THE INFLUENCE OF POTASSIUM

CHLORIDE ON THE REINFORCED

MARINE CLAY FOR FOUNDATION

SOIL BEDS

Koteswara Rao. D J. Purna Chandra Rao

Associate Professor Graduate Students-2010 Department of Civil Engineering

University College of Engineering KAKINADA- 533 003:: INDIA.

ABSTRACT

Weak marine soil deposits have been found both on the coast and in several offshore areas spread over many parts of the world. When clay particles precipitate in salt water, there is a tendency for the clay particles to flocculate and stick together giving rise to some sort of edge-to-face arrangement. As a result, clay, silt, and fine sand particles settle almost at the same rate and the final sediment formed consists of particles with a very loose card house-like structure. Hence the marine sediments can be considered loose sediments, usually formed with high void ratios. Problems are associated with these fine-grained soils deposited at a soft consistency. Fine-grained soils are very sensitive to changes in the stress system, moisture content and system chemistry of the pore fluid. In addition to these, the problems arising out of high compressibility and low shear strength of these weak marine deposits expose geotechnical engineers to considerable changes in the construction of various coastal and offshore structures. In this present investigation, the performance of the potassium chloride on the strength characteristics of the marine clay has been studied and also the reinforcement effect on the improvement of load bearing capacity of the KCl treated marine clay has been studied.

KEY WORDS: OMC, MDD, FSC, KCl, Load Bearing Capacity, Strength Characteristics

1.1 INTRODUCTION

The marine clay is available at fully saturated condition in the costal corridor and the natural water content of the marine clays is always greater than its liquid limit. The comprehensive review of literature shows that a considerable amount of work is related for the determination of deformation characteristics and strength characteristics of marine clay worldwide. From the various contributions, the investigations on strength characteristics of marine clay conducted by S. Narasimha Rao et.al (1987,1996), Shridharan et al.(1989) , Mathew et al. (1997) and G. Rajasekaran et.al (2002), Ali M.A. Abd-Allah(2009) are worthy of note. Improving the strength of the marine clay by the stabilization technique was performed by Supakij Nontananandh et al. (2004). Countable study on engineering properties of marine clays was performed by Basack et al (2009).

1.2 OBJECTIVES

This investigation has been carried with the following objects.

To study influence of KCl on the Marine Clay + GBFS mix for the foundation Soil beds.

To investigate the efficiency of geotextile as a reinforcement and separator in the treated marine clay foundation soil bed.

To indentify the improvement in the load carrying capacity of the untreated and treated marine clay foundation soil bed at OMC & FSC.

1.3 MATERIALS USED

Marine clay: The marine clay used for this study was collected from the Kakinada Sea Ports Limited, Kakinada, A.P, India and the soil was air dried prior to the laboratory investigation. The various geotechnical properties were determined and tabulated in the table 1.

Geotextile: PP woven Geotextile-GWF-40-220, manufactured by GARWARE –WALL ROPES LTD, Pune, India, is used in this investigation. The tensile strength of woven geotextile is 60.00 kN /m for warp and 45.00 kN / m for weft.

Potassium Chloride: Laboratory grade potassium chloride consisting of 98% KCl was used in this work. The amount potassium chloride was varied between 0 to 2.0% by dry weight of soil.

Table 1: Properties of Untreated and Treated Marine Clay

Sl. No

Property Marine Clay (MC) Marine clay

+20% GBFS

1% KCl + 20% GBFS + M.C

1 Gravel 0 % --- ---

2 Sand 14% --- ---

3 Fines

Silt 30% --- ---

Clay 56% --- ---

4 Liquid Limit 74.5 % 64.7 % 55.30

5 Plastic Limit 26.9 % 28.9 % 26.75

6 Plastic Index 47.6 % 35.8 % 28.55

7 Shrinkage limit 10.678 % 15.45% 18.15

8 Soil Classification CH CH CH

9 Specific Gravity 2.35 2.45 2.52

10 D FS (%) 80 45 30

11 O M C 35% 23.5% 15.6

12 M D D 1.27 gm / cc 1.635 gm / cc 1.81

13 Cohesion 12 .20 t /m2 9.12 t /m2 7.50

14 Angle of Internal Friction 20 70 100

15 CBR Value ( %) 0.754 3.58 5.37

16 NMC % 86.15 --- ---

Granulated Blast Furnace Slag: Granulated blast furnace slag used for this study was brought from Vizag steel plant, Visakhapatnam, Andhra Pradesh, A.P,India. Various laboratory tests were conducted to determine the properties of GBFS as per IS codes of practice.The physical properties of GBFS were given in the table 2.

Gravel: Locally available gravel has been used as cushion on the treated marine clay soil for conducting static plate load test. The physical properties of gravel were presented in the table 3.

1.4 LABORATORY EXPERIMENTATION

Index properties:

clay mix has been increased with addition of KCl up to 1% and beyond the addition of 1% KCl, the MDD values of the 20%GBFS + marine clay mix has been decreased as presented in the table 5 & Fig 5&6.

Table 2: Physical Properties of GBFS

Sl.No PROPERTY VALUE

1 Specific Gravity 2.116

2 Grain Size Distribution

Gravel Size (%) (>4.75mm) Sand Size (%) (4.75-0.075mm) Silt Size (%) (0.075-0.002mm)

0 98.44 1.56

3 OMC (%)

MDD(g/cc)

12 1.42 4 Cohesion(kN/m2)

Angle of internal friction(φ)

0 40

5 C BR (%) 15

Table 3: Physical Properties of Gravel

Sl.No Property Value

1 Gravel (%) 61.54

2 Sand(%) 29.58

3 Silt & Clay (%) 8.88

4 Maximum Dry Density kN/m3 19.94

5 OMC (%) 11.51

6 Liquid limit (%) 23.14

7 Plastic limit (%) 17.11

8 Plasticity Index 6.03

9 CBR % 16.42

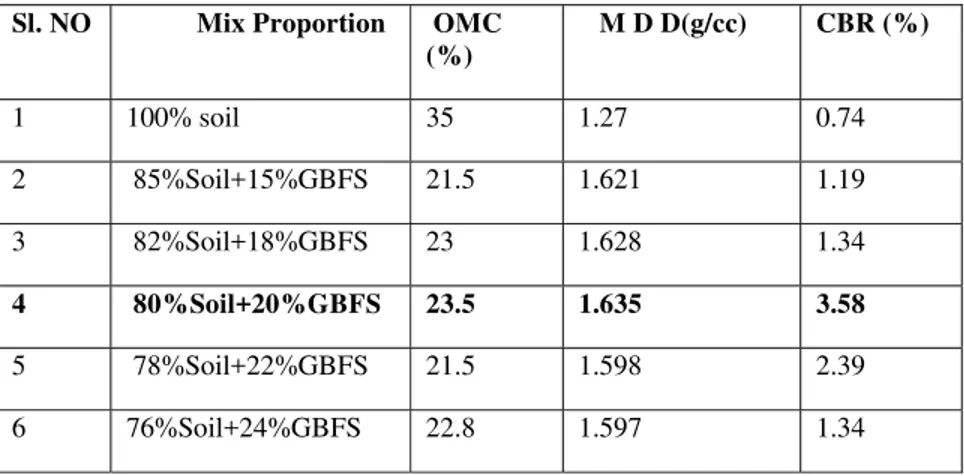

Table 4: OMC and MDD Values of Marine Clays and GBFS

Sl. NO Mix Proportion OMC (%)

M D D(g/cc) CBR (%)

1 100% soil 35 1.27 0.74

2 85%Soil+15%GBFS 21.5 1.621 1.19

3 82%Soil+18%GBFS 23 1.628 1.34

4 80%Soil+20%GBFS 23.5 1.635 3.58

5 78%Soil+22%GBFS 21.5 1.598 2.39

6 76%Soil+24%GBFS 22.8 1.597 1.34

Table 5 : O M C and MDD Values of 20% GBFS + Marine Clay Mix with % Variation of Potassium Chloride

Sl. No Mix Proportion OMC (%)

MDD(g/cc) CBR(%)

1 100% soil 35 1.27 0.74

2 80% soil+20%GBFS 23.5 1.635 3.80

3 80% soil+20%GBFS+0.25%KCl 22 1.611 3.88

4 80% soil+20%GBFS+0.5% KCl 21.5 1.664 4.18

5 80%Soil+20%GBFS+1% KCl 19 1.751 5.37

6 80% soil+20%GBFS+1.5% KCl 20.5 1.701 4.78

7 80% soil+20%GBFS+2% KCl 23.5 1.651 4.48

Fig 1: Variation in MDD Values of Marine Clay with Different % of GBFS

COMPACTION CURVES

1.1 1.2 1.3 1.4 1.5 1.6 1.7

10 20 30 40 50

WATER CONTENT(%)

DR

Y

DE

NSI

T

Y

(g

/c

c

100% SOIL

85% SOIL+15% GBFS 82% SOIL+18% GBFS 80% SOIL+20% GBFS 78% SOIL+22% GBFS

76% SOIL+24% GBFS

15, 1.614

18, 1.622 20, 1.635

22, 1.625

24, 1.601 1.59

1.6 1.61 1.62 1.63 1.64

10 12 14 16 18 20 22 24 26

OM

C

g

/c

c

% GBFS

Fig 2: Effect of % Variation of GBFS on the MDD Values of

Marine Clay

Fig3: Load Vs Deflections of Marine Clay with Different % of GBFS SOAKED CBR TEST RESULTS

0 10 20 30 40 50 60 70 80 90 100

0 10 20

DEFLECTION(mm)

LO

A

D

(k

g)

Series1

85%SOIL+15%GBFS 82%SOIL+18%GBFS 80%SOIL+20%GBFS 78%GBFS+22%GBFS 76%SOIL+20%GBFS

15, 1.19 18, 1.34

20, 3.8

22, 2.39

24, 1.34

0 1 2 3 4

14 16 18 20 22 24 26

CBR (%)

% GBFS

Fig 5: Compaction Curves of 20% GBFS+ Marine Clay Mix with % Variation of Potassium Chloride

COMPACTION CURVES

1.4 1.5 1.6 1.7 1.8

15 20 25 30 35

WATER CONTENT

DRY

DE

NSIT

Y 80%SOIL+20%GBFS

80%SOIL+20%GBFS+0.25%kcl 80%SOIL+20%GBFS+0.5%kcl 80%SOIL+20%GBFS+1%kcl 80%SOIL+20%GBFS+1.5%kcl 80%SOIL+20%GBFS+2%kcl

0.25, 1.611 0.5, 1.664

1, 1.751

1.5, 1.701

2, 1.651

1.6 1.62 1.64 1.66 1.68 1.7 1.72 1.74 1.76

0 0.5 1 1.5 2 2.5

MD

D g

/cc

% KCl

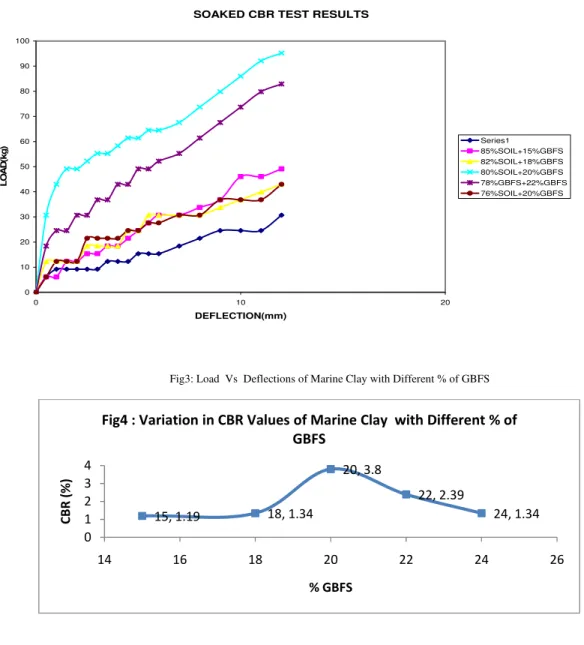

Fig 7: CBR Curves of 20% GBFS + Marine Clay Mix with % Variation of KCl

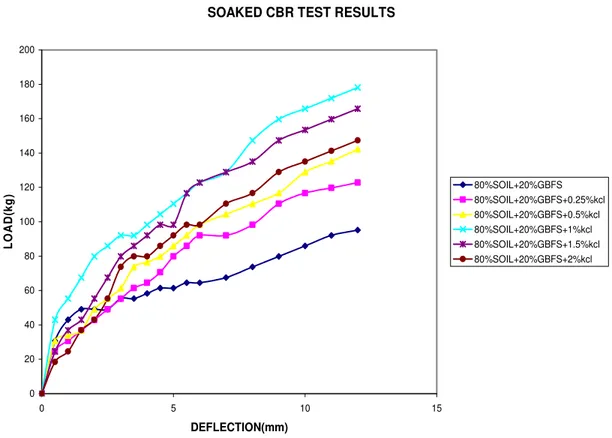

1.4 PLATE LOAD TESTS ON MODEL FOUNDATION SOIL BED

General: Four model foundation soil bedswere prepared in the laboratory by using 60cm diameter mild steel tank with different alternatives as presented in table 6 for this investigation. The gravel was used as cushion in the four models and was laid uniformly on the untreated and treated & reinforced marine clay foundation soil bed. The tests were conducted at OMC and fully saturated condition (FSC).

Preparation of Foundation Soil Bed: The untreated and treated marine clay was compacted in layers of 5cm thickness at its OMC and MDD to a total compacted thickness of 30cm. In case of preparing untreated marine clay and “marine clay + GBFS” mix, the OMC of the natural marine clay and “marine clay + GBFS” mix were used respectively and the required quantity of chemical(1%KCl) was dissolved in marine clay first and then

SOAKED CBR TEST RESULTS

0 20 40 60 80 100 120 140 160 180 200

0 5 10 15

DEFLECTION(mm)

LO

AD(

k

g

) 80%SOIL+20%GBFS80%SOIL+20%GBFS+0.25%kcl

80%SOIL+20%GBFS+0.5%kcl 80%SOIL+20%GBFS+1%kcl 80%SOIL+20%GBFS+1.5%kcl 80%SOIL+20%GBFS+2%kcl

0.25, 3.88 0.5, 4.18

1, 5.37

1.5, 4.78

2, 4.21

3 3.5 4 4.5 5 5.5

0 0.5 1 1.5 2 2.5

CBR %

% KCl

only the GBFS was mixed. On the prepared foundation soil a sand layer of 1.0 cm thickness is provided and then the geotextile was placed. The geotextile was anchored to create the tensile force to offer max load carrying capacity and distributed equally over the stabilized foundation soil.

Preparation of Gravel Cushion for Foundation Soil Bed: On the prepared untreated and treated & reinforced marine clay foundation bed, uniformly mixed gravel at OMC was laid in each layer of 5cm compacted thickness for a total thickness of 15.0cm. The gravel cushion layer was compacted to its MDD and OMC and the Plate.1 presents a prepared marine clay model foundation soil bed.

Static Plate Load Test: Static plate load tests were conducted in a model tank of circular in shape, having 60 cm diameter and 45 cm height as shown in the plate 2. The load was applied through the circular plate of 15cm diameter on to the untreated and treated & reinforced marine clay foundation soil bed at OMC and FSC.

Plate 1: Prepared Model Foundation Soil Bed

Plate 2: Static Plate Load Test Setup (Second Author is Conducting the Test)

Table 6: Load Carrying Capacity of the Marine Clay Foundation Soil bed with Various mix Proportions and their Settlements at OMC and FSC

Sl

No Foundatio n Soil bed

Gravel Cushion

Ultimate Load

Carrying Capacity in kN/m2

Settlement in mm

At OMC At FSC At OMC At FSC

1 Marine Clay Gravel 146.50 35.10 2.21 2.95

2. Marine Clay +20%GBFS Gravel 404.256 159.70 1.60 1.90

3 MC+20%GBFS+1% KCl Gravel 500.107 177.90 1.40 1.80

4

MC+20%GBFS+1% KCl + Geotextile

as reinforcement & separator between stabilized marine clay soil and gravel cushion

Gravel

1385.903 509.107 1.11 1.51

1.5 CONCLUSIONS

The following conclusions were drawn based on the laboratory studies carried out on this work.

It was observed that the MDD and CBR values of marine clay has been improved by 28.74% and 383.78% respectively with the addition of 20% BGFS

Further, it was noticed that the MDD and CBR values of “Marine clay +20% GBFS” mix has been increased by 37.87% and 625.67% respectively with the addition of 1% KCl

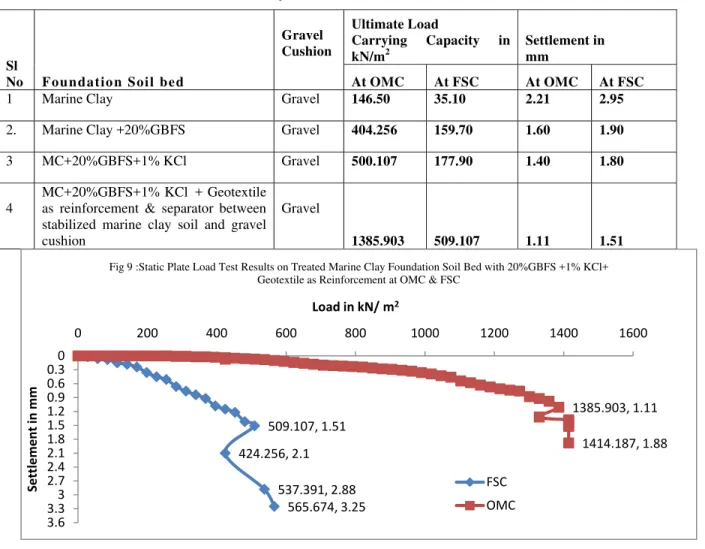

It was investigated that the load carrying capacity of the marine clay foundation soil bed has been improved by 175.94%, 241.36% and 846.01% with the addition of 20%GBFS, 1% KCl +20%GBFS and 1% KCl +20%GBFS+ with the provision of geotextile as reinforcement & separator respectively at OMC

It was investigated that the load carrying capacity of the marine clay foundation soil bed has been improved by 354.98%, 406.83% and 1350.44% with the addition of 20%GBFS, 1% KCl +20%GBFS and 1% KCl+20%GBFS+ with the provision of geotextile as reinforcement & separator respectively at FSC.

It was observed that the total deformation values of the marine clay foundation soil bed has been improved by 27.60%, 36.65% and 49.77% with the addition of 20%GBFS, 1% KCl +20%GBFS and 1%KCl +20%GBFS+ with the provision of geotextile as reinforcement & separator respectively at OMC.

It was observed that the total deformation values of the marine clay foundation soil bed has been improved by 35.59%, 38.98% and 48.81% with the addition of 20%GBFS, 1% KCl +20%GBFS and 1% KCL +20%GBFS+ with the provision of geotextile as reinforcement & separator respectively at FSC. 509.107, 1.51 424.256, 2.1 537.391, 2.88 565.674, 3.25 1385.903, 1.11 1414.187, 1.88 0 0.3 0.6 0.9 1.2 1.5 1.8 2.1 2.4 2.7 3 3.3 3.6

0 200 400 600 800 1000 1200 1400 1600

Settlement in

mm

Load in kN/ m2

Fig 9 :Static Plate Load Test Results on Treated Marine Clay Foundation Soil Bed with 20%GBFS +1% KCl+ Geotextile as Reinforcement at OMC & FSC

FSC

1.6 DISCUSSIONS

The reductions in deformation values were due to the chemical reactions between the added chemical and the replacement of clay mineralogy by GBFS.

Further, an increase in the load carrying capacity was observed by introducing the geotextile as reinforcement & separator. The reason for appreciable improvement in the load carrying capcity of the treated marine clay foundation soil bed was that the load was equally distributed on treated marine clay foundation soil by providing the geotextile as separator & reinforcement.

Form the results it was clearly observed that the efficiency of the geotextile as a reinforcement & separator.

References

[1] A, Rao SM, Chandrasekaran S (1989), “Engineering Properties of Cochin and Mangalore Marine Clays”, Indian Geotech, J.1:265-278. [2] Anandakrishnan, M. and Dhaliwal, S.S.(1966), Effect of various concentrations of Sodium Chloride and Calcium Chloride on the pore pressure parameters and on strength parameters of Black Cotton Soil, Research Report, Dept. of Civil Engg., IIT, Kanpur, India, 1966. [3] Appamma, P (1998), Strength characteristics of Ca -Rice husk ash stabilized soil mixes, M.Tech., thesis, Department of Civil Engg.

JNTU, Kakinada, 1998.

[4] Ashwani Kumar and H.S. Mehta (1998), Laboratory Investigations on Use of Stabilized Granulated Blast Furnace Slag in Roads, Indian Highways, December 1998.

[5] Basack and Purkayastha (2009). “Engineering properties of Marine Clays from the eastern coast of India.”Journal of Engineering and Technology Research Vol.1(6),pp.109-114,September, Shridharan 2009.

[6] Bhadra, T. K and Sandhawar, R. R (2002), Design of roads using waste products from steel plants, Indian Highways.

[7] Chandrashekar, B.P., Prasada Raju, G.V.R (1999), Relative Performance of Lime and Calcium Chloride on Properties of Expansive Soil For Pavement Subgrades, Proc. Of IGC-99, Calcutta, 1999, pp 279-282.

[8] Guram, D., Marienfelf, M. and Hayes, C (1994), Evaluation of Non Woven Geotextile versus Lime-Treated Subgrade in Atoka Country, Oklahoma, TRR-1439,TRB, 1994, pp.7-11.

[9] Higgins D. D. (2005), Soil Stabilization with Ground Granulated Blast Furnace Slag, UK Cementitious Slag Makers Association (CSMA), September 2005.

[10] Koteswara Rao,D (2006), Laboratory investigations on GBFS-CH soil mixes for the utilization of foundation beds, CONCEPTS-2006, J.N.T. University College of Engineering, Kakinada, July 2006.

[11] Prasada Raju,G.V.R (2001), Evaluation of Flexible Pavement Performance with Reinforcement and Chemical Stabilization of Expansive Soil Subgrade, a Ph.D. thesis , Kakathiya University, Warangal,(A.P).

[12] Saha and Saha, P (1991), Improvement of Soils by Use of Chemicals,IGC-91.

[13] Sivanna, G.S (1976), Strength and consolidation characteristics of black cotton soil with chemical additives- & ,Report prepared by Karnataka Engg. Research Station, Krishnarajasagar, India, 1976.

[14] Sivapullaiah, P.V. et al (1994), Role of Electrolytes on the Shear Strength of clayey soil, Proc. of IGC-94, Warangal, 1994, pp. 199-202.