S

C

I

E

N

T

I

F

I

C

-T

E

C

H

N

I

C

A

L

Biodegradation of films of low density polyethylene (LDPE),

poly(hydroxibutyrate-co-valerate) (PHBV), and LDPE/PHBV

(70/30) blend with Paecilomyces variotii

Thayse Marques Passos

1, José Carlos Marconato

1and Sandra Mara Martins Franchetti

11

Departamento de Bioquímica e Microbiologia, Instituto de Biociências,

Universidade Estadual Paulista “Júlio de Mesquita Filho” - UNESP, Rio Claro, SP, Brasil

*samaramf@rc.unesp.brAbstract

The increased consumption of plastics in the world has been a subject of great concern and special attention by the

scientiic community. The aim is to promote development of materials that are biodegradable in a shorter time upon disposal in the environment. The most used synthetic plastics are dificult to biodegrade because they are made of long hydrocarbon chains, such as polyethylene (PE), polypropylene (PP), poly(vinyl chloride) (PVC), which are hydrophobic and resistant to the action of microbial enzymes. The use of alternative materials (natural polyesters) can minimize the harm to dumps and landills upon their disposal, because they are susceptible to the action of microorganisms. In this study we evaluated the biodegradation/biodeterioration of PHBV (poly(3-hydroxybutyrate-co-hydroxyvalerate) ilms, LDPE (low density polyethylene) and the blend of LDPE/PHBV (70/30) by the fungus Paecilomyces variotii, using different methods: optical microscopy (OM), scanning electronic microscopy (SEM) and Fourier Transform Infrared spectroscopy (FTIR).

Keywords: Biodegradation, P. variotii, FTIR, SEM.

1. Introduction

In recent years, has been increasing the concern with environmental issues, since new technologies are continually being developed and incorporated into our daily lives; thus, is necessary to adopt new techniques to deal

with the waste produced by the use of these technologies. The application of one of these technologies is associated with the use of polymer materials in food packaging, coatings and products in contemporary society. With the increased consumption of these materials and

uncontrolled waste disposal, is necessary to provide an adequate and sustainable management for the waste, since they may pollute the environment and taking too many

years to degrade[1]. In this sense, a number of proposals

have been assessed, in order to increase the degradation

rate. The proposals include: (a) the insertion of elements in the packaging structure which promotes photodegradation

(photosensitizers, metal salts, quinones, benzophenol, etc.),

(b) a study on the use of polymers (polyamides, polyesters, polyurethanes) containing hydrophilic structures in their composition, predisposing them to degradation by the action

of the environmental moisture, (c) the development of new

packaging materials, based on synthetic polymers with modified starch or other polymers which exhibit natural

sensitivity to the attack by environmental microorganisms (d) biodegradation studies in different environments,

aerobic and anaerobic[2-5].

Biodegradation is the process by which organic substances in the environment are converted into simple

compounds under appropriate conditions of temperature and

oxygenation; this process is mediated by microorganisms

that are able to promote the biodegradation through the enzymes released during their catabolic process[6]. There

are evidences that natural and synthetic polymers are

biodegraded by these enzymes, which are able to hydrolyze these substrates by using them as carbon source to grow these microorganisms[7].

The fungus Paecilomyces variotii Bainier is an ascomycete commonly found in soil, indoors, plants,

animals, and in pasteurized food. It is a fast-growing thermotolerant and is also able to grow in low levels of

oxygen[8]. Some tests with different species of filamentous fungi, including Paecilomyces variotii, were carried out

using polymeric materials such as PVC, plastics, organic

silicone, polyamides, rubbers, and fluoroplastics, and the results showed that there was a significant growth of microorganism on this polymers, leading to the release of

aggressive metabolites which caused their degradation[9]. Furthermore, in studies to examine the biodegradation of hydrocarbons presents in oil and diesel oil, the occurrence

of this fungus was observed, indicating its tolerance to contaminated environments and its potential in degrading

these pollutants[10-12].

The polymers used in this work have special

characteristics and potential to be used in commercial products. The polyethylene (PE) is a flexible semi-crystalline

polymer whose properties are influenced by the relative

(LDPE), which has a crystallinity about 50-60%, a melting

temperature in the range of 110-115 °C and branched

chains that determines the degree of crystallinity and the transition temperatures[13]. The results from a previous study on the degradation of this polymer in different conditions

showed positive effects, especially when the photo and biodegradation experiments have been carried out in

combination[14-16].

The PHBV (poly(3-hydroxybutyrate-co-hydroxyvalerate) is a natural biodegradable polymer

(produced by microorganisms), also referred to as biopolymer or bioplastic[2-5]. It is less brittle than its

homopolymer, PHB (poly (3-hydroxybutyrate)[17] and its physical and thermal properties depends on the content of

hydroxyvalerate units (HV)[18]. Biodegradation experiments were performed with this polymer and the researchers

observed that degradation of the samples occurred in just

4 weeks[19].

Polymer blends, homogeneous or heterogeneous

mixtures of different polymers, have great biotechnological

importance due to changes in its mechanical properties

compared to the original polymers, as the improvement in

impact strength at low temperatures and heat resistance[20,21].

In addition, some blends facilitate the biodegradation of

the non-biodegradable component[22] or in some cases; the biodegradation is controlled by one of the components in the

mixture, as already observed by some research groups[23,24]. The preparation of mixtures produces a matrix which is morphologically heterogeneous, especially when immiscible or partially miscible polymers were used, such as the blend

of PHB/LDPE[25]. A multiphase structure organization promotes the degradation rate due to the increase of both,

effective transport coefficients and functional group accessibility for (bio) corrosive agents[26]. Experimental

studies of blends of P(HB-3)/poly(propiolactone), P(HB-3)/poly(ethylene adipate), and P(HB-3)/poly (3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) have

shown that the degradation was found to be faster in the polymer blends when compared to pure polymer, which can be attributed to the phase separation process of components in the blends[27].

Furthermore, in a study of poly (ε-caprolactone (PCL) and cellulose acetate blends, it was observed that the higher the PCL percentage present in the formulation, the greater is the degradation rate, due to the fact of the PCL morphology,

containing spherulites and roughness, which facilitate the

microbial activity and water absorption[28].

2. Material and Methods

2.1 Preparation of films

T h e p o l y m e r s P o l y h y d r o x y b u t y r a t e c o

-valerate-18% HV (PHBV) (donated by the Department of Materials Engineering - Federal University of São Carlos), Low Density Polyethylene (LDPE) (CP 681/59 - Fortymil

- density 0.922 - donated by the Department of Engineering

- Mackenzie University) were used in this study. The homopolymers and blends of LDPE/PHBV, mass proportion of 70/30 were processed in an internal mixer (Haake Polylab

model 900) at 170 °C and 60 rpm, during 15 minutes to ensure

a good dispersion of the components.

The polymeric films were obtained by melting 0.2 g of each polymer, between aluminum foil in a hydraulic press

(SOLAB), at a temperature of 170 °C and pressures of

53.4 Kgf./cm2 to the blend and PE, and 44.5 Kgf./cm2 to

PHBV, for a period of 3 minutes each. Subsequently the films were cooled in a controlled environment conditions (25 °C)

at the Laboratory of Polymers Treatment, Department of

Biochemistry and Microbiology - UNESP/Rio Claro.

2.2 Fungus

The microorganism used was Paecilomyces variotii

(ATCC 16023), recommended by ASTM-ISO 846. The standard strain used in this study was acquired from the Tropical Culture Collection, André Tosello Foundation, Campinas, SP.

2.3 Culture media

30 g of anhydrous dextrose, 2.0 g NaNO3,

0.7 g KH2PO4, 0.3 g K2HPO4, 0.5 g KCl, 0.5 g MgSO4.7H2O; 0.01 g FeSO4.7H2O, 20g agar and 1000 ml of distilled water.

2.4 Preparation of the spore suspension

In a tube containing the sporulated culture of the fungus,

9 ml of a saline solution (0.85%) were introduced and

subsequently the surface of the culture was scraped with a sterile loop, in order to obtain an aqueous spore suspension.

After this procedure, the filtration of the suspension was performed in a glass funnel containing glass wool and cotton

(sterile) to remove the mycelial fragments. The concentration

of the suspension was adjusted to 106 spores/ml (using a

Neubauer chamber).

2.5 Inoculation method

The experiment was performed by incubating the polymer films in the medium, in accordance with the Standard test

method BS EN ISO 846:1997, containing the corresponding carbon source, which is required for fungal growth to occur. The polymers, after being analyzed by FTIR, weighed and sterilized with UV radiation for 15 minutes, were placed on the

surface of the solid medium in Petri dishes, and then sprayed with 0.1 ml of the spore suspension. After these procedures, the

dishes were incubated in a bacteriological incubator (SOLAB) at a temperature of 28 °C.

2.6 Analysis: Measurements of mass, optical microscopy, scanning electron microscopy and FTIR

After 30 days of growth, the dishes containing the

inoculums were removed from the incubator. Each film was removed from the dish, washed with distilled water, dried

between sheets of filter paper and then placed in a desiccator

during a period of 4 days. Subsequently the films were weighed on an analytical balance (Chyo - JK model 200), observed under an optical microscope (BEL® brand Photonics), Scanning Electron Microscopy (Hitachi TM 300 - tableloop microscope), and analyzed by FTIR (Shimadzu, model FTIR

and LDPE/PHBV (70/30) blend with Paecilomyces variotii

3. Results and Discussion

Table 1 shows the results of mass loss of the different films. At the beginning of the experiment, due to the presence of carbon in the medium, a fungal growth was

observed. Throughout the experiment, probably, the source

of carbon has changed and the fungus has also attacked the polymer films. Among the polymers used in this work,

PHBV showed the largest mass loss, due to its structure containing hydrolysable ester groups, however in the blend

the mass loss was lower, due to the different morphology, i.e., the PE fraction (more hydrophobic) caused a controlling

effect over the biodegradation process, occurring in the two

polymers interphase[24,29] .

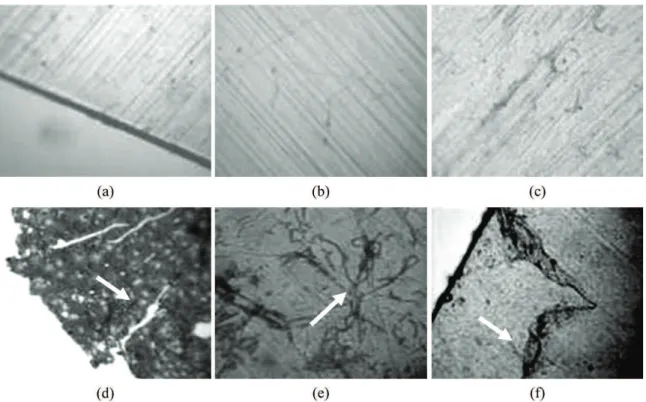

Through the optical microscopy (Figure 1), is possible

to observe the adhesion of the fungal hyphae on the polymer,

the presence of spores and appearance of holes and flaking (indicated by arrows), on the surface of the three different films. Despite LDPE being more hydrophobic (just carbon structure) than the other films (containing ester groups), it

was possible to observe adhesion of fungal hyphae.

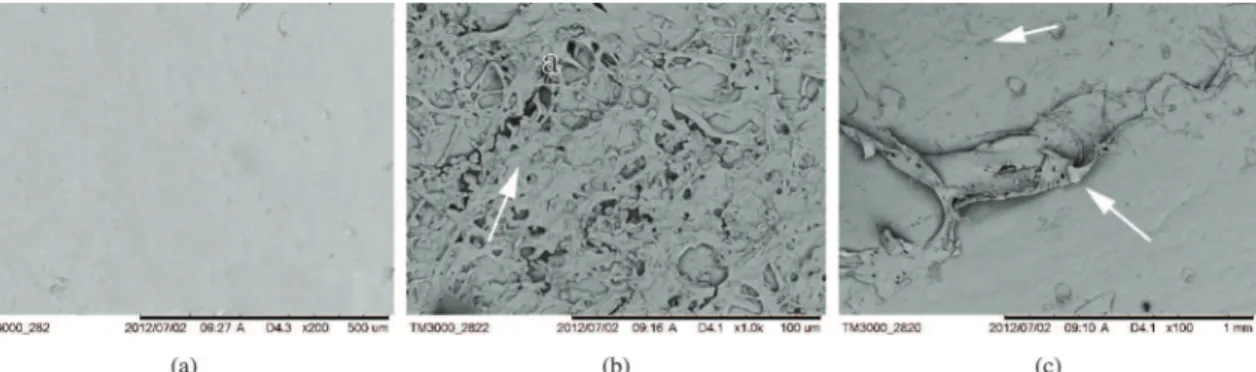

These different structures across the films can be

best viewed by Scanning Electronic Microscopy (SEM)

in Figures 2-4, detailing the biotreated polymers, which

shows adhered spores and exfoliated parts. In Figure 2b is noted a significantly different morphology, presenting an entangled of hyphae and spores in the surface (1000 X).

In Figure 2c, can be observed the occurrence of flaking,

which is well noted even though the smaller magnification

(100 X) seeming to be further out of the film. This last ones

indicates PHBV fraction biodegradation[30] and similar to the biodegradation of polypropylene/poly(hydroxide

butyrate) blends treated in a polluted river water[24].The Figure 3 shows the changes on the PHBV surface. After the biotreatment (Figures 3b), is evident the presence of spores and hyphae adhered to the polymer, forming a layer on it.

The LDPE SEM can be observed in the Figure 4, where is also clear the capacity of the fungus P. variotii to adhere to these polymer surface, what is an important step for the biodegradation process.

The films analyzed by FTIR are shown in Figure 5. The spectra of the blends were normalized by the intensity of 1465 cm–1 absorbance band, regarded as internal standard, since it did not change.

The observed spectral changes were associated with the

increase or decrease in intensity of the bands, as well as the possible displacement of these bands or their appearance

or disappearance. The LDPE and PHBV films showed no

significant changes, but the blend showed some interesting changes, pointed in Figure 5.

In the blend spectra, the band 1750 cm–1 (C=O groups stretching in the amorphous phase) suffered a decrease in

intensity, 1720 cm–1 (C=O groups stretching in the crystalline phase) does not suffered change and new bands appeared at 1643 cm–1 and 1546 cm–1, corresponding to C=O acid Table 1. Percentage of mass loss of polymer after treatment.

% mass loss (g) Polymer

PHBV 43

PE 0,2

Blend 4

Figure 1. Optical Micrographies of films of PHBV, LDPE, and Blend (a, b and c)- before biotreatment; (d, e and f) PHBV, PE and blend

Figure 2. SEM of LDPE/PHBV (70/30) blends. a - before the biotreatment (200 X), b-c after the biotreatment, at 28 °C, for 1 month

(1000x and 100 X, respectively). (Note b: rough and more heterogeneous; c: spores and exfoliated part, indicated by arrows).

Figure 3. SEM of PHBV. a - before the biotreatment (3000 X), b-c after the biotreatment, at 28 °C, for 1 month (1000 X and 3000X,

respectively). (Note b: crackles and c: spores and hyphae adhered to the surface).

Figure 4. SEM of LPDE. a - before the biotreatment (1000 X), b-c after the biotreatment, at 28 °C, for 1 month (400x and 1000 X,

respectively). (Note b: spores adhered to the surface).

and LDPE/PHBV (70/30) blend with Paecilomyces variotii

and C=C vibration bands, respectively. The appearance of the band at 3370 cm–1 (extended band) corresponds to the

O-H vibration of acids. These changes suggest the presence

of 2-butenoic acid, formed by enzymatic hydrolysis reaction[31]. The bands at 1280 cm–1 (CH

3 deformation), 1228 cm–1 and 1055 cm–1 (C-O-C stretching) (all of these

bands are sensitive to the polymer crystallization[32] suffered a decrease in intensity, indicating a decrease in the film

crystallinity and in the C-O-C ester group.

A significant structural change of the polymeric matrix,

denoted in the FTIR, showed that the blend LDPE/PHBV (70/30) was biodegraded by the fungus P. variotii, through the enzymatic hydrolysis facilitated by the phase separation

morphology of this blend. It is caused by the interphase

presence, formed by the two different polymers which seem to be not organized, promoting the microbial action[29].

4. Conclusions

The results showed that PHBV degraded, in the blend, as observed by the presence of unsaturated acid in the

chain. The LDPE (homopolymer) demonstrated resistance to the microbial enzymes action during the study period, but adhered fungus hyphae were found.

Significant changes in the morphology of the PHBV, PE

and blend films showed the ability of the P. variotii to adhere

on hydrophilic and hydrophobic surfaces. Besides that, this fungus acts mainly in the PHBV fraction of the blend.

5. Acknowledgments

The authors acknowledge CAPES (Brazil) for financial

support.

6. References

1. Vinhas, G. M., Almeida, Y. M. B., Lima, M. A. G. A., & Santos, A. S. (2007). Estudo das propriedades e biodegradabilidade de

blendas de poliéster/amido submetidas ao ataque microbiano. Quimica Nova, 30(7), 1584-1588. http://dx.doi.org/10.1590/

S0100-40422007000700016.

2. Franchetti, S. M. M., & Marconato, J. C. (2006).

Polímeros biodegradáveis – uma solução parcial para diminuir a quantidade dos resíduos plásticos. Quimica

Nova, 29(4), 811-816. http://dx.doi.org/10.1590/S0100-40422006000400031.

3. Lucas, N., Bienaime, C., Belloy, C., Queneudec, M.,

Silvestre, F., & Nava-Saucedo, J. E. (2008). Polymer

biodegradation: mechanisms and estimation techniques. Chemosphere, 73(4), 429-442. http://dx.doi.org/10.1016/j. chemosphere.2008.06.064. PMid:18723204

4. Lomas-Esteban, M. C. (1996) Food packs and packing in

view of environmental directive.Alimentación, Equipos y

Tecnología 1: 39-43.

5. Shah, A. A., Hasan, F., Hameed, A., & Ahmed, S. (2008).

Biological degradation of plastics: a comprehensive review. Biotechnology Advances, 26(3), 246-265. http://dx.doi.

org/10.1016/j.biotechadv.2007.12.005. PMid:18337047 6. Gaboardi, F. (2007). Avaliação das propriedades mecânicas,

térmicas e de biodegradação de blendas de PHB e PEBD com e sem aditivos pró-oxidantes(Dissertação de mestrado).

University São Francisco, Itatiba.

7. Gu, J. D. (2003). Microbiological deterioration and degradation

of synthetic polymeric materials: recent research Advances. International Biodeterioration & Biodegradation, 52(2), 69-91.

http://dx.doi.org/10.1016/S0964-8305(02)00177-4. 8. Houbraken, J., Varga, J., Rico-Munoz, E., Johnson, S., &

Samson, R. A. (2008). Sexual reproduction as the cause of

heat resistance in the food spoilage fungus Byssochlamys spectabilis (anamorph Paecilomyces variotii). Applied and

Environmental Microbiology, 74(5), 1613-1619. http://dx.doi.

org/10.1128/AEM.01761-07. PMid:18192427

9. Lugauskas, A., Jaskelevicius, B., Levinskaite, E. & Prosycevas,

I. I. (2004). Prosycevas I. Influence of biological factors in

aging of polimeric materials under natural environmental

conditions. Material Science 10(1): 24-29.

10. Bucker, F. (2009). Biodeterioração de misturas de diesel e biodiesel e seu controle com biocidas(Dissertação de

mestrado). Universidade Federal do Rio Grande do Sul, Porto Alegre.

11. Bento, F. M., & Gaylarde, C. C. (2001). Biodeterioration

of stored diesel oil: studies in Brazil.International Biodeterioration & Biodegradation, 47(2), 107-112. http:// dx.doi.org/10.1016/S0964-8305(00)00112-8.

12. Garcia-Peña, I., Ortiz, I., Hernández, S., & Revah, S. (2008).

Biofiltration of BTEX by the fungus Paecilomyces variotii. International Biodeterioration & Biodegradation, 62(4), 442-447. http://dx.doi.org/10.1016/j.ibiod.2008.03.012. 13. Coutinho, F. M. B., Mello, I. L., & Maria, L. C. S. (2003).

Polietileno: principais tipos, propriedades e aplicações.

Polímeros, 13(1), 1-13. http://dx.doi.org/10.1590/S0104-14282003000100005.

14. Alhamdan, A. M., & Al-Helal, I. M. (2009). Mechanical

deterioration of polyethylene greenhouses covering

under arid conditions. Journal of Materials Processing Technology, 209(1), 63-69. http://dx.doi.org/10.1016/j. jmatprotec.2008.01.052.

15. Kaczmarek, H., & Oldak, D. (2006). The effect of UV-irradiation on composting of polyethylene modified by cellulose. Polymer Degradation & Stability, 91(10), 2282-2291. http://dx.doi. org/10.1016/j.polymdegradstab.2006.04.024.

16. Roy, P. K., Surekha, P., Rajagopal, C., Chatterjee, S. N., & Choudhary, V. (2007). Studies on the photo-oxidative degradation of LDPE films in the presence of oxidised p o l y e t h y l e n e . P o l y m e r D e g r a d a t i o n & S t a b i l i t y, 9 2( 6 ) , 11 5 1 - 11 6 0 . h t t p : / / d x . d o i . o r g / 1 0 . 1 0 1 6 / j .

polymdegradstab.2007.01.010.

17. Avella, M., La Rota, G., Martuscelli, E., Raimo, M., Sadocco, P., Elegir, G., & Riva, R. (2000).

Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) and wheat straw fibre composites: thermal, mechanical properties and biodegradation behaviour. Journal of Materials Science, 35(4), 829-836. http://dx.doi.

org/10.1023/A:1004773603516.

18. Kansiz, M., Domínguez-Vidal, A., McNaughton, D., & Lendl,

B. (2007). Fourier-transform infrared (FTIR) spectroscopy for monitoring and determining the degree of crystallisation of

polyhydroxyalkanoates (PHAs).Analytical and Bioanalytical Chemistry, 388(5-6), 1207-1213. http://dx.doi.org/10.1007/

s00216-007-1337-5. PMid:17530232

19. Sridewi, N., Bhubalan, K., & Sudesh, K. (2006). Degradation of commercially important polyhydroxyalkanoates in

tropical mangrove ecosystem. Polymer Degradation & Stability, 91(12), 2931-2940. http://dx.doi.org/10.1016/j.

polymdegradstab.2006.08.027.

20. Fox, D. W., & Allen, R. B. (1991). High performance polymers and composites. New York: John-Wiley.

21. Billingham, N. C., Hoad, O. J., Chenard, F., & Whiteman, D.

rubber – toughened PP. Macromolecular Symposia, 115(1), 203-214. http://dx.doi.org/10.1002/masy.19971150113. 22. Campos, A., Marconato, J. C., Franchetti, S. M. M., Agnelli,

J. A. M., & Monteiro, M. R. (2007) Biodegradation of blend

films in soil and soil with chorume. I. PVC/PCL.Research Journal of Biotechnology2(4): 20-25.

23. Campos, A., Marconato, J. C., & Franchetti, S. M. M. (2010). Biodegradação de Filmes de PP/PCL em Solo e Solo

com Chorume. Polímeros, 20(4), 295-300. http://dx.doi. org/10.1590/S0104-14282010005000039.

24. Faria, A. U., & Martins-Franchetti, S. M. (2010). Biodegradação de Filmes de Polipropileno (PP), Poli(3-hidroxibutirato)

(PHB) e Blenda de PP/PHB por Microrganismos das Águas do Rio Atibaia. Polímeros, 20(2), 141-147. http://dx.doi. org/10.1590/S0104-14282010005000024.

25. Subramamnian, P. M., & Plotzker, I. G. (2000). Polymer blends. New York: John-Wiley.

26. Iordanskii, A. L., Ol’khov,O. V., Startsev, G. E., Zaikov,U. J., & Hanggi,U. J. (2004). Water transport in synthetic polymers.

New York: Nova Science Press.

27. Kumagai, Y., & Doi, Y. (1992). Enzymatic degradation of binary blends of microbial poly(3-hydroxybutyrate)

with enzymatically active polymers. P o l y m e r Degradation & Stability, 37(3), 253-256. http://dx.doi.

org/10.1016/0141-3910(92)90167-4.

28. Rosa, D. S, & Bardi, M. A. G. (2007) Avaliação da

biodegradação em solo simulado de poli (ε-caprolactona),

acetato de celulose e suas blendas. Revista Brasileira de

Aplicações de Vácuo,26(1): 43-47.

29. Gonçalves, S. P. C., Martins-Franchetti, S. M., & Chinaglia, D. L. (2009). Biodegradation of the Films of PP, PHBV and

Its Blend in Soil.Journal of Polymers and the Environment, 17(4), 280-285. http://dx.doi.org/10.1007/s10924-009-0150-y. 30. Corrêa, M. C. S., Rezende, M. L., Rosa, D. S., Agnelli, J.

A. M., & Nascente, P. A. P. (2008). Surface composition and morphology of poly(3-hydroxybutyrate) exposed to biodegradation. Polymer Testing, 27(4), 447-452. http://

dx.doi.org/10.1016/j.polymertesting.2008.01.007.

31. Gonzalez, A., Irusta, L., Fernández-Berridi, M. J., Iriarte, M., & Iruin, J. J. (2005). Application of pyrolysis/gas chromatography/Fourier transform infrared spectroscopy

and TGA techniques in the study of thermal degradation

of poly (3-hydroxybutyrate). Polymer Degradation & Stability, 87(2), 347-354. http://dx.doi.org/10.1016/j. polymdegradstab.2004.09.005.

32. Bloembergen, S., Holden, D. A., Hamer, G. K., Bluhm, T. L., & Marchessault, R. H. (1986). Studies of composition and cristalinity of bacterial

poly(ß-hydroxybutyrate-co-ß-hyroxyvalerate). Macromolecules, 19(11), 2865-2871. http:// dx.doi.org/10.1021/ma00165a034.