Waghner C. Rocha, José J.R. Silva, Tiago A. Pires and Leonardo M. Costa

An increase in ^ the axial restraining levei or in load levei reduced the criticai time and

temperature of the^columns. However the influence of these parameters was not significant-fo~r

the fire behavior of the columns. Ali tests presented less than 10 min for the criticai "time "and

criticai temperatures between 500°C and 700°C. This criticai time is lower than th^minimal"flre

resistance required by the NBR 14432:2001 that is 30min.

IFireSS - International Fire Safety Symposium

Coimbra, Portugal, 20th-22"d Ãpril 2015

FIRÍJÍE^TION?. F CONCRETEWITH AND WITHOUT PP FIBRES:

EXPERIMENTAL

ANALYSIS AND

NUMERÍCÀLÍrM

ULATION"""

4. CONCLUSIONS

TNS.Paper_presenteda series of 8 fire tests on cold formed columns developed in laboratory of

structuresand materials of Federal universlty °f Pernambuco. The main"conclusÍons"of'íhïs

research were:

' The ^iÍica'time. oMhe tested_columns were less than 10min and criticai temperature

was between 500°C and 700°C;

. The higher load levei or axial restraining to thermal elongation, the lower is the fire

resjstance ofthe columns;

' ^B^So'Od(t3hO'nÏm"' are lowe> 'han 'he minim" r"° re"SBnce ^re'ented

5. AKNOWLEDGMENTS

LO

F.NWMCIdueJhe.

p;qlect

"planeiamento de Emergência de Complexos Industriais e noseu Entorno" n° 01. 08. 0618. 03 that

support7he"devdopmaento'f°th^

re^a^hA

US '"UUSInals e no6. MAIN REFERENCES

[1]

[2]

[3]

pire.sLT.A'c" Rodrigues-.. J-p'c' & Rê9° s"va' JJ- - Hre Resistance of concrete filled

CJK

U!^ho"ow.

col.

umns with ^trainedthermal, Journal ofConstructionalsteemesearch.

., p. 82-94. ----. -.,,

(:orre'a;A:J-M'c-; &,Rodri9ues, J.P.C. - Fire Resistance of steel columns with restrained

tion, Fire Safety Journal, 50, 2012, p. 1-11.

Almejda'-s, j'c' ^Análise do comportamento a temperaturas elevadas de elementos de

arço. formados a. friocomPrimidos considerando restrição ao alongamento"térmi'co^

Jhesis, University of Sao_Paulo - USP - Brazil, 2012, 292 p. (in portuguease)'"'""""'

[4]Íam;.. L;-Rodri9ues'J'. p'c;;. & &lva' Ls- - Experimenta^nalysisTn^-formed steel

beams subjected to fire, Thin-Walled Structures, 74, 2014, p. 104--1l7

Paulo Piloto6

Professor

Poly. Inst. Bragança

Portugal

Luís M. R. Mesquita

Professor

Poly. Inst. Bragança

Portugal

Carlos Balsa

Professor

Poly. Inst. Bragança

Portugal

Keywords: Fire reaction; Concrete; PP fibres; Thermal performance; heat release rate.

1. INTRODUCTION

Sï, ïal dements-ofre'nforced concrete-in generai- Present 9°°d performance in case of fíre.

Hnole

;eLmorlrecenLstructures.

have adapted newt^es-

^^^S

s;reang

ü's^-^SÏg. Jte:Lpresenting Ïfferent thermo me^hanical behaviour:"acquiringa"sp^al

;^<^^^'^ï:9^:e^e^°^:p^e^:^:ni^^

Ï. add!t'^tí^ypropylen<flbres. (pp) to n^l"cx>mpone^7^du^g"t^ ^^n^>S

pressure of the material through the channels created by the fusion of thefibres.'

^edeTspeh^ean;lÏd^ï:lT^de;fírc^nd'tion.

san^thedevelopment

of new numen^'^de's^has_a"owed.

theassessment of more or less^Plex'phenomena"tol

ïdeute'rcm'^

temperature evolution and other state variables, enabling

differentle^s'of"app°rol

achueT'u's;^

^pmd"ls wt)lw ~Departmel" °fAPP"ed Mecl'amcs-POMCChBic Inslïule ofBraEM'a- campus s^ Apolonia, ap. 1134, 5301-857 B.a..nca.

Paulo Piloto, Luís M. R. Mesquita and Carlos Bolsa

coupled or uncoupled field interaction (thermal, mechanical, hydrodynamic, chemical). This

investigation studies the thermal performance of a two dimensional model, using nonlinear and

transient finite element analysis.

2. MATERIAL AND METHODS

The experimental analysis is based on calorimetric test using small-scale samples of concrete, with dimensions 100x100x40 mm using the test method EN ISO 13927 [1]. In addition to the standard test, normally used to determine the mass loss rate and the heat relesse rate, four thermocouples type k were positioned in different coordinates of the samples ana the infrared thermography camera (FLIR 365) was used to evaluate temperature field in one lateral surface of each sample. A numerical simulation model was defined to evaluate the thermal performance

of samples when submitted to different heat fluxes 35 and 75 [kW/m2] and different levei of

fibres contents, see table 1. In arder to use the cone calorimeter experiments to validate the numerical model, small changes to standard test procedure were made.

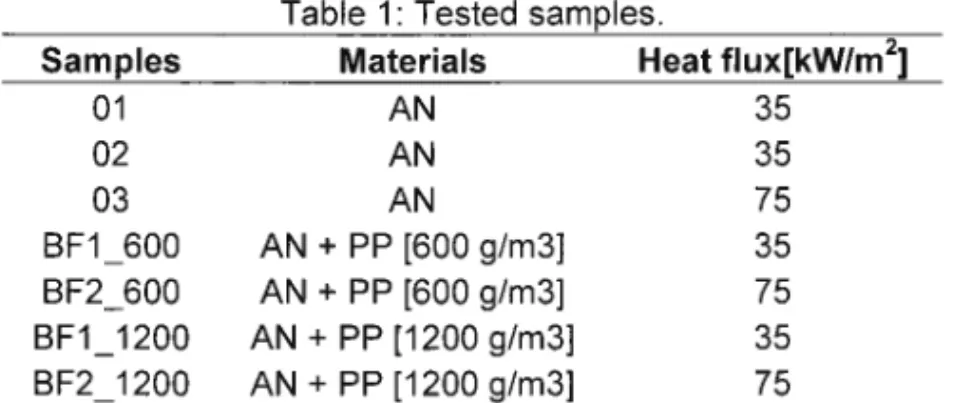

Table 1: Tested samples.

Samples Materiais

Heat flux[kW/m^]

01 02 03 BF1 600 BF2 600 BF1 1200 BF2 1200

AN AN AN

AN + PP [600 g/m3]

AN + PP [600 g/m3]

AN+PP[1200g/m3]

AN+PP[1200g/m3]

35 35 75 35 75 35

75

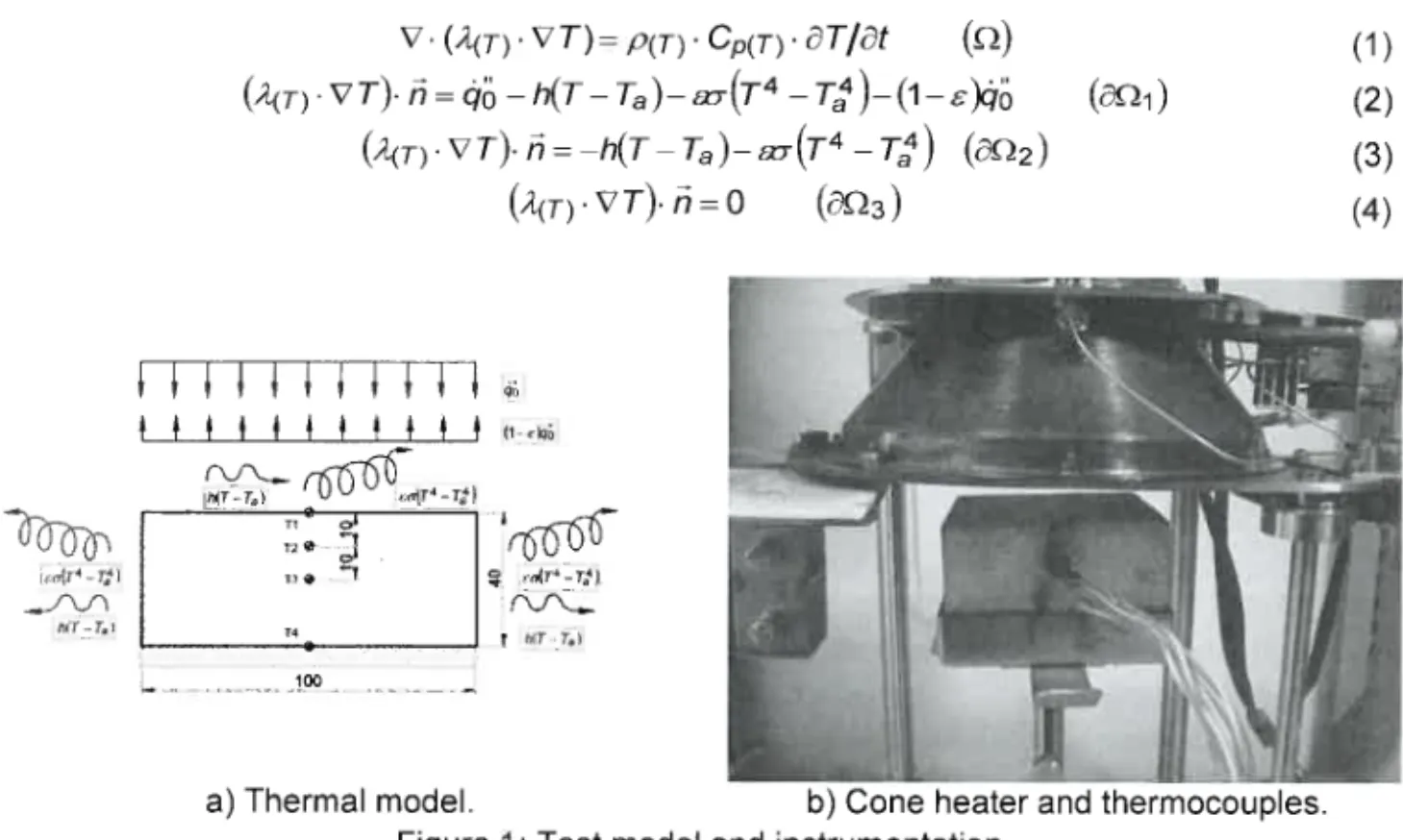

The thermal performance of the samples depends on the thermal balance in the boundaries.

The Eq. 1 should be solved in the two dimensional domain of the sample (fí), taking into

account the exchange of heat with the surroundings (ô0;). On the top surface of the sample

(3Qi), the heat flow balance (input and output) should verify Eq. 2. The net incident heat flux at

the top surface of the sample is composed by the heat flux coming from the cone heater,

radiation reflected from the surface, convective and radiative heat lesses. On the lateral

surfaces ofthe sample (002) the convective and radiative heat losses should be considered by

Eq. 3 and at the bottom surface of the domain (õQs) the adiabatic condition may be assumed,

Eq. 4. In these equations T represents the main state variable (temperature), the thermal

properties of concrete are represented by the specific mass P(J), specific heat CP(T-) and

conductivity /I(T-). The emissivity of concrete s was considered equal to 0.7. The

Stefan-Boltzmann coefficient is denoted by o- and h represents the convection coefficient that was

approximated by an experimental correlation for a hot horizontal plate in air, with the hot surface

Paulo Piloto, Luís M. R. Mesquita and Carlos Balsa

uppermost [2]. Tg represents the ambient temperature. These equations should consider the

nonlinear behaviour of material properties [3]. The balance model is represented in figure 1, as

well as the setup used in experiments.

V. (^T). VT) p(T)-Cp(T)-ST/Bt

(Q)

(^). VT). n=qo-/7(7--Ta)-aT(T4-Ta4)-(l-f)90

(3Ql)

(Â(T). Vr). n=-/7(T-7a)-aT(7-4-Ta4) (5^2)

(A(D. VT). n=0

(003)

(1)

(2)

(3)

(4)

^?Rn

»fl (tf (t( ( n..tó

|W-7;y ^U" - :c«(T'-ffl

lr^

a) Thermal model. b) Cone heater and thermocouples. Figure : Test model and instrumentation.

3. RESULTS

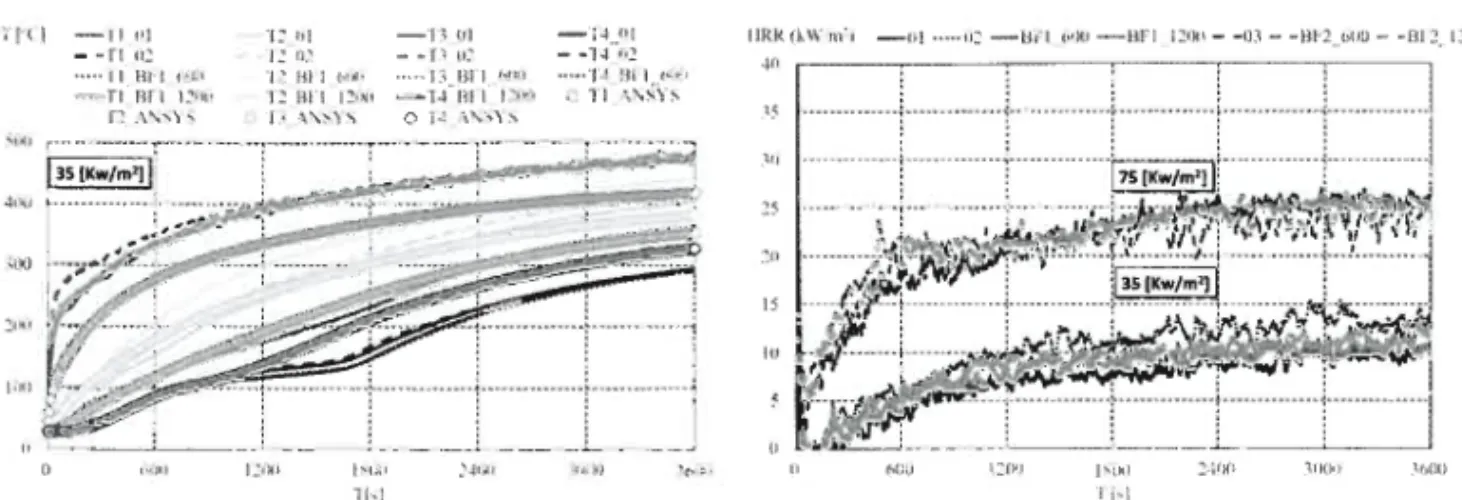

Figure 2 presents the thermocouple measurements during tests. These values are useful to

validate the numerical thermal model. The heat release rate was also measured and there was

no significant difference between samples with and without PP fibres for the heat flux levei of 35

Paulo Piloto, Luís M. R. Mesquita and Carlos Bolsa

coupled or uncoupled field interaction (thermal, mechanical, hydrodynamic, chemical). This

investigation studies the thermal performance of a two dimensional model, using nonlinear and

transient finite element analysis.

2. MATERIAL AND METHODS

The experimental analysis is based on calorimetric test using small-scale samples of concrete, with dimensions 100x100x40 mm using the test method EN ISO 13927 [1]. In addition to the standard test, normally used to determine the mass loss rate and the heat relesse rate, four thermocouples type k were positioned in different coordinates of the samples ana the infrared thermography camera (FLIR 365) was used to evaluate temperature field in one lateral surface of each sample. A numerical simulation model was defined to evaluate the thermal performance

of samples when submitted to different heat fluxes 35 and 75 [kW/m2] and different levei of

fibres contents, see table 1. In arder to use the cone calorimeter experiments to validate the numerical model, small changes to standard test procedure were made.

Table 1: Tested samples.

Samples Materiais

Heat flux[kW/m^]

01 02 03 BF1 600 BF2 600 BF1 1200 BF2 1200

AN AN AN

AN + PP [600 g/m3]

AN + PP [600 g/m3]

AN+PP[1200g/m3]

AN+PP[1200g/m3]

35 35 75 35 75 35

75

The thermal performance of the samples depends on the thermal balance in the boundaries.

The Eq. 1 should be solved in the two dimensional domain of the sample (fí), taking into

account the exchange of heat with the surroundings (ô0;). On the top surface of the sample

(3Qi), the heat flow balance (input and output) should verify Eq. 2. The net incident heat flux at

the top surface of the sample is composed by the heat flux coming from the cone heater,

radiation reflected from the surface, convective and radiative heat lesses. On the lateral

surfaces ofthe sample (002) the convective and radiative heat losses should be considered by

Eq. 3 and at the bottom surface of the domain (õQs) the adiabatic condition may be assumed,

Eq. 4. In these equations T represents the main state variable (temperature), the thermal

properties of concrete are represented by the specific mass P(J), specific heat CP(T-) and

conductivity /I(T-). The emissivity of concrete s was considered equal to 0.7. The

Stefan-Boltzmann coefficient is denoted by o- and h represents the convection coefficient that was

approximated by an experimental correlation for a hot horizontal plate in air, with the hot surface

Paulo Piloto, Luís M. R. Mesquita and Carlos Balsa

uppermost [2]. Tg represents the ambient temperature. These equations should consider the

nonlinear behaviour of material properties [3]. The balance model is represented in figure 1, as

well as the setup used in experiments.

V. (^T). VT) p(T)-Cp(T)-ST/Bt

(Q)

(^). VT). n=qo-/7(7--Ta)-aT(T4-Ta4)-(l-f)90

(3Ql)

(Â(T). Vr). n=-/7(T-7a)-aT(7-4-Ta4) (5^2)

(A(D. VT). n=0

(003)

(1)

(2)

(3)

(4)

^?Rn

»fl (tf (t( ( n..tó

|W-7;y ^U" - :c«(T'-ffl

lr^

a) Thermal model. b) Cone heater and thermocouples. Figure : Test model and instrumentation.

3. RESULTS

Figure 2 presents the thermocouple measurements during tests. These values are useful to

validate the numerical thermal model. The heat release rate was also measured and there was

no significant difference between samples with and without PP fibres for the heat flux levei of 35

Paulo Piloto, Lias M. R. Mesquita and Carlos Balsa

.'[. 11 -l

- -r n l: ni l: n.' -r. n --r', li: -;-i.ni--1^'.; tí( ! < l, » l' Hl i (.'il- .."' I \ M } M'-! "". Í . W i^---'

RFt i'nc I;HIt l^y< -14hit t'**'1 > 11 \\^ ^ \\s-<i>. !. ^^<. ^^ O i- \\^s

flRR(-kWm'i -«í -D: -BrÉ f')0 -tíFJ !2<H'- -03 ~ "tít'2 L>UÜ - -BI 2 12t)n

,

" u

'l

^

"" ; - ^'7':.

;lsÍ's

:,^s;sSS sw^,

;-y^í^^'^^-1"-''-\ . -'...'~|-.ï.

'.^f-SSS

^^A. ^^ï'-';. -^'

1:0-) ) siri 2-. W ^0(ï')

11-1

Figure 2: Thermal performance with simulation results and hleat Release Rate ofsame

samples.

IFireSS International Fire Safety Symposium

Coimbra, Portugal, 20th-22"d April 2015

EXPERIMENTAL INVESTIGATION ON THE BEHAVIOUR OF

COLD-FORMED STEEL COLUMNS SUBJECTED TO FIRE

4. CONCLUSIONS

The thermal behaviour of concrete samples, with and without polypropylene fibres was

presented, when submitted to a uniform heat fíux of 35 and 75 [kW/m ]. This study was

performed experimentally with two methods and numerically, with the validation ofthe numerical model. The numerical model hás the limitation of predicting the motion of the moisture in the samples.

It can also be concluded that addition of different amounts of polypropylene fibres hás no significant effect on the heat release rate and on the thermal performance of the samples.

5. REFERENCES

[1] CEN, EN ISO 13927. Plastics - Simple heat release test using a conical radiant heater and a thermopile detector. Brussels: CEN - Comité Européen de Normalisation." 2003. [2] Staggs, J. E. J. ; Whiteley, R. H. Modelling the combustion of solid-phase fuels in cone

calohmeter experíments. Fire and Materiais, vol. 23, issue 2, 1999, p. 63-69.

[3] CEN EN 199212. Eurocode 2: Design of concrete structures Part 12: General rules -Structural fire design. Brussels, December 2004.

Hélder D. Craveiro PhD student

University of

Coimbra

João P. Rodrigues

Professor

University of

Coimbra

Luís Laím Researcher

University of

Coimbra

Keywords: cold-formed steel, column, restraining, buckling

1. INTRODUCTION

The market share of cold-formed structural steelwork keeps growing over the past decade, especially in low rise residential, industrial and commercial buildings. This led to an understanding on how the fire safety design for cold-formed steel (CFS) structures is important. However, só far, most research hás been focusing on hot-rolled steel members which present significant differences when compared with cold-formed steel members, due to their manufacturing processes and geometry. It is clear that accurate design rules under fire conditions for cold-formed steel members are needed. The EN 1993-1-2:2005 [1] predicts that the design methodology for hot-rolled steel members is also applicable to cold-formed steel members with class 4 cross-sections, establishing the same reduction factors for the yield strength ofthe steel and limiting the criticai temperature to 350°C. The investigation carried out in the field hás shown that these design guidelines are not accurate [2-5]. Só far the research conducted hás been focusing on the individual buckling phenomena such as local, distortional ana global [5-7]. Moreover the research carried out does not consider the influence of restraint

to thermal elongation on the structural behavior of CFS columns. However this type of

Correspndent Author - Departamento de Engenliaria Civil da Faculdade de Ciências e Tecnologia da Universidade de Coimbra. Rua Luís Reis Santos. Polo