselectedbasedontheconcentrationofthe

chemi-calmarkers,chlorogenicacid(CGA)andcaffeicacid(CFA),inthe

extracts.Oraladministration(400mg/kg)ofethanolextracts4d20

and8d20improvedglucosetolerance,andthiseffectwas

signif-icant at15minfor 4d20extract and at15, 30,60 and 180min

for8d20extractwhencomparedwiththehyperglycemiccontrol

group.Ontheotherhand,theoraltreatmentswith6d50ethanol

extractaswellasthe8020and9030aqueousextractswerenot

abletoreducethebloodglucoselevels.Asexpected,afterstarting

theglucosetolerancetesttheserumglucoseconcentrationwas

sig-nificantlyincreasedwhencomparedwithzerotime.Tolbutamide

(100mg/kg)anoralhypoglycemicagentofsulfonylureaclasswas

usedasapositivecontrolandproducedatypicalserumglucose

lowering at15, 30 and 60mincompared tothe hyperglycemic

group(Fig.1C).

Consideringtheglucosehomeostasis,somespeciesofCecropia

havebeendescribed toimproveglucosemetabolism.The

hypo-glycemiceffectofmethanol leafextractsof C.obtusifoliaandC.

peltatawereevaluatedinhealthymice.Bothextractsproduceda

significanthypoglycemiceffectat2and4hafteroral

administra-tion.However,C.peltatashowedabettereffectthanC.obtusifolia,

which may be correlated to thedifference in chlorogenic acid

content between them (Nicasio et al., 2005). Additionally, an

investigationoftheC.pachystachyamethanolextractconfirmed

ahypoglycemiceffectthat canbeexplainedbythepresenceof

chlorogenicacidand C-glycosylated flavonesas themajor

con-stituents.

Basedontheseresults,thechemicalmarkerswereevaluated

ontheglucosetolerancecurveandtheresultsareshowninFig.8.

ItcanbeobservedthatCGAat15mg/kgwasnotabletoreduce

Temperature (°C) Time (min.)

70 10

Temperature (°C) Time (min.)

80

90

20 30

170 185 200 215

230 9.00

7.75

6.50

5.25

4.00

30

20

10

80

90

70

6.15

4.61

3.07

1.54

0.00

1 2 3

Rank

1 2 3

Rank A B

AB 11.67

10.37

9.08

7.78

6.48

5.19

3.89

2.59

1.30

0.00 A

B

AB

CFA (

μ

g/ml)

CGA (

μ

g/ml)

t-Value of

|Effect

|

t-Value of

|Effect

|

Bonferroni Limit 3.53411

t-Value Limit 2.57058

a

b

c

d

Bonferroni Limit 3.53411

t-Value Limit 2.57058

Fig.5.Graphoftemperature(A)andtime(B)versusCGA(a)andCFA(b)inthedecoctionmethod,andsignificanceoftheeffects(*)onParetochart:CGA(c);CFA(d);positive effects(#);negativeeffects(##).

significanteffectat15and30minafterthetreatment.Also,CFA

atthedose(2mg/kg)showedarapideffectat15mincomparedto

thecontrolgroup.Inordertoevaluateifthesecompoundshave

anadditiveeffecttheywerestudiedtogetherintheoralglucose

tolerancecurve.Atthedoseof2mg/kgCGAandCFAwereableto

significantlyreducetheglycemiaatbetween15minand60min

afteroralgavagetreatment.

Caffeicandchlorogenicacidshavealreadybeendemonstrated

toreducebloodglucoselevelsinhyperglycemicaswellasin

dia-beticratsacting viaseveralmechanismsagainst hyperglycemia

(Meng et al., 2013; Dhungyahet al., 2014).They regulate beta

cellfunctionandincreaseinsulinsecretion,up-regulateadipocytes

GLUT-4 contentand increase glucose uptake in adipocytesand

in muscles. Additionally, CFA and CGA inhibit alpha-amylase

0.1 0.3 1 3 10 30 100

Concentration (μg/ml)

Acethylcholine-log [M]

8 7 6

9 100

75 50 25 0

Relaxation (%)

4d20

8d20

3090

8020

100 75 50 25 0

Relaxation (%)

a

b

60 30

15 180

Time (min) Time (min)

60 30

15 180

50 100 150 200 250

Hyperglycemic control

8020 400 mg/kg

9030 400 mg/kg 4d20 400 mg/kg

8d20 400 mg/kg

6d50 400 mg/kg Hyperglycemic control 250

200

150

100

50

Serum glucose levels (mg/dl) Serum glucose levels (mg/dl)

a

b

Fig.7.Effectofmaceration(A)anddecoction(B)extractsfromCecropiaglazioviiSnethlonglucosetolerancecurve.Valuesareexpressedasmean±S.E.M;n=6induplicate foreachtreatment.Statisticallysignificantdifferencefromthecorrespondinghyperglycemicgroup;*p≤0.05;***p≤0.001).

and alpha-glucosidase activity in the gastrointestinal tract and

increasesglucokinaseactivityinthehepatocytes(Jungetal.,2006;

Touschetal.,2008;Bassolietal.,2008;Karthikesanetal.,2010;Ong etal.,2012,2013;Mengetal.,2013;Dhungyahetal.,2014).

Caf-feicacidandchlorogenicacidalsolowerglucose-6-phosphatase,

glucose-6-translocase and phosphoenolpyruvate carboxykinase

activities,componentsofgluconeogenesis andglycogenolysisin

ratliverresultinginareductionofthehepaticglucoseproduction

(Schwabetal.,2001).ConsideringthatCGAandCFAarethemajor

constituentsofC.glazioviiextracts,itcanbesuggestedthatthe

anti-hyperglycemicandthehypoglycemiceffectobservedhereintoC.

glazioviiextractsandtoCFAandCGAcouldbemediatedthrough

differenttargetsofactioninvolvinghepaticglucoseoutput,glucose

uptakeininsulintargettissues,intestinalglucoseabsorptionand

insulinsecretion.

Basedonthecontent oftheCGA and CFAoneach of theC.

glazioviiextractivesolutionsandbasedontheliterature,itis

sug-gestedthattheantihyperglycemiceffectofthedifferentextracts

mayberelated withthecontent/concentration ofthe chemical

markersandalsototheratiobetweenthem.Thebestresultson

glycemiawereobservedwiththeextractsthatcontainedthe

low-estconcentrationsofCGAandCFA(8d20and4d20)andalsothe

ratiocloseto1:1(Fig.7aandb/Table1).Thisresultisinlinewith

thoseobservedforCGAandCFAontheglucosetolerancecurve,in

Serum glucose levels (mg/dl)

CGA 15 mg/kg Hyperglycemic control

230

170

110

50

30

15 60

Time (min) 180

CGA 2 mg/kg

CFA 2 mg/kg

CGA + CFA 2 mg/kg

Fig.8. Effectofthechemicalmarkerschlorogenicacid(CGA)andcaffeicacid (CFA),andtheassociationonglucosetolerancecurve.Valuesareexpressedas mean±S.E.M;n=6induplicateforeachtreatment.Statisticallysignificant differ-encefromthecorrespondinghyperglycemicgroup;**p≤0.01.

whichthelowestdoseofCGAaswellastheassociationofboth,CGA

andCFApresentedthemostpronouncedeffect(Fig.8)showinga

dose-dependentpatternofactionontheglucosetolerancecurve.

Additionally,inordertocomplementtheglycemicprofile,the

differentextractsofC. glazioviiandthechemical markerswere

studiedinvivo,usinganalloxan-induceddiabeticratmodel(unable

tosecretinsulin).Fig.9showstheeffectofethanolandaqueous

extractsaswellasCGAonglycemiainalloxan-induceddiabetic

rats.Theaqueousextracts,8020and9030,wereabletoreduce

significantlytheglycemia,at1handat2h,respectively,afterthe

oral treatments (400mg/kg),when compared withthe diabetic

controlgroup.Also, itcan beobservedthattheethanol extract

8d20presentedaslightreductioninglycemiaat2hafterthe

treat-ment.Additionally,whenthechemicalmarkers,CGAandCFAwere

evaluated,justthehigherdoseofCGA(15mg/kg)presenteda

sig-nificanteffectonreducingthebloodglucoselevelsat2and3hafter

thetreatment.TheCFA,CGAaswellastheassociationofbothat

2mg/kgwereineffectiveinthisapproach(datanotshown).

Con-trarytothatobservedinhyperglycemicnormalrats,theabsenceof

and/ortheslighteffectoftheethanolextractsinalloxan-induced

diabeticratsmayberelatedtotheinsufficientconcentrationofCGA

andCFAintheextracts,sincewhenthesecompoundswere

eval-uatedonlythehigherdoseofCGAwaseffectiveinthisapproach.

Also,theaqueousextractsthatpresentedahigherconcentration

ofCGAwereeffectiveinthediabeticanimals.Itispossiblethat

toexertitseffectasaninsulinomimeticagentindiabeticrats,C.

glazioviiextracts/compoundsmusthavehigherconcentrationsof

themainconstituents,CGAandCFA.

CGA 15 mg/kg 8020 400 mg/kg 9030 400 mg/kg 8d20 400 mg/kg Diabe tic control

250 300 350 400 450 500

Serum glucose levels (mg/dl)

1 2 3

Time (h)

Fig.9. Effectoftheethanolicandaqueousextractsandthechlorogenicacid(CGA) ontheserumglucoselevelinalloxan-induceddiabeticrats.Valuesareexpressedas mean±S.E.M;n=6induplicateforeachtreatment.Statisticallysignificant differ-encefromthecorrespondingzerotimevalueofeachgroup;*p≤0.05.Statistically

RecentstudieshaveshownthehypoglycemiceffectofCecropia

speciesindiabeticanimalmodels.Aqueousandbutanolextracts

preparedfromC.obtusifoliaandC.peltatawereevaluatedin

strep-tozotocindiabeticratsandtheresultsshowedasignificantdecrease

inserumglucoseat3haftertheoraltreatmentaswellasonthe

oralglucosetolerancecurve.Moreover,itissuggestedthat

chloro-genicacidisinvolvedinthehypoglycemiceffectofC.obtusifolia

and C. peltata because it wasone of the majorconstituents of

theextracts(Andrade-CettoandWiedenfeld,2001;Andrade-Cetto

andVázquez,2010).ThemethanolextractfromtheleavesofC. pachystachyaalsoproduceda significanthypoglycemiceffectin

alloxan-induceddiabeticrats,probablyduetothechlorogenicacid

contentinthisspecies(Aragãoetal.,2010;Karthikesanetal.,2010).

Inconclusion,thisstudyprovidesthefirstreportonthe

antihy-perglycemicactionoftheextractsofC.glazioviileavesimproving

glucosetolerance.Inaddition,thepotentrelaxingeffectofethanol

extractsonthoracicaortawasdemonstrated.Independentofthe

exactmechanismofactioninvolved,theseresultscanprobablybe

associatedwiththeconcentrationsofthephenolicconstituentsof

theextracts.Theresultspresentedheregiveinitialexperimental

supportforfuture experiments,astheylinkthis effecttomore

classesofsecondarycompoundsaswellasevaluationofthe

iso-latedcompoundspresentintheextractivesolutions.

Authors’contributions

DPA(MScstudent)contributedinrunningthelaboratorywork,

chromatographic analysis, analysis of thedata and draftedthe

paper.TCScontributedindraftingthemanuscript.LHCandMAH

contributedtobiologicalstudies.DS,ALGS,RMRVandFRMBS

con-tributedtocriticalreadingofthemanuscript.AMCdesignedthe

study,supervised thelaboratoryworkand contributed to

criti-calreadingofthemanuscript.Alltheauthorshavereadthefinal

manuscriptandapprovedthesubmission.

Conflictsofinterest

Theauthorsdeclarenoconflictsofinterest.

Acknowledgments

The authors thank FAPESC (Grant Number 05798, edict

008/2006),CNPqandÍlioMontanariJr.researcheratCPQBA.

References

Alonso-Castro,A.J.,Miranda-Torres,A.C.,González-Chávez,M.M.,Salazar-Olivo,L.A., 2008.CecropiaobtusifoliaBertolanditsactivecompound,chlorogenicacid, stim-ulate2-NBDglucoseuptakeinbothinsulin-sensitiveandinsulin-resistant3T3 adipocytes.J.Ethnopharmacol.120,458–464.

Andrade-Cetto,A.,Cárdenas,R.,Ramírez-Reyes,B.,2007.Hypoglycemiceffectof CecropiapeltataL.onN5-STZtype2diabeticrats.Pharmacology3,203–210. Andrade-Cetto,A.,Vázquez,R.C.,2010.Gluconeogenesisinhibitionand

phytochem-icalcompositionoftwoCecropiaspecies.J.Ethnopharmacol.130,93–97. Andrade-Cetto,A.,Wiedenfeld,H.,2001.HypoglycemiceffectofCecropiaobtusifolia

onstreptozotocindiabeticrats.J.Ethnopharmacol.78,145–149.

Andriambeloson,E.,Stoclet,J.C.,Andriantsitohaina,R.,1999.Mechanismof endothe-lialnitricoxide-dependentvasorelaxationinducedbywinepolyphenolsinrat thoracicaorta.J.Cardiovasc.Pharm.33,248–254.

Aragão,D.M.O.,Guarize,L.,Lanini,J.,daCosta,J.C.,Garcia,R.M.G.,Scio,E.,2010. HypoglycemiceffectsofCecropiapachystachyainnormalandalloxan-induced diabeticrats.J.Ethnopharmacol.128,629–633.

Arend,D.P.,dosSantos,T.C.,Sonaglio,D.,dosSantos,A.L.G.,Reginatto,F.H.,de Cam-pos,A.M.,2011.Experimentaldesignasatooltoevaluatechlorogenicandcaffeic acidsextractedfromCecropiaglazioviiSneth.J.Pharm.Biomed.Anal.54,58–66. Bassoli,B.K.,Cassolla,P.,Borba-Murad,G.R.,Constantin,J.,Salgueiro-Pagadigorria, C.L.,Bazotte,R.B.,Silva,R.S.S.F.,Souza,H.M.,2008.Chlorogenicacidreducesthe plasmaglucosepeakintheoralglucosetolerancetest:effectsonhepaticglucose releaseandglycaemia.CellBiochem.Funct.26,320–328.

Benthin,B.,Danz,H.,Hamburger,M.,1999.Pressurizedliquidextractionofmedicinal plants.J.Chromatogr.A837,211–219.

2010.Farmacopéia Brasileira,5thed. AgênciaNacionaldeVigilânciaSanitária, Brasília.

Chan,S.W.,Lee,C.Y.,Yap,C.F.,WanAida,W.M.,Ho,C.W.,2009.Optimisationof extractionconditionsforphenoliccompoundsfromlimaupurut(Citrushystrix) peels.IFRJ16,203–213.

Cheung,L.M.,Cheung,P.C.K.,Ooi,V.E.C.,2003.Antioxidantactivityandtotal pheno-licsofediblemushroomextracts.FoodChem.81,249–255.

Delarcina,S.,Lima-Landman,M.T.R.,Souccar,C.,Cysneiros,R.M.,Tanae,M.M.,Lapa, A.J.,2007.Inhibitionofhistamine-inducedbronchospasminguineapigstreated withCecropiaglazioviSnethandcorrelationwiththeinvitroactivityintracheal muscles.Phytomedicine14,328–332.

Dhungyah,B.,Koirala,P.,Sharma,C.,Jha,D.K.,2014.Caffeicacid–apotent phyto-compoundagainstdiabetesmellitusareview.SMUMed.J.1,152–161. Folador,P.,Cazarolli,L.H.,Gazola,A.C.,Reginatto,F.H.,Schenkel,E.P.,Silva,F.R.M.B.,

2010.Potentialinsulinsecretagogueeffectsofisovitexinandswertisin iso-latedfromWilbrandiaebracteata rootsinnon-diabeticrats.Fitoterapia81, 1180–1187.

Genta,S.B., Cabrera,W.M.,Mercado,M.I., Grau,A.,Catalán,C.A.,Sánchez,S.S., 2010.HypoglycemicactivityofleaforganicextractsfromSmallanthus sonchi-folius:constituentsof themostactive fractions.Chem.Biol.Interact. 185, 143–152.

Herrera,M.C.,LuquedeCastro,M.D.,2005.Ultrasound-assistedextractionof phe-noliccompoundsfromstrawberriespriortoliquidchromatographicseparation andphotodiodearrayultravioletdetection.J.Chromatogr.A1100,1–7. Hsu,F.-L.,Chen,Y.-C.,Cheng,J.-T.,2000.Caffeicacidasactiveprinciplefromthefruit

ofXanthiumstrumariumtolowerplasmaglucoseindiabeticrats.PlantaMed. 66,228–230.

Is¸ık,E.,S¸ahin,S.,Demir,C.,Türkben,C.,2011.Determinationoftotalphenoliccontent ofraspberryandblackberrycultivarsbyimmobilizedhorseradishperoxidase bioreactor.J.FoodCompos.Anal.24,944–949.

Jacques,R.A.,dosSantosFreitas,L.,Pérez,V.F.,Dariva,C.,deOliveira,A.P.,deOliveira, J.V.,Caramão,E.B.,2007.TheuseofultrasoundintheextractionofIlex paraguar-iensisleaves:acomparisonwithmaceration.Ultrason.Sonochem.14,6–12. Jain,S.C.,Pancholi,B.,Singh,R.,Jain,R.,2010.Pharmacognosticalstudiesofimportant

aridzoneplants.Rev.Bras.Farmacogn.20,659–665.

Jung,U.J.,Lee,M.-K.,Park,Y.B.,Jeon,S.-M.,Choi,M.-S.,2006.Antihyperglycemicand antioxidantpropertiesofcaffeicacidindb/dbmice.J.Pharmacol.Exp.Ther.318, 476–483.

Juntachote,T., Berghofer, E., Bauer, F.,Siebenhandl, S., 2006. Theapplication ofresponsesurfacemethodologytotheproductionofphenolicextractsof lemongrassgalangal,holybasilandrosemary.Int.J.FoodSci.Technol.41, 121–133.

Karthikesan,K.,Pari,L.,Menon,V.P.,2010.Combinedtreatmentof tetrahydrocur-cumin and chlorogenic acid exerts potential antihyperglycemic effect on streptozotocin–nicotinamide-induceddiabeticrats.Gen.Physiol.Biophys.29, 23–30.

Katsube,T.,Tsurunaga,Y.,Sugiyama,M.,Furuno,T.,Yamasaki,Y.,2009.Effectof air-dryingtemperatureonantioxidantcapacityandstabilityofpolyphenolic compoundsinmulberry(MorusalbaL.)leaves.FoodChem.113,964–969. Kolb,N.,1999. Microbiologicalstatus ofuntreatedHerbalmaterials.Deutsche

Lebensmittel-Rundschau95,263–269.

Kosalec,I.,Cvek,J.,Tomi´c,S.,2009.ContaminantsofMedicinalHerbsandHerbal Products.ArhHigRadaToksikol,pp.485.

Li,B.B.,Smith,B.,Hossain,M.M.,2006.Extractionofphenolicsfromcitruspeels:II. Enzyme-assistedextractionmethod.Sep.Purif.Technol.48,189–196. Lima-Landman,M.T.R.,Borges,A.C.R.,Cysneiros,R.M.,DeLima,T.C.M.,Souccar,C.,

Lapa,A.J.,2007.Antihypertensiveeffectofastandardizedaqueousextractof CecropiaglazioviiSnethinrats:aninvivoapproachtothehypotensive mecha-nism.Phytomedicine14,314–320.

Ma,Y.-Q.,Chen,J.-C.,Liu,D.-H.,Ye,X.-Q.,2009.Simultaneousextractionofphenolic compoundsofcitruspeelextracts:effectofultrasound.Ultrason.Sonochem.16, 57–62.

Meng,S.,Cao,J.,Feng,Q.,Peng,J.,Hu,Y.,2013.Rolesofchlorogenicacidonregulating glucoseandlipidsmetabolism:areview.Evid.BasedComplement.Altern.Med. 2013,1–11.

Montgomery,D.C.,2005.DesignandAnalysisofExperiments,6aed,NewJersey.

Nicasio,P.,Aguilar-Santamaría,L.,Aranda,E.,Ortiz,S.,González,M.,2005. Hypo-glycemiceffectandchlorogenicacidcontentintwoCecropiaspecies.Phytother. Res.19,661–664.

Ninahuaman,M.F.M.L.,Souccar,C.,Lapa,A.J.,Lima-Landman,M.T.R.,2007.ACE activityduringthehypotensionproducedbystandardizedaqueousextractof CecropiaglazioviiSneth:acomparativestudytocaptoprileffectsinrats. Phy-tomedicine14,321–327.

Olthof,M.R.,Hollman,P.C.H.,Katan,M.B.,2001.Chlorogenicacidandcaffeicacidare absorbedinhumans.J.Nutr.131,66–71.

Ong,E.S.,2004.Extractionmethodsandchemicalstandardizationofbotanicalsand herbalpreparations.J.Chromatogr.B812,23–33.

Ong,K.W.,Hsu,A.,Tan,B.K.H.,2012.Chlorogenicacidstimulatesglucosetransport inskeletalmuscleviaAMPKactivation:acontributortothebeneficialeffectsof coffeeondiabetes.PLoSONE7,e32718.

Ong,K.W.,Hsu,A.,Tan,B.K.H.,2013.Anti-diabeticandanti-lipidemiceffectsof chlorogenicacidaremediatedbyAMPKactivation.Biochem.Pharmacol.85, 1341–1351.

Rocha,F.F., Lapa,A.J.,De Lima,T.C.M., 2002.Evaluationof theanxiolytic-like effectsofCecropiaglaziouiSneth inmice.Pharmacol. Biochem.Behav.71, 183–190.

Rocha,F.F.,Lima-Landman,M.T.R.,Souccar,C.,Tanae,M.M.,DeLima,T.C.M.,Lapa, A.J.,2007.Antidepressant-likeeffectofCecropiaglaziouiSnethandits con-stituents–invivoandinvitrocharacterizationoftheunderlyingmechanism. Phytomedicine14,396–402.

RodriguezdeSotillo,D.V.,Hadley, M.,2002. Chlorogenicacidmodifiesplasma andliverconcentrationsof:cholesterol,triacylglycerol,andmineralsin(fa/fa) Zuckerrats.J.Nutr.Biochem.13,717–726.

Schwab,D.,Herling,A.W.,Hemmerle,H., Schubert,G.,Hagenbuch,B.,Burger, H.-J., 2001. Hepatic uptake of synthetic chlorogenic acid derivatives by the organic anion transport proteins. J. Pharmacol. Exp. Ther. 296, 91–98.

Seeram,N.P.,Lee,R.,Scheuller,H.S.,Heber,D.,2006.Identificationofphenolic com-poundsinstrawberriesbyliquidchromatographyelectrosprayionizationmass spectroscopy.FoodChem.97,1–11.

Silva,I.T.,Costa,G.M.,Stoco,P.H.,Schenkel,E.P.,Reginatto,F.H.,Simões,C.M.O.,2010. InvitroantiherpeseffectsofaC-glycosylflavonoid-enrichedfractionofCecropia glazioviiSneth.Lett.Appl.Microbiol.51,143–148.

Souccar,C.,Cysneiros,R.M.,Tanae,M.M.,Torres,L.M.B.,Lima-Landman,M.T.R., Lapa,A.J.,2008.Inhibitionofgastricacidsecretionbyastandardizedaqueous extractofCecropiaglazioviiSnethandunderlyingmechanism.Phytomedicine 15,462–469.

Spigno,G.,Tramelli,L.,DeFaveri,D.M.,2007.Effectsofextractiontime,temperature andsolventonconcentrationandantioxidantactivityofgrapemarcphenolics. J.FoodEng.81,200–208.

Stevanato,R.,Fabris,S.,Momo,F.,2004.Newenzymaticmethodforthe deter-minationoftotalphenoliccontentinteaandwine.J.Agric.FoodChem.52, 6287–6293.

Tousch,D.,Lajoix,A.D.,Hosy,E.,Azay-Milhau,J.,Ferrare,K.,Jahannault,C.,Cros,G., Petit,P.,2008.Chicoricacidanewcompoundabletoenhanceinsulinrelease andglucoseuptake.Biochem.Biophys.Res.Commun.377,131–135. Varley,H.,Gowenlock,A.H.,Bell,M.,1976.PracticalBiochemistry,London. Velioglu,Y.S.,Mazza,G.,Gao,L.,Oomah,B.D.,1998.Antioxidantactivityandtotal

phenolicsinselectedfruits,vegetables,andgrainproducts.J.Agric.FoodChem. 46,4113–4117.

Vila-Jato,J.L.,1997.TecnologiaFarmacéutica.Aspectosfundamentalesdelos sis-temasfarmacêuticosyoperacionesbásicas.Madrid,EditorialSintesis. WHO,1998.Qualitycontrolmethodsformedicinalplantmaterials.In:WorldHealth

Organization(Ed.),WHOLibraryCataloguing-in-PublicationData.

Wolfgang,K.,Erich,C.,Brigitte,K.,2002.Microbialcontaminationofmedicinal plants.Areview.PlantaMed.68,5–15.

Yu,L.,Haley,S.,Perret,J.,Harris,M.,Wilson,J.,Qian,M.,2002.Freeradicalscavenging propertiesofwheatextracts.J.Agric.FoodChem.FoodChem.50,1619–1624. Zhang,Y.,Seeram,N.P.,Lee,R.,Feng,L.,Heber,D.,2008.Isolationandidentificationof