Braz. J. of Develop., Curitiba, v. 5, n. 12, p.33083-33100 dec 2019 . ISSN 2525-8761

Influence on rheological behavior of montar with addition of fly ash from

bayer process fluidized bed boilers and construction/

Influencia no comportamento reologico de materiais cimenticios com

adicao de cinza volante de caldeiras de leito fluidizados advindas do

processo bayer e residuos de construcao e demolicao

DOI:10.34117/bjdv5n12-362

Recebimento dos originais: 10/11/2019 Aceitação para publicação: 27/12/2019

Dilson Nazareno Pereira Cardoso

Doutor em Engenharia de Recursos Naturais da Amazônia - PRODERNA Instituição: Universidade Federal do Pará - UFPA

Endereço: 66075-110, Belém, PA, Brasil. E-mail: dnpcardoso@gmail.com

Clesianu Rodrigues de Lima

Mestre em Ciência dos Materiais pelo Instituto Militar de Engenharia - IME Instituição: Universidade Federal do Oeste do Pará - UNIFESSPA

Endereço: 68507-590, Marabá, PA, Brasil. E-mail: clesianu@unifesspa.edu.br

Breno de Abreu Elias Graduado em Engenharia Química

Instituição: Universidade Federal do Pará - UFPA Endereço: 66075-110, Belém, PA, Brasil.

E-mail: brenoelias16@gmail.com

Lêda de Azevedo Racanelli Mestre em Engenharia de Processos

Instituição: Universidade Federal do Pará - UFPA Endereço: 66075-110, Belém, PA, Brasil.

E-mail: lbsracanelli@hotmail.com

Alcebiades Negrão Macêdo Doutor em em Engenharia de Estruturas.

Instituição: Escola de Engenharia de São Carlos Universidade de São Paulo, EESC-USP, Brasil.

Endereço: 66075-110, Belém, PA, Brasil. E-mail: anmacedo@ufpa.br

Braz. J. of Develop., Curitiba, v. 5, n. 12, p.33083-33100 dec 2019 . ISSN 2525-8761

José Antônio Da Silva Souza

Doutor em Engenharia de Recursos Naturais da Amazônia - PRODERNA Instituição: Universidade Federal do Pará - UFPA

Endereço: 66075-110, Belém, PA, Brasil. E-mail: jass@ufpa.br

Augusta Maria Paulain Ferreira Felipe Doutora em Engenharia Mecânica

Instituição: Universidade Estadual de Campinas, UNICAMP, Brasil. Endereço: 66075-110, Belém, PA, Brasil.

E-mail: ampf@ufpa.br ABSTRACT

Fly ash obtained from coal combustion in fluidized bed boilers has been used in civil construction to partially replace Portland cement, due to its pozzolanic activities, and thus minimizing the accumulation of industrial waste. The rheological characteristics of six composition of mortars were studied on six differents proportions of cement, construction waste generation (CWG) and fly ash (FA). For the rheological tests, a coaxial cylinder viscometer was used, varying the shear rate from 0 to 600 s-1 at 28 ºC, [1] in the interval time of 120s (in 120s time interval). Granulometric analysis, X-ray diffraction (XRD), X-ray fluorescence (XRF) and scanning electron microscope (SEM) tests were performed. The results showed that fly ash incorporation is the main factor for changing behavior from rheopecthic to thixotropic, in the avaluated traces. The experimental data was well fitted in Herschel-Bulkley rheological model.

Keywords: Mortars, pozzolanic activity, rheology, apparent viscosity

RESUMO

As cinzas volantes obtidas da combustão do carvão em caldeiras de leito fluidizado têm sido utilizadas na construção civil para substituir parcialmente o cimento Portland, devido às suas atividades pozolânicas, minimizando o acúmulo de resíduos industriais. As características reológicas de seis composições de argamassas foram estudadas em seis proporções diferentes de cimento, geração de resíduos de construção (CWG) e cinzas volantes (FA). Para os testes reológicos, foi utilizado um viscosímetro de cilindro coaxial, variando a taxa de cisalhamento de 0 a 600 s-1 a 28 ºC, [1] no intervalo de 120s (no intervalo de 120s). Foram realizadas análises granulométricas, difração de raios X (DRX), fluorescência de raios X (XRF) e microscopia eletrônica de varredura (MEV). Os resultados mostraram que a incorporação de cinzas volantes é o principal fator para mudar o comportamento de reopético para tixotrópico, nos traços avaliados. Os dados experimentais foram bem ajustados no modelo reológico de Herschel-Bulkley.

Braz. J. of Develop., Curitiba, v. 5, n. 12, p.33083-33100 dec 2019 . ISSN 2525-8761 1 INTRODUCTION

Solid waste has been studied and researched to be incorporated into the civil construction industry due to its high potential for solving environmental problems such as residual accumulation. Furthermore, it can be used to reduce the final cost of production with fly ash (FA) incorporation, reusing the civil waste generation (CWG) [1].

The industries have tried to improve the durability of their products, thus, in the Portland cement materials; this substitution is done partially replacing the Portland clinker by mineral addition. These additions results in significant modifications, changing the characteristics of the fresh and hardened State, as well as its microstructure [2].

The use of FA can modify the cement paste composition, influencing on hydration, decreasing the permeability and increasing its resistance [3]. The mortars have plastic and adhesive characteristics in fresh state, and become rigid and resistant after certain time period. These facts determine its main use in civil construction [4].

The study of mortars rheological properties in fluid state is crucial, both in its application and process [5]. Several factors influence on mortars rheology. Among these factors, the mixtures characteristic (water content, type of aggregate, cement and additives) and experimental conditions, which the mixtures were made, can be emphasized. The size and geometry of particles that constitute the product can influence the agglomeration factor, actin on Bulk density of mixture, facilitating or hindering the stream, since the amount of water is designed to promote hydration reactions and facilitating the connections of the cement particles and aggregates [6,7]. This study aims to evaluate the rheology of mixture in fresh state by the application of rotational rheometry, and understand the insertion of these materials in its, which influences afterwards its hardened State characteristics.

2 MATERIALS AND METHODS 2.1 MATERIALS

2.1.1 Fly Ash (Fa)

The FA was obtained from Hydro, located in Barcarena - Pará. It was produced on boilers of circulating fluidized bed by mineral coal combustion, as long as limestone was injected on boiler to material desulfurization during mineral coal combustion (since Limestone is injected into the boiler in burning coal for material desulfurization).

Braz. J. of Develop., Curitiba, v. 5, n. 12, p.33083-33100 dec 2019 . ISSN 2525-8761 FA samples were dried at 100ºC for 24h and milled for 5min in a ball mil (CIMAQ Model Work Index serie: 005) to turn the material in homogeneous mixture that increases reactivity with calcium hydroxide in cement hydration.

2.1.2 Construction waste generation (CWG)

The CWG was collected in UFPA on Chemistry engineer laboratory reform. The collected material was separated from undesired residues by separation process. The specified material (masonry, plaster and non-structural concrete) was submitted to primary and secondary crushing to adjust the raw material to ABNT NBR 7217. For this step was used the CIMAQ Work Index ball mill and the MARCONI MA700 serie (100690037) disc mill

2.1.3 Portland Cement

Portland Cement classified as CP II – E 32, due to it not higher pozzolanic. The four analyzed samples were prepared in a mechanic mixer SOLDTEST for 5 minutes to complete the material homogenization for rheological analysis.

In traces analysis, 35% H2O refers to the total value of 100% mixture (CWG, cement and FA)

and the other 65% refers to solid content in the mixture, see Table 1.

Table 1 Mix proportion.

MATRIX ANALYSIS Formulas WCR (%) Cement (%) FA (%) Water (%) Tr 1 85 5 10 35 Tr 2 80 5 15 35 Tr 3 75 5 20 35 Tr 4 70 5 25 35 2.2 METHODS 2.2.1 Granulometric analysis

The grain size analysis was proceeded in a laser particle sizer analysette 22 Fritsch with software MaScontrol to acquire experimental data.

2.2.2 Mineralogic characterization

FA and CWG were characterized by x-ray fluorescence spectrometry and x-ray diffraction (Axios Minerals PANalytical).

Braz. J. of Develop., Curitiba, v. 5, n. 12, p.33083-33100 dec 2019 . ISSN 2525-8761 The sample was analyzed by two prepare modes:

I) Fused disc: 1 g of sample + 6 g of flux (lithium tetraborate - Li 2 B 4 O 7), melt blend at 1000 ° C for 10 min.

II) Pressed tablet: 3.0 g of sample + 0.9 g of binder (paraffin wax), pressed mixture with a load of 20 tonnes.

Software Super Q Manager - PANalytical was used in data treatment.

X-Ray diffraction analysis (DRX) proceed in X-Ray diffractometer model X´Pert Pro MPD (PW 3040/60) PANalytical, with goniometer PW3050 / 60 (θ-θ) and X-ray tube (Kα1 = 1.540598 Å) model PW3373 / 00, long fine focus, Kβ Ni filter, X'Celerator RTMS (Real Time Multiple Scanning) detector in the scanning mode and with activelength 2,122º. The following instrumental conditions were used: scanning 4 ° to 75 ° 2θ, 40 kV, 30 mA, step 0.02 ° in 2θ and time / step of 20 s, fixed slot 1/4 ° and anti-spreading 1/2 °, mask 10 mm, spinning sample movement, with 1 rps.

2.2.3 Microstructural characterization

FA microstructural characterization was proceeded by scanning electron microcopy (SEM) using HITACHI, model TM 3000, Brazil.

2.2.4 Samples preparation

For the preparation of traces, the dosage ratios of materials were described in Table I. A binder water ratio (a / g) of 0.35, adapted experimentally according to the working time, was determined by the curing effects of the material, obeying the limitations of the viscometer test. For the complete homogenization of the mixtures a mechanical mixer of the mark SOLDTEST with capacity of 130 liters was used. After preparation, the mixtures stand for 15 minutes to minimize the effects of homogenization, which causes air bubbles to become interfering with the rheological analysis, followed by rheological analysis, as shown in Fig.1 below.

Braz. J. of Develop., Curitiba, v. 5, n. 12, p.33083-33100 dec 2019 . ISSN 2525-8761

Fig.1. Process flow diagram.

2.2.5 Rheological analysis

In hardening curves analysis, a controlled ramp (CR) methodology was used, which a shear rate of 53.4 s-1 was programmed in the software of the viscometer (Reowin 2.94) in a total time of 1 h and 45 min at 15 min intervals for the torque curve versus time curve.

The apparent viscosity measurements were determined in Haake VT 550 Model Viscometer coupled to the configuration system of SV coaxial cylinders and SV1 cylinders at 28 ° C in order to obtain the hardening curves and the flow curves versus the shear rate measurements between 0 and 600 s-1 in 120 s, the shear rate (γ) becomes constant at 600 s-1 for 30s and then it ramps down from 600 to 0 s-1 in 120 s.

Cement (CP II – E32) Fly Ash (FA) Construction Waste (CCW)

Comminuted (Crushing and Grind)

Sieving Characterization CCW < 138µm Mortar Preparation Beater Tr (1, 2, 3 and 4) Water 15 min Rheological Test

Braz. J. of Develop., Curitiba, v. 5, n. 12, p.33083-33100 dec 2019 . ISSN 2525-8761 3 RESULTS AND DISCUSSION

3.1 Granulometric analysis of materials

Cement CP II – E 32, fly ash and CWG exhibited 17,13 μm, 25,50 μm and 50,25 μm average diameter (d50), respectively, as shown in Fig. 2.

Fig.2. Granulometric analysis.

3.2 CWG X-RAY FLUORESCENCE SPECTROPHOTOMETRY

CWG composition was analyzed by XRF. In the major, 77.08% silicon oxides (SiO2)

were detected, due to concrete and plaster residue origin, that was made based on cement, coarse aggregate, and sand. CaO, Al2O3, Fe2O3, MgO, TiO, K2O were identified at low

Braz. J. of Develop., Curitiba, v. 5, n. 12, p.33083-33100 dec 2019 . ISSN 2525-8761

Table 2 X-ray fluorescence of CWG.

Construction waste generation (CWG) Component Conc. (%) SiO2 77,08 CaO 9,21 Al2O3 2,46 Fe2O3 1,18 MgO 0,96 TiO 0,49 K2O 0,12 Fire loss 7,53 3.3 CWG X-RAY DIFFRACTION

The mineralogic composition of WG was studied by X-ray diffractometer, presented in Fig.3 Quartz (SiO2) major peak matched XRF analysis silicon high prevalence as well as

Calcite (CaCO3) and Albite (NaAlSi3O8) peaks.

Fig.3. X-ray diffraction of CWG. Q Q C Q A Q Q C A Q 1900ral 1913ral 1927ral 1941ral 1954ral 1968ral 1982ral 1995ral 10 20 30 40 50 60 70 80 In te n sit y (CP S ) 2θ (grau) Q - Quartz (SiO2) C - Calcite (CaCO3) A - Albite (NaAlSi3O8)

Braz. J. of Develop., Curitiba, v. 5, n. 12, p.33083-33100 dec 2019 . ISSN 2525-8761 3.4 FLY ASH MICROSTRUCTURAL CHARACTERIZATION

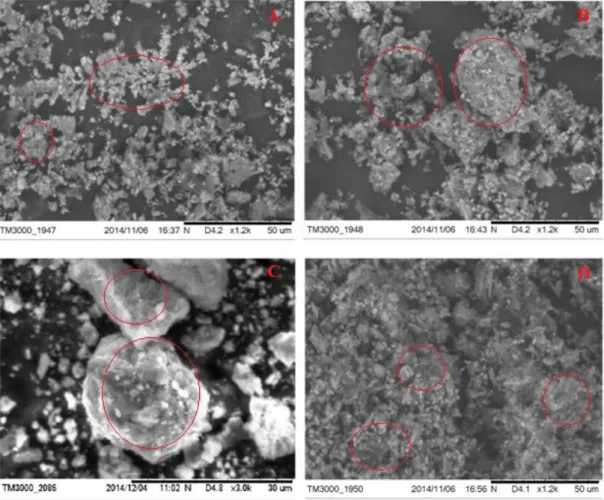

Scanning electron microscopy exhibited, at Fig.4. FA pseudo-spheric form (A and C) and particles cluster formation (B and D), due to fly ash fine grain size that can reduce cement mass workability in fresh state.

Fig. 4. SEM analysis of the samples FA, which were used in the analysis.

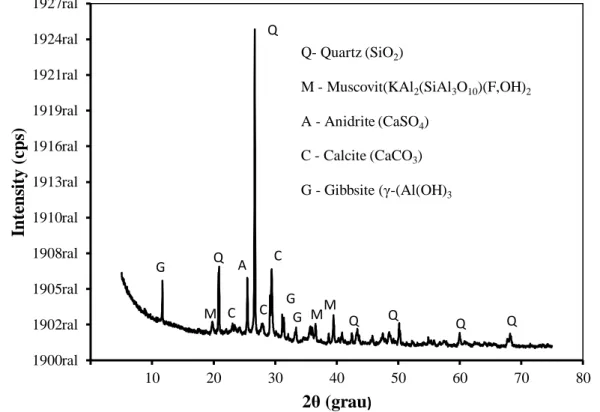

3.5 FLY ASH X-RAY DIFFRACTION

FA XRD analysis, at Fig.5.exposed Quartz (SiO2), Muscovite

(KAl2(SiAl3O10)(F,OH)2, Anhydrite (CaSO4), Calcite (CaCO3) e Gibbsite (γ-(Al(OH)3

mineralogic phase presence. Previous studies showed Quartz (SiO2), Muscovite

(KAl2(SiAl3O10)(F,OH)2, Anhydrite (CaSO4) and Gibbsite (γ-(Al(OH)3 presence in

Braz. J. of Develop., Curitiba, v. 5, n. 12, p.33083-33100 dec 2019 . ISSN 2525-8761

Fig. 5. X-ray diffraction of the FA

3.6 FA X-RAY FLUORESCENCE SPECTROPHOTOMETRY

XRF analysis, Table 3, demonstrated Al2O3 (10,49%), CaO (10,22%) and silicon

oxides (SiO2)(38,72%) fly ash composition that matches burning mineral coal ash constituents

[10]. The results qualify fly ash as a pozzolanic material [11].

Table 3 Chemical analysis of fly ash (FA).

COMPONENT CONCENTRATION (%) Al2O3 10,49 CaO 10,22 Cr2O3 0,011 Fe2O3 3,23 K2O 1,12 MgO 1,63 MnO 0,04 Na2O 0,58 SiO2 38,72 TiO2 0,51 P2O5 0,11 Tot/C 16,21 Fire Loss 16,15 G M Q C A Q C C G G MM Q Q Q Q 1900ral 1902ral 1905ral 1908ral 1910ral 1913ral 1916ral 1919ral 1921ral 1924ral 1927ral 10 20 30 40 50 60 70 80 In te n sit y (c p s) 2θ (grau) Q- Quartz (SiO2)

M - Muscovit(KAl2(SiAl3O10)(F,OH)2

A - Anidrite (CaSO4)

C - Calcite (CaCO3)

Braz. J. of Develop., Curitiba, v. 5, n. 12, p.33083-33100 dec 2019 . ISSN 2525-8761 3.7 RHEOLOGICAL ANALYSIS RESULTS

The Fig. 6. showed an increase on torque during the time of experiment, due to cement hydration that reduces free water content in mixture fluidization. However, increasing FA amount in the mixture, more significant was the behavior exhibited on the graph, that could be a luting activity result of FA pozzolanic characteristic. Another explanation is the filler physical effect, that is characteristic of high fines mixtures, resulting in a higher water absorption by the system that enhances particles intern friction, reduces plasticity and increases its consistency. That effect consequence is the workability decrease [12,13].

Fig.6. Hardening curves of the mortars studied.

The Fig.7. demonstrated the fluids behavior of non-newtonians time dependent. Studies indicated that suspended particles system, depending on incorporated material composition, has non-newtonians time dependent characteristic that can present rheopecthic or thixotropic behavior, providing apparent viscosity decreases due to rate enhancement [14,15]. Rheological curves traces 1, 2 and 3 on Fig. 7 showed less apparent viscosity numbers than trace 4, due to CWG and FA contribution on an association that provided a gradual increase on its packing densities by CWG and FA fine particles reaction with water that generated cohesive interplanar forces, increasing flocculation tendency and shear rates [16].

Braz. J. of Develop., Curitiba, v. 5, n. 12, p.33083-33100 dec 2019 . ISSN 2525-8761

Fig.7. Flow curve (voltage versus trace) and (apparent viscosity versus rate) for each trace.

Trace 1 (rheopecthic), on Fig.8, showed a gradual change compared with traces 2, 3, and 4 (thixotropic). That could be attributed to trace 1 composition, constituted of thin particles and CWG inert which shows less pozzolonic activity than cement without FA. Rheopetic behavior was attribuited to an agglomerate formation due to attraction between the thin particles in the misture that increased the apparent viscosity of suspension [17]. Although, even the trace 4 showing thixotropic characteristics, were observed an increase in hysteresis area that rises the necessary energy to deflocculation and it uses in cement turn in a bad parameter to workability and settlement-coating application.

Braz. J. of Develop., Curitiba, v. 5, n. 12, p.33083-33100 dec 2019 . ISSN 2525-8761

Fig.8. Rheological Hysteresis of traces from 1 to 4 compared with the traces (1 and 2), (2 and 3) and (3 and 4).

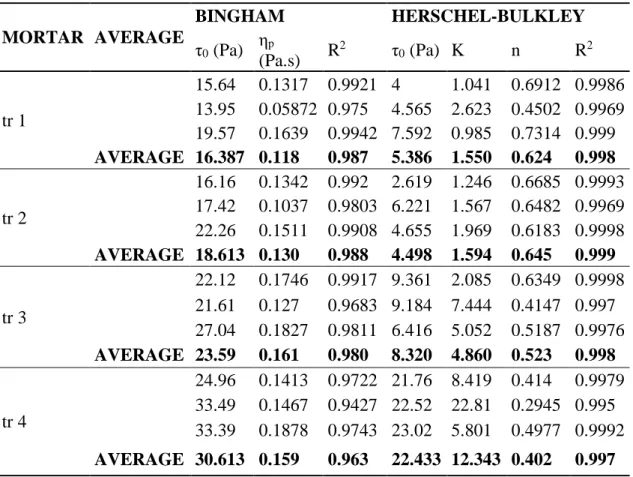

The Table 4 presents proposed Bingham and Herschel-Bulkley rheological models adjustments to traces 1 to 4 experimental results. The traces 2, 3 and 4 results, which FA composition is higher, showed better correlation R² with Herschel-Bulkley rheological model. Studies generally use Bingham and Herschel-Bulkley models to evaluate the rheological behavior of cementitious pastes. In Bigham model, the rheological behavior can be characterized by two parameters: flow limit tension τ0 and apparent viscosity (η).

Herschel-Bulkley expression is also flow limit tension τ0 dependent due to parameters that relate

consistence indices (k) and fluid behavior indices (n), involving properties that can considerate mixture components reaction effects (chemical reactions, kneading water contents, etc.) [6,18], and presenting better correlation R² terms that made Herschel-Bulkley more significant on analyzed pastes.

Braz. J. of Develop., Curitiba, v. 5, n. 12, p.33083-33100 dec 2019 . ISSN 2525-8761

Table 4 Rheological models of Bingham and Herschel-Bulkley for traces 1-4 of mortars.

MORTAR AVERAGE BINGHAM HERSCHEL-BULKLEY τ0 (Pa) ηp (Pa.s) R 2 τ 0 (Pa) K n R2 tr 1 15.64 0.1317 0.9921 4 1.041 0.6912 0.9986 13.95 0.05872 0.975 4.565 2.623 0.4502 0.9969 19.57 0.1639 0.9942 7.592 0.985 0.7314 0.999 AVERAGE 16.387 0.118 0.987 5.386 1.550 0.624 0.998 tr 2 16.16 0.1342 0.992 2.619 1.246 0.6685 0.9993 17.42 0.1037 0.9803 6.221 1.567 0.6482 0.9969 22.26 0.1511 0.9908 4.655 1.969 0.6183 0.9998 AVERAGE 18.613 0.130 0.988 4.498 1.594 0.645 0.999 tr 3 22.12 0.1746 0.9917 9.361 2.085 0.6349 0.9998 21.61 0.127 0.9683 9.184 7.444 0.4147 0.997 27.04 0.1827 0.9811 6.416 5.052 0.5187 0.9976 AVERAGE 23.59 0.161 0.980 8.320 4.860 0.523 0.998 tr 4 24.96 0.1413 0.9722 21.76 8.419 0.414 0.9979 33.49 0.1467 0.9427 22.52 22.81 0.2945 0.995 33.39 0.1878 0.9743 23.02 5.801 0.4977 0.9992 AVERAGE 30.613 0.159 0.963 22.433 12.343 0.402 0.997 4 CONCLUSIONS

In the analyzes of the torque vs. time curves, as expected, a significant increase of the torque with the passage of time occurred, verified in traces 1 and 2, due to the mixture initially presenting less amount of free water in its fluidification. However, it was observed that for the mixture with higher FA increase as in traces 3 and 4, this increase was higher because FA gave it a higher cementing characteristic with higher and more accelerated water absorption in the mixture, increasing the torque value.

In the rheological flow curves traces 1, 2 and 3 have lower values of apparent viscosity in relation to trace 4 with higher FA content, which together with the fines coming from the CWG, cause a greater tendency to flocculation thus raising the shear stress according to the increase of the shear rate.

In the graphs of hysteresis curves the best expected effect occurred only for traces 2 and 3 with thixotropic characteristics in which their hysteresis areas were decreased as a function of the FA insertion in conjunction with the CWG, the same was not observed in trace 4, because even presenting a thixotropic characteristic, it did not present the same effect of

Braz. J. of Develop., Curitiba, v. 5, n. 12, p.33083-33100 dec 2019 . ISSN 2525-8761 decreasing the area verified in the previous traces requiring greater energy in its deflocculation, becoming less viable in terms of workability.

The Bingham model presented correlations that may be considered satisfactory for all analyzed traces, but the results show that, the experimental data were better fitted to the Herschel-Bulkley model, in terms of correlations R2 and for presenting expressions that relate the consistency index (k) and the fluid behavior index (n), which are dependent on the chemical and physical properties of the mixture as (chemical reactions, water content, granulometry, etc.), making this model the most significant.

ACKNOWLEDGEMENTS

The authors are thankful to PRODERNA/UFPA and Institute of Geosciences for Mineralogic characterization for analyzes of materials in study.

REFERENCES

A. J. Curtius, H. D. Fiedler, Analysis of metals and analytical quality. Environment and coal: exploration and use impacts. Porto Alegre: FEPAM, 2002. p. 211-227 [in Portuguese].

C.E. Pozzobon, Technological applications for coal ash produced at the Jorge Lacerda thermoelectric complex. 1999, 113p. Dissertation (master degree in civil engineering) - Post-graduation program in civil engineering, Federal University of Santa Catarina, Florianópolis [in Portuguese].

J. P. Scandolara, Properties of mortars obtained by the partial replacement of Portland cement with particulate brick tailings. 2010. Dissertation (Master in Science and Materials Engineering) - Federal University of Santa Catarina, Center of Technological Sciences - CCT, Joinville [in Portuguese].

C. S Poon, Y.L.Wong e L. Lam, The influence of different curing conditions on the pore structure and related properties of fly-ash cement pastes and mortars. Construction and building, v. 11. Great Britain, p. 383-393, 1997.

Braz. J. of Develop., Curitiba, v. 5, n. 12, p.33083-33100 dec 2019 . ISSN 2525-8761 J.J.Beaudoin, Handbook of analytical techniques in concrete science and technology, New York, Noyes / William Andrew V.S. Ramachandran, 2001.

L. Senff, D. Hotza, W.L. Repette, Rhelogycal behaviour of cement pastes with addition of silica fume, nanosilica and polycarboxilic dispersant Revista Matéria, v. 15, nº 1, p. 012 – 020, 2010.

A. L. G. Gastaldini e G. C. Isaia, Chloride permeability of high performance concrete with mineral addition: binary and ternary mixtures. INTERNATIONAL CONFERENCE ON HIGH PERFORMANCE CONCRETE, 2. Gramado, Brasil, Proceedings, 1999. 1 CD-ROM.

Brazilian Association of Technical Standards, NBR 7217, Determination of granulometric composition of aggregates, Rio de Janeiro, 1987.

Brazilian Association of Technical Standards, NBR 7211, Aggregates for concrete - specification, Rio de Janeiro, 2005.

C. A. F. Rocha Junior, S. C. A. Santos, C. A. Souza, R. S. Angélica, R. F. Neves, Synthesis of zeolites from fly ash from boilers: physical, chemical and mineralogical characterization. Cerâmica 58 (2012), 43-52.

J. S. Siqueira, C. A. G. Souza, J. A. S. Souza, Reuse of ash coal in the formulation of mortars. Cerâmica 58 (2012) 275-279 [in Portuguese].

P. F. G Banfill, M. Criado, A Palomo, A.Fernández-Jiménez, Alkali activated fly ash: Effect of admixtures on paste rheology. Rheologica Acta, v. 48, nº. 4, 2009, p. 447-455.

L. Senff, D. Hotza., J.A. Labrincha, Effect of red mud addition on the rheological behaviour and on hardened state characteristics of cement mortar, Civil Engineering Dimension, Vol. 12, nº. 1, March 2010, 18- 22.

P. Santos Souza, Ciência e Tecnologia de Argilas,2ª Ed., Vol. 2. São Paulo: Edgar Blucher, (1989) 113. [in Portuguese].

Braz. J. of Develop., Curitiba, v. 5, n. 12, p.33083-33100 dec 2019 . ISSN 2525-8761 G. A., Schramm, Practical approach to rheology and rheometry. 2ª. Ed.. Karlsruche: Gebrueder HAAKE GmbH, 2000.

I. Oliveira, A. Studart, R. Pillegi, V. Pandolfelli, Dispersão e empacotamento de partículas – Princípios e aplicações em processamento cerâmico.18ª ed. São Paulo, Fazendo Arte, 2000 [in Portuguese].

K.Wang, M.S. Konsta-Gdoutos e S.P.Shah, Hydration, rheology, and strength of ordinary Portland cement (OPC) cement kiln dust (CKD) slag binders, ACI materials journal, 99(2), March-April, 173-179 (2002).

A. Camões, R.M. Ferreira, B. Aguiar, e S. JALALI, Durability of high performance concrete with fly ash, Concrete for Extreme Conditions, Proceedings of the International Conference Challenges of Concrete Construction, Dundee, Scotland, U.K. , 357-366 (2002).